Are Nitinol alloy blocks biocompatible?

2025-03-17 21:14:06

Nitinol alloy blocks are indeed biocompatible, making them an excellent choice for various medical applications. This unique material, composed of nickel and titanium, exhibits remarkable properties that contribute to its biocompatibility. The formation of a stable titanium oxide layer on the surface of nitinol alloy blocks provides a protective barrier, reducing the risk of adverse reactions when in contact with biological tissues. This passive layer enhances corrosion resistance and minimizes the release of potentially harmful ions into the body. Furthermore, nitinol's superelastic and shape memory characteristics allow for the creation of medical devices that can adapt to the body's natural movements, reducing tissue irritation and improving overall compatibility. Numerous studies have demonstrated the successful use of nitinol alloy blocks in implants, stents, and other medical devices, showcasing their ability to integrate seamlessly with the human body without triggering significant immune responses or complications. The biocompatibility of nitinol alloy blocks, combined with their unique mechanical properties, has revolutionized the field of biomaterials and continues to drive innovation in medical technology.

Biocompatibility of Nitinol Alloy Blocks

Surface Characteristics and Oxide Layer Formation

The biocompatibility of nitinol alloy blocks is largely attributed to their surface characteristics. When exposed to oxygen, a thin, stable titanium oxide layer forms on the surface of the material. This passive layer acts as a protective barrier, significantly enhancing the corrosion resistance of the alloy. The oxide layer also plays a crucial role in preventing the release of nickel ions, which could potentially cause adverse reactions in some individuals. The thickness and stability of this oxide layer can be further improved through various surface treatments, such as electropolishing or heat treatments, optimizing the biocompatibility of nitinol alloy blocks for specific medical applications.

Corrosion Resistance and Ion Release

One of the key factors contributing to the biocompatibility of nitinol alloy blocks is their exceptional corrosion resistance. The formation of the titanium oxide layer significantly reduces the material's susceptibility to corrosion in biological environments. This resistance is crucial in preventing the release of potentially harmful metal ions into the surrounding tissues. Studies have shown that properly processed nitinol alloy blocks exhibit minimal nickel ion release, well below the levels that could cause concern in most patients. The corrosion resistance of nitinol also ensures the long-term stability and integrity of medical devices made from this material, contributing to their safety and efficacy in various biomedical applications.

Tissue Response and Biointegration

The interaction between nitinol alloy blocks and biological tissues is a critical aspect of their biocompatibility. Research has demonstrated that nitinol elicits a favorable tissue response, with minimal inflammation or foreign body reactions observed in most cases. The material's ability to integrate with surrounding tissues, known as biointegration, is particularly beneficial for implantable devices. Nitinol's unique mechanical properties, such as superelasticity and shape memory, allow for the design of devices that can adapt to the natural movements and contours of the body. This adaptability reduces stress on surrounding tissues and promotes better healing and integration. Moreover, the surface of nitinol alloy blocks can be modified to enhance cell adhesion and tissue growth, further improving their biocompatibility and performance in medical applications.

Applications of Biocompatible Nitinol Alloy Blocks in Medicine

Cardiovascular Devices and Stents

The biocompatibility of nitinol alloy blocks has revolutionized the field of cardiovascular medicine, particularly in the development of stents and other intravascular devices. Nitinol's superelastic properties allow for the creation of self-expanding stents that can be compressed into a small delivery system and then expand to their predetermined shape once deployed in the blood vessel. This characteristic, combined with the material's biocompatibility, has led to significant improvements in the treatment of coronary artery disease and peripheral vascular disorders. Nitinol stents exhibit excellent long-term patency rates and reduced risks of restenosis compared to earlier stent materials. The material's ability to withstand cyclic loading without fatigue failure makes it ideal for applications in the constantly moving cardiovascular system, ensuring the longevity and effectiveness of these life-saving devices.

Orthopedic Implants and Devices

In the field of orthopedics, biocompatible nitinol alloy blocks have found numerous applications due to their unique combination of properties. The material's shape memory effect allows for the creation of implants that can change shape in response to body temperature, facilitating minimally invasive surgical procedures. For instance, nitinol bone staples can be cooled and easily inserted, then expand to their original shape when warmed by body heat, providing secure fixation. The superelasticity of nitinol also makes it an excellent choice for spinal implants, as it can flex and bend with the natural movements of the spine while maintaining its strength and shape. Additionally, nitinol's biocompatibility and osseointegration properties make it suitable for long-term implants, such as joint replacement components and fracture fixation devices, where it can provide stable, durable solutions with reduced risk of rejection or adverse tissue reactions.

Dental Applications and Orthodontics

The biocompatibility of nitinol alloy blocks has made a significant impact in the field of dentistry and orthodontics. Nitinol archwires used in orthodontic treatment offer several advantages over traditional materials. The superelastic properties of nitinol allow for the application of continuous, gentle forces over a wide range of tooth movement, reducing patient discomfort and potentially shortening treatment times. These wires can be bent and twisted without permanent deformation, making them ideal for complex orthodontic cases. In endodontics, nitinol files have revolutionized root canal treatments due to their flexibility and resistance to fracture, allowing for more effective cleaning of curved canals while reducing the risk of procedural errors. The biocompatibility of nitinol also makes it an excellent choice for dental implants and other intraoral devices, where its corrosion resistance and tissue-friendly properties contribute to long-term success and patient comfort.

Future Prospects and Ongoing Research

Advancements in Surface Modification Techniques

The ongoing research into surface modification techniques for nitinol alloy blocks holds promising potential for further enhancing their biocompatibility. Scientists are exploring various methods to optimize the surface properties of nitinol, including plasma treatment, ion implantation, and nanocoating technologies. These advanced techniques aim to improve the stability of the oxide layer, reduce ion leaching, and promote better cell adhesion and tissue integration. For instance, some researchers are investigating the application of bioactive coatings that can stimulate bone growth around nitinol implants, potentially revolutionizing orthopedic and dental treatments. Additionally, the development of antimicrobial surface modifications could significantly reduce the risk of implant-associated infections, addressing one of the major challenges in biomedical implants. As these surface modification techniques continue to evolve, we can expect to see nitinol alloy blocks with even greater biocompatibility and functionality in a wide range of medical applications.

Emerging Applications in Minimally Invasive Surgery

The biocompatibility and unique properties of nitinol alloy blocks are driving innovation in minimally invasive surgical techniques. Researchers and medical device manufacturers are developing new instruments and implants that leverage nitinol's shape memory and superelastic properties to perform complex procedures through small incisions. For example, nitinol-based surgical clips and staples that can change shape upon deployment are being developed for laparoscopic surgeries, offering improved precision and reduced tissue trauma. In neurosurgery, nitinol alloy blocks are being used to create flexible, shape-memory microcatheters for the treatment of aneurysms and other vascular abnormalities in the brain. The biocompatibility of nitinol is particularly crucial in these applications, where the material comes into direct contact with sensitive tissues. As minimally invasive techniques continue to advance, the role of nitinol alloy blocks in enabling safer, more effective surgical interventions is expected to grow significantly.

Integration with Smart Materials and Biosensors

The future of biocompatible nitinol alloy blocks lies in their integration with smart materials and biosensor technologies. Researchers are exploring ways to combine nitinol's unique properties with other advanced materials to create multifunctional medical devices. For instance, the development of nitinol-based scaffolds with embedded biosensors could enable real-time monitoring of tissue regeneration in orthopedic applications. In cardiovascular medicine, smart stents incorporating nitinol and biosensing elements could provide continuous information on blood flow and vessel health, allowing for early detection of potential complications. The biocompatibility of nitinol makes it an ideal substrate for these advanced applications, as it ensures long-term stability and minimal interference with biological processes. Furthermore, the shape memory properties of nitinol could be harnessed to create adaptive implants that can adjust their configuration based on physiological feedback, opening up new possibilities in personalized medicine. As research in this field progresses, we can anticipate a new generation of intelligent, biocompatible medical devices that offer unprecedented levels of functionality and patient care.

Conclusion

Nitinol alloy blocks have proven to be highly biocompatible, offering a unique combination of properties that make them invaluable in medical applications. Their corrosion resistance, favorable tissue response, and adaptability have revolutionized various fields of medicine. As research continues to advance, we can expect even more innovative uses for these remarkable materials, further improving patient outcomes and pushing the boundaries of medical technology. If you want to get more information about this product, you can contact us at baojihanz-niti@hanztech.cn.

Other related product catalogues

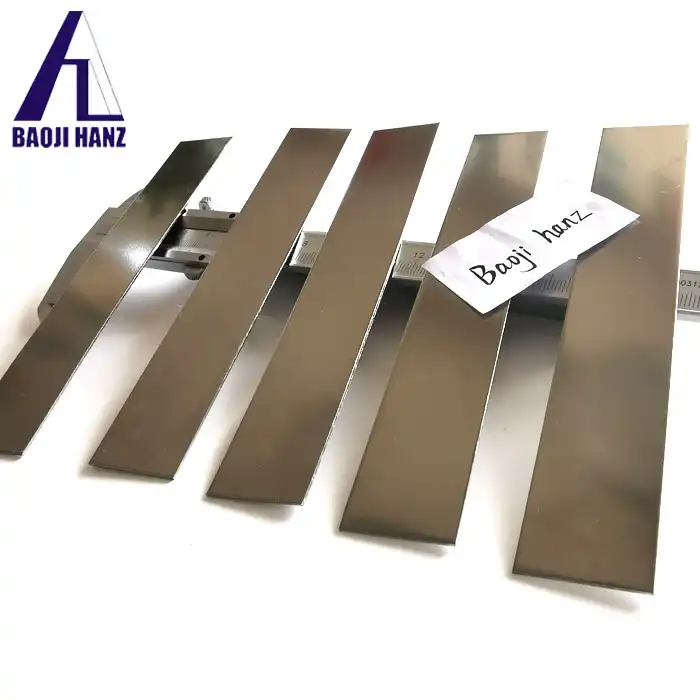

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1. Shabalovskaya, S. A. (2002). Surface, corrosion and biocompatibility aspects of Nitinol as an implant material. Bio-Medical Materials and Engineering, 12(1), 69-109.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

3. Es-Souni, M., Es-Souni, M., & Fischer-Brandies, H. (2005). Assessing the biocompatibility of NiTi shape memory alloys used for medical applications. Analytical and Bioanalytical Chemistry, 381(3), 557-567.

4. Petrini, L., & Migliavacca, F. (2011). Biomedical Applications of Shape Memory Alloys. Journal of Metallurgy, 2011, 501483.

5. Jani, J. M., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

6. Bansiddhi, A., Sargeant, T. D., Stupp, S. I., & Dunand, D. C. (2008). Porous NiTi for bone implants: A review. Acta Biomaterialia, 4(4), 773-782.