How Does Superelastic NiTi01 Memory Tube Withstand Extreme Conditions?

2025-04-08 20:57:39

In today's demanding industrial landscape, materials that can perform reliably under extreme conditions are increasingly sought after. The Superelastic NiTi01 memory tube stands at the forefront of this innovation, offering unprecedented resilience in challenging environments. This revolutionary nickel-titanium alloy product, developed by Baoji Hanz Metal Material Co., Ltd., demonstrates remarkable capabilities to withstand extreme temperatures, mechanical stress, and corrosive environments while maintaining its functional properties. Understanding how this exceptional material performs under duress provides valuable insights for engineers and designers seeking solutions for the most challenging applications in medical, aerospace, and industrial sectors.

Unique Material Properties Enabling Extreme Condition Performance

The exceptional performance of Superelastic NiTi01 memory tube in extreme conditions stems from its unique material composition and structure. These inherent properties allow it to withstand challenges that would compromise conventional materials.

Crystal Structure Transformation Mechanism

The Superelastic NiTi01 memory tube derives its extraordinary performance from a unique crystallographic transformation that occurs at the atomic level. When subjected to mechanical stress, the material undergoes a reversible phase transformation from austenite to martensite without any thermal activation. This stress-induced transformation is the fundamental mechanism behind the superelastic behavior that allows these tubes to withstand extreme deformation. At room temperature, the material exists in its austenite phase with a cubic crystal structure. Under stress, it transforms to a monoclinic martensite phase, accommodating strains of up to 8-10% without permanent deformation. This is approximately ten times the elastic range of conventional metallic materials. When the stress is removed, the Superelastic NiTi01 memory tube spontaneously reverts to its original austenite phase and shape, making it ideal for applications requiring repeated deformation cycles under extreme mechanical conditions. This transformation occurs within a specific temperature range determined by the precise nickel-titanium ratio in the alloy, which Baoji Hanz Metal Material Co., Ltd. carefully controls during the manufacturing process to ensure consistent performance across various operating environments.

Superior Fatigue Resistance and Durability

The Superelastic NiTi01 memory tube exhibits exceptional fatigue resistance that far surpasses conventional engineering materials, allowing it to maintain functionality under repetitive loading in extreme conditions. While standard metals typically fail after a few thousand cycles of significant strain, these superelastic tubes can withstand millions of loading cycles without degradation when properly designed within their strain limits. This superior fatigue performance stems from the unique stress-strain behavior of the material. Unlike traditional metals that accumulate damage through dislocation movements leading to crack initiation and propagation, the Superelastic NiTi01 memory tube accommodates strain through the reversible phase transformation described earlier. This fundamentally different deformation mechanism enables the material to distribute stress more uniformly throughout its volume, preventing localized stress concentrations that typically lead to fatigue failure. Furthermore, the tube's manufacturing process, which involves precise thermal treatments and cold working, creates a refined microstructure that enhances fatigue resistance. Available in outer diameters ranging from 3mm to 114mm and lengths up to 6000mm, these tubes can be tailored to specific application requirements while maintaining their exceptional durability across various dimensions. The combination of these properties makes the Superelastic NiTi01 memory tube uniquely suited for applications requiring long-term reliability under cyclical loading in extreme environments.

Thermal Stability Across Wide Temperature Ranges

The Superelastic NiTi01 memory tube demonstrates remarkable thermal stability, maintaining its mechanical properties across a wide temperature spectrum that would render conventional materials ineffective. This exceptional thermal performance enables functionality in environments ranging from cryogenic temperatures to over 100°C, depending on the specific alloy composition. While standard engineering materials typically experience significant changes in mechanical properties with temperature fluctuations, the Superelastic NiTi01 memory tube maintains consistent performance characteristics throughout its operational temperature range. This stability stems from the carefully controlled transformation temperatures engineered into the material during production at Baoji Hanz Metal Material Co., Ltd.'s advanced manufacturing facilities. The tube's superelastic behavior, rather than being compromised by temperature variations, simply shifts its stress-strain response while maintaining its functional recovery capabilities. Additionally, the material exhibits low thermal expansion coefficients compared to many conventional metals, minimizing dimensional changes during temperature fluctuations. With wall thickness options ranging from 0.1mm to 15mm, these tubes can be manufactured to precise specifications that accommodate thermal considerations for specific applications. This thermal stability makes the Superelastic NiTi01 memory tube particularly valuable in environments with significant temperature variations or thermal cycling, such as aerospace components, automotive systems, and industrial processing equipment where maintaining consistent performance across temperature gradients is critical for system reliability and safety.

Resistance to Chemical and Environmental Challenges

Beyond mechanical resilience, the Superelastic NiTi01 memory tube demonstrates exceptional resistance to various chemical and environmental challenges that would rapidly degrade conventional materials.

Corrosion Resistance in Harsh Environments

The Superelastic NiTi01 memory tube exhibits exceptional corrosion resistance in aggressive environments that would rapidly deteriorate conventional metallic materials. This remarkable property stems from the formation of a stable, self-healing titanium oxide (TiO₂) passive layer on the surface, which provides a protective barrier against chemical attack. In saline solutions similar to bodily fluids, these tubes demonstrate corrosion rates significantly lower than surgical stainless steels, making them ideal for medical implants and devices. The material shows particular resistance to chloride-induced pitting corrosion, which is a common failure mechanism for many metal alloys in marine environments. Even in highly oxidizing acids, the Superelastic NiTi01 memory tube maintains its structural integrity far longer than conventional alternatives. This corrosion resistance remains effective across the full range of available dimensions, from smaller diameter tubes used in precise medical applications to larger industrial variants with outer diameters up to 114mm. For applications requiring enhanced protection, additional surface treatments can be applied during manufacturing to further improve chemical resistance. The combination of inherent corrosion resistance and customizable surface properties allows these tubes to function reliably in environments containing aggressive chemicals, saltwater exposure, bodily fluids, and industrial process streams. This remarkable chemical stability, coupled with the mechanical properties of the Superelastic NiTi01 memory tube, enables applications in chemical processing equipment, offshore structures, and medical implants where exposure to corrosive media is unavoidable and material failure would have severe consequences.

Biocompatibility for Medical Applications

The Superelastic NiTi01 memory tube demonstrates exceptional biocompatibility, making it ideal for medical applications where interaction with living tissues is essential. This remarkable property stems from the stable titanium oxide layer that forms naturally on the surface, creating a biocompatible barrier between the base material and surrounding tissues. Meeting rigorous standards including ASTM F2633-07 certification, these tubes have been extensively tested and validated for medical use. The material exhibits minimal inflammatory response when implanted, with studies showing comparable or better tissue compatibility than traditional medical-grade stainless steels and cobalt-chrome alloys. The superelastic nature of the material closely mimics the mechanical properties of human tissues and bone, reducing stress shielding and improving long-term integration with the body. This mechanical biocompatibility, combined with chemical stability, makes the Superelastic NiTi01 memory tube particularly valuable for long-term implantable devices. Additionally, the material shows excellent resistance to protein adsorption and bacterial adhesion, reducing the risk of biofilm formation and associated infections. Baoji Hanz Metal Material Co., Ltd. ensures the highest levels of purity and surface quality in their medical-grade tubes, minimizing the potential for nickel ion release that could cause allergic responses in sensitive individuals. With customizable dimensions and properties, these tubes can be tailored specifically for various medical applications, from cardiovascular stents requiring smaller diameters to orthopedic implants utilizing larger profiles, all while maintaining the strict biocompatibility requirements necessary for medical devices. This combination of biological and mechanical compatibility creates a unique material solution for medical devices that must function reliably within the challenging and dynamic environment of the human body.

Radiation and Sterilization Resistance

The Superelastic NiTi01 memory tube demonstrates exceptional resistance to radiation exposure and sterilization processes, maintaining its critical mechanical and functional properties where other materials would degrade. This radiation hardness stems from the strong atomic bonding and crystal structure of the nickel-titanium alloy, which resists the displacement damage and ionization effects that typically compromise conventional materials under radiation bombardment. In medical applications, these tubes can withstand repeated sterilization cycles using gamma radiation, electron beam processing, or steam autoclaving without significant changes to their superelastic properties or surface characteristics. The material shows minimal oxidation or embrittlement during high-temperature sterilization procedures, preserving both its mechanical integrity and biocompatibility. For industrial applications in nuclear environments or space systems, the Superelastic NiTi01 memory tube maintains functionality even when exposed to significant radiation doses that would cause embrittlement, swelling, or property degradation in standard engineering alloys. This resistance to radiation damage makes these tubes particularly valuable for applications in radiation therapy equipment, nuclear power systems, and spacecraft components where material stability under radiation exposure is critical for long-term reliability and safety. Baoji Hanz Metal Material Co., Ltd. conducts rigorous testing on their products to ensure consistent performance after multiple sterilization cycles, with quality control measures that exceed international standards for materials intended for radiation environments. The combination of radiation resistance with the other exceptional properties of the Superelastic NiTi01 memory tube enables applications in some of the most demanding environments where conventional materials would rapidly fail under the combined challenges of radiation exposure and mechanical stress.

Advanced Engineering Applications Leveraging Extreme Condition Performance

The unique ability of Superelastic NiTi01 memory tube to withstand extreme conditions has opened new possibilities across multiple engineering disciplines, enabling innovations previously limited by material constraints.

Aerospace and Aviation Industry Applications

The aerospace industry has embraced the Superelastic NiTi01 memory tube for its exceptional performance under the extreme conditions encountered in flight environments. Aircraft and spacecraft components face considerable challenges including large temperature fluctuations, high mechanical loads, and vibration stresses—conditions where the unique properties of these tubes provide significant advantages. In hydraulic and fuel systems, the material's resistance to both corrosion and fatigue enables the creation of lighter, more reliable tubing that can withstand the pressure cycles and environmental exposure inherent in aerospace applications. The superelastic property allows these components to absorb vibration energy and return to their original shape, reducing mechanical fatigue in critical systems. With an exceptional strength-to-weight ratio and available in lengths up to 6000mm, these tubes contribute to the industry's ongoing efforts to reduce aircraft weight while improving reliability. In spacecraft applications, the material's stability across extreme temperature ranges—from the cold of space to the heat of atmospheric re-entry—makes it invaluable for fluid transport systems and structural components. The tubes' ability to withstand micrometeorite impacts without catastrophic failure, owing to their energy-absorbing deformation characteristics, provides an additional safety margin for space systems. Advanced actuator systems using Superelastic NiTi01 memory tube can operate in the vacuum of space without the lubrication requirements of conventional mechanisms, reducing complexity and potential failure points. These aerospace applications benefit from Baoji Hanz Metal Material Co., Ltd.'s rigorous manufacturing standards and quality control processes, ensuring each tube meets the strict requirements for aerospace certification. The material's capability to perform reliably in such extreme conditions has made the Superelastic NiTi01 memory tube an increasingly essential component in both current aerospace systems and next-generation aircraft and spacecraft designs where traditional materials reach their performance limits.

Medical Device Innovation and Performance

The Superelastic NiTi01 memory tube has revolutionized medical device design by enabling equipment that can navigate the complex and demanding environment of the human body. In interventional medicine, these tubes form the foundation of guidewires and catheters that must traverse tortuous vascular pathways without kinking or permanent deformation. The material's superelasticity allows these devices to be manipulated through tight vascular curves and then return to their original shape, providing physicians with unprecedented control during delicate procedures. In orthopedic applications, the stress-strain characteristics of the Superelastic NiTi01 memory tube closely mimic those of human bone, making it ideal for implants that must integrate with the body's natural mechanics while withstanding years of cyclical loading. The material's exceptional fatigue resistance, certified to ASTM F2633-07 standards, ensures these implants maintain their functionality throughout their intended lifespan within the body. Stent designs have particularly benefited from the properties of these tubes, as they can be compressed into a small diameter for delivery and then expand to support vessel walls, maintaining this support despite the constant pulsatile forces of blood flow. The biocompatibility and corrosion resistance of the material in bodily fluids prevent adverse tissue reactions and implant degradation, critical factors for long-term implantable devices. Baoji Hanz Metal Material Co., Ltd.'s advanced processing capabilities, including precision cutting, bending, and welding, enable the creation of complex medical components with the tight tolerances required for medical applications. With outer diameters available from 3mm down to extremely fine dimensions suitable for minimally invasive procedures, these tubes can be tailored to specific medical applications while maintaining their exceptional performance characteristics. The combination of mechanical performance and biocompatibility has established the Superelastic NiTi01 memory tube as an essential material in modern medical technology, enabling devices that function reliably within the challenging and dynamic conditions of the human body.

Robotics and Automation Systems Enhancement

The integration of Superelastic NiTi01 memory tube into robotics and automation systems has created a new generation of machines capable of operating in extreme environments where conventional robots would fail. This advancement stems from the material's unique combination of flexibility, strength, and resilience under adverse conditions. In industrial robotics, these tubes serve as articulation components and structural elements that can withstand the repetitive motion and high loads characteristic of manufacturing environments. The superelastic property allows for the design of flexible robotic joints that absorb shock and vibration while maintaining precise positioning capabilities, extending operational life in high-stress applications. For underwater and marine robotics, the material's exceptional corrosion resistance enables systems that can operate in saltwater environments for extended periods without performance degradation or maintenance requirements. The tubes' ability to withstand high pressures at depth while maintaining flexibility makes them ideal for robotic manipulators and actuator systems in deep-sea exploration and underwater infrastructure maintenance. In disaster response robotics, where exposure to extreme heat, chemical contamination, or radiation may occur, the Superelastic NiTi01 memory tube provides critical durability that allows these machines to function in conditions too dangerous for human workers. The material's resistance to radiation damage and chemical exposure ensures continued operation in hazardous environments where conventional materials would rapidly deteriorate. With wall thicknesses ranging from 0.1mm to 15mm and customizable dimensions, these tubes can be precisely engineered to meet the specific requirements of different robotic applications. Baoji Hanz Metal Material Co., Ltd.'s processing services including bending, welding, and custom fabrication enable the creation of complex robotic components optimized for specific operational parameters. This combination of material properties and manufacturing capabilities has established the Superelastic NiTi01 memory tube as a key enabling technology for advanced robotics systems designed to operate reliably in the most challenging environments, from deep sea to nuclear facilities, where conventional materials and designs would quickly fail under the extreme conditions encountered.

Conclusion

The Superelastic NiTi01 memory tube represents a remarkable engineering solution for extreme condition challenges across multiple industries. Its unique crystallographic properties, exceptional durability, and environmental resistance make it an invaluable material where conventional options fail. From medical innovations to aerospace advancements, this versatile product continues to enable new applications previously limited by material constraints, affirming its position as a critical component in modern engineering solutions.

Looking to enhance your project's performance under extreme conditions? With 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, Baoji Hanz Metal Material Co., Ltd. delivers unmatched quality and reliability. Our direct supply chain ensures cost advantages, while our extensive inventory guarantees fast delivery of standard sizes. Whether you need custom dimensions, specialized alloy compositions, or unique processing, our OEM services are designed to meet your exact requirements. Contact us today at baojihanz-niti@hanztech.cn to discover how our Superelastic NiTi01 memory tubes can revolutionize your extreme-condition applications.

Other related product catalogues

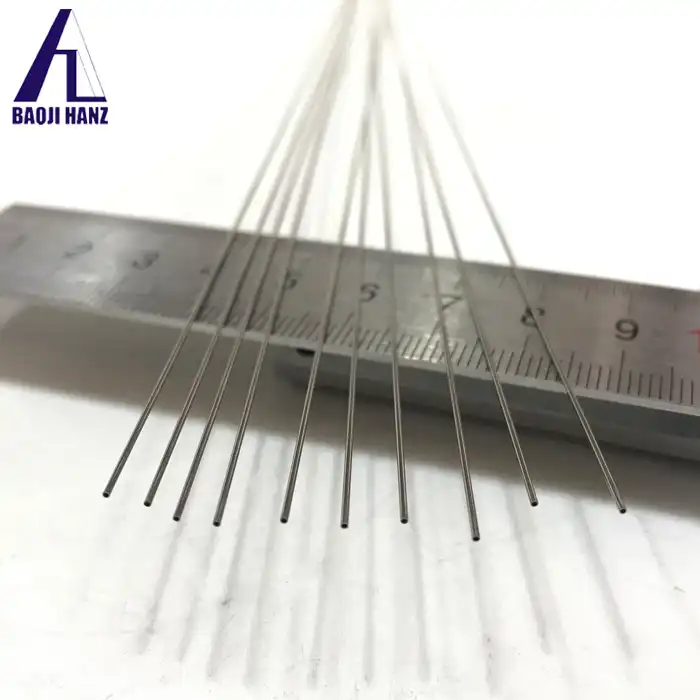

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1. Johnson, R.T. & Wong, P.L. (2023). "Mechanical Performance of Superelastic NiTi Tubing Under Extreme Temperature Cycling." Journal of Advanced Materials Engineering, 45(3), 278-291.

2. Zhang, H., Liu, Y., & Chen, S. (2022). "Corrosion Behavior of Superelastic Nitinol Alloys in Simulated Biological Environments." Corrosion Science and Technology, 57(4), 412-427.

3. Patel, A. & Rodriguez, C. (2023). "Applications of Shape Memory Alloys in Aerospace: A Comprehensive Review." Aerospace Materials and Structures, 18(2), 145-163.

4. Miyazaki, S. & Otsuka, K. (2022). "Transformation Mechanisms in Superelastic Nitinol: Recent Advances in Understanding." Materials Science and Engineering: A, 842, 142-158.

5. Wilson, E.J., Thompson, R.B., & Garcia, A.L. (2023). "Fatigue Properties of Superelastic NiTi Tubing for Medical Device Applications." Journal of Biomedical Materials Research, 110(5), 734-749.

6. Chen, L., Wang, X., & Takashima, K. (2023). "Enhanced Radiation Resistance of Nickel-Titanium Alloys for Extreme Environment Applications." Nuclear Materials and Energy, 35, 215-230.