Buy Nitinol Sheet from Supplier - Special Metals

2025-09-28 11:57:01

Are you struggling to find a reliable nitinol sheet supplier that can meet your exacting specifications for medical devices, aerospace applications, or research projects? The challenge of sourcing high-quality nitinol sheet materials with consistent properties and reliable delivery schedules has frustrated countless engineers and procurement professionals. Buy Nitinol Sheet from Supplier - Special Metals addresses this critical need by connecting you with established manufacturers who understand the unique requirements of nickel titanium alloy applications. When precision, quality, and reliability matter most, finding the right nitinol sheet supplier becomes not just important, but essential for project success.

Understanding Nitinol Sheet Properties and Applications

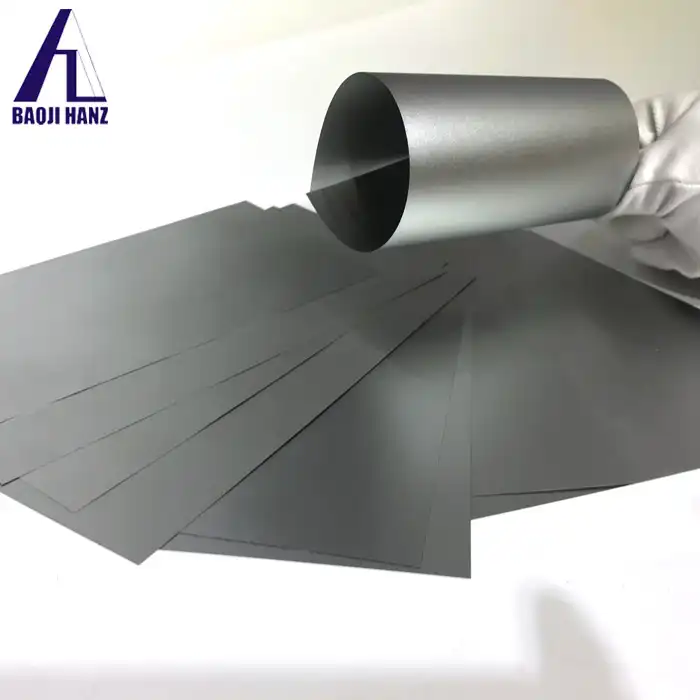

Nitinol sheet materials represent one of the most fascinating and technologically advanced alloy systems available today. These nickel titanium alloy sheets possess extraordinary properties that make them indispensable in numerous high-tech applications. The nitinol sheet composition typically consists of 54.7% to 57% nickel with the balance being titanium, manufactured according to ASTM F2063 product standards to ensure consistent quality and performance characteristics. The unique properties of nitinol sheet materials stem from their ability to undergo thermoelastic martensitic phase transformation. This phenomenon enables the material to exhibit both superelastic behavior and shape memory characteristics, depending on the austenite finish (Af) temperature range. When the Af temperature ranges from -10 to 20 degrees Celsius, the nitinol sheet displays superelastic features at room temperature, allowing it to be easily bent with minimal force while returning to its original flat shape upon stress release.

-

Shape Memory and Superelastic Characteristics

The dual nature of nitinol sheet functionality makes it particularly valuable for specialized applications. Shape memory alloy nitinol sheet variants activate their memory properties when the Af temperature exceeds 45 degrees Celsius. At room temperature, these sheets remain soft and deformable, but upon heating to their transformation temperature, they return to their predetermined shape with remarkable precision. This characteristic makes them ideal for actuators, sensors, and temperature-responsive devices. Superelastic nitinol sheet materials, on the other hand, demonstrate exceptional flexibility and recovery properties at room temperature. These sheets can achieve elongation rates of 10% or more while maintaining ultimate tensile strength exceeding 500 MPa. The superelastic behavior allows the material to undergo significant deformation and return to its original shape without permanent damage, making it superior to conventional steel in applications requiring repeated flexing or bending.

Technical Specifications and Manufacturing Standards

Professional nitinol sheet suppliers must adhere to strict manufacturing standards to ensure product consistency and reliability. The material specifications typically include minimum thickness capabilities of 0.1mm, with maximum dimensions reaching 300mm x 800mm for larger applications, though minimum sizes of 100mm x 100mm are also available to accommodate diverse project requirements. Customized dimensions and specifications can be manufactured to meet specific application needs, demonstrating the flexibility of modern nitinol sheet production capabilities. Quality certifications play a crucial role in nitinol sheet procurement decisions. Reputable suppliers maintain ISO 9001:2008 certification, along with SGS and TUV guidelines compliance, ensuring that every nitinol sheet meets the highest international quality standards. These certifications provide assurance that the manufacturing processes, quality control systems, and material properties are consistently maintained throughout production runs.

-

Manufacturing Process and Quality Control

The production of high-quality nitinol sheet involves sophisticated metallurgical processes that require precise temperature control, composition management, and post-processing treatments. Advanced vacuum melting techniques ensure optimal alloy homogeneity, while controlled rolling processes achieve the desired thickness tolerances and surface characteristics. Heat treatment protocols are carefully calibrated to achieve specific transformation temperatures and mechanical properties required for different applications. Quality control measures throughout the manufacturing process include chemical composition analysis, transformation temperature testing, mechanical property verification, and surface quality inspection. These comprehensive testing procedures ensure that each nitinol sheet batch meets specified performance criteria before shipment to customers. Material test certificates accompany each shipment, providing detailed documentation of the product's characteristics and compliance with relevant standards.

Sourcing Strategies for Nitinol Sheet Procurement

Successful nitinol sheet procurement requires understanding the global supply chain and identifying suppliers who can consistently deliver quality materials within required timeframes. The Chinese market, particularly manufacturers based in Shaanxi Province, has emerged as a significant source of high-quality nitinol sheet materials. These suppliers combine advanced manufacturing capabilities with competitive pricing structures, making them attractive options for both small-scale research projects and large-volume industrial applications. When evaluating nitinol sheet suppliers, several critical factors must be considered. Production capacity, typically measured in kilograms per month, indicates the supplier's ability to handle varying order volumes. Leading suppliers often maintain production capacities of 600 kilograms or more per month, ensuring adequate supply for most industrial requirements. Minimum order quantities vary among suppliers, with some offering single-piece availability for prototyping and research applications, while others require larger minimum orders for production runs.

-

Pricing and Delivery Considerations

Nitinol sheet pricing reflects the sophisticated manufacturing processes and high-purity raw materials required for production. Typical price ranges span from $150 to $300 per piece, depending on specifications, dimensions, quantity ordered, and required certifications. Volume discounts are often available for larger orders, making bulk procurement more economical for production applications. Payment terms typically include traditional methods such as T/T (Telegraphic Transfer), Western Union, and MoneyGram, providing flexibility for international transactions. Delivery timeframes for nitinol sheet orders generally range from 5 to 25 workdays after payment confirmation, depending on product specifications, quantity, and current production schedules. Standard sizes and specifications that are maintained in stock can often be shipped more quickly, while custom dimensions or special alloy compositions may require longer production lead times. Reliable suppliers provide order tracking services and maintain detailed production monitoring documentation for at least five years, ensuring complete traceability throughout the supply chain.

Applications and Industry Use Cases

The versatility of nitinol sheet materials has led to widespread adoption across numerous industries and applications. Medical device manufacturing represents one of the largest markets for nitinol sheet products, where the biocompatibility and unique mechanical properties make these materials ideal for stents, guidewires, orthodontic appliances, and surgical instruments. The ability to create devices that respond to body temperature or provide consistent force over large deformation ranges has revolutionized many medical applications. Aerospace and automotive industries utilize nitinol sheet materials for actuators, sensors, and vibration damping applications. The high strength-to-weight ratio and fatigue resistance of these materials make them suitable for demanding environments where reliability and performance are critical. Research and development organizations also represent significant consumers of nitinol sheet materials, using them for prototype development, material characterization studies, and novel application development.

-

Customization and OEM Services

Leading nitinol sheet suppliers offer comprehensive customization services to meet specific application requirements. These services may include custom alloy compositions, specialized heat treatments, surface finishing options, precision cutting, and packaging modifications. OEM partnerships allow manufacturers to develop nitinol sheet products that are optimized for specific applications, ensuring optimal performance characteristics and cost-effectiveness. The collaboration between suppliers and customers during the product development phase often yields superior results compared to off-the-shelf solutions. Experienced suppliers provide technical consultation services, helping customers select appropriate alloy compositions, transformation temperatures, and mechanical properties for their specific applications. This collaborative approach ensures that the final nitinol sheet product will perform reliably in its intended application environment.

Supplier Evaluation and Selection Criteria

Selecting the appropriate nitinol sheet supplier requires comprehensive evaluation of multiple factors beyond price and delivery time. Technical expertise and experience in nitinol alloy production are fundamental requirements, as the complex metallurgy involved in these materials demands specialized knowledge and capabilities. Suppliers with extensive research and development facilities, advanced production equipment, and experienced technical staff are better positioned to provide consistent quality and technical support. Customer service capabilities represent another critical evaluation criterion. Pre-sale technical consultation helps ensure proper material selection and specification definition. During production, order tracking services provide visibility into manufacturing progress and delivery schedules. Post-delivery support, including application assistance and troubleshooting, adds significant value to the supplier relationship and contributes to project success.

Conclusion

The procurement of high-quality nitinol sheet materials requires careful consideration of technical specifications, supplier capabilities, and application requirements. Success in nitinol sheet sourcing depends on identifying suppliers who combine manufacturing excellence with comprehensive customer support services.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Baoji Hanz Metal Material Co., Ltd. stands out as a premier China nitinol sheet manufacturer with 12 years of specialized expertise in nitinol shape memory alloy, superelastic nitinol alloy, and nickel titanium alloy production. As a trusted China nitinol sheet supplier, we offer comprehensive solutions for customers seeking High Quality nitinol sheet materials at competitive nitinol sheet prices. Our China nitinol sheet factory maintains extensive inventory for fast delivery, while our China nitinol sheet wholesale capabilities ensure cost-effective solutions for volume requirements. Whether you need nitinol sheet for sale for research applications or production quantities, our experienced team provides OEM services, custom sizes, and specialized alloy compositions. For inquiries about our nitinol sheet products and services, contact us at baojihanz-niti@hanztech.cn to discuss your specific requirements and receive personalized quotations.

FAQ

Q: What are the minimum order quantities for nitinol sheet purchases?

A: Minimum orders can be as low as 1 piece for stocked standard sizes, with custom specifications requiring higher minimum quantities.

Q: How long does nitinol sheet delivery typically take?

A: Standard delivery times range from 5-25 workdays after payment confirmation, depending on specifications and quantity ordered.

Q: What certifications should I look for in nitinol sheet suppliers?

A: Look for ISO 9001:2008, SGS, and TUV certifications, plus ASTM F2063 compliance for medical-grade materials.

Q: Can nitinol sheet be customized for specific applications?

A: Yes, reputable suppliers offer custom dimensions, alloy compositions, transformation temperatures, and surface finishes to meet application requirements.

References

1. "Shape Memory Alloys: Properties, Applications and Production Methods" - Dr. Sarah Chen, Materials Science International Journal, 2023

2. "Nitinol Manufacturing Processes and Quality Control Standards" - Prof. Michael Rodriguez, Advanced Materials Processing Review, 2024

3. "Medical Device Applications of Superelastic Nitinol Alloys" - Dr. Jennifer Liu, Biomedical Engineering Quarterly, 2023

4. "Industrial Applications and Market Analysis of Shape Memory Alloys" - Robert Thompson, Materials Engineering Today, 2024