How does super elasticity in nitinol work?

2025-02-26 15:08:17

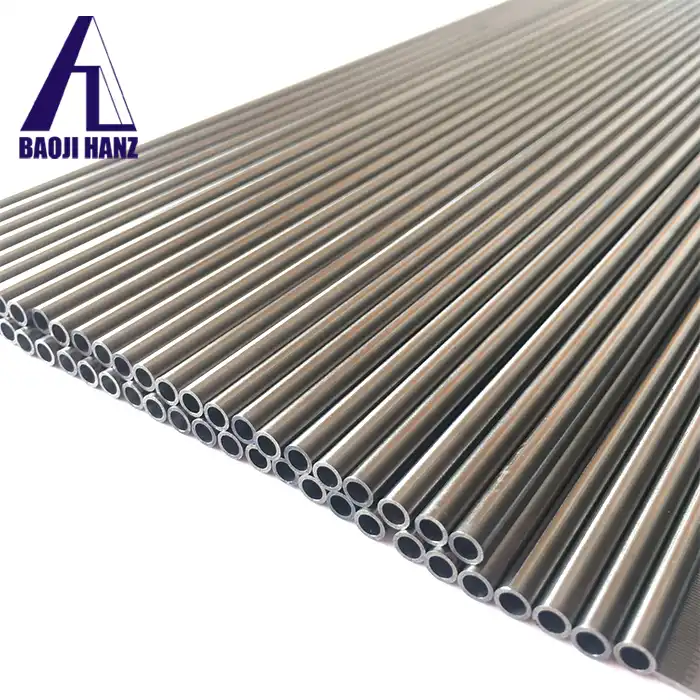

Nitinol, a remarkable alloy of nickel and titanium, has captivated the materials science world with its extraordinary properties, particularly its super elasticity. This unique characteristic allows super elastic nitinol pipe to undergo significant deformation and return to its original shape without permanent damage. Understanding the mechanics behind super elasticity in nitinol is crucial for engineers, researchers, and industries leveraging this material's potential. This blog delves into the intricate workings of super elasticity in nitinol, exploring its atomic structure, phase transformations, and practical applications. We'll unravel the science behind this fascinating property and shed light on how it's harnessed in various fields, from medical devices to aerospace engineering.

The Science Behind Nitinol's Super Elasticity

Atomic Structure and Crystal Phases

At the heart of nitinol's super elasticity lies its unique atomic structure. Nitinol exists in two primary crystal phases: austenite and martensite. The austenite phase, stable at higher temperatures, has a cubic crystal structure. In contrast, the martensite phase, prevalent at lower temperatures, exhibits a more complex monoclinic structure. The interplay between these phases is key to understanding nitinol's super elastic behavior. When stress is applied to nitinol in its austenitic phase, it undergoes a reversible phase transformation to the martensitic phase. This transformation occurs without the breaking of atomic bonds, allowing the material to accommodate large strains. Upon removal of the stress, the material reverts to its austenitic structure, recovering its original shape. This phase transformation is the cornerstone of nitinol's super elasticity.

Temperature-Dependent Behavior

The temperature at which nitinol transitions between its austenitic and martensitic phases is crucial to its super elastic properties. This transition temperature can be tailored during the manufacturing process to suit specific applications. Above the transition temperature, nitinol exhibits super elastic behavior, while below it, the material displays shape memory effects. In the super elastic regime, nitinol can withstand strains of up to 8% without permanent deformation. This is significantly higher than conventional metals, which typically yield at strains of less than 1%. The temperature-dependent nature of nitinol's behavior allows for precise control of its mechanical properties, making it invaluable in various engineering applications.

Stress-Induced Martensite Formation

When stress is applied to super elastic nitinol pipe, it induces the formation of martensite. This stress-induced martensite is different from thermally-induced martensite, as it occurs above the material's transition temperature. The stress causes the austenitic crystal structure to shear and rearrange into the martensitic structure, accommodating the applied strain. As the stress increases, more martensite forms, allowing the material to deform without permanent damage. When the stress is removed, the martensite becomes thermodynamically unstable and reverts to the austenite phase, restoring the original shape. This reversible process is what gives nitinol its remarkable ability to "remember" its shape after deformation.

Applications Leveraging Nitinol's Super Elasticity

Medical Devices and Implants

The medical field has embraced nitinol's super elasticity for numerous applications. Stents, which are used to keep blood vessels open, benefit greatly from nitinol's ability to compress into a small diameter for insertion and then expand to its pre-set shape once in place. This property allows for minimally invasive procedures and reduces the risk of vessel damage. Orthodontic archwires made from super elastic nitinol provide consistent, gentle forces for tooth movement over extended periods. These wires can undergo large deflections without permanent deformation, making them ideal for treating misaligned teeth. Additionally, nitinol is used in surgical instruments, such as guidewires and catheters, where its flexibility and kink resistance are invaluable.

Aerospace and Automotive Industries

In aerospace applications, super elastic nitinol pipe finds use in vibration damping systems and adaptive structures. Its ability to absorb and dissipate energy makes it excellent for reducing vibrations in aircraft components. Nitinol actuators and fasteners are also employed in aerospace designs, taking advantage of the material's shape recovery properties to create smart, responsive structures. The automotive industry utilizes super elastic nitinol in various components, including impact absorption systems and valve springs. Nitinol's high fatigue resistance and ability to operate over a wide temperature range make it suitable for demanding automotive applications. Its use in engine components can lead to improved fuel efficiency and reduced emissions.

Consumer Products and Wearable Technology

Super elastic nitinol pipe has found its way into numerous consumer products. Eyeglass frames made from nitinol are virtually indestructible, able to bend and twist without breaking. This property has revolutionized the durability of glasses, particularly beneficial for active wearers or children. In the realm of wearable technology, nitinol's super elasticity is harnessed for creating flexible, comfortable devices. From smartwatch bands to fitness trackers, nitinol components allow for devices that conform to the body's contours while maintaining their functionality. The material's biocompatibility and resistance to corrosion make it ideal for prolonged skin contact in these applications.

Manufacturing and Processing Super Elastic Nitinol

Alloy Composition and Heat Treatment

The production of super elastic nitinol requires precise control over the alloy's composition and heat treatment processes. The typical composition ranges from 54.5% to 57% nickel by weight, with the remainder being titanium. Minor variations in this composition can significantly affect the material's properties, including its transition temperature and super elastic behavior. Heat treatment plays a crucial role in determining nitinol's final properties. The material undergoes a series of heating and cooling cycles to set its shape and optimize its super elastic characteristics. This process, known as shape setting, involves heating the nitinol to temperatures around 500°C and then rapidly cooling it. The specific heat treatment parameters are carefully tailored to achieve the desired super elastic properties for each application.

Forming and Machining Challenges

Working with super elastic nitinol presents unique challenges in forming and machining processes. Traditional machining techniques often struggle with nitinol's high strength and work hardening properties. Specialized cutting tools and techniques, such as electrical discharge machining (EDM) and laser cutting, are frequently employed to shape nitinol components accurately. Forming super elastic nitinol into complex shapes requires consideration of its unique stress-strain behavior. Cold working can alter the material's properties, necessitating additional heat treatments to restore its super elastic characteristics. Advanced forming techniques, including superplastic forming at elevated temperatures, have been developed to overcome these challenges and produce intricate nitinol structures.

Quality Control and Testing

Ensuring the consistency and reliability of super elastic nitinol products demands rigorous quality control measures. Non-destructive testing methods, such as X-ray diffraction and differential scanning calorimetry, are used to analyze the material's crystal structure and phase transformation behavior. These techniques help verify that the nitinol components meet the required specifications for super elasticity. Mechanical testing is essential to characterize the super elastic properties of nitinol products. Stress-strain curves are generated through cyclic loading tests, allowing engineers to assess the material's elastic recovery and fatigue resistance. Additionally, thermomechanical testing is conducted to evaluate the temperature dependence of nitinol's super elastic behavior, ensuring that components perform as intended across their operational temperature range.

Conclusion

Super elastic nitinol pipe is a remarkable property that stems from its unique atomic structure and phase transformations. This characteristic enables nitinol to undergo significant deformation and return to its original shape, making it invaluable in various industries. From medical devices to aerospace applications, super elastic nitinol continues to push the boundaries of material science and engineering, offering innovative solutions to complex design challenges. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge university press.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

4. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

5. Pelton, A. R., Stöckel, D., & Duerig, T. W. (2000). Medical uses of nitinol. Materials Science Forum, 327, 63-70.

6. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.