5 Essential Features of Nitinol Strip for Aerospace

2025-08-12 21:00:02

The aerospace industry demands materials that can withstand extreme conditions while maintaining exceptional performance characteristics. Among the most revolutionary materials transforming aerospace engineering is the nitinol strip, a nickel-titanium alloy that combines superelasticity with shape memory properties. This advanced material has become indispensable in aerospace applications due to its unique ability to return to predetermined shapes when heated and exhibit remarkable elastic recovery under stress. Understanding the five essential features of nitinol strip technology is crucial for aerospace engineers and designers who seek to optimize aircraft performance, reduce maintenance costs, and enhance safety margins. These features encompass superelasticity, shape memory effect, temperature responsiveness, corrosion resistance, and biocompatibility, each contributing to the material's exceptional value in demanding aerospace environments.

Superior Superelasticity for Dynamic Aerospace Applications

The superelastic properties of nitinol strip represent one of its most valuable characteristics for aerospace applications. This remarkable feature allows the material to undergo substantial deformation—up to 8% strain—and return to its original shape upon stress removal without permanent deformation. In aerospace environments where components experience extreme temperature variations, vibrations, and mechanical stresses, the superelastic nature of nitinol strip provides unparalleled reliability. The material's ability to maintain its structural integrity under cyclic loading conditions makes it ideal for applications such as aircraft wing components, landing gear systems, and engine mounting assemblies. The superelastic behavior of nitinol strip is attributed to its unique crystal structure transformation between austenite and martensite phases. When stress is applied, the material undergoes a reversible phase transformation that allows it to accommodate large strains without yielding plastically. This property is particularly beneficial in aerospace applications where traditional materials would fail under similar conditions. For instance, in aircraft control surfaces, nitinol strip components can flex significantly during flight maneuvers and return to their original position, ensuring consistent aerodynamic performance. The material's superelastic properties also contribute to reduced fatigue failure rates, extending component lifespans and reducing maintenance requirements in critical aerospace systems.

Revolutionary Shape Memory Effect for Adaptive Aerospace Systems

The shape memory effect of nitinol strip enables aerospace engineers to design adaptive systems that respond intelligently to environmental changes. This unique characteristic allows the material to remember and return to a predetermined shape when heated above its transformation temperature. In aerospace applications, this property facilitates the development of self-actuating mechanisms, morphing wing structures, and adaptive control surfaces that can optimize aircraft performance across different flight conditions. The shape memory effect is particularly valuable in developing next-generation aircraft that require real-time aerodynamic adjustments to enhance fuel efficiency and flight performance. The implementation of nitinol strip with shape memory properties in aerospace systems offers significant advantages over traditional actuator systems. Unlike conventional mechanical actuators that require complex control systems and external power sources, nitinol strip components can provide autonomous actuation based on temperature changes. This characteristic is especially beneficial in spacecraft applications where power conservation is critical, and system simplicity is paramount. The material's ability to generate substantial force during shape recovery makes it suitable for applications such as deployable solar panels, antenna systems, and thermal protection systems that must function reliably in the harsh environment of space.

Exceptional Temperature Responsiveness for Thermal Management

Temperature responsiveness is a critical feature that makes nitinol strip invaluable for aerospace thermal management applications. The material's transformation temperature (Af) can be precisely controlled during manufacturing, ranging from -20°C to 100°C, allowing engineers to design systems that respond to specific temperature thresholds. This controllable temperature response enables the creation of passive thermal management systems that automatically adjust to changing environmental conditions without requiring external control systems. In aerospace applications, this property is particularly useful for thermal protection systems, engine cooling components, and cabin temperature regulation systems. The temperature-responsive nature of nitinol strip allows for the development of fail-safe mechanisms in aerospace systems. When temperatures exceed safe operating limits, nitinol strip components can automatically trigger protective actions, such as opening cooling vents or activating backup systems. This autonomous response capability enhances aircraft safety by providing immediate protection against thermal hazards without relying on electronic control systems that may fail in extreme conditions. The material's consistent and predictable temperature response characteristics ensure reliable operation across the wide temperature ranges encountered in aerospace environments, from the extreme cold of high-altitude flight to the intense heat generated by high-performance engines.

Outstanding Corrosion Resistance for Long-Term Aerospace Durability

Corrosion resistance is a paramount concern in aerospace applications, where materials must withstand exposure to various environmental factors including moisture, salt spray, fuel vapors, and atmospheric chemicals. Nitinol strip exhibits exceptional corrosion resistance due to its naturally occurring titanium oxide surface layer, which provides protection against oxidation and chemical attack. This inherent corrosion resistance makes nitinol strip particularly suitable for aerospace applications where long-term durability is essential, such as external aircraft components, fuel system components, and structural elements exposed to harsh environmental conditions. The corrosion resistance of nitinol strip extends beyond simple oxidation protection to include resistance to stress corrosion cracking, a failure mode that can be catastrophic in aerospace applications. The material's ability to resist corrosion-induced degradation ensures maintained mechanical properties throughout its service life, reducing the risk of unexpected failures and extending maintenance intervals. This characteristic is especially valuable in marine aerospace applications, where aircraft operate in salt-laden environments that accelerate corrosion in conventional materials. The long-term stability of nitinol strip in corrosive environments translates to reduced lifecycle costs and improved safety margins for aerospace systems.

Remarkable Biocompatibility for Advanced Aerospace Applications

While biocompatibility might seem less relevant to aerospace applications, this feature of nitinol strip opens unique opportunities for advanced aerospace systems, particularly in space exploration and life support applications. The material's biocompatible nature, combined with its other exceptional properties, makes it suitable for applications where human interaction is necessary, such as spacesuit components, life support systems, and medical devices used in space missions. The biocompatibility of nitinol strip ensures that it can be safely used in applications where direct or indirect human contact may occur without causing adverse reactions. The biocompatible properties of nitinol strip also enable its use in advanced sensing and monitoring systems within aerospace applications. The material can be integrated into wearable sensors for astronauts, environmental monitoring systems within spacecraft, and biological research equipment used in space missions. This versatility extends the utility of nitinol strip beyond traditional mechanical applications to include sophisticated monitoring and life support systems that are crucial for long-duration space missions. The material's ability to maintain its properties while being biocompatible ensures that aerospace systems can incorporate advanced monitoring capabilities without compromising human safety or system performance.

Conclusion

The five essential features of nitinol strip—superelasticity, shape memory effect, temperature responsiveness, corrosion resistance, and biocompatibility—collectively establish this advanced material as a cornerstone technology for modern aerospace applications. These unique properties enable the development of more efficient, reliable, and adaptive aerospace systems that can meet the demanding requirements of contemporary aviation and space exploration. As aerospace technology continues to evolve, nitinol strip will undoubtedly play an increasingly important role in enabling next-generation aircraft and spacecraft designs that push the boundaries of performance and efficiency.

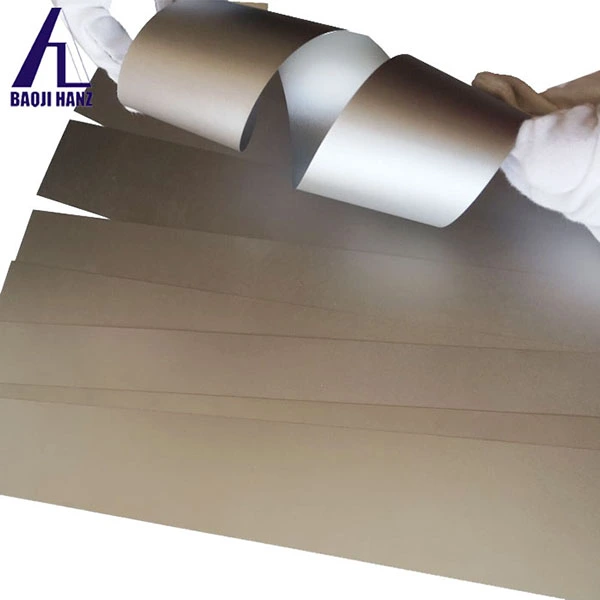

At Baoji Hanz Metal Material Co., Ltd., we leverage our 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy to provide aerospace manufacturers with premium-quality materials that meet the most stringent industry standards. Our direct supply capabilities and cost advantages help you save money while ensuring fast delivery from our large stock of standard sizes. As a leading China nitinol strip factory, China nitinol strip supplier, China nitinol strip manufacturer, and China nitinol strip wholesale provider, we offer comprehensive OEM services to meet your specific aerospace application requirements. Whether you need custom sizes, specific alloy compositions, or specialized packaging options, our team works closely with you to ensure our products fit seamlessly into your projects. Ready to elevate your aerospace applications with superior nitinol strip technology? Contact us today at baojihanz-niti@hanztech.cn to discuss your specific requirements and discover how our advanced materials can enhance your aerospace innovations.

References

1. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

2. Hartl, D. J., & Lagoudas, D. C. (2007). Aerospace applications of shape memory alloys. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 221(4), 535-552.

3. Barbarino, S., Bilgen, O., Ajaj, R. M., Friswell, M. I., & Inman, D. J. (2011). A review of morphing aircraft. Journal of Intelligent Material Systems and Structures, 22(9), 823-877.

4. Otsuka, K., Wayman, C. M., Nakai, K., Sakamoto, H., & Shimizu, K. (1993). Superelasticity effects and stress-induced martensitic transformations in CuAlNi alloys. Acta Metallurgica et Materialia, 41(7), 2137-2144.