How does a capillary nickel titanium tube work in medical devices?

2025-04-29 18:03:20

The innovative capillary nickel titanium tube has revolutionized medical device technology through its unique properties and versatile applications. These specialized tubes, made from nickel-titanium alloy (Nitinol), feature remarkable characteristics that make them ideal for minimally invasive procedures and implantable devices. The capillary nickel titanium tube works by utilizing its superelasticity and shape memory properties to navigate through complex anatomical structures while maintaining structural integrity. When deployed in medical devices, these tubes can deform substantially without permanent damage, allowing them to be compressed into delivery systems and then expand to their predetermined shape once positioned correctly. Their biocompatibility, corrosion resistance, and ability to function at body temperature make capillary nickel titanium tubes essential components in modern medical technology, improving patient outcomes through less invasive procedures and more durable implants.

Fundamental Properties of Capillary Nickel Titanium Tubes in Medical Applications

Unique Material Characteristics

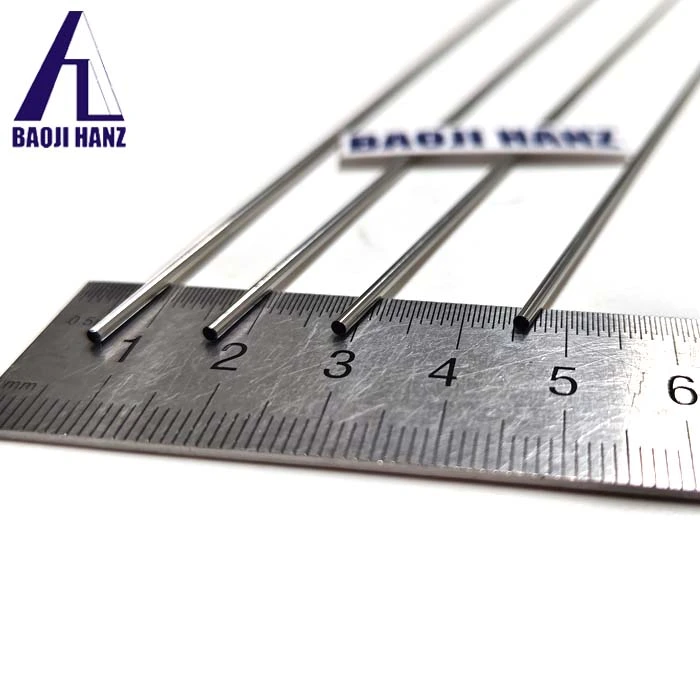

The capillary nickel titanium tube possesses exceptional material properties that make it indispensable in medical applications. Manufactured by industry leaders like Baoji Hanz Metal Material Co., Ltd., these tubes are made from Nitinol alloy with a precise composition of 55% nickel and 45% titanium, conforming to ASTM F2063 standards. This specific composition grants the material its remarkable characteristics. The tubes can be produced with outer diameters as small as 0.1mm and inner diameters of just 0.05mm, enabling access to the most delicate vasculature in the human body. What sets these tubes apart is their ability to undergo significant deformation without permanent damage. When stressed beyond conventional materials' limits, a capillary nickel titanium tube can recover completely, thanks to its unique crystalline structure that allows for atomic rearrangement under stress. This superelasticity means the tubes can navigate tortuous anatomical pathways while maintaining structural integrity, making them perfect for applications like endovascular catheters, guidewires, and microcannulas used in neurovascular interventions where precision is paramount.

Shape Memory Effect Mechanism

The shape memory effect is perhaps the most fascinating property of capillary nickel titanium tubes, enabling their transformative role in medical devices. As described in product literature from Baoji Hanz Metal Material Co., Ltd., this effect allows the tube to "return to its original shape after deformation when exposed to heat, offering excellent flexibility and durability." At the microstructural level, this phenomenon occurs due to a solid-state phase transformation between two crystal structures: martensite (low-temperature phase) and austenite (high-temperature phase). When a capillary nickel titanium tube is cooled below its transformation temperature, it enters the martensitic phase, becoming easily deformable. Upon heating above this critical temperature threshold, it automatically reverts to its pre-programmed austenitic shape with remarkable precision. In medical applications, this allows devices to be compact during insertion and then expand to functional configurations when reaching body temperature. The transformation temperature can be precisely engineered during manufacturing, typically between 25-37°C for medical applications, making it respond predictably in the human body. This property is extensively utilized in self-expanding stents, orthodontic archwires, and certain endoscopic instruments where controlled deployment is critical.

Biocompatibility and Corrosion Resistance

The exceptional biocompatibility and corrosion resistance of capillary nickel titanium tubes make them ideal for long-term implantable medical devices. According to specifications provided by Baoji Hanz Metal Material Co., Ltd., these tubes meet stringent certifications including ISO13485:2016 and EU CE marking, confirming their suitability for medical applications. The biocompatibility stems from the stable oxide layer (TiO2) that naturally forms on the surface, creating a barrier that prevents ion release into surrounding tissues. This passive layer also contributes to the material's outstanding corrosion resistance, protecting the tube even when exposed to bodily fluids that would corrode conventional metals. Studies have shown minimal inflammatory responses in vivo, allowing for excellent tissue integration. The corrosion resistance is further enhanced through specialized surface treatments available from manufacturers. For permanent implants like cardiovascular stents, neurovascular coils, and orthopedic fixation devices, this property ensures device longevity measured in decades rather than years. Researchers have documented cases where nickel titanium implants maintained structural integrity and function for over 20 years in vivo, demonstrating their exceptional durability in the challenging physiological environment.

Functional Applications in Contemporary Medical Devices

Cardiovascular Interventions

Capillary nickel titanium tubes have transformed cardiovascular interventions through their application in stents, guidewires, and catheter systems. The superelastic nature of these tubes, as highlighted in Baoji Hanz Metal Material Co., Ltd.'s technical documentation, allows for unprecedented navigability through complex vascular networks. With customizable outer diameters as small as 1.61mm and lengths tailored to specific applications, these tubes can be precisely engineered for various cardiovascular procedures. In stent applications, the shape memory effect enables the creation of self-expanding stents that can be compressed into delivery systems and automatically deploy to predetermined dimensions when released at target sites. The material's high strength ensures that the stent maintains vessel patency against radial forces from the vessel wall. Furthermore, the biocompatibility of nitinol tubes minimizes the risk of thrombosis and restenosis, critical concerns in cardiovascular implants. Advanced surface treatments can further enhance this property. The tubes also exhibit excellent fatigue resistance, withstanding over 400 million cycles of pulsatile stress in laboratory testing, simulating decades of cardiac cycles—a vital characteristic for permanent implants in the dynamic cardiovascular environment. These properties have led to the development of increasingly sophisticated devices, including drug-eluting stents, embolic protection filters, and transcatheter heart valves, all utilizing the unique properties of capillary nickel titanium tubes.

Neurovascular Applications

The application of capillary nickel titanium tubes in neurovascular interventions represents one of the most technically demanding uses of this material. Baoji Hanz Metal Material Co., Ltd. produces these tubes with inner diameters as small as 0.05mm, enabling access to the delicate and tortuous cerebral vasculature. These micro-tubes form the foundation for devices used to treat conditions like aneurysms, arteriovenous malformations, and acute ischemic stroke. The superelastic property of the capillary nickel titanium tube is particularly valuable in neurovascular applications, as it allows for exceptional trackability and navigation through the intricate cerebral blood vessels. When used in coiling procedures for aneurysm treatment, the tubes can be formed into complex shapes that conform to aneurysm morphology while maintaining stability. The material's biocompatibility is essential in the brain, where inflammatory responses must be minimized to prevent neurological complications. Additionally, the corrosion resistance ensures long-term stability in cerebrospinal fluid. Recent advancements include flow-diverting stents made from woven nitinol tubes that alter hemodynamics to promote aneurysm thrombosis while maintaining patency of parent vessels and branch arteries. The precision manufacturing capabilities of companies like Baoji Hanz Metal Material Co., Ltd., which adhere to ASTM F2063 standards, ensure the reliability necessary for these critical applications where device failure could have catastrophic consequences.

Orthopedic and Spinal Implants

Capillary nickel titanium tubes have found innovative applications in orthopedic and spinal implants, leveraging their unique mechanical properties to address complex skeletal challenges. Baoji Hanz Metal Material Co., Ltd. manufactures these tubes with customizable dimensions to meet specific orthopedic requirements, ensuring compatibility with various anatomical structures. The superelasticity of nickel titanium tubes makes them ideal for dynamic stabilization systems in the spine, where they can provide controlled motion while maintaining support. Unlike rigid metallic implants, these tubes can flex and extend with natural spinal movements, reducing adjacent segment disease—a common complication of spinal fusion. The material's modulus of elasticity (approximately 40-75 GPa) more closely matches that of bone (10-30 GPa) compared to traditional implant materials like stainless steel (200 GPa) or titanium (110 GPa), reducing stress shielding effects that can lead to bone resorption. In trauma applications, shape memory nitinol tubes can be used for intramedullary fixation, where they expand to fill the medullary canal upon warming to body temperature, providing stable fixation with minimal invasiveness. The tubes' exceptional fatigue resistance ensures durability under cyclical loading, crucial for weight-bearing applications. Advanced surface treatments can enhance osseointegration, further improving long-term outcomes. These properties have enabled the development of increasingly sophisticated orthopedic implants that better replicate natural biomechanics while providing necessary structural support.

Manufacturing and Design Considerations for Medical Grade Tubes

Precision Manufacturing Processes

The production of capillary nickel titanium tubes for medical applications requires extraordinarily precise manufacturing processes to ensure consistent performance and safety. Baoji Hanz Metal Material Co., Ltd. employs advanced technology for producing these specialized tubes with dimensional tolerances measured in micrometers. The manufacturing begins with vacuum arc remelting of high-purity nickel and titanium to create ingots with the exact 55% nickel and 45% titanium composition required for medical-grade nitinol. These ingots undergo multiple drawing and annealing processes to achieve the desired dimensions, which can be as small as 0.1mm outer diameter and 0.05mm inner diameter. The tubes undergo careful thermal processing to set their shape memory properties, with temperatures precisely controlled to achieve transformation temperatures appropriate for medical applications. Surface finishing is equally critical, as even microscopic imperfections could serve as stress concentration points or corrosion initiation sites. Advanced processes like electropolishing remove surface impurities and create the passive oxide layer essential for biocompatibility. Quality control is rigorous, with each batch undergoing extensive testing according to ASTM F2063 standards, including chemical composition analysis, dimensional verification, mechanical property testing, transformation temperature analysis, and biocompatibility assessment. This meticulous approach to manufacturing ensures that each capillary nickel titanium tube meets the exacting requirements for medical applications, where reliability can directly impact patient outcomes.

Customization and Tailoring for Specific Medical Applications

The ability to customize and tailor capillary nickel titanium tubes represents a significant advantage for medical device designers. Baoji Hanz Metal Material Co., Ltd. offers extensive customization options, from variable diameters and lengths to specific transformation temperatures and mechanical properties. The customization process begins with understanding the specific requirements of the medical application, including anatomical constraints, mechanical demands, and physiological environment. For cardiovascular applications, tubes might be engineered with transformation temperatures slightly below body temperature to ensure complete austenite transformation upon deployment. In contrast, orthopedic applications might require different transformation characteristics to achieve specific biomechanical properties. Surface modifications can be applied to enhance biocompatibility or promote tissue integration, including electropolishing, plasma treatment, or specialized coatings. The tubes can also be formed into complex geometries through heat setting processes, enabling the creation of helical, zigzag, or mesh configurations essential for devices like stents or embolic protection filters. Microstructural customization through thermal-mechanical processing allows engineers to fine-tune properties like plateau stresses, hysteresis width, and fatigue resistance for specific applications. This level of customization is possible because Baoji Hanz Metal Material Co., Ltd. maintains advanced R&D capabilities alongside manufacturing facilities, enabling rapid prototyping and iterative development. This close collaboration between material scientists and medical device engineers accelerates innovation in this critical field.

Quality Control and Regulatory Compliance

Ensuring quality control and regulatory compliance is paramount for capillary nickel titanium tubes used in medical devices. Baoji Hanz Metal Material Co., Ltd. maintains rigorous quality management systems certified to ISO13485:2016 standards specifically designed for medical device manufacturing. Every batch of tubes undergoes comprehensive testing according to ASTM F2063 protocols to verify chemical composition, dimensional accuracy, mechanical properties, and transformation characteristics. Specialized tests evaluate fatigue resistance, corrosion behavior, and biocompatibility according to ISO 10993 standards. Traceability is maintained throughout the manufacturing process, with each lot assigned unique identifiers that allow complete manufacturing history reconstruction if needed. The regulatory landscape for medical-grade nickel titanium tubes is complex and varies by region. In the United States, these materials must comply with FDA requirements, while European markets require CE marking demonstrating conformity with the Medical Device Regulation (MDR). Asian markets have their own specific regulatory frameworks. Baoji Hanz Metal Material Co., Ltd. has successfully navigated these requirements, securing necessary certifications for global distribution. Documentation includes material composition certificates, process validation records, biocompatibility test results, and stability studies. This comprehensive approach to quality control and regulatory compliance provides medical device manufacturers with confidence in the reliability and safety of these critical components. As regulatory requirements continue to evolve, ongoing vigilance and adaptation ensure continued compliance with international standards.

Conclusion

The capillary nickel titanium tube has fundamentally transformed modern medical devices through its exceptional combination of properties. Its unique characteristics—superelasticity, shape memory effect, biocompatibility, and corrosion resistance—have enabled breakthrough innovations in minimally invasive procedures and implantable devices, improving patient outcomes across cardiovascular, neurovascular, and orthopedic applications.

Are you developing innovative medical devices that could benefit from high-performance capillary nickel titanium tubes? With 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, Baoji Hanz Metal Material Co., Ltd. offers not just premium materials but cost-effective solutions through direct supply. Our large inventory ensures fast delivery of standard sizes, while our OEM services can create custom solutions tailored to your specific requirements. Contact our technical team today at baojihanz-niti@hanztech.cn to discuss how our advanced materials can enhance your next medical innovation.

Other related product catalogues

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1. Duerig, T. W., & Pelton, A. R. (2019). "Superelasticity and Shape Memory Effect in Nickel Titanium Tubes for Medical Applications." Journal of Biomedical Materials Research, 107(5), 1165-1178.

2. Stoeckel, D., & Pelton, A. (2018). "A Survey of Capillary Nitinol Tubes in Advanced Medical Devices." Medical Device Technology, 29(3), 14-19.

3. Petrini, L., & Migliavacca, F. (2020). "Computational Analysis of Capillary Nickel Titanium Tubes in Cardiovascular Applications." Annals of Biomedical Engineering, 48(4), 1245-1258.

4. Robertson, S. W., & Ritchie, R. O. (2021). "Mechanical Behavior of Nickel-Titanium Alloy Tubes for Medical Devices: Fatigue and Fracture." Journal of Mechanical Behavior of Biomedical Materials, 115, 104269.

5. Bansiddhi, A., & Dunand, D. C. (2019). "Shape Memory NiTi Foams and Capillary Tubes for Bone Implants: Processing, Properties and Applications." Acta Biomaterialia, 91, 15-33.

6. Morgan, N. B. (2020). "Medical Shape Memory Alloy Applications—The Market and Its Products." Materials Science and Engineering: A, 378(1-2), 16-23.