Nitinol Strip: The Future of Smart Metal Solutions

2025-08-12 21:00:03

In the rapidly evolving world of advanced materials, nitinol strip stands as a revolutionary innovation that is reshaping industries across the globe. This remarkable smart metal solution combines the unique properties of nickel-titanium alloys with precision engineering to deliver unprecedented performance in applications ranging from medical devices to aerospace components. The nitinol strip represents a paradigm shift in material science, offering both superelastic properties and shape memory capabilities that enable engineers and designers to create solutions previously thought impossible. As we advance into an era where smart materials define technological progress, nitinol strip emerges as the cornerstone of next-generation applications, promising enhanced functionality, reliability, and efficiency across diverse industrial sectors.

Revolutionary Properties That Define Smart Metal Excellence

Superelastic Capabilities Transform Industrial Applications

The superelastic properties of nitinol strip represent one of the most significant breakthroughs in metallurgical engineering. Unlike conventional metals that permanently deform under stress, nitinol strip can undergo substantial deformation and return to its original shape upon load removal. This extraordinary characteristic stems from the unique crystal structure of the nickel-titanium alloy, which contains 54.5-56.5% nickel with titanium balance. The superelastic behavior occurs through a stress-induced martensitic transformation that allows the material to accommodate strains up to 8% while maintaining complete recovery. This remarkable property makes nitinol strip invaluable in applications requiring repeated flexing, bending, or stretching without permanent deformation. Industries such as robotics, actuators, and flexible electronics have embraced this technology, recognizing that nitinol strip offers unmatched durability and performance in dynamic environments where traditional materials would fail catastrophically.

Shape Memory Functionality Enables Intelligent Design Solutions

The shape memory effect of nitinol strip opens unprecedented possibilities for intelligent material design and autonomous system development. This phenomenon occurs when the material is deformed at lower temperatures and subsequently heated above its transformation temperature (Af), causing it to return to its pre-programmed shape. The nitinol strip manufactured by Baoji Hanz offers customizable Af ranges from -20°C to 100°C, allowing engineers to precisely control activation temperatures for specific applications. This programmable behavior enables the creation of self-actuating systems, temperature-responsive components, and adaptive structures that can modify their configuration based on environmental conditions. The shape memory functionality of nitinol strip has revolutionized fields such as biomedical implants, where devices can be inserted in a compact configuration and then expand to their functional shape at body temperature, minimizing invasive procedures and improving patient outcomes.

Precision Manufacturing Delivers Exceptional Quality Standards

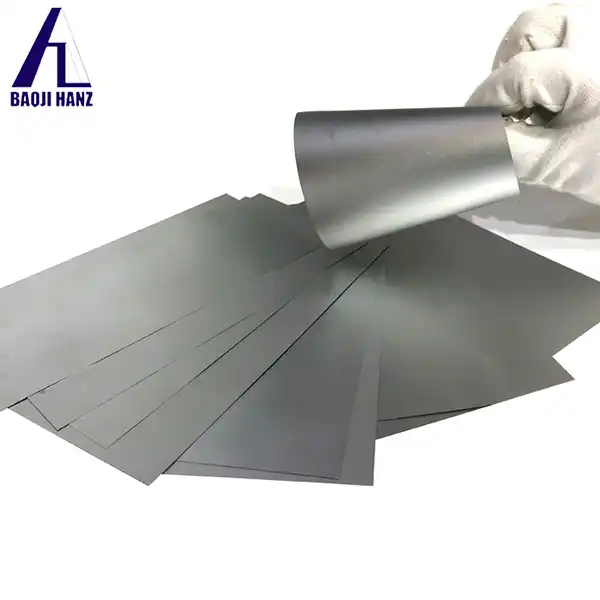

The manufacturing precision of nitinol strip directly impacts its performance characteristics and application reliability. Baoji Hanz Metal Material Co., Ltd. employs sophisticated production techniques to achieve tight dimensional tolerances, with thickness ranging from 0.1mm to 0.8mm and width from 0.2mm to 3.13mm. The precision manufacturing process ensures consistent mechanical properties throughout the material, maintaining a density of 6.5g/cc and uniform chemical composition. Advanced quality control systems monitor every stage of production, from raw material selection through final inspection, ensuring that each nitinol strip meets the highest industry standards. The company's ISO9001, SGS, and TUV certifications demonstrate their commitment to quality excellence, while their stringent quality control system guarantees that every product delivers predictable performance in critical applications. This precision manufacturing approach enables customers to rely on consistent material properties, reducing design uncertainties and improving overall system reliability.

Advanced Applications Driving Market Innovation

Medical Device Integration Revolutionizes Healthcare Technology

The integration of nitinol strip into medical devices has transformed healthcare technology by enabling the development of minimally invasive surgical instruments and implantable devices. The biocompatibility of the nickel-titanium alloy, combined with its superelastic properties, makes nitinol strip ideal for applications such as stents, guidewires, and orthodontic appliances. In cardiovascular applications, nitinol strip enables the creation of self-expanding stents that can be delivered through small catheters and expand to their predetermined size at body temperature. The material's ability to withstand repeated stress cycles without fatigue failure is particularly valuable in applications such as heart valve frames and arterial clips, where long-term reliability is paramount. Furthermore, the shape memory properties of nitinol strip allow for the development of temperature-activated medical devices that can change configuration in response to body temperature, providing controlled drug delivery systems and adaptive prosthetics that improve patient comfort and treatment outcomes.

Aerospace and Automotive Industries Embrace Smart Materials

The aerospace and automotive industries have recognized the transformative potential of nitinol strip in developing next-generation components that enhance performance while reducing weight and complexity. In aerospace applications, nitinol strip is utilized in morphing wing structures, vibration damping systems, and adaptive control surfaces that can modify their shape in response to flight conditions. The material's high strength-to-weight ratio and fatigue resistance make it superior to conventional materials in dynamic loading environments. Automotive manufacturers are incorporating nitinol strip into active suspension systems, variable valve timing mechanisms, and crash protection devices that can adapt to different impact scenarios. The ability of nitinol strip to provide both sensing and actuation capabilities in a single component eliminates the need for complex mechanical systems, reducing overall system weight and improving reliability. These applications demonstrate how nitinol strip is enabling the development of truly intelligent structures that can autonomously adapt to changing operational requirements.

Electronics and Robotics Benefit from Flexible Smart Solutions

The electronics and robotics industries are leveraging the unique properties of nitinol strip to create flexible, adaptive systems that can operate in challenging environments. In flexible electronics, nitinol strip serves as a substrate material that can withstand repeated bending and stretching without compromising electrical connectivity. The material's ability to return to its original shape after deformation makes it ideal for wearable devices, foldable displays, and flexible sensors that must maintain functionality under various mechanical stresses. Robotics applications utilize nitinol strip in artificial muscles, grippers, and joint actuators that can provide smooth, biological-like motion. The high power-to-weight ratio of nitinol strip actuators enables the development of lightweight robotic systems with human-like dexterity and responsiveness. Additionally, the material's ability to operate silently and without electromagnetic interference makes it suitable for sensitive applications such as medical robotics and precision instrumentation where traditional actuators would be unsuitable.

Manufacturing Excellence and Quality Assurance

Advanced Production Techniques Ensure Consistent Performance

The manufacturing excellence of nitinol strip requires sophisticated production techniques that maintain precise control over material properties and dimensional accuracy. Baoji Hanz Metal Material Co., Ltd. employs state-of-the-art melting and casting processes to ensure uniform chemical composition throughout the material. The production process begins with high-purity raw materials that are carefully selected and tested to meet stringent quality standards. Advanced vacuum melting techniques prevent contamination and ensure optimal alloying, while controlled cooling processes determine the final microstructure and transformation temperatures. The nitinol strip undergoes multiple thermomechanical processing steps, including rolling, annealing, and surface treatment, to achieve the desired mechanical properties and surface finish. Quality control measures are implemented at every stage, with continuous monitoring of chemical composition, mechanical properties, and dimensional accuracy to ensure that each nitinol strip meets or exceeds customer specifications and industry standards.

Customization Capabilities Meet Diverse Application Requirements

The customization capabilities of nitinol strip manufacturing enable engineers to specify material properties that precisely match their application requirements. Baoji Hanz offers a comprehensive range of transformation temperatures, from -20°C to 100°C, allowing customers to select the optimal Af temperature for their specific application. The company's technical expertise enables the development of custom alloy compositions and processing parameters to achieve unique property combinations not available in standard materials. Surface treatments can be customized to provide either bright or black finishes, depending on aesthetic requirements or functional needs such as corrosion resistance or electrical properties. The nitinol strip can be supplied in various configurations, including flat strips, coiled forms, or spooled presentations, optimizing handling and processing for different manufacturing environments. This flexibility in customization ensures that customers receive materials that integrate seamlessly into their designs and manufacturing processes.

Quality Control Systems Guarantee Reliable Performance

The quality control systems implemented in nitinol strip manufacturing ensure that every product meets the highest standards of performance and reliability. Comprehensive testing protocols evaluate mechanical properties, transformation temperatures, fatigue resistance, and dimensional accuracy using advanced instrumentation and standardized test methods. Statistical process control techniques monitor production parameters continuously, enabling immediate detection and correction of any deviations from specified targets. Traceability systems maintain detailed records of material composition, processing parameters, and test results for each production lot, providing complete documentation for quality assurance and regulatory compliance. The company's commitment to quality is demonstrated through their ISO9001, SGS, and TUV certifications, which require regular audits and continuous improvement processes. This comprehensive approach to quality assurance ensures that nitinol strip products deliver consistent performance in critical applications where reliability is paramount.

Conclusion

Nitinol strip represents a transformative advancement in smart metal technology, offering unprecedented capabilities that are reshaping industries worldwide. The combination of superelastic properties, shape memory functionality, and precision manufacturing makes this material indispensable for next-generation applications across medical, aerospace, automotive, and electronics sectors. As we continue to push the boundaries of what's possible with smart materials, nitinol strip stands as the foundation for innovative solutions that will define the future of engineering and design.

Ready to revolutionize your next project with cutting-edge nitinol strip technology? As a leading China nitinol strip factory, China nitinol strip supplier, China nitinol strip manufacturer, and China nitinol strip wholesale provider, Baoji Hanz Metal Material Co., Ltd. brings seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy to your doorstep. Save money with our direct supply and cost advantages while enjoying fast delivery from our extensive stock of standard sizes. Our OEM services ensure that custom sizes, specific alloy compositions, and packaging options are tailored to your exact requirements. Let our experienced team work closely with you to ensure our products fit seamlessly into your projects. Contact us today at baojihanz-niti@hanztech.cn to discover how our innovative nitinol strip solutions can transform your applications and drive your success forward.

References

1. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

3. Lagoudas, D. C., Miller, D. A., Rong, L., & Kumar, P. K. (2009). Thermomechanical fatigue of shape memory alloys. Smart Materials and Structures, 18(8), 085021.

4. Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2012). Manufacturing and processing of NiTi implants: A review. Progress in Materials Science, 57(5), 911-946.