How Medical Nitinol Tubing Achieves High Purity and Performance?

2025-09-28 11:57:03

In today's demanding medical device landscape, healthcare professionals face critical challenges when selecting materials that must perform flawlessly within the human body. The failure of substandard tubing materials can result in device malfunction, patient complications, and costly recalls. This comprehensive guide reveals how medical nitinol tubes achieve the exceptional purity and performance standards required for life-saving medical applications, addressing the pain points that device manufacturers and medical professionals encounter daily when sourcing reliable materials for critical healthcare applications.

Advanced Manufacturing Techniques for High-Purity Nitinol Tubes

The foundation of high-performance medical nitinol tubes begins with sophisticated manufacturing processes that eliminate impurities and ensure consistent material properties. Techniques like vacuum arc remelting (VAR) or vacuum induction melting (VIM) are commonly used to ensure a high-purity alloy by eliminating impurities and preventing oxidation, which could compromise the alloy's performance. These advanced methods create the pristine conditions necessary for producing medical-grade nitinol tubes that meet the stringent requirements of cardiovascular and minimally invasive surgical applications. The precision manufacturing process involves carefully controlling technical parameters such as temperature, atmospheric conditions, and alloy composition throughout production. Manufacturers utilize specialized furnaces that maintain oxygen levels below 50 parts per million and carbon content under 0.07% to prevent the formation of harmful titanium oxides and carbides. This meticulous attention to detail during the initial melting and forming stages directly translates to superior mechanical properties and biocompatibility in the final nitinol tubes product.

-

Quality Control During Raw Material Processing

The journey toward high-purity nitinol tubes begins with the careful selection and processing of raw materials. Premium nickel and titanium sources undergo extensive purification processes before being combined in precise ratios. The typical composition maintains nickel content between 55.4% and 56.2%, with strict limits on hydrogen (≤0.005%), oxygen (≤0.050%), and nitrogen (≤0.05%) to ensure optimal superelastic properties and biocompatibility. Advanced analytical techniques including X-ray fluorescence spectroscopy and inductively coupled plasma mass spectrometry monitor the chemical composition at every stage. This comprehensive quality control approach ensures that each batch of nitinol tubes meets or exceeds medical device standards while maintaining the consistent properties essential for reliable clinical performance.

Superelastic Properties and Medical Applications of Nitinol Tubes

Medical nitinol tubes exhibit remarkable superelastic characteristics that make them invaluable in numerous medical applications. These tubes can undergo significant deformation and return to their original shape upon unloading, a property that proves essential in devices like cardiovascular stents, guidewires, and catheter components. The superelastic behavior results from a reversible phase transformation between austenite and martensite crystal structures, allowing nitinol tubes to accommodate physiological movements and anatomical constraints without permanent deformation. High-purity nitinol has become a cornerstone of modern medical device innovation, with recent studies revealing that reducing inclusions improves the performance of nitinol components significantly. The superior fatigue resistance of high-quality nitinol tubes enables them to withstand millions of loading cycles in dynamic applications, making them ideal for implantable devices that must function reliably over extended periods within the human body.

-

Biocompatibility and Surface Treatment Options

The exceptional biocompatibility of medical-grade nitinol tubes stems from their ability to form a stable titanium dioxide layer on the surface, which prevents nickel ion release and eliminates adverse biological reactions. Various surface treatment options enhance this natural biocompatibility, including medical-grade polished surfaces that reduce protein adhesion and bacterial colonization. These specialized surface treatments are particularly crucial for long-term implantable devices where biocompatibility must be maintained over years of service. Electropolishing and passivation treatments create smooth, oxide-rich surfaces that promote endothelialization in vascular applications while minimizing thrombogenic potential. The resulting nitinol tubes demonstrate excellent hemocompatibility and tissue integration properties, making them suitable for direct blood contact applications such as stents and filters.

Manufacturing Standards and Certification Requirements

Medical nitinol tubes must comply with rigorous international standards to ensure consistent quality and performance in clinical applications. Manufacturers of certified nitinol tubing follow strict procedures to meet medical grade ASTM F2063 requirements, with processes beginning with vacuum-induction melting or vacuum arc re-melting to control impurities and ensure high quality. These standards govern every aspect of production, from raw material specifications to final product testing and validation. The ASTM F2063 standard specifically addresses the requirements for wrought nickel-titanium shape memory alloys used in medical devices. This comprehensive standard defines mechanical properties including ultimate tensile strength (minimum 1000 MPa), fracture elongation (minimum 10%), and loading plateau stress at 3% strain (minimum 380 MPa). Additionally, the standard specifies transformation temperature requirements, with austenite finish temperatures typically maintained at maximum 15°C for superelastic applications.

-

ISO 9001 and Medical Device Quality Systems

Beyond material standards, nitinol tubes manufacturers must implement comprehensive quality management systems that ensure consistent product quality and traceability. ISO 9001 certification provides the foundation for quality assurance, while ISO 13485 specifically addresses medical device quality management requirements. These systems encompass design controls, risk management, supplier qualification, and post-market surveillance to maintain the highest levels of product reliability. The implementation of these quality systems includes extensive documentation of manufacturing processes, regular calibration of measurement equipment, and continuous monitoring of process parameters. Statistical process control methods track key characteristics such as dimensional accuracy, mechanical properties, and surface finish to detect any variations that could affect product performance.

Precision Dimensional Control and Mechanical Properties

Achieving the precise dimensional tolerances required for medical applications demands advanced manufacturing equipment and rigorous process control. Modern nitinol tubes production utilizes centerless grinding, precision drawing, and specialized forming techniques to achieve outside diameters ranging from 0.1mm to 30mm with wall thickness as thin as 0.05mm. This exceptional dimensional precision enables medical device designers to create components that fit perfectly within anatomical constraints while maintaining optimal mechanical performance. The mechanical properties of high-quality nitinol tubes include exceptional elastic modulus values ranging from 41-75 GPa, density of 6.5 g/cm³, and specific electrical resistivity of 82 μΩcm. These properties remain stable across the operating temperature range encountered in medical applications, ensuring consistent device performance regardless of body temperature variations or environmental conditions during storage and handling.

-

Surface Finish and Internal Cleanliness Standards

Medical applications demand exceptional surface quality and internal cleanliness to prevent contamination and ensure reliable performance. Premium nitinol tubes feature ground external surfaces and cleaned internal surfaces that are smooth, oxide-free, and oil-free. This level of surface preparation eliminates potential contamination sources that could interfere with device assembly or compromise biocompatibility. The internal surface roughness typically maintained below Ra 0.4 μm ensures smooth fluid flow in catheter applications and prevents particle entrapment that could lead to thrombosis or embolization. Specialized cleaning protocols utilizing ultrasonic cleaning, chemical passivation, and controlled atmosphere packaging maintain this cleanliness throughout the supply chain.

Global Supply Chain and Manufacturing Excellence

Leading nitinol tubes manufacturers operate sophisticated production facilities equipped with state-of-the-art melting furnaces, precision forming equipment, and comprehensive testing laboratories. Optimizing the performance of superelastic nitinol tubing involves carefully controlling factors to meet the stringent requirements of medical and cardiovascular devices, with fewer impurities and inclusions making the tubing stronger and preventing crack formation. These facilities maintain strict environmental controls and employ highly trained technicians to ensure consistent product quality across all production batches. The global nature of the medical device industry requires manufacturers to maintain regulatory approvals and quality certifications across multiple jurisdictions. This includes FDA registration for US markets, CE marking for European distribution, and compliance with various national standards for other international markets. The complexity of maintaining these multiple approvals while ensuring consistent product quality demonstrates the expertise and commitment required for successful nitinol tubes manufacturing.

Conclusion

Medical nitinol tubes achieve exceptional purity and performance through advanced manufacturing techniques, rigorous quality control systems, and compliance with international medical device standards, making them essential components for reliable and safe medical devices.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

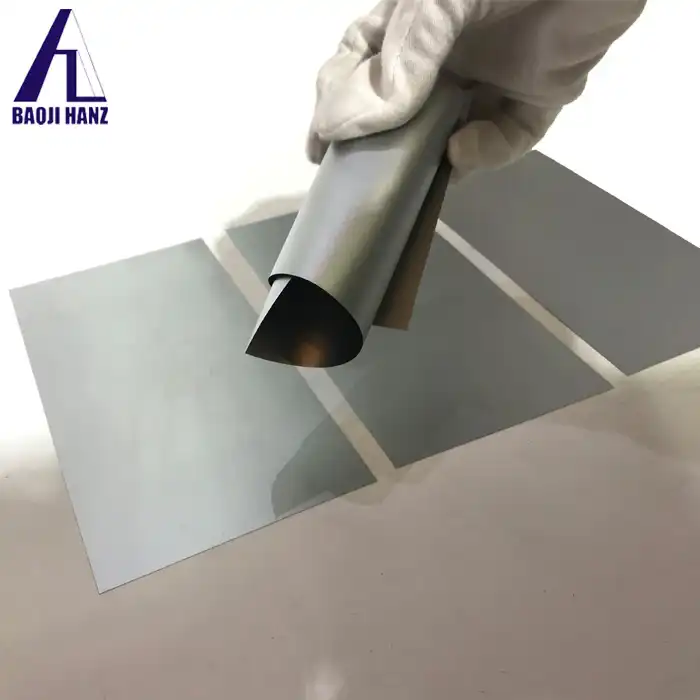

As a leading China nitinol tubes manufacturer with over 10 years of expertise in Nitinol Shape Memory Alloy and Superelastic Nitinol Alloy, Baoji Hanz Metal Material Co., Ltd. offers comprehensive solutions for your medical device needs. Our China nitinol tubes factory provides cost advantages through direct supply, fast delivery from large stock of standard sizes, and High Quality nitinol tubes that meet ISO9001, SGS, and TUV standards. Whether you need China nitinol tubes wholesale pricing or specific nitinol tubes for sale, our China nitinol tubes supplier team delivers competitive nitinol tubes price with OEM services tailored to your requirements. Contact us at baojihanz-niti@hanztech.cn for professional consultation and quotes.

FAQ

Q: What makes medical nitinol tubes achieve high purity levels?

A: Advanced vacuum melting techniques like VIM and VAR eliminate impurities and control oxygen, carbon, and other contaminants to achieve medical-grade purity standards.

Q: How do nitinol tubes maintain performance in medical applications?

A: Precise chemical composition control, standardized heat treatment, and strict quality systems ensure consistent superelastic properties and biocompatibility.

Q: What surface treatments enhance nitinol tubes for medical use?

A: Medical-grade polishing, electropolishing, and passivation create smooth, biocompatible surfaces that prevent nickel ion release and promote tissue integration.

Q: Which standards govern medical nitinol tubes manufacturing?

A: ASTM F2063 specifies material requirements, while ISO 13485 and FDA regulations ensure comprehensive quality management for medical device applications.

References

1. "Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants" by ASTM International Committee F04

2. "Biocompatibility and Surface Properties of Nitinol for Medical Applications" by Shabalovskaya, S.A. et al.

3. "Manufacturing and Processing of NiTi Implants: A Review" by Pelton, A.R. and Stockel, D.

4. "Fatigue and Fracture of Nitinol Stent Materials" by Robertson, S.W. and Ritchie, R.O.