Best Nitinol Square Wire Finishes for Medical Applications

2025-12-18 14:00:14

When medical device manufacturers face critical decisions about implantable components, one wrong choice in surface finish can lead to device failure, biocompatibility issues, or patient complications. The selection of appropriate nitinol square wire finishes directly impacts device performance, patient safety, and regulatory approval. Understanding which surface treatments deliver optimal results for cardiovascular stents, orthodontic devices, and minimally invasive surgical instruments is essential for achieving superior clinical outcomes and meeting stringent medical standards. This comprehensive guide explores the most effective nitinol square wire surface finishes specifically designed to address the unique challenges of medical applications.

Understanding Nitinol Square Wire Surface Finishes and Their Medical Significance

Medical-grade nitinol square wire represents a specialized category of nickel-titanium alloy materials where the surface finish plays a critical role in determining device functionality and biocompatibility. Unlike standard wire products, nitinol square wire features a unique geometric cross-section that provides enhanced mechanical properties, including improved resistance to bending and torsion compared to round wire configurations. The surface finish applied to this material fundamentally influences friction coefficients, corrosion resistance, tissue interaction, and overall implant longevity within the human body.

The importance of proper surface treatment cannot be overstated when dealing with medical applications. Surface finishes affect not only the immediate biocompatibility of the device but also long-term performance characteristics such as fatigue resistance and the potential for nickel ion release. Medical device manufacturers must carefully evaluate how different finishing techniques interact with the superelastic and shape memory properties inherent to nitinol materials. The flat filament structure of nitinol square wire already provides mechanical advantages, but the correct surface finish amplifies these benefits while minimizing potential complications during device deployment and long-term implantation.

Primary Surface Finish Types for Medical-Grade Nitinol Square Wire

Medical device manufacturing relies on several distinct surface finish categories, each offering specific advantages for particular applications. Natural oxide finishes represent the most basic treatment, where a thin titanium oxide layer forms naturally on the wire surface during processing. This finish provides adequate biocompatibility for many applications while maintaining cost effectiveness. However, the oxide layer thickness and uniformity can vary significantly depending on processing conditions and subsequent handling.

Light oxide finishes undergo controlled oxidation processes to create a more uniform and predictable surface layer. This treatment enhances corrosion resistance while maintaining a relatively smooth surface texture suitable for devices requiring moderate friction characteristics. The light oxide layer typically appears golden or straw-colored and offers improved consistency compared to natural oxide finishes. Medical device manufacturers frequently select this finish for components where balanced performance characteristics are required without the additional cost of more extensive surface treatments.

Black oxide finishes result from more intensive oxidation processes that create thicker oxide layers on the nitinol square wire surface. This treatment produces excellent corrosion resistance and enhanced biocompatibility due to the stable titanium dioxide layer that forms. The darker appearance indicates a more substantial oxide thickness, which can provide additional protection against nickel ion release in physiological environments. Black oxide finishes work particularly well for implantable devices where long-term stability within the body is paramount.

Advanced Surface Treatments: Pickled and Etched Finishes

Pickled surface finishes involve chemical removal of the oxide layer along with a slight amount of base metal from the nitinol square wire surface. This aggressive treatment creates a clean, though somewhat rough textured surface that provides excellent adhesion characteristics for subsequent coatings or treatments. The pickling process removes surface contaminants and irregularities that might compromise device performance or biocompatibility. While the resulting surface texture is rougher than other finishes, this characteristic can be advantageous for applications requiring enhanced mechanical interlocking with surrounding tissues or coating materials.

Chemical etching represents a more refined approach to surface modification, where controlled chemical processes remove material uniformly across the wire surface. Etched nitinol square wire exhibits improved dimensional consistency and surface cleanliness compared to pickled finishes. The etching process can be precisely controlled to achieve specific surface roughness parameters, making it ideal for applications where predictable surface characteristics are critical. This finish type frequently serves as a preparatory treatment before applying additional surface modifications or functional coatings.

Etched and mechanically polished finishes combine chemical etching with subsequent mechanical polishing operations to achieve superior surface quality. This multi-step process produces nitinol square wire with a stainless steel-like appearance and exceptional smoothness. While microscopic examination may reveal minor surface scratches, the overall finish provides the lowest friction coefficients among standard surface treatments. Medical devices utilizing this finish benefit from reduced insertion forces, improved maneuverability through tortuous anatomy, and minimal tissue trauma during deployment. The combination of chemical cleaning and mechanical polishing creates an optimal balance between surface cleanliness, smoothness, and dimensional precision.

Specialized Polished and Ground Finishes for Precision Applications

Mechanically polished finishes represent premium surface treatments specifically engineered for high-performance medical applications. The polishing process removes surface irregularities through controlled abrasive action, creating an exceptionally smooth surface that minimizes friction during device insertion and manipulation. Polished nitinol square wire exhibits superior surface uniformity compared to chemically treated alternatives, making it the preferred choice for precision sliding components in catheter-based systems and guidewires. The smooth surface reduces particulate generation during device use, an important consideration for cardiovascular and neurological applications where embolic complications must be avoided.

Centerless ground finishes achieve the highest level of dimensional accuracy and surface uniformity available for nitinol square wire products. This precision grinding process removes material uniformly around the wire's perimeter while maintaining strict tolerance controls. The resulting surface combines exceptional smoothness with precise dimensional consistency, critical factors for components requiring tight assembly tolerances or predictable mechanical performance. Centerless ground nitinol square wire proves particularly valuable in applications where multiple wire segments must interact seamlessly or where the device design demands minimal dimensional variation across production batches.

The selection between polished and ground finishes depends largely on specific application requirements and performance priorities. Polished surfaces excel in applications demanding minimal friction and smooth tissue interaction, while ground finishes provide superior dimensional control for precision assemblies. Both finish types significantly enhance the inherent properties of nitinol square wire, including its superelasticity and shape memory characteristics. Medical device engineers must weigh factors such as production costs, performance requirements, and regulatory considerations when specifying these advanced surface treatments for their nitinol components.

Material Specifications and Performance Characteristics of Medical-Grade Nitinol Square Wire

The performance of surface finishes on nitinol square wire cannot be separated from the underlying material properties that define this unique alloy. Medical-grade nitinol square wire manufactured to ASTM F2063 standards contains nickel content above fifty-four percent and titanium content of at least forty-four percent, creating the specific atomic structure responsible for superelastic and shape memory behaviors. This precise compositional control ensures consistent transformation temperatures and mechanical properties essential for reliable medical device performance. The density of six point five grams per cubic centimeter provides an optimal balance between strength and flexibility for minimally invasive applications.

The cold-rolled manufacturing technique used to produce nitinol square wire significantly influences how surface finishes perform on the final product. Cold working creates specific microstructural characteristics that affect both the base material properties and the behavior of surface oxide layers. The resulting material exhibits a tensile strength of approximately eight hundred fifty megapascals, providing sufficient mechanical robustness for demanding medical applications while maintaining the flexibility required for navigation through complex anatomical pathways. Surface finishes applied to cold-rolled nitinol square wire must accommodate the unique stress states and microstructural features created during the forming process.

Biocompatibility Considerations and Surface Finish Selection

Biocompatibility represents the paramount concern when selecting surface finishes for medical-grade nitinol square wire. The excellent biocompatibility inherent to nickel-titanium alloys stems primarily from the stable titanium oxide layer that forms on exposed surfaces. Different surface finishing techniques create oxide layers with varying thickness, composition, and stability characteristics, directly affecting how the material interacts with biological tissues and fluids. Medical device manufacturers must ensure that selected surface treatments enhance rather than compromise the natural biocompatibility of nitinol materials.

The concern regarding nickel ion release from nitinol devices drives much of the emphasis on proper surface finishing. While the stable titanium oxide layer typically prevents significant nickel leaching, surface damage or inadequate oxide formation can lead to increased ion release into surrounding tissues. More robust surface finishes, particularly those involving controlled oxidation processes, create thicker and more stable barrier layers that minimize this risk. Polished and ground finishes must be evaluated carefully to ensure that the mechanical surface modification processes do not compromise oxide layer integrity or create conditions favoring accelerated corrosion.

Different medical applications impose varying biocompatibility requirements that influence surface finish selection for nitinol square wire. Cardiovascular devices implanted in blood-contact applications demand the highest levels of hemocompatibility, often requiring surface finishes that minimize platelet activation and thrombosis potential. Orthodontic applications may tolerate slightly rougher surface finishes while emphasizing long-term stability in the oral environment. Surgical instruments and temporary implants face different biocompatibility challenges than permanent implants, allowing for broader finish selection based primarily on functional performance characteristics.

Mechanical Performance and Fatigue Characteristics

Surface finish quality profoundly impacts the fatigue performance of nitinol square wire in cyclic loading applications. Surface irregularities, scratches, or contamination can serve as stress concentration points where fatigue cracks initiate during repeated loading cycles. High-quality surface finishes minimize these potential failure initiation sites, enabling nitinol components to achieve their theoretical fatigue life potential. Medical devices such as stents and occlusion devices undergo millions of loading cycles during their service life, making fatigue resistance a critical performance parameter directly influenced by surface finish quality.

The superelastic behavior that makes nitinol square wire valuable for medical applications creates unique surface finish requirements. During superelastic deformation, the material undergoes a reversible phase transformation that allows recovery from strains up to eight percent without permanent deformation. Surface finishes must remain stable and intact throughout these deformation cycles without cracking, spalling, or otherwise compromising protective oxide layers. More flexible surface treatments, particularly those involving controlled oxidation rather than rigid mechanical coatings, typically perform better under these demanding cyclic deformation conditions.

Mechanical property optimization achieved through proper surface finishing extends beyond fatigue resistance to include wear characteristics, friction behavior, and resistance to surface damage during handling and deployment. The flat filament structure of nitinol square wire already provides enhanced resistance to bending and torsion compared to round wire geometries. Appropriate surface finishes amplify these advantages by creating low-friction surfaces suitable for precision sliding parts and reducing the potential for surface damage that might compromise mechanical performance. Device designers must consider how surface finish selection interacts with intended loading conditions, deployment mechanisms, and long-term mechanical requirements.

Application-Specific Surface Finish Recommendations

Cardiovascular and Interventional Devices

Cardiovascular applications of nitinol square wire demand the most stringent surface finish requirements due to blood contact, the critical nature of device function, and long-term implantation periods. Stent applications typically utilize either centerless ground finishes for dimensional precision or etched and mechanically polished finishes for optimal smoothness and minimal friction. The low-friction bright surface created by advanced polishing techniques proves particularly valuable for self-expanding stents that must deploy reliably from catheter delivery systems. Surface finish quality directly affects deployment force requirements, positioning accuracy, and the potential for vessel wall trauma during stent placement.

Guidewire applications leverage the unique mechanical properties of nitinol square wire combined with optimal surface finishes to achieve superior torque transmission and flexibility. Polished surface finishes reduce friction as the guidewire navigates through tortuous vascular anatomy, improving device handling characteristics and reducing procedure times. The reduced friction also minimizes endothelial trauma and the potential for vascular complications. Guidewires incorporating nitinol square wire with precision surface finishes enable physicians to access challenging anatomical locations that would be difficult or impossible to reach with conventional materials.

Embolic protection devices and filters represent another cardiovascular application where surface finish selection critically impacts performance. These devices must deploy reliably, maintain position within blood vessels, and minimize thrombogenic potential throughout their service life. Black oxide or controlled light oxide finishes provide excellent hemocompatibility while maintaining the superelastic properties required for device function. The enhanced corrosion resistance provided by these surface treatments ensures long-term stability even in the challenging environment of flowing blood with its complex mixture of proteins, cells, and electrolytes.

Orthodontic and Dental Applications

Orthodontic wire applications utilize nitinol square wire with surface finishes optimized for the oral environment's unique challenges. The oral cavity presents a corrosive environment containing saliva, food acids, temperature variations, and mechanical stresses from chewing forces. Light oxide or black oxide finishes provide adequate corrosion protection while maintaining the low friction characteristics desired for efficient tooth movement. The shape memory properties of nitinol orthodontic wires allow sustained force application over extended periods, and appropriate surface finishes ensure these properties remain stable throughout treatment.

Dental file and instrument applications demand surface finishes that balance flexibility, cutting efficiency, and resistance to fracture. The enhanced bending and torsion resistance of nitinol square wire makes it valuable for endodontic instruments navigating curved root canals. Pickled or etched finishes may prove advantageous in these applications where slight surface roughness aids in debris removal and provides tactile feedback to the clinician. The exceptional fatigue resistance of properly finished nitinol square wire extends instrument life while maintaining consistent performance characteristics throughout multiple sterilization and use cycles.

Long-term orthodontic appliances such as palatal expanders and space maintainers benefit from the dimensional stability and biocompatibility of appropriately finished nitinol square wire. These devices must maintain their mechanical properties and appearance over months or years of continuous wear within the oral environment. More robust surface finishes, particularly those involving controlled oxidation processes, provide enhanced resistance to staining, corrosion, and aesthetic degradation. The combination of superior mechanical properties and optimal surface finishes makes nitinol square wire an increasingly popular choice for advanced orthodontic applications.

Surgical Instruments and Specialized Medical Devices

Minimally invasive surgical instruments increasingly incorporate nitinol square wire components with specialized surface finishes tailored to specific functional requirements. Graspers, retrieval baskets, and manipulation tools benefit from the superelastic properties that allow extreme deformation during use followed by complete recovery. Polished or ground finishes provide the smooth surfaces required for atraumatic tissue interaction while maintaining sufficient mechanical robustness to withstand repeated sterilization and clinical use. The low-friction characteristics of advanced surface finishes enable these instruments to navigate through small access ports and work within confined anatomical spaces.

Temperature-activated devices represent a unique application category where shape memory effects complement optimal surface finishes. These devices exploit the ability of nitinol to remember and return to predetermined shapes when heated above their transformation temperature. Surface finishes for shape memory applications must remain stable across the full range of operating temperatures while maintaining biocompatibility and mechanical integrity. Natural oxide or controlled light oxide finishes typically prove suitable for these applications, providing adequate surface protection without compromising the precise thermal response characteristics required for reliable device function.

Eyeglass frame applications, while not strictly medical devices, demonstrate how nitinol square wire surface finishes can be optimized for long-term consumer use involving repeated flexing and environmental exposure. The low density, high toughness, and stability of nitinol combined with appropriate surface treatments create durable, comfortable frames that resist deformation and corrosion. Consumer applications often utilize polished or bright surface finishes that provide aesthetic appeal while maintaining functional performance. The success of nitinol in this application illustrates how proper surface finishing can extend the material's utility beyond traditional medical device applications.

Quality Standards and Manufacturing Considerations

ASTM F2063 Compliance and Certification Requirements

Compliance with ASTM F2063 standards represents the fundamental requirement for medical-grade nitinol square wire regardless of selected surface finish. This specification establishes requirements for wrought nickel-titanium shape memory alloys used in medical devices and surgical implants. The standard addresses compositional requirements, transformation temperature specifications, mechanical property ranges, and surface finish options. Medical device manufacturers must ensure that their nitinol square wire suppliers provide material meeting these specifications along with appropriate documentation demonstrating compliance through chemical composition analysis, transformation temperature testing, and mechanical property verification.

Surface finish specifications within ASTM F2063 recognize several acceptable treatments, each defined by specific processing methods and resulting surface characteristics. The standard permits natural oxide, pickled, etched, centerless ground, and mechanically cleaned finishes among others, providing manufacturers with flexibility to select the most appropriate treatment for their specific application. However, the standard also emphasizes that surface finish selection must consider the intended use, exposure to biological environments, and mechanical loading conditions. Manufacturers must document their surface finish selection rationale and demonstrate that chosen treatments maintain the required nitinol properties while meeting application-specific performance requirements.

Additional certifications and quality system requirements complement ASTM F2063 compliance for medical device applications. ISO thirteen thousand four hundred eighty-five certification demonstrates that manufacturers maintain comprehensive quality management systems appropriate for medical device production. TUV, SGS, and similar third-party certifications provide independent verification of manufacturing capabilities and quality systems. These certifications become particularly important when sourcing nitinol square wire from international suppliers, as they provide assurance that manufacturing processes meet recognized international standards for medical device components.

Manufacturing Process Control and Surface Finish Consistency

Achieving consistent surface finish quality across production batches requires rigorous manufacturing process control at every stage of nitinol square wire production. The cold rolling process that creates the square cross-section must be carefully controlled to prevent surface damage or contamination that could compromise subsequent finishing operations. Drawing die materials, lubrication systems, and processing speeds all influence the as-formed surface characteristics that serve as the foundation for final surface treatments. Manufacturers must maintain detailed process monitoring documents for at least five years, enabling traceability and facilitating problem resolution should quality issues arise.

Surface finishing operations themselves require careful process parameter control to ensure reproducible results. Chemical etching processes must maintain precise solution composition, temperature, and exposure time to achieve consistent material removal rates and surface characteristics. Mechanical polishing operations demand controlled abrasive characteristics, contact pressures, and processing speeds. Even seemingly simple treatments like controlled oxidation require precise temperature and atmosphere control to achieve the desired oxide layer thickness and composition. Advanced manufacturing facilities implement statistical process control methods to monitor critical parameters and detect process drift before it affects product quality.

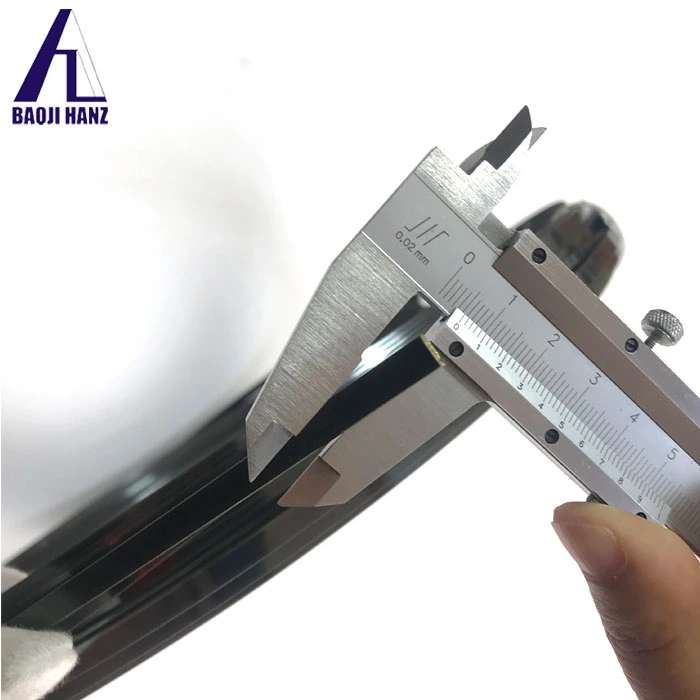

Quality verification for finished nitinol square wire includes surface finish characterization along with dimensional verification and mechanical property testing. Surface roughness measurements provide quantitative assessment of finish quality, while visual inspection identifies obvious defects or irregularities. More sophisticated characterization techniques such as scanning electron microscopy or atomic force microscopy may be employed for critical applications requiring detailed surface analysis. Chemical composition verification ensures that surface treatments have not altered the base material chemistry in ways that might compromise performance or biocompatibility.

Conclusion

Selecting appropriate surface finishes for nitinol square wire in medical applications requires careful consideration of biocompatibility requirements, mechanical performance demands, and specific device functionality. The diverse range of available finishes from natural oxide through centerless ground enables optimization for applications ranging from cardiovascular stents to orthodontic appliances and surgical instruments. Proper surface treatment enhances the inherent advantages of nitinol square wire including superelasticity, shape memory capabilities, and superior mechanical properties while ensuring long-term stability in demanding biological environments.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Baoji Hanz Metal Material Co., Ltd. stands as your trusted China nitinol square wire manufacturer with seven years of specialized expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy production. As a leading China nitinol square wire factory and China nitinol square wire supplier, we offer comprehensive OEM services tailored to your precise specifications. Our advanced production capabilities ensure High Quality nitinol square wire with competitive nitinol square wire price advantages through direct supply. We maintain large stock inventories for fast delivery of standard sizes while providing customization for your unique requirements. Our products comply with ISO9001, SGS, and TUV certifications, guaranteeing consistent quality backed by professional pre-sale consultation, order tracking with five-year document retention, and comprehensive after-sales support. Whether you need nitinol square wire for sale for medical devices, industrial applications, or specialized projects, our expert team delivers solutions that meet ASTM F2063 and GB 24627 standards. Contact us today at baojihanz-niti@hanztech.cn to discuss your China nitinol square wire wholesale requirements and discover how our proven expertise can advance your projects with reliable, high-performance materials.

References

1. Duerig, T., Pelton, A., & Stöckel, D. "An Overview of Nitinol Medical Applications." Materials Science and Engineering A.

2. Stoeckel, D., Pelton, A., & Duerig, T. "Self-Expanding Nitinol Stents: Material and Design Considerations." European Radiology.

3. Shabalovskaya, S.A. "Surface, Corrosion and Biocompatibility Aspects of Nitinol as an Implant Material." Bio-Medical Materials and Engineering.

4. Morgan, N.B. "Medical Shape Memory Alloy Applications - The Market and Its Products." Materials Science and Engineering A.

5. ASTM International. "ASTM F2063: Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants." ASTM Standards.