Do nitinol sheets have memory properties?

2024-07-16 16:49:39

Can Nitinol Sheets Be Used in Industrial Applications?

Yes, Nitinol sheets can be used in industrial applications due to their unique properties, such as shape memory, superelasticity, and high corrosion resistance. They are used in actuators, where their ability to return to a pre-defined shape upon heating is beneficial. In robotics, Nitinol sheets provide flexibility and durability. They are also used in aerospace for components that require flexibility and resistance to fatigue. Additionally, Nitinol's biocompatibility and corrosion resistance make it suitable for medical devices. Its versatility and unique properties make Nitinol sheets valuable across various industrial sectors.

What Are the Advantages of Using Nitinol Sheets in Manufacturing?

Nitinol sheets offer several advantages in manufacturing. Their shape memory and superelasticity allow for the creation of components that can return to their original shape after deformation, enhancing durability and functionality. Nitinol’s high corrosion resistance ensures longevity, even in harsh environments. Its flexibility and strength make it ideal for producing intricate and resilient parts. Additionally, Nitinol’s biocompatibility is crucial for medical device manufacturing. These unique properties reduce maintenance costs, improve product performance, and enable innovative designs, making Nitinol sheets highly advantageous in various manufacturing applications.

How Do Nitinol Sheets Compare to Other Industrial Materials?

Nitinol sheets stand out compared to other industrial materials due to their unique shape memory and superelasticity properties, which are not found in traditional metals like steel or aluminum. They offer superior flexibility and can return to their original shape after deformation, providing enhanced durability. Nitinol’s high corrosion resistance and biocompatibility make it ideal for medical and harsh environment applications. While it may be more expensive than conventional materials, its unique advantages often justify the cost in specialized applications, offering performance and reliability that other materials cannot match.

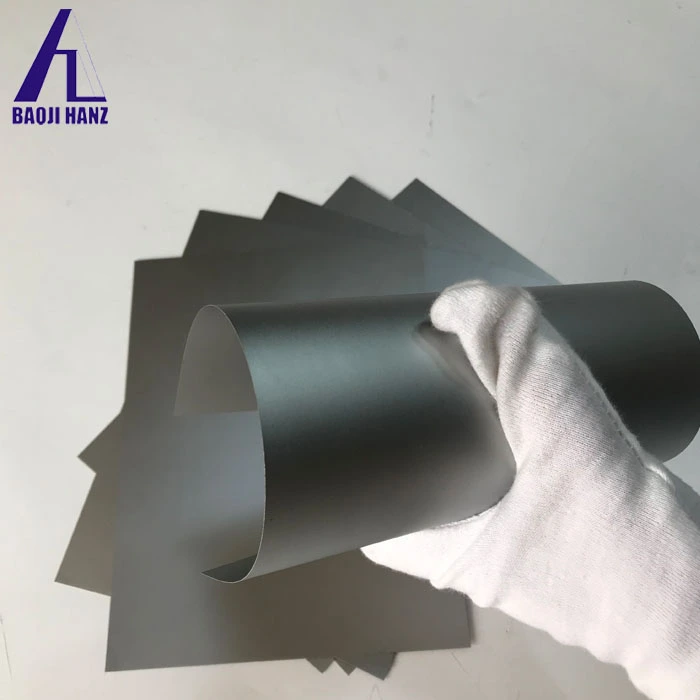

Introduction to Nitinol Sheets

Nitinol, a shape memory alloy primarily composed of nickel and titanium, exhibits extraordinary properties that differentiate it from conventional metals. Its ability to return to a predetermined shape after deformation (shape memory effect) and withstand large strains without permanent deformation (superelasticity) has revolutionized numerous industrial applications.

Industrial Applications of Nitinol Sheets

Industrial Nitinol sheets are tailored for specific applications where these unique properties are advantageous. They are extensively used in sectors such as:

-

Medical Devices: Nitinol's biocompatibility and shape memory properties make it ideal for surgical tools, stents, and other implantable devices. The ability to navigate through constrained spaces and then expand to a predetermined shape within the body cavity showcases its utility.

-

Aerospace and Automotive Industries: Nitinol's lightweight nature combined with its robust mechanical properties makes it suitable for aerospace components, including actuators, sensors, and deployable structures. In automotive applications, it contributes to improved fuel efficiency and enhanced safety features.

-

Consumer Electronics: From smart eyeglass frames to mobile phone antennas, Nitinol's flexibility and durability enable innovative designs that improve user experience and product longevity.

Key Properties of Nitinol Sheets

To fully grasp Nitinol's suitability for industrial use, it's essential to understand its key properties:

-

Shape Memory Effect: Nitinol can "remember" its original shape and return to it when heated above a critical temperature.

-

Superelasticity: Unlike traditional materials that undergo plastic deformation under stress, Nitinol can undergo large deformations and recover completely upon unloading.

-

Biocompatibility: Nitinol's inertness and biocompatibility make it suitable for long-term implantation in medical devices without adverse reactions from the body.

Comparative Analysis with Traditional Materials

When compared to materials like steel and titanium, Nitinol offers distinct advantages:

-

Weight and Flexibility: Nitinol is significantly lighter than steel and more flexible than titanium, making it suitable for applications requiring both strength and adaptability.

-

Cost Considerations: While Nitinol can be more expensive than traditional metals, its unique properties often justify the cost through improved performance and longevity.

Challenges and Considerations

Despite its many advantages, working with Nitinol presents challenges such as:

-

Processing Complexity: Fabricating Nitinol requires specialized knowledge and equipment due to its unique properties and behavior during processing.

-

Stress Relaxation: Nitinol can exhibit stress relaxation over time, which may affect long-term performance in certain applications if not carefully managed.

Conclusion

In conclusion, Nitinol sheets are indeed endowed with memory properties, making them invaluable across a spectrum of industrial applications. Whether in healthcare, aerospace, or consumer electronics, their unique combination of shape memory and superelasticity continues to drive innovation. By understanding these properties and their applications, industries can leverage Nitinol to enhance product performance and competitiveness in the global market.

References

- "Shape Memory Alloys" - Materials Science and Engineering: An Introduction, 10th Edition

- "Applications of Shape Memory Alloys in Medicine" - Journal of the Mechanical Behavior of Biomedical Materials

- "Superelasticity in Nitinol Alloys" - Shape Memory and Superelasticity