0.1-5mm Custom Nitinol Sheet: 99.999% Purity Guaranteed

2025-08-22 20:09:38

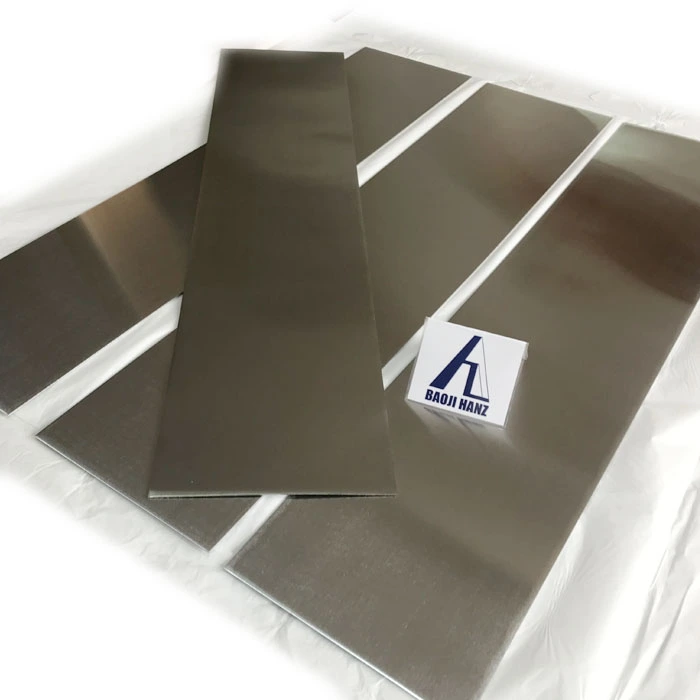

When precision engineering meets advanced metallurgy, the result is our premium 0.1-5mm custom nitinol sheet collection, manufactured with an unprecedented 99.999% purity guarantee. These nitinol sheets represent the pinnacle of shape memory alloy technology, offering exceptional superelastic properties and consistent performance across diverse industrial applications. Our custom nitinol sheet solutions are meticulously engineered to meet the exacting demands of medical device manufacturing, aerospace components, and high-precision mechanical systems. With thickness options ranging from 0.1mm to 5mm and customizable dimensions up to 300mm × 800mm, these nitinol sheets provide unparalleled versatility for specialized applications requiring superior material properties and dimensional accuracy.

Superior Material Properties and Specifications

Advanced Alloy Composition and Chemical Integrity

Our nitinol sheet manufacturing process begins with precisely controlled alloy composition, maintaining nickel content between 54.7% and 57% with titanium balance, strictly adhering to ASTM F2063 product standards. This specific composition ensures optimal shape memory and superelastic characteristics that define high-quality nitinol sheet products. The 99.999% purity guarantee represents our commitment to eliminating impurities that could compromise the material's unique properties, including its ability to undergo reversible phase transformations and maintain consistent mechanical behavior throughout its operational lifecycle. Our advanced vacuum induction melting process, combined with electron beam remelting techniques, ensures homogeneous microstructure distribution throughout each nitinol sheet, eliminating segregation and enhancing overall material reliability.

Mechanical Properties and Performance Characteristics

The mechanical properties of our nitinol sheet products demonstrate exceptional performance metrics that surpass conventional metallic materials. With ultimate tensile strength exceeding 500 MPa and elongation capabilities reaching 10% or more, these nitinol sheets exhibit remarkable resilience under mechanical stress. The superelastic behavior manifests at room temperature when the Af transformation temperature ranges between -10°C and 20°C, allowing the nitinol sheet to recover its original shape after deformation loads are removed. This unique characteristic enables applications requiring repeated flexing, bending, and shape recovery without permanent deformation or fatigue failure, making our nitinol sheet ideal for dynamic mechanical systems and biomedical applications requiring consistent performance over extended operational periods.

Dimensional Precision and Customization Capabilities

Our nitinol sheet manufacturing capabilities encompass a comprehensive range of dimensional specifications, with minimum thickness starting at 0.1mm and standard dimensions ranging up to 300mm × 800mm maximum size. Custom dimensions are readily available based on specific application requirements, with minimum order quantities as low as one piece for stocked configurations. The precision manufacturing process ensures consistent thickness tolerances across the entire nitinol sheet surface, with surface finish quality meeting stringent medical and aerospace industry standards. Our advanced rolling and annealing processes maintain uniform grain structure and mechanical properties throughout the nitinol sheet, ensuring predictable performance characteristics regardless of the specified dimensions or thickness requirements.

Manufacturing Excellence and Quality Assurance

Advanced Production Technology and Equipment

Our manufacturing facility employs state-of-the-art production equipment specifically designed for nitinol sheet processing, including precision rolling mills, controlled atmosphere furnaces, and advanced heat treatment systems. The production process incorporates multiple quality control checkpoints, ensuring each nitinol sheet meets our rigorous specifications before shipment. Our sophisticated vacuum induction melting furnaces maintain precise temperature control and atmospheric conditions necessary for achieving the 99.999% purity levels that distinguish our nitinol sheet products. The integration of computer-controlled processing parameters ensures consistent metallurgical properties across all production batches, while our advanced testing equipment validates mechanical properties, chemical composition, and dimensional accuracy throughout the manufacturing process.

Quality Control and Certification Standards

Our quality assurance program encompasses comprehensive testing protocols that verify every aspect of nitinol sheet performance and composition. Each production batch undergoes rigorous chemical analysis, mechanical property testing, and dimensional verification before receiving certification. Our ISO 9001:2008 certification, combined with SGS and TUV compliance, demonstrates our commitment to maintaining international quality standards throughout the nitinol sheet manufacturing process. Material test certificates (MTC) accompany each shipment, providing detailed documentation of chemical composition, mechanical properties, and dimensional specifications. Our quality control laboratory maintains calibrated testing equipment capable of verifying transformation temperatures, stress-strain characteristics, and fatigue resistance properties essential for nitinol sheet applications.

Production Capacity and Delivery Performance

Our manufacturing facility maintains a production capacity of 600 kilograms per month, ensuring reliable supply availability for both standard and custom nitinol sheet requirements. The combination of efficient production processes and strategic inventory management enables delivery timeframes ranging from 5 to 25 workdays following payment confirmation. Our commitment to on-time delivery extends beyond mere scheduling, incorporating comprehensive production monitoring and documentation retention spanning five years for complete traceability. The nitinol sheet production process includes multiple staging areas and quality checkpoints, allowing for flexible scheduling and priority handling of urgent requirements while maintaining consistent quality standards across all production runs.

Applications and Technical Advantages

Medical and Biomedical Applications

The exceptional biocompatibility and unique mechanical properties of our nitinol sheet make it the preferred choice for advanced medical device manufacturing. In cardiovascular applications, nitinol sheets are transformed into stents, guidewires, and surgical instruments that require precise shape recovery and consistent performance within the human body. The superelastic characteristics of our nitinol sheet enable medical devices to undergo significant deformation during insertion procedures while recovering their functional geometry once positioned. Orthodontic applications benefit from the controlled force delivery capabilities of nitinol sheet products, providing gentle, continuous pressure for tooth movement while maintaining comfort for patients throughout extended treatment periods.

Aerospace and Industrial Engineering

Our nitinol sheet products serve critical roles in aerospace applications where weight reduction, reliability, and performance under extreme conditions are paramount. The unique combination of strength, elasticity, and corrosion resistance makes nitinol sheet ideal for actuator components, coupling mechanisms, and structural elements requiring precise dimensional control. Industrial automation systems utilize nitinol sheet components for temperature-activated switching mechanisms, vibration damping systems, and precision positioning devices. The shape memory properties enable nitinol sheet applications in thermal management systems, where controlled geometry changes respond to temperature variations, providing automatic adjustment capabilities without external power sources or complex control systems.

Research and Development Applications

The versatility of our nitinol sheet products extends to research and development applications across multiple scientific disciplines. Materials research laboratories utilize nitinol sheet samples for investigating advanced metallurgical phenomena, studying phase transformation kinetics, and developing new applications for shape memory alloys. The consistent properties and dimensional accuracy of our nitinol sheet products enable researchers to conduct repeatable experiments and develop predictive models for material behavior under various conditions. Educational institutions benefit from the availability of small-quantity nitinol sheet samples for demonstration purposes, allowing students to observe and measure the unique properties of smart materials in controlled laboratory environments.

Conclusion

Our 0.1-5mm custom nitinol sheet with 99.999% purity guarantee represents the pinnacle of shape memory alloy technology, combining exceptional material properties with manufacturing excellence. The comprehensive range of specifications, from ultra-thin 0.1mm configurations to robust 5mm thickness options, ensures optimal solutions for diverse applications requiring superior performance characteristics. Our commitment to quality assurance, dimensional precision, and reliable delivery performance establishes our nitinol sheet products as the preferred choice for demanding applications across medical, aerospace, and industrial sectors.

Ready to experience the superior performance of premium nitinol sheet technology? As a leading China nitinol sheet factory with seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, we offer direct supply advantages that save you money while ensuring fast delivery from our extensive stock of standard sizes. Our China nitinol sheet supplier status means we're equipped to provide OEM services tailored to your specific requirements, whether you need custom sizes, specific alloy compositions, or specialized packaging options. As your trusted China nitinol sheet manufacturer, we work closely with you to ensure our products integrate seamlessly into your projects, while our China nitinol sheet wholesale capabilities support both large-scale production and specialized research applications. Contact us today at baojihanz-niti@hanztech.cn to discuss your nitinol sheet requirements and discover how our advanced materials can enhance your next project.

References

1. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

2. Otsuka, K., & Wayman, C. M. (1998). Shape Memory Materials: Fundamentals of Nickel-Titanium Shape Memory Alloys. Cambridge University Press.

3. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

4. Lagoudas, D. C. (2008). Shape Memory Alloys: Modeling and Engineering Applications. Springer Science & Business Media.