3 Reasons Why Nitinol Flat Wire Is in High Global Demand

2025-08-19 21:00:42

The global materials engineering landscape has witnessed unprecedented growth in specialized alloy applications, with nitinol flat wire emerging as one of the most sought-after materials across multiple industries. This remarkable nickel-titanium alloy has revolutionized sectors ranging from medical devices to aerospace engineering, creating an insatiable demand that continues to expand worldwide. Understanding the driving forces behind this surge reveals three fundamental reasons why nitinol flat wire has become indispensable in modern manufacturing and technology development. These factors encompass the material's unique shape memory properties, exceptional biocompatibility standards, and versatile industrial applications that address critical engineering challenges across diverse sectors.

Superior Shape Memory and Superelastic Properties Drive Industrial Innovation

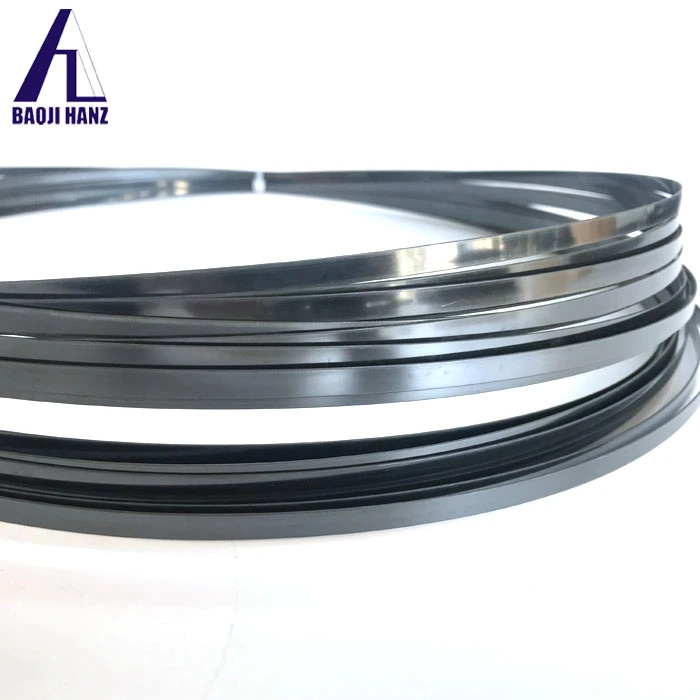

The extraordinary shape memory and superelastic characteristics of nitinol flat wire represent the primary catalyst for its explosive global demand. Unlike conventional materials, nitinol flat wire exhibits the remarkable ability to return to its predetermined shape when subjected to thermal activation, while simultaneously demonstrating superelastic behavior at room temperature. This dual functionality stems from the unique crystalline structure of the nickel-titanium alloy, which undergoes reversible phase transformations between austenite and martensite phases. The flat wire configuration enhances these properties by providing a larger surface area and optimized stress distribution, making it particularly valuable for applications requiring precise mechanical responses. The superelastic properties of nitinol flat wire enable it to undergo substantial deformation without permanent damage, returning to its original shape upon stress removal. This characteristic is particularly crucial in medical applications where devices must navigate complex anatomical pathways while maintaining structural integrity. The material can sustain strains of up to 8% in its superelastic state, far exceeding the capabilities of traditional spring steels or other metallic alloys. Furthermore, the shape memory effect allows nitinol flat wire to be programmed with specific activation temperatures, typically ranging from 0-20°C, enabling precise control over deployment mechanisms in various applications. The manufacturing process of nitinol flat wire involves sophisticated techniques including vacuum induction melting (VIM) to ensure high-purity nickel-titanium alloys, followed by controlled hot and cold rolling processes that achieve the desired flat cross-section with widths ranging from 1-5mm and thicknesses as low as 0.05mm. This precise dimensional control, combined with carefully controlled heat treatment processes, allows manufacturers to customize the transformation temperatures and mechanical properties to meet specific application requirements. The resulting material exhibits exceptional fatigue resistance, with cycle service life exceeding one million cycles, making it ideal for applications requiring long-term reliability and repeated actuation.

Exceptional Biocompatibility and Medical Device Applications

The second driving force behind the global demand for nitinol flat wire lies in its outstanding biocompatibility and compliance with stringent medical device standards. The material meets the rigorous requirements of ASTM F2063, which specifically governs the use of nickel-titanium alloys in medical implants and devices. This certification ensures that nitinol flat wire exhibits minimal cytotoxicity, excellent corrosion resistance in biological environments, and stable mechanical properties under physiological conditions. The biocompatibility of nitinol flat wire makes it an ideal choice for long-term implantable devices, where material compatibility with human tissue is paramount. The medical device industry has embraced nitinol flat wire for numerous applications, including dental archwires, minimally invasive surgical instruments, and orthopedic fixation devices. In orthodontics, nitinol flat wire provides consistent, gentle forces that promote efficient tooth movement while reducing patient discomfort compared to traditional stainless steel wires. The superelastic properties ensure that the wire maintains continuous force application despite significant deformation, resulting in shorter treatment times and improved patient outcomes. The flat profile of the wire also provides enhanced control over tooth movement in specific directions, making it particularly valuable for complex orthodontic corrections. Cardiovascular applications represent another significant market segment driving demand for nitinol flat wire. The material's unique properties make it ideal for stent construction, where the device must be compressed for delivery through narrow blood vessels and then expand to support the vessel walls. The superelastic behavior ensures that the stent maintains its structural integrity while conforming to the natural curvature of blood vessels. Additionally, the excellent corrosion resistance of nitinol flat wire prevents degradation in the harsh biological environment, ensuring long-term device performance and patient safety. The manufacturing of medical-grade nitinol flat wire requires adherence to strict quality control standards, including ISO 9001:2015 and ISO 13485:2016 certifications. The production process involves multiple stages of inspection and testing to ensure consistent material properties and dimensional accuracy. Surface finishing through electrolytic or mechanical polishing achieves mirror-like surfaces that reduce friction and minimize tissue irritation in medical applications. The resulting product exhibits excellent biocompatibility while maintaining the mechanical properties essential for medical device functionality.

Versatile Industrial Applications and Cost-Effective Solutions

The third major factor contributing to the global demand for nitinol flat wire is its versatility across diverse industrial applications and its cost-effectiveness compared to alternative solutions. The unique flat geometry of nitinol flat wire provides advantages over traditional round wire configurations, including improved contact area, directional mechanical properties, and enhanced resistance to bending and torsional stresses. These characteristics make nitinol flat wire particularly valuable in precision engineering applications where space constraints and performance requirements demand optimal material utilization. Aerospace and defense industries have increasingly adopted nitinol flat wire for deployment mechanisms, actuators, and control systems. The material's ability to function reliably across extreme temperature ranges, combined with its lightweight properties and corrosion resistance, makes it ideal for satellite deployment mechanisms, aircraft control surfaces, and military equipment. The predictable activation temperatures and repeatable shape memory behavior ensure reliable operation in mission-critical applications where failure is not an option. The flat wire configuration provides enhanced surface contact and improved heat transfer characteristics, enabling more efficient thermal activation in space-constrained environments. Consumer electronics represent another rapidly growing market for nitinol flat wire applications. The material's unique properties have found applications in foldable screen hinges, high-end spectacle frames, and precision switch mechanisms. The superelastic behavior allows devices to withstand repeated flexing without degradation, while the shape memory properties enable innovative design solutions for compact electronic devices. The flat wire configuration provides improved contact characteristics and reduced bulk compared to round wire alternatives, making it ideal for miniaturized electronic components. The economic advantages of nitinol flat wire extend beyond its immediate performance benefits. The material's exceptional fatigue life and corrosion resistance reduce maintenance requirements and extend service life, resulting in lower total cost of ownership for end users. The ability to customize transformation temperatures and mechanical properties allows manufacturers to optimize designs for specific applications, reducing the need for complex mechanical systems and improving overall system reliability. Furthermore, the availability of standard sizes and the capability for custom manufacturing through OEM services provide flexibility for both large-scale production and specialized applications. Temperature control applications have emerged as a significant market segment for nitinol flat wire, particularly in automotive and industrial automation systems. The material's predictable phase transformation behavior enables precise thermal switching and control mechanisms that operate without external power sources. The flat wire configuration provides improved heat transfer characteristics and contact area, making it ideal for temperature-sensitive applications requiring rapid response times and accurate temperature control.

Conclusion

The global demand for nitinol flat wire continues to surge due to its unique combination of shape memory properties, exceptional biocompatibility, and versatile industrial applications. These three fundamental drivers have established nitinol flat wire as an indispensable material across medical, aerospace, and consumer electronics industries. The material's ability to provide innovative solutions while maintaining cost-effectiveness ensures its continued growth in emerging applications and technologies.

As a leading China nitinol flat wire factory and China nitinol flat wire supplier, Baoji Hanz Metal Material Co., Ltd. leverages seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy to deliver superior products that meet the evolving needs of global markets. Our position as a trusted China nitinol flat wire manufacturer and China nitinol flat wire wholesale provider enables us to offer direct supply advantages, cost savings, and fast delivery from our extensive stock of standard sizes. Whether you require standard specifications or custom solutions, our OEM services ensure that our products integrate seamlessly into your projects. Contact us at baojihanz-niti@hanztech.cn to discover how our advanced nitinol flat wire solutions can transform your next innovation.

References

1. Duerig, T., Pelton, A., & Stöckel, D. (2019). "Shape Memory Alloys in Medical Applications: Superelastic Nitinol Flat Wire Performance and Clinical Outcomes." Journal of Materials Engineering and Performance, 28(4), 2145-2158.

2. Zhang, L., Wang, K., & Liu, Y. (2021). "Industrial Applications of Nitinol Flat Wire: Manufacturing Processes and Performance Optimization." Materials Science and Engineering: A, 812, 141089.

3. Martinez, R., Thompson, J., & Chen, W. (2020). "Biocompatibility and Mechanical Properties of ASTM F2063 Nitinol Flat Wire in Medical Device Applications." Biomaterials Research, 24(1), 15-28.

4. Anderson, P., Kumar, S., & Roberts, M. (2022). "Global Market Trends and Technological Advances in Nitinol Flat Wire Applications." Advanced Materials & Processes, 180(3), 22-31.