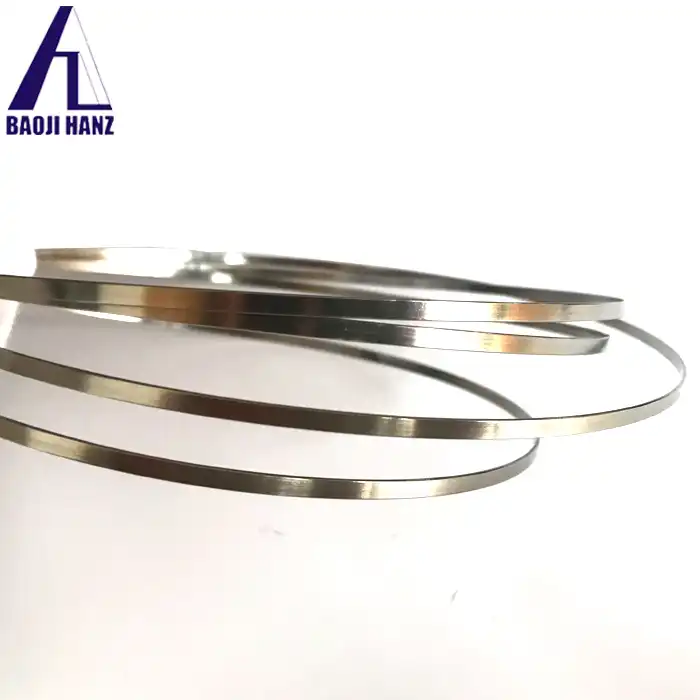

Best shape memory nitinol square wire suppliers & OEM tips

2025-12-19 20:43:54

When sourcing materials for precision medical devices, aerospace components, or advanced robotics, choosing the wrong shape memory nitinol square wire supplier can derail your entire production timeline and compromise product quality. The global demand for specialized nickel-titanium alloys continues to escalate, yet finding manufacturers who combine technical expertise, consistent quality standards, and reliable OEM customization services remains a significant challenge for engineers and procurement specialists worldwide.

Understanding Shape Memory Nitinol Square Wire Applications and Selection Criteria

Shape memory nitinol square wire represents a specialized form of nickel-titanium alloy engineered to deliver exceptional performance in applications requiring precise actuation, biocompatibility, and structural resilience. Unlike traditional round wire configurations, square wire geometry offers distinct advantages in certain mechanical assemblies where uniform contact surfaces and predictable force distribution are critical. The composition of shape memory nitinol square wire typically consists of approximately 55-56% nickel and 44-45% titanium by weight, though minor compositional variations can dramatically influence transformation temperatures and mechanical properties.

The selection of appropriate shape memory nitinol square wire requires careful evaluation of several technical parameters. The austenite finish temperature, commonly denoted as AF temperature, determines the point at which the material completes its transformation to the austenitic phase and recovers its memorized shape. For shape memory nitinol square wire, this critical temperature typically ranges from -25°C to +100°C, allowing engineers to specify materials optimized for room temperature applications, low-temperature environments, or high-temperature operational scenarios. Understanding your specific application's thermal profile enables precise material selection that maximizes performance reliability while minimizing unnecessary costs associated with over-specification.

Critical Material Properties for Industrial and Medical Applications

The mechanical strength of shape memory nitinol square wire remains a fundamental consideration for design engineers evaluating material suitability. High-quality shape memory nitinol square wire exhibits tensile strength values approaching 950 MPa in the fully transformed condition, providing exceptional load-bearing capacity relative to the material's lightweight characteristics. This strength-to-weight advantage makes shape memory nitinol square wire particularly valuable in aerospace applications, portable medical devices, and consumer electronics where mass reduction directly correlates with improved system performance and user experience.

Corrosion resistance represents another critical performance attribute of shape memory nitinol square wire that extends operational lifetimes in challenging environments. The titanium-rich oxide layer that naturally forms on the surface of shape memory nitinol square wire provides excellent protection against chemical degradation in biological fluids, saltwater exposure, and many industrial chemical environments. This inherent corrosion resistance, combined with the material's biocompatibility, has established shape memory nitinol square wire as a preferred material for long-term implantable medical devices, marine instrumentation, and chemical processing equipment where material failure would result in catastrophic consequences.

Evaluating Manufacturing Capabilities of Shape Memory Nitinol Square Wire Suppliers

Distinguishing between suppliers who merely distribute shape memory nitinol square wire and manufacturers who possess comprehensive production capabilities represents a critical step in establishing reliable supply chains. Leading producers of shape memory nitinol square wire maintain integrated manufacturing operations encompassing raw material preparation, precision melting and casting, thermomechanical processing, and final finishing operations. This vertical integration provides enhanced quality control, reduced lead times for custom specifications, and the technical flexibility to accommodate evolving design requirements throughout product development cycles.

The production of premium shape memory nitinol square wire begins with precise control of alloy chemistry during vacuum melting operations. Even minute variations in elemental composition or residual impurity levels can significantly alter transformation temperatures and mechanical performance characteristics of the finished shape memory nitinol square wire. Manufacturers employing advanced analytical techniques including optical emission spectroscopy and X-ray fluorescence can verify compositional accuracy throughout production, ensuring each batch of shape memory nitinol square wire meets the stringent requirements established by international standards such as ASTM F2063 and GB 24627.

Advanced Processing Services for Customized Shape Memory Nitinol Square Wire Solutions

Contemporary applications frequently demand shape memory nitinol square wire that has undergone specialized processing beyond basic wire drawing operations. Heat treatment protocols establish the material's transformation temperatures and mechanical properties, with precise temperature control and atmosphere management determining the final performance characteristics of shape memory nitinol square wire. Shape setting procedures enable manufacturers to pre-form shape memory nitinol square wire into complex three-dimensional geometries that the material will recover upon thermal activation, eliminating the need for end-users to perform this technically demanding operation.

Surface finishing options for shape memory nitinol square wire extend beyond aesthetic considerations to influence functional performance in specific applications. Electropolishing removes surface irregularities and work-hardened layers from shape memory nitinol square wire, producing ultra-smooth surfaces that minimize friction in sliding contact applications and reduce the risk of particulate generation in cleanroom environments. Alternative surface treatments including oxide layer coloration and specialized coatings can be applied to shape memory nitinol square wire to achieve specific optical properties, enhance corrosion resistance in particularly aggressive environments, or facilitate subsequent assembly operations.

Quality Assurance and Certification Requirements for Shape Memory Nitinol Square Wire

Regulatory compliance represents a non-negotiable requirement for shape memory nitinol square wire destined for medical device applications, with manufacturers required to demonstrate adherence to comprehensive quality management systems. ISO 9001 certification provides baseline assurance of consistent manufacturing practices, while ISO 13485 specifically addresses medical device quality management requirements. Suppliers of shape memory nitinol square wire serving medical markets should maintain current certifications and welcome customer audits to verify ongoing compliance with applicable regulatory frameworks.

Material traceability systems enable manufacturers to track individual batches of shape memory nitinol square wire from raw material receipt through final inspection and shipment. This documentation capability proves essential when addressing customer inquiries, responding to regulatory inspections, or conducting root cause investigations in the event of field performance issues. Premium suppliers of shape memory nitinol square wire maintain production records for a minimum of five years, significantly exceeding regulatory minimums to support long-term device manufacturing and post-market surveillance activities.

Testing Protocols Validating Shape Memory Nitinol Square Wire Performance

Comprehensive mechanical testing programs verify that shape memory nitinol square wire meets specified performance requirements before shipment to customers. Tensile testing quantifies ultimate strength, yield behavior, and elongation characteristics of shape memory nitinol square wire under standardized loading conditions. Differential scanning calorimetry precisely measures transformation temperatures, ensuring that shape memory nitinol square wire will activate within the intended operational temperature range. These fundamental characterization techniques provide objective data confirming material compliance with purchasing specifications.

Advanced testing methodologies reveal subtle performance attributes of shape memory nitinol square wire that may influence long-term reliability in demanding applications. Fatigue testing subjects shape memory nitinol square wire to repeated loading cycles, simulating years of operational use in compressed test durations to identify potential failure modes before devices reach the marketplace. Biocompatibility testing conducted according to ISO 10993 standards confirms that shape memory nitinol square wire intended for medical applications produces no adverse biological responses, protecting both patients and manufacturers from liability concerns.

Optimizing OEM Partnerships for Custom Shape Memory Nitinol Square Wire

Successful OEM relationships transcend simple buyer-seller transactions to establish collaborative partnerships where suppliers contribute technical expertise throughout product development. Forward-thinking manufacturers of shape memory nitinol square wire employ applications engineers who understand diverse industry requirements and can recommend optimal material specifications, processing parameters, and quality assurance protocols. This consultative approach helps customers avoid costly design iterations and accelerates time-to-market for innovative products incorporating shape memory nitinol square wire.

Flexibility in order quantities and delivery scheduling represents another dimension of value that distinguished OEM suppliers provide. While mass production of standardized shape memory nitinol square wire benefits from economies of scale, development projects and specialized applications often require smaller quantities with abbreviated lead times. Manufacturers maintaining strategic inventory of common shape memory nitinol square wire configurations can accommodate prototype quantities measured in hundreds of meters while seamlessly scaling to production volumes spanning thousands of meters as customer programs mature.

Value-Added Services Enhancing Shape Memory Nitinol Square Wire Integration

Progressive manufacturers of shape memory nitinol square wire recognize that customers require more than raw materials to successfully commercialize innovative products. Providing secondary operations including precision cutting to length, custom packaging configurations, and direct shipment to contract manufacturers streamlines supply chains and reduces customers' internal handling costs. Some suppliers offer consignment inventory programs where shape memory nitinol square wire remains supplier-owned until consumed by the customer, improving working capital efficiency for both parties.

Technical documentation supporting shape memory nitinol square wire shipments extends beyond basic certificates of conformance to include detailed test reports, material safety data sheets, and handling recommendations. This comprehensive documentation package facilitates customers' incoming inspection procedures, supports regulatory submission requirements for medical device applications, and provides valuable reference information for troubleshooting unexpected performance issues. Suppliers investing in robust documentation systems demonstrate commitment to customer success that extends beyond initial material delivery.

Conclusion

Selecting appropriate shape memory nitinol square wire suppliers requires balancing technical capabilities, quality assurance practices, and value-added services that collectively support successful product commercialization across diverse industries.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

As a China shape memory nitinol square wire manufacturer with seven years of specialized expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, Baoji Hanz Metal Material Co., Ltd. delivers High Quality shape memory nitinol square wire that meets international standards including ISO9001, SGS, and TUV certifications. Our position as a China shape memory nitinol square wire factory and China shape memory nitinol square wire supplier enables direct supply cost advantages and fast delivery from extensive stock of standard sizes. We offer comprehensive OEM services for custom sizes, specific alloy compositions, and packaging options with shape memory nitinol square wire for sale at competitive shape memory nitinol square wire price points. As a trusted China shape memory nitinol square wire wholesale provider, we maintain production monitoring documents for five years and provide complete after-sales support. Contact our team at baojihanz-niti@hanztech.cn to discuss your requirements and receive detailed quotations for your next project.

References

1. Otsuka, K., & Wayman, C.M. (1998). "Shape Memory Materials." Cambridge University Press.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). "An Overview of Nitinol Medical Applications." Materials Science and Engineering A.

3. Morgan, N.B. (2004). "Medical Shape Memory Alloy Applications: The Market and Its Products." Materials Science and Engineering A, Volume 378, Issues 1-2.

4. Miyazaki, S., Fu, Y.Q., & Huang, W.M. (2009). "Thin Film Shape Memory Alloys: Fundamentals and Device Applications." Cambridge University Press.

5. Elahinia, M.H., Hashemi, M., Tabesh, M., & Bhaduri, S.B. (2012). "Manufacturing and Processing of NiTi Implants: A Review." Progress in Materials Science, Volume 57, Issue 5.