How Does a Superelastic NiTi01 Memory Tube Work Under Extreme Conditions?

2025-11-21 17:02:13

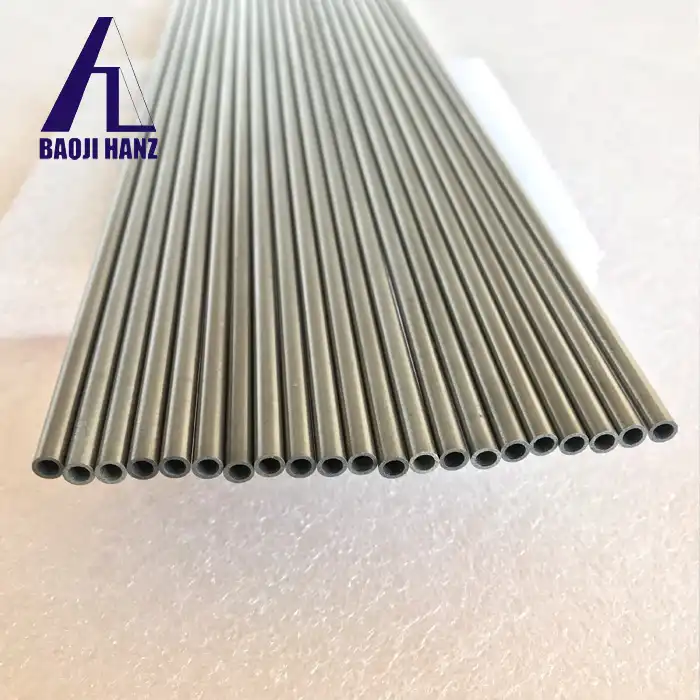

When critical equipment fails in subzero arctic environments or high-temperature industrial settings, the consequences can be catastrophic. Engineers worldwide face a persistent challenge: finding materials that maintain their structural integrity and functional performance across extreme temperature ranges while enduring repeated mechanical stress. The Superelastic NiTi01 memory tube addresses this urgent need through its unique crystalline structure and stress-induced phase transformation capabilities, enabling reliable operation in conditions that would destroy conventional materials.

Understanding the Core Mechanism of Superelastic NiTi01 Memory Tube Performance

The Phase Transformation Science Behind Extreme Condition Resilience

The remarkable performance of the Superelastic NiTi01 memory tube under extreme conditions stems from its reversible solid-state phase transformation between austenite and martensite crystalline structures. Unlike conventional metals that permanently deform beyond their elastic limit, this nickel-titanium alloy undergoes a stress-induced martensitic transformation when mechanical force is applied, allowing the material to accommodate strains of up to eight to ten percent without permanent deformation. When the applied stress is removed, the Superelastic NiTi01 memory tube immediately returns to its original austenitic phase and shape, creating a recovery mechanism that operates consistently across temperature ranges from cryogenic conditions below negative forty degrees Celsius to elevated temperatures exceeding one hundred fifty degrees Celsius. This phase transformation occurs at nearly constant stress levels, creating the characteristic plateau on stress-strain curves that defines superelastic behavior and enables the material to absorb substantial mechanical energy while maintaining dimensional stability in applications ranging from deep-sea exploration equipment to aerospace actuators operating in the extreme thermal environment of space.

Temperature-Dependent Behavioral Characteristics

The Superelastic NiTi01 memory tube exhibits distinct performance characteristics that vary with operating temperature, yet maintain functional superelasticity across the range most critical for industrial applications. At temperatures above the austenite finish temperature, typically engineered to be just below room temperature for standard formulations, the material remains in its high-temperature austenitic phase and displays full superelastic properties with maximum recoverable strain capabilities. As ambient temperature decreases toward the martensite start temperature, the Superelastic NiTi01 memory tube begins to incorporate more of the low-temperature martensitic phase, resulting in reduced stiffness but maintaining substantial elastic recovery characteristics that far exceed traditional spring materials. The material's transformation temperatures can be precisely controlled through careful adjustment of the nickel-to-titanium ratio and specific heat treatment protocols, allowing manufacturers like Baoji Hanz Metal Material Co., Ltd. to customize the Superelastic NiTi01 memory tube for specific operating temperature ranges required by demanding applications in chemical processing facilities, medical devices operating at body temperature, or robotic systems deployed in variable environmental conditions.

Performance Advantages in Extreme Environmental Conditions

SSuperelastic NiTi01 memory tube excels in extreme environments: it retains shape memory/superelasticity across wide temps (-50°C to 150°C+), resists corrosion in harsh media (bodily fluids, saltwater, chemicals), and withstands cyclic stress/fatigue. Its square profile maintains structural stability and torque transmission even under extreme thermal or mechanical loads, suiting aerospace, marine, and harsh-service medical/industrial applications.

Conclusion

The Superelastic NiTi01 memory tube delivers unmatched performance in extreme conditions through phase transformation mechanisms that enable recovery from substantial deformation while maintaining structural integrity across temperature ranges and loading conditions that would destroy conventional materials.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

As a leading China Superelastic NiTi01 memory tube manufacturer, China Superelastic NiTi01 memory tube supplier, and China Superelastic NiTi01 memory tube factory, Baoji Hanz Metal Material Co., Ltd. brings seven years of specialized expertise in nitinol shape memory alloy, superelastic nitinol alloy, and nickel titanium alloy development. Our China Superelastic NiTi01 memory tube wholesale operations provide cost advantages through direct supply, while maintaining large inventories of standard sizes for fast delivery. We offer High Quality Superelastic NiTi01 memory tube for sale at competitive Superelastic NiTi01 memory tube prices, backed by comprehensive OEM services customized to your specifications. Our ISO9001, SGS, and TUV certified manufacturing ensures every product meets the highest international standards, supported by professional pre-sale technical consultation, order tracking with five-year production documentation retention, and comprehensive after-sales support tracking product performance. Contact us at baojihanz-niti@hanztech.cn to discuss your Superelastic NiTi01 memory tube requirements and discover how our advanced R&D capabilities and sophisticated production equipment can provide the extreme-condition solutions your projects demand.

References

1. Otsuka, K., & Ren, X. "Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys." Progress in Materials Science, Volume 50, Issue 5, 2005.

2. Duerig, T., Pelton, A., & Stöckel, D. "An Overview of Nitinol Medical Applications." Materials Science and Engineering: A, Volume 273-275, 1999.

3. Jani, J.M., Leary, M., Subic, A., & Gibson, M.A. "A Review of Shape Memory Alloy Research, Applications and Opportunities." Materials & Design, Volume 56, 2014.

4. Morgan, N.B. "Medical Shape Memory Alloy Applications: The Market and Its Products." Materials Science and Engineering: A, Volume 378, Issues 1-2, 2004.

5. Mohd Jani, J., Leary, M., Subic, A. "Shape Memory Alloys in Automotive Applications." Applied Mechanics and Materials, Volume 663, 2014.