5 Key Features That Define Premium Nitinol Strip

2025-10-31 19:40:21

The world of advanced materials science has witnessed remarkable innovations, but few alloys command as much attention as nitinol strip in specialized applications. Understanding what defines premium quality nitinol strip is crucial for industries ranging from medical devices to aerospace engineering. Premium nitinol strip represents the pinnacle of shape memory alloy technology, combining exceptional mechanical properties with unmatched reliability for critical applications.

Exceptional Shape Memory Effect and Temperature Precision

Premium nitinol strip exhibits outstanding shape memory properties, allowing the material to "remember" its original shape when subjected to specific temperature changes. The most sophisticated nitinol strip formulations demonstrate precise transformation temperatures, with Austenite finish (Af) temperatures ranging from -20°C to 100°C depending on the specific application requirements. Baoji Hanz Metal Material Co., Ltd. produces nitinol strip with carefully controlled Af ranges including -20°C~0°C, 0~20°C, 20~40°C, 40~60°C, 60~80°C, and 80~100°C, ensuring optimal performance across diverse operating conditions.The shape memory effect in premium nitinol strip is achieved through precise control of the nickel-titanium composition, typically maintaining 54.5~56.5% nickel with titanium balance. This narrow compositional window is critical for achieving consistent transformation temperatures and reliable shape memory behavior. During the manufacturing process, the material undergoes specialized thermal treatments that program the desired shape into the crystal structure. When cooled below the transformation temperature, the nitinol strip can be deformed into temporary shapes, but upon heating above the Af temperature, it returns to its programmed configuration with remarkable accuracy. This property makes premium nitinol strip invaluable for applications requiring predictable, repeatable shape changes triggered by temperature variations.

Superior Superelasticity and Mechanical Performance

The superelastic properties of nitinol strip allow for exceptional flexibility and the ability to bend and flex during operation without permanent deformation. Premium nitinol strip demonstrates superelastic behavior at temperatures above the Af point, enabling the material to undergo significant strains (up to 8-10%) and return to its original shape upon unloading. This extraordinary elastic recovery capability far exceeds that of conventional metals and even high-performance alloys.The mechanical performance of premium nitinol strip is characterized by its unique stress-strain relationship, featuring a distinctive plateau region during loading and unloading cycles. This plateau corresponds to the stress-induced martensitic transformation, which allows the material to accommodate large deformations while maintaining relatively constant stress levels. Baoji Hanz's nitinol strip exhibits excellent fatigue resistance, capable of withstanding millions of loading cycles without degradation in performance. The density of 6.5g/cc provides an optimal strength-to-weight ratio, making it particularly attractive for applications where weight is a critical factor. The superelastic nitinol strip maintains its mechanical properties across a wide temperature range, ensuring consistent performance in varying environmental conditions.

Precise Dimensional Control and Surface Quality

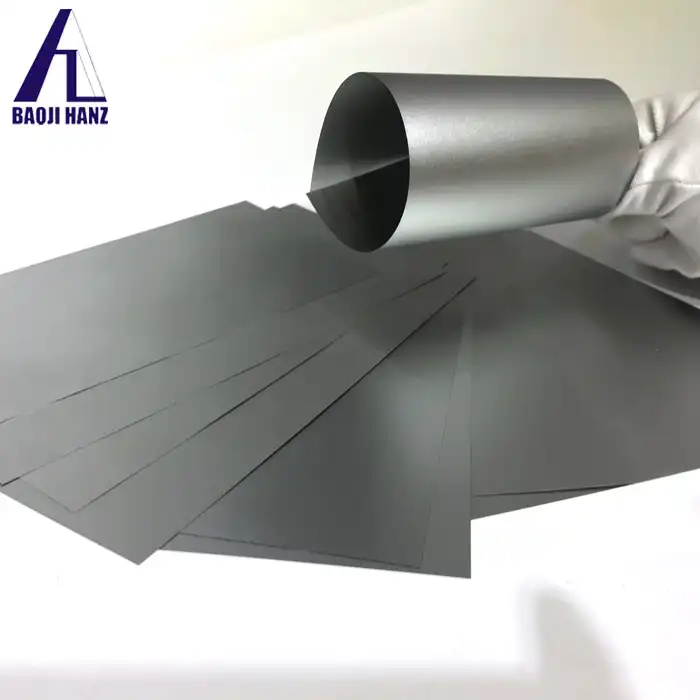

Premium nitinol strip manufacturing requires exceptional dimensional precision and surface quality control. Baoji Hanz Metal Material Co., Ltd. produces nitinol strip with thickness tolerances ranging from 0.1mm to 0.8mm and width specifications from 0.2mm to 3.13mm, achieving tight dimensional control essential for precision applications. The manufacturing process employs advanced rolling and annealing techniques to ensure uniform thickness distribution and consistent mechanical properties throughout the strip length.Surface quality represents another hallmark of premium nitinol strip, with options for both bright and black surface finishes. The bright finish is achieved through careful control of the annealing atmosphere and subsequent surface treatments, resulting in an oxide-free surface with excellent corrosion resistance. The black oxide finish provides enhanced biocompatibility for medical applications while maintaining the inherent corrosion resistance of the nitinol alloy. Premium nitinol strip undergoes rigorous surface inspection to ensure freedom from defects such as inclusions, scratches, or surface irregularities that could compromise performance. The strip can be supplied in various configurations including flat strip, coiled, or spooled formats to meet specific application requirements and facilitate downstream processing.

Chemical Composition Control and Purity Standards

The chemical composition of premium nitinol strip is meticulously controlled to achieve optimal transformation temperatures and mechanical properties. The narrow compositional range of 54.5~56.5% nickel with titanium balance requires sophisticated melting and refining processes to maintain consistency. Baoji Hanz employs advanced vacuum induction melting techniques followed by multiple remelting processes to ensure chemical homogeneity and minimize impurity levels.Trace elements play a crucial role in determining the properties of nitinol strip. Premium grades maintain extremely low levels of carbon, oxygen, and other interstitial elements that can adversely affect transformation temperatures and mechanical performance. The presence of even small amounts of impurities can shift transformation temperatures, reduce fatigue life, or cause premature failure in critical applications. Advanced analytical techniques including inductively coupled plasma spectroscopy and combustion analysis are employed to verify chemical composition and ensure compliance with stringent specifications. The controlled atmosphere processing environments used in premium nitinol strip production prevent contamination and maintain the purity levels required for demanding applications.

Advanced Processing and Quality Assurance

Premium nitinol strip production incorporates sophisticated processing techniques and comprehensive quality assurance protocols. The manufacturing process begins with careful selection of raw materials, followed by vacuum melting to produce homogeneous ingots. These ingots undergo hot working operations including forging and hot rolling to break down the cast structure and achieve proper grain refinement. The subsequent cold rolling operations are carefully controlled to achieve the desired thickness while maintaining uniform properties.Heat treatment represents the most critical aspect of nitinol strip processing, as it determines the final transformation temperatures and mechanical properties. Premium nitinol strip undergoes precisely controlled solution annealing treatments in protective atmospheres to prevent oxidation and contamination. The cooling rates, annealing temperatures, and holding times are optimized for each specific composition and application requirement. Baoji Hanz Metal Material Co., Ltd. maintains comprehensive process documentation and implements statistical process control to ensure consistent quality. Each batch of nitinol strip undergoes extensive testing including differential scanning calorimetry for transformation temperature verification, mechanical property testing, and metallographic examination to confirm microstructural integrity.

Conclusion

Premium nitinol strip represents the convergence of advanced metallurgy, precision manufacturing, and rigorous quality control. The five key features that define premium nitinol strip - exceptional shape memory effect, superior superelasticity, precise dimensional control, optimized chemical composition, and advanced processing - work synergistically to deliver unparalleled performance in demanding applications. Baoji Hanz Metal Material Co., Ltd. stands at the forefront of nitinol technology, leveraging seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy production to deliver world-class materials that meet the most stringent industry standards.

Ready to experience the superior quality of premium nitinol strip for your next project? As a leading China nitinol strip manufacturer and China nitinol strip supplier, Baoji Hanz offers competitive wholesale pricing and customized nitinol strip solutions tailored to your specific requirements. Our China nitinol strip factory maintains large inventory stocks for fast delivery, and we provide nitinol strip for sale with comprehensive technical support. Whether you need standard specifications or customized nitinol strip with specific properties, our team is ready to provide detailed nitinol strip price quotations and arrange nitinol strip free samples for your evaluation. Contact our experienced technical team today at baojihanz-niti@hanztech.cn to discuss your requirements and discover how our premium nitinol strip can enhance your applications. Don't wait – secure your competitive advantage with the finest nitinol materials available in the global market.

References

1. Buehler, W. J., & Wang, F. E. (1968). A Summary of Recent Research on the Nitinol Alloys and Their Potential Application in Ocean Engineering. Ocean Engineering, 1(1), 105-120.

2. Duerig, T. W., Melton, K. N., Stockel, D., & Wayman, C. M. (1990). Engineering Aspects of Shape Memory Alloys. London: Butterworth-Heinemann.

3. Otsuka, K., & Wayman, C. M. (1998). Shape Memory Materials. Cambridge: Cambridge University Press.

4. Pelton, A. R., Dicello, J., & Miyazaki, S. (2000). Optimisation of Processing and Properties of Medical Grade Nitinol Wire. Minimally Invasive Therapy & Allied Technologies, 9(2), 107-118.