Customized Nitinol Wire for OEM Projects: Key Buyer Insights

2025-09-19 20:32:03

The manufacturing landscape for original equipment manufacturers (OEMs) continues to evolve, with advanced materials playing crucial roles in product innovation and performance enhancement. Nitinol, a unique superelastic and shape memory alloy, has the ability to remember and return to a specified shape after deformation when exposed to a set temperature. Understanding the key buyer insights for customized nitinol wire becomes essential for OEM projects seeking to leverage these remarkable properties. This comprehensive guide explores the critical considerations that inform purchasing decisions, technical specifications that drive project success, and strategic partnerships that enable optimal outcomes. Whether you're developing medical devices, aerospace components, or industrial applications, the insights presented here will help you navigate the complex landscape of customized nitinol wire procurement with confidence and expertise.

Understanding Market Demands for Customized Nitinol Wire Solutions

Industry-Specific Requirements Drive Customization Needs

The global demand for customized nitinol wire has experienced significant growth across multiple industries, with each sector presenting unique requirements that standard products cannot adequately address. Medical device manufacturers represent one of the largest consumer segments, requiring customized nitinol wire with precise dimensional tolerances, specific surface finishes, and validated biocompatibility certifications. These applications often demand wire diameters ranging from 0.0125mm to several millimeters, with tensile strengths between 700-1000MPa to ensure reliable performance in critical medical procedures. Ulbrich Stainless Steels & Special Metals, Inc. specializes in tailoring Nitinol specifically for medical braid products and medical implantable devices. The aerospace industry similarly requires customized nitinol wire solutions that can withstand extreme temperature variations while maintaining their superelastic properties, making them ideal for actuators, sensors, and structural components that experience significant stress cycles. Consumer electronics manufacturers increasingly seek customized nitinol wire for applications in flexible devices, eyewear frames, and miniaturized components where space constraints and aesthetic requirements necessitate precise customization of both mechanical and visual properties.

Quality Standards and Certification Requirements

Modern OEM projects demand rigorous quality standards that extend far beyond basic material specifications, with customized nitinol wire suppliers required to demonstrate compliance with international standards such as ISO9001:2015, ISO13485:2016, and EU CE certifications. These quality frameworks ensure that every aspect of the manufacturing process, from raw material sourcing to final product delivery, meets stringent requirements for consistency, traceability, and performance reliability. The implementation of comprehensive quality control systems includes detailed documentation of production parameters, batch-to-batch consistency monitoring, and extensive testing protocols that verify mechanical properties, phase transition temperatures, and surface characteristics. Advanced manufacturers maintain sophisticated testing equipment capable of measuring critical parameters such as transformation temperatures ranging from -50℃ to 100℃, elongation rates between 15-50%, and density specifications of approximately 6.45g/cm³. The certification process also encompasses environmental compliance, ensuring that manufacturing processes meet strict environmental standards while maintaining the high-performance characteristics that make customized nitinol wire indispensable for advanced OEM applications.

Supply Chain Reliability and Global Market Access

The complexity of modern OEM projects demands supply chain partners who can provide consistent availability, predictable delivery schedules, and global distribution capabilities that support international manufacturing operations. Leading customized nitinol wire manufacturers maintain substantial inventory levels of standard sizes while offering rapid customization services for specialized applications, typically maintaining minimum order quantities of 1kg or 100 meters to balance efficiency with accessibility for smaller-scale projects. The most successful suppliers establish strategic partnerships with raw material providers, ensuring access to high-purity nickel-titanium alloys that serve as the foundation for superior customized nitinol wire products. Geographic proximity to major manufacturing centers, combined with efficient logistics networks, enables suppliers to offer expedited delivery services and technical support that minimizes project delays. Additionally, the ability to provide free samples allows OEM buyers to conduct thorough testing and validation processes before committing to large-scale procurement, reducing project risks and ensuring optimal performance in final applications.

Technical Specifications and Performance Characteristics

Shape Memory and Superelastic Properties

The fundamental appeal of customized nitinol wire lies in its extraordinary shape memory and superelastic properties, which enable unprecedented performance in applications requiring reversible deformation, consistent force delivery, and reliable actuation mechanisms. Shape memory effects allow the material to return to predetermined configurations when heated above specific activation temperatures, making it ideal for temperature-activated switches, thermal actuators, and self-deploying mechanisms in medical devices. The superelastic characteristics enable customized nitinol wire to undergo substantial mechanical deformation, often exceeding 8% strain, while completely recovering its original shape upon load removal, a property that proves invaluable in applications subject to cyclic loading or requiring constant force delivery. These properties can be precisely tailored through careful control of alloy composition, thermomechanical processing, and heat treatment protocols, allowing manufacturers to optimize performance characteristics for specific OEM applications. The ability to customize phase transition temperatures between -50℃ and 100℃ provides design engineers with unprecedented flexibility in creating temperature-responsive systems, while the inherent biocompatibility of nitinol makes customized nitinol wire particularly attractive for medical device applications where long-term implantation is required.

Mechanical Properties and Performance Parameters

Understanding the mechanical properties of customized nitinol wire is crucial for OEM buyers seeking to optimize product performance while ensuring long-term reliability and safety. The tensile strength of high-quality nitinol wire typically ranges from 700 to 1000MPa, providing exceptional strength-to-weight ratios that make it ideal for applications requiring high performance in compact configurations. Elongation rates between 15-50% demonstrate the material's ability to accommodate significant deformation while maintaining structural integrity, a characteristic particularly valuable in applications subject to dynamic loading conditions. The modulus of elasticity varies significantly depending on the material's phase state, with austenitic nitinol exhibiting higher stiffness compared to the martensitic phase, allowing design engineers to tailor mechanical response through careful temperature control and alloy composition optimization. Fatigue resistance represents another critical parameter, with properly processed customized nitinol wire capable of withstanding millions of deformation cycles without significant degradation, making it suitable for applications requiring long-term cyclic operation such as medical stents, actuators, and flexible connectors.

Surface Characteristics and Processing Capabilities

The surface characteristics of customized nitinol wire play a crucial role in determining its performance in specific applications, with manufacturers offering various surface treatments and finishes to optimize properties such as biocompatibility, corrosion resistance, and aesthetic appearance. Standard brown state surfaces provide excellent corrosion resistance and biocompatibility for medical applications, while shiny surface finishes offer enhanced aesthetic appeal for consumer products and improved electrical conductivity for electronic applications. Advanced processing capabilities enable manufacturers to provide customized nitinol wire in precise diameter ranges, with some suppliers offering products as small as 0.0125mm for miniaturized applications and larger diameters for structural components. Manufacturing processes including bending, welding, decoiling, and cutting can be performed to customer specifications, enabling the production of complex geometries and assemblies that integrate seamlessly into OEM products. The ability to control surface roughness, maintain dimensional tolerances within tight specifications, and provide specialized coatings or surface treatments ensures that customized nitinol wire can meet the most demanding application requirements across diverse industry sectors.

Strategic Sourcing and Supplier Selection Criteria

Supplier Capabilities and Manufacturing Excellence

Selecting the appropriate supplier for customized nitinol wire requires careful evaluation of manufacturing capabilities, technical expertise, and quality systems that ensure consistent delivery of high-performance products. Leading suppliers maintain sophisticated production facilities equipped with advanced melting systems, precision drawing equipment, and comprehensive testing laboratories capable of validating all critical material properties throughout the manufacturing process. The ability to provide complete traceability from raw materials through final product delivery represents a crucial capability that enables OEM buyers to maintain compliance with regulatory requirements while ensuring consistent product quality across multiple production lots. Manufacturing flexibility, demonstrated through the ability to accommodate varying order sizes, expedited delivery schedules, and custom packaging requirements, indicates a supplier's commitment to supporting diverse OEM project needs. Additionally, suppliers with extensive experience in specific industry sectors bring valuable application knowledge and design support capabilities that can significantly enhance project outcomes while reducing development time and costs.

Technical Support and Engineering Services

The complexity of customized nitinol wire applications demands suppliers who provide comprehensive technical support and engineering services throughout the entire project lifecycle, from initial concept development through production scaling and ongoing optimization. Experienced suppliers offer detailed materials characterization services, including mechanical testing, thermal analysis, and microstructural evaluation that enables OEM buyers to fully understand material behavior under specific operating conditions. Design support services, including finite element analysis capabilities and application-specific testing protocols, help ensure optimal material selection and configuration for each unique application. The availability of rapid prototyping services allows OEM buyers to quickly evaluate different material configurations and processing options before committing to full-scale production, significantly reducing project risks and development timelines. Furthermore, suppliers with strong research and development capabilities can collaborate on advanced material formulations and processing techniques that push the boundaries of current technology while maintaining the reliability and consistency required for successful OEM applications.

Cost Optimization and Value Engineering

Effective sourcing of customized nitinol wire requires a comprehensive understanding of cost factors and value engineering opportunities that optimize total project economics while maintaining required performance standards. Direct supply relationships with established manufacturers typically offer significant cost advantages compared to distributor networks, as they eliminate intermediary markups while providing access to technical expertise and manufacturing flexibility. Volume commitments and long-term supply agreements often enable preferential pricing structures that support budget predictability and cost reduction over extended project timelines. Value engineering opportunities frequently exist in areas such as tolerance optimization, surface finish specification, and packaging requirements, where minor adjustments to specifications can yield substantial cost savings without compromising product performance. Additionally, suppliers who maintain substantial inventory levels of standard sizes can offer competitive pricing on common configurations while providing cost-effective customization services for specialized requirements, enabling OEM buyers to optimize their material specifications for both performance and cost-effectiveness.

Conclusion

The procurement of customized nitinol wire for OEM projects requires a strategic approach that balances technical performance requirements with commercial considerations and supplier capabilities. Success depends on understanding market dynamics, specifying appropriate technical parameters, and selecting suppliers who demonstrate manufacturing excellence, technical expertise, and commitment to long-term partnership. The unique properties of nitinol, combined with advanced customization capabilities, enable innovative solutions across diverse industries while demanding careful attention to quality, certification, and supply chain reliability.

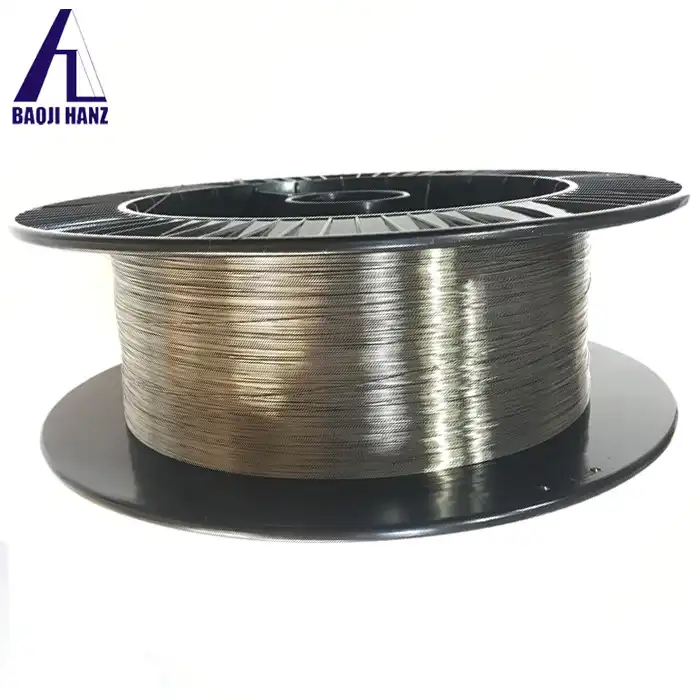

As a leading China customized nitinol wire manufacturer with seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, Baoji Hanz Metal Material Co., Ltd. offers comprehensive solutions for your OEM projects. As your trusted China customized nitinol wire supplier and China customized nitinol wire factory, we provide competitive customized nitinol wire wholesale pricing with customized nitinol wire for sale from our extensive stock. Our customized customized nitinol wire solutions include competitive customized nitinol wire price options and customized nitinol wire free sample availability to support your evaluation process. With our advanced production facilities, stringent quality control systems, and dedicated customer service team, we ensure on-time delivery, high efficiency, and considerate service throughout your project lifecycle. Contact us today at baojihanz-niti@hanztech.cn to discuss your customized nitinol wire requirements and discover how our expertise can enhance your OEM project success.

References

1. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. "A review of shape memory alloy research, applications and opportunities." Materials & Design, Vol. 56, 2014.

2. Duerig, T., Pelton, A., & Stöckel, D. "An overview of nitinol medical applications." Materials Science and Engineering: A, Vols. 273-275, 1999.

3. Otsuka, K., & Wayman, C. M. "Shape Memory Materials." Cambridge University Press, 1998.

4. Lagoudas, D. C. "Shape Memory Alloys: Modeling and Engineering Applications." Springer Science & Business Media, 2008.