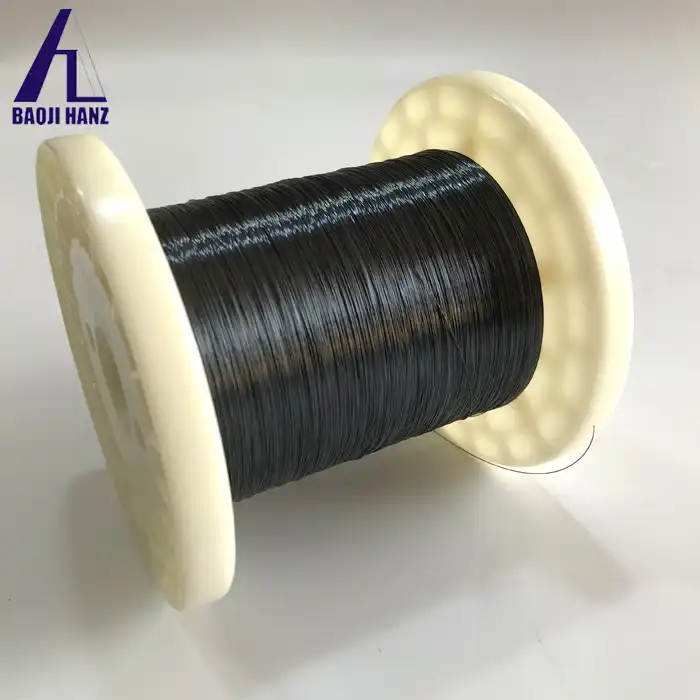

How Nickel Titanium Wire Improves Durability and Efficiency?

2025-09-19 20:32:02

Nickel titanium wire represents a revolutionary advancement in materials science, offering unparalleled durability and efficiency across diverse industrial applications. Nitinol wire is more durable than titanium or stainless steel alloys, allowing it to withstand more demanding or long-term use in medical applications, while simultaneously providing exceptional operational efficiency through its unique superelastic and shape memory properties. This remarkable alloy combines the best characteristics of both nickel and titanium to create a material that not only lasts longer but also performs better than conventional alternatives, making it the preferred choice for industries requiring reliable, long-lasting solutions.

Superior Material Properties Drive Enhanced Durability

The exceptional durability of nickel titanium wire stems from its unique metallurgical composition and inherent material characteristics that distinguish it from traditional wire materials. Understanding these fundamental properties provides insight into why this alloy has become indispensable across numerous high-performance applications.

Exceptional Fatigue Resistance for Long-Term Performance

Nickel titanium wire exhibits remarkable fatigue resistance, making it capable of withstanding millions of stress cycles without significant degradation in performance. This exceptional characteristic results from the alloy's unique crystalline structure, which allows it to absorb and distribute mechanical stress more effectively than conventional materials. The wire's ability to maintain its structural integrity under repeated loading and unloading cycles is particularly valuable in applications such as medical stents, where the material must function reliably within the human body for extended periods. Industrial applications benefit similarly, as components made from nickel titanium wire require less frequent replacement, reducing maintenance costs and system downtime. The fatigue life of nickel titanium wire often exceeds that of stainless steel by several orders of magnitude, making it an economically advantageous choice despite its higher initial cost. This superior fatigue performance directly translates to enhanced durability, ensuring that systems incorporating nickel titanium wire maintain their functionality over extended operational lifespans.

Corrosion Resistance in Harsh Environments

The corrosion resistance properties of nickel titanium wire significantly contribute to its enhanced durability, particularly in challenging environmental conditions where traditional materials would quickly degrade. This resistance stems from the formation of a stable titanium oxide layer on the wire's surface, which acts as a protective barrier against various corrosive agents including acids, bases, and salt solutions. In marine applications, where exposure to saltwater would rapidly corrode conventional steel wires, nickel titanium wire maintains its structural integrity and mechanical properties indefinitely. The biocompatibility aspect of this corrosion resistance makes nickel titanium wire particularly valuable in medical applications, where the material must remain stable in the body's physiological environment without releasing harmful ions or undergoing degradation. Chemical processing industries benefit from this property when handling corrosive substances that would typically require frequent equipment replacement. The combination of excellent corrosion resistance and mechanical durability makes nickel titanium wire an ideal choice for applications where both environmental stability and long-term performance are critical requirements.

Superior Strength-to-Weight Ratio Optimization

The outstanding strength-to-weight ratio of nickel titanium wire provides significant durability advantages while simultaneously improving system efficiency through weight reduction. This characteristic allows engineers to design lighter components without sacrificing strength or reliability, leading to improved overall system performance. In aerospace applications, where weight reduction directly impacts fuel efficiency and payload capacity, nickel titanium wire enables the creation of high-strength components that contribute to overall vehicle performance optimization. The material's high tensile strength, typically reaching 850 MPa, combined with its relatively low density, allows for the development of robust yet lightweight structures that maintain their integrity under extreme operating conditions. Medical device manufacturers leverage this property to create instruments that are both strong enough to perform their intended function and light enough for precise manipulation during surgical procedures. The strength-to-weight optimization provided by nickel titanium wire extends component lifespan while reducing the energy requirements for system operation, making it an environmentally sustainable choice for modern engineering applications.

Unique Superelastic Properties Enable Operational Efficiency

The superelastic characteristics of nickel titanium wire provide unmatched operational efficiency through its ability to undergo large deformations and return to its original shape without permanent damage, revolutionizing how engineers approach design challenges across multiple industries.

Shape Memory Effect for Adaptive Performance

The shape memory effect inherent in nickel titanium wire enables adaptive performance characteristics that significantly improve operational efficiency in temperature-sensitive applications. This remarkable property allows the wire to remember and return to a predetermined shape when heated above its transformation temperature, providing automatic actuation capabilities without external power sources. In HVAC systems, nickel titanium wire actuators can automatically adjust dampers and valves based on temperature changes, optimizing energy efficiency while reducing maintenance requirements. The automotive industry utilizes this property in engine cooling systems, where nickel titanium wire components automatically regulate coolant flow based on operating temperature, improving engine efficiency and longevity. Aerospace applications benefit from the shape memory effect in deployable structures, where nickel titanium wire components can automatically unfold solar panels or antennas when exposed to sunlight, eliminating the need for complex mechanical deployment systems. This self-actuating capability reduces system complexity while improving reliability, as there are fewer mechanical components that can fail during operation. The shape memory effect essentially provides built-in intelligence to mechanical systems, enabling them to respond appropriately to environmental changes without requiring sophisticated control systems or external power sources.

Stress-Induced Transformation for Load Distribution

The stress-induced martensitic transformation characteristic of nickel titanium wire provides exceptional load distribution capabilities that enhance operational efficiency through improved stress management. This unique property allows the material to undergo a reversible phase transformation under mechanical stress, enabling it to accommodate large deformations while distributing loads more evenly throughout the structure. During loading, the austenitic phase transforms to martensite, allowing the wire to deform significantly while maintaining its structural integrity and load-bearing capacity. Upon unloading, the material returns to its original austenitic state, restoring its initial shape and mechanical properties. This transformation mechanism effectively dampens vibrations and shock loads, protecting connected components from damage and reducing wear throughout the system. In seismic isolation systems, nickel titanium wire components can absorb and dissipate earthquake energy, protecting buildings and infrastructure from damage while maintaining structural integrity. Medical applications benefit from this property in orthodontic wires, where the material can apply consistent, gentle forces to teeth while accommodating the natural variations in jaw movement and biting forces. The stress-induced transformation provides a natural shock absorption mechanism that improves system longevity and reduces maintenance requirements.

Enhanced Elasticity for Dynamic Applications

The superelastic behavior of nickel titanium wire enables unprecedented elasticity that far exceeds conventional materials, providing significant efficiency improvements in dynamic applications requiring frequent flexing or movement. NiTi wires exhibit "elastocaloric" effect, which is stress-triggered heating/cooling, demonstrating the material's unique ability to convert mechanical energy into thermal energy and vice versa. This enhanced elasticity allows the wire to undergo strains of up to 8-10% while returning completely to its original shape, compared to typical metals that exhibit permanent deformation at much lower strain levels. In robotics applications, this property enables the creation of artificial muscles and flexible joints that can operate continuously without degradation, improving robot mobility and reducing maintenance requirements. The telecommunications industry utilizes this enhanced elasticity in fiber optic cables, where nickel titanium wire reinforcement allows cables to flex and bend repeatedly without signal degradation or structural failure. Wind energy systems benefit from components made with nickel titanium wire, as the material can withstand the constant flexing and vibration associated with wind turbine operation while maintaining optimal performance characteristics. This enhanced elasticity translates directly to improved operational efficiency through reduced downtime, lower maintenance costs, and extended equipment lifespan.

Advanced Manufacturing Excellence Ensures Quality Performance

The manufacturing processes and quality control measures employed in producing nickel titanium wire directly impact both durability and efficiency outcomes, making advanced production techniques essential for achieving optimal performance characteristics.

Precision Alloy Composition Control

Achieving optimal durability and efficiency in nickel titanium wire requires precise control over alloy composition, with even minor variations in nickel-to-titanium ratios significantly affecting material properties and performance characteristics. Advanced manufacturing processes employ sophisticated melting techniques such as vacuum arc remelting (VAR) and electron beam melting (EBM) to ensure consistent chemical composition throughout the material. The typical composition maintains a near-equiatomic ratio of nickel and titanium, with precise control over trace elements that can influence transformation temperatures and mechanical properties. Quality control measures include spectroscopic analysis of each production batch to verify chemical composition meets stringent specifications, ensuring consistent performance across different wire lots. The manufacturing process also controls grain structure and phase distribution through carefully managed cooling rates and heat treatment procedures, optimizing the material's superelastic and shape memory characteristics. Baoji Hanz Metal Material Co., Ltd. employs state-of-the-art production technology to maintain composition tolerances within ±0.1%, ensuring that each wire batch meets ASTM F2063 standards and customer specifications. This precision in alloy composition control directly translates to predictable and reliable performance characteristics, enabling engineers to design systems with confidence in the material's long-term durability and operational efficiency.

Specialized Heat Treatment Processes

The heat treatment processes applied to nickel titanium wire are critical for developing optimal superelastic and shape memory properties that directly impact both durability and efficiency performance. These specialized thermal treatments involve precise temperature control and timing to achieve the desired austenite finish temperature and phase transformation characteristics. The annealing process removes internal stresses introduced during wire drawing operations while establishing the optimal grain structure for superelastic behavior. Solution annealing at temperatures between 400-500°C followed by controlled cooling establishes the austenitic phase structure that provides the wire's unique mechanical properties. Age hardening treatments can be employed to fine-tune transformation temperatures and mechanical properties for specific applications, allowing customization of material characteristics to meet particular performance requirements. The heat treatment atmosphere must be carefully controlled to prevent surface oxidation and contamination that could compromise material properties and biocompatibility. Baoji Hanz Metal Material Co., Ltd. utilizes controlled atmosphere furnaces and precise temperature monitoring systems to ensure consistent heat treatment results across all production batches. These specialized thermal processes are essential for achieving the optimal balance between strength, elasticity, and corrosion resistance that makes nickel titanium wire superior to conventional alternatives in demanding applications.

Rigorous Quality Assurance Testing

Comprehensive quality assurance testing protocols ensure that nickel titanium wire meets the demanding performance requirements necessary for optimal durability and efficiency in critical applications. Mechanical testing procedures evaluate tensile strength, elastic modulus, and fatigue life under various loading conditions to verify that the material will perform reliably throughout its intended service life. Transformation temperature testing determines the precise temperatures at which phase transformations occur, ensuring that shape memory and superelastic behaviors activate at the specified conditions. Corrosion testing in various environments validates the material's resistance to degradation in the intended application environment, providing confidence in long-term durability performance. Biocompatibility testing for medical applications ensures that the material meets stringent safety requirements for human implantation, including cytotoxicity and ion release assessments. Surface quality inspection using advanced microscopy techniques identifies any defects or irregularities that could compromise performance or initiate failure modes. Baoji Hanz Metal Material Co., Ltd. maintains an in-house testing laboratory equipped with cutting-edge analytical instruments to perform comprehensive quality assessments on every production batch. These rigorous quality assurance measures ensure that customers receive nickel titanium wire that consistently meets or exceeds specification requirements, providing the reliability and performance necessary for critical applications where failure is not an option.

Conclusion

Nickel titanium wire significantly improves durability and efficiency through its unique combination of superelastic properties, exceptional fatigue resistance, and superior corrosion resistance. The material's ability to withstand millions of stress cycles while maintaining structural integrity, combined with its adaptive shape memory characteristics, makes it an invaluable solution for industries requiring long-term reliability and optimal performance. Advanced manufacturing processes ensure consistent quality and predictable behavior, enabling engineers to design more efficient systems with reduced maintenance requirements and extended operational lifespans.

As a leading China nickel titanium wire factory and trusted China nickel titanium wire supplier, Baoji Hanz Metal Material Co., Ltd. offers comprehensive solutions for your specialized applications. With 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy manufacturing, we provide cost-effective solutions through direct supply advantages and fast delivery from extensive standard size inventory. Our China nickel titanium wire manufacturer capabilities include OEM services for Customized nickel titanium wire specifications, ensuring your unique requirements are met with precision. We offer competitive nickel titanium wire price options and China nickel titanium wire wholesale opportunities for bulk requirements. Contact us today for nickel titanium wire for sale inquiries and request your nickel titanium wire Free Sample to experience our superior quality firsthand. Our professional team stands ready to provide technical consultation and comprehensive support for your projects.

For inquiries and orders, contact us at: baojihanz-niti@hanztech.cn

References

1. Otsuka, K., & Ren, X. (2005). Physical metallurgy of Ti–Ni-based shape memory alloys. Progress in Materials Science, 50(5), 511-678.

2. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

3. Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2012). Manufacturing and processing of NiTi implants: A review. Progress in Materials Science, 57(5), 911-946.

4. Petrini, L., & Migliavacca, F. (2011). Biomedical applications of shape memory alloys. Journal of Metallurgy, 2011, Article ID 501483.