Nitinol Bar Price Per Kg and Its Impact on Production Cost

2026-01-15 11:18:15

For manufacturers working with advanced materials, few challenges are as persistent as managing raw material costs while maintaining product quality. When your production timeline depends on securing high-grade nitinol bar price per kg that fits your budget, every fluctuation in pricing can ripple through your entire operation—affecting project feasibility, profit margins, and competitive positioning. Understanding how nitinol bar pricing influences your total production cost isn't just about numbers; it's about strategic sourcing decisions that determine whether your innovative medical device, aerospace component, or industrial application succeeds or stalls before reaching the market.

Understanding Nitinol Bar Price Per Kg Market Dynamics

The nitinol bar price per kg varies significantly based on multiple interconnected factors that manufacturers must understand to make informed purchasing decisions. Nitinol, a nickel-titanium alloy containing approximately 54% nickel minimum, represents one of the most sophisticated shape memory alloys available today. The pricing structure reflects not only raw material costs but also the complex manufacturing processes required to achieve the precise superelastic and shape memory properties that make this material invaluable across industries. Current market conditions show that nitinol bar price per kg typically ranges based on specifications such as diameter, length, surface finish, and required austenite finish temperature. Premium-grade materials with mechanical polishing surfaces and customized AF temperatures between -20℃ to 10℃ command higher prices due to the additional processing steps involved. The density of 6.45g/cm³ and strict compositional requirements mean that production cannot cut corners without compromising the fundamental characteristics that users depend upon. Manufacturing facilities with advanced cold drawing and heat treatment capabilities can offer more competitive nitinol bar price per kg rates while maintaining the strict dimensional tolerances essential for high-performance applications.

Raw Material Composition and Purity Requirements

The foundation of nitinol bar price per kg begins with the purity and composition of constituent metals. Nickel and titanium must meet exacting standards, with nickel content maintained at minimum 54% to ensure proper phase transformation characteristics. High-purity metal preparation processes, including ultra-large and ultra-thin casting techniques, contribute substantially to base costs. Manufacturers sourcing from suppliers with ISO9001, SGS, and TUV certifications can expect consistent quality but must factor these quality assurance processes into their cost calculations. The conversion of scientific research results into commercial-grade products requires sophisticated R&D and testing equipment, expenses ultimately reflected in the final nitinol bar price per kg offered to industrial and medical application customers.

Processing Complexity and Technical Specifications

Beyond raw materials, the processing complexity dramatically influences nitinol bar price per kg structures. The transformation from raw alloy to precision-engineered bars involves multiple stages: melting, casting, hot working, cold drawing, and carefully controlled heat treatment protocols. Each diameter specification, whether standard inventory sizes or customized dimensions, requires specific tooling and process parameters. Surface treatments like mechanical polishing add value but also increase costs. The ability to customize shape memory temperatures according to exact application requirements involves sophisticated thermal processing that not all manufacturers can execute reliably. These technical capabilities separate suppliers offering commodity-grade materials from those providing engineered solutions, with corresponding differences in nitinol bar price per kg positioning.

Cost Impact Analysis on Manufacturing Operations

When evaluating nitinol bar price per kg in the context of total production costs, manufacturers must consider both direct material expenses and indirect cost implications. For medical device producers, the material cost might represent 30-40% of the component cost, making nitinol bar pricing a critical factor in product profitability. Industrial applications with larger volume requirements face different economics, where even small percentage differences in nitinol bar price per kg can translate to substantial annual savings or overruns. The superelasticity and shape memory effect that characterize quality nitinol materials directly impact manufacturing efficiency. Superior raw materials with consistent properties reduce scrap rates, minimize secondary processing, and improve production yields. A lower nitinol bar price per kg from an unreliable source may initially appear attractive but can generate hidden costs through increased rejection rates, inconsistent performance, and customer returns. Conversely, premium materials from established suppliers like Baoji Hanzhen Metal Materials Co., Ltd. offer precisely designed shape memory alloy components that perform reliably even in extreme environments, reducing total cost of ownership despite potentially higher upfront nitinol bar price per kg.

Direct Material Cost Calculations

Calculating the true impact of nitinol bar price per kg requires understanding minimum order quantities and volume pricing structures. With MOQ typically set at 1kg, small-scale developers and research institutions can access materials without prohibitive inventory investments. However, bulk supply options for large orders provide significant cost advantages for established manufacturers. The price differential between standard sizes available for dispatch within three working days and fully customized specifications with longer lead times must be factored into project planning. Material utilization efficiency—the percentage of purchased nitinol bar converted into finished components versus scrap—varies based on design optimization and manufacturing capabilities, directly affecting the effective nitinol bar price per kg impact on production economics.

Indirect Cost Considerations and Supply Chain Efficiency

Beyond the quoted nitinol bar price per kg, manufacturers must account for supply chain costs including logistics, inventory carrying costs, and procurement administration. Suppliers offering fast delivery of standard inventory reduce working capital requirements and enable just-in-time manufacturing approaches. Technical support from professional engineering teams providing pre-sale consultation and after-sale solution assistance can dramatically reduce development time and troubleshooting expenses. The retention of production process monitoring documents for at least five years supports quality traceability and compliance requirements, particularly critical for medical applications where regulatory documentation must demonstrate material consistency. These value-added services, while sometimes increasing the nominal nitinol bar price per kg, frequently deliver net cost reductions through improved operational efficiency.

Strategic Sourcing for Cost Optimization

Optimizing nitinol procurement requires balancing immediate nitinol bar price per kg considerations against long-term partnership value. Manufacturers developing new products benefit from suppliers capable of supporting iterative design processes with flexible customization options covering diameter, length, shape memory temperature, and surface finish specifications. The ability to adjust parameters based on performance testing without incurring excessive retooling costs or extended lead times accelerates time-to-market and reduces development expenses that dwarf material cost differences. Quality certifications provide essential risk mitigation that justifies premium nitinol bar price per kg positioning. Materials meeting the highest quality requirements as stipulated in ISO9001, SGS, and TUV guidelines, backed by stringent quality control systems, minimize the probability of catastrophic failures in critical applications. For aerospace components operating in extreme conditions or medical implants where human safety depends on material reliability, the cost of quality assurance represents genuine value rather than unnecessary expense. Competitive advantage comes not from the lowest nitinol bar price per kg but from the optimal balance of cost, quality, technical capability, and supplier reliability.

Vendor Evaluation and Partnership Development

Selecting nitinol suppliers involves comprehensive evaluation extending well beyond nitinol bar price per kg quotes. Manufacturers should assess production capacity, technical expertise demonstrated through completed major projects, R&D capabilities supporting continuous improvement, and customer service infrastructure providing responsive support throughout the product lifecycle. Suppliers with complete sets of sophisticated production and processing equipment, excellent technology, and professional sales and after-sales teams deliver value through reduced technical risk and streamlined communication. The tracking of detailed product usage and provision of comprehensive industry solutions represents partnership rather than transactional relationships, ultimately contributing more to production cost optimization than marginal differences in raw material pricing.

Conclusion

The nitinol bar price per kg significantly influences production economics across medical, industrial, and aerospace applications, but optimal cost management requires comprehensive analysis beyond simple price comparison. Strategic sourcing balances material costs against quality assurance, technical support, supply chain efficiency, and long-term supplier partnership value to minimize total production costs while ensuring reliable performance in demanding applications.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

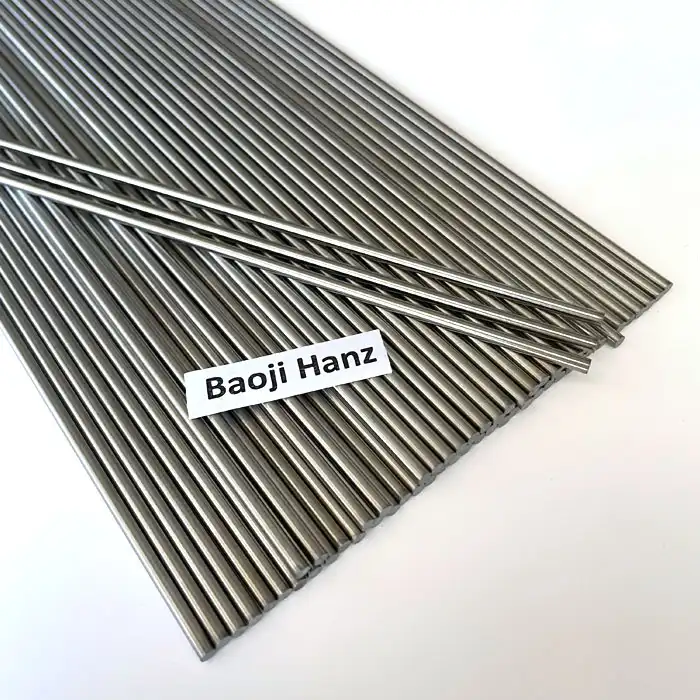

As a leading China nitinol bar price per kg manufacturer, China nitinol bar price per kg supplier, and China nitinol bar price per kg factory, Baoji Hanz Metal Material Co., Ltd. offers High Quality nitinol bar price per kg with competitive nitinol bar price per kg for sale through our China nitinol bar price per kg wholesale programs. With 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, we provide cost advantages through direct supply and fast delivery from extensive standard size inventory. Our OEM services customize sizes, alloy compositions, and packaging to seamlessly integrate into your projects. Contact our professional team at baojihanz-niti@hanztech.cn for technical consultation, competitive quotations, and comprehensive solutions that optimize your production costs while ensuring superior material performance. Bookmark this resource and reach out whenever nitinol sourcing questions arise.

References

1. "Shape Memory Alloys for Biomedical Applications: Processing, Properties, and Performance" - Miyazaki, S. and Otsuka, K., ISIJ International

2. "Nickel-Titanium Shape Memory Alloys: Manufacturing, Engineering, and Clinical Applications" - Morgan, N.B., Materials Science and Engineering

3. "Cost Analysis and Economic Considerations in Medical Device Manufacturing with Advanced Alloys" - Chen, W. and Zhang, L., Journal of Materials Processing Technology

4. "Phase Transformation Characteristics and Mechanical Properties of Nitinol Alloys" - Duerig, T.W. and Pelton, A.R., Materials Science Forum

5. "Quality Control and Standardization in Shape Memory Alloy Production for Industrial Applications" - International Organization for Standardization Technical Committee