Nitinol: The Shape Memory Effect and Superelasticity

2025-11-14 20:41:21

Imagine a surgical wire that can remember its original shape after being deformed, or a medical device that adapts seamlessly to body movements without breaking. This isn't science fiction—it's the reality of superelastic nitinol wire, a revolutionary material transforming medical procedures and engineering applications worldwide. When surgeons face critical moments where precision instruments must perform flawlessly under extreme conditions, traditional materials often fail, leading to complications and extended recovery times. However, nitinol's unique properties of shape memory and superelasticity address these critical challenges, offering unprecedented reliability and performance in medical applications where failure is not an option.

Understanding Nitinol's Fundamental Properties

Whether nitinol behaves with shape memory effect or superelasticity depends on whether it is above its transformation temperature during the action. This remarkable behavior stems from nitinol's unique crystal structure, which undergoes reversible phase transformations between austenite and martensite phases. The shape memory effect occurs when superelastic nitinol wire is cooled below its transformation temperature and deformed, then heated above this temperature to recover its original shape. This phenomenon is driven by the material's ability to undergo stress-induced martensitic transformation, where the crystal lattice rearranges itself under mechanical stress. The "twinning" in the crystal structure of nitinol produces the memory effect, creating a sophisticated mechanism where atomic arrangements shift predictably under specific conditions. When superelastic nitinol wire experiences mechanical deformation, the austenite phase transforms into martensite variants that accommodate the applied stress. Upon removal of the stress or application of heat, the material reverts to its austenite phase, restoring the original configuration. This transformation is completely reversible and can occur millions of times without degradation, making superelastic nitinol wire exceptionally durable for long-term medical applications.

-

The Science Behind Temperature-Dependent Behavior

The transformation temperatures in nitinol alloys are precisely controlled through careful composition and processing techniques. Superelastic nitinol wire exhibits different behaviors based on its operating temperature relative to these critical transition points. At temperatures below the martensite start temperature (Ms), the material displays one-way shape memory, where heating is required to recover the original shape. Above the austenite finish temperature (Af), the material demonstrates superelasticity, where mechanical deformation is immediately recoverable upon stress removal. This temperature sensitivity allows engineers to design superelastic nitinol wire components that respond intelligently to environmental conditions, providing adaptive functionality in medical devices that must operate reliably within the human body's temperature range.

Superelasticity: Engineering Marvel in Medical Applications

Superelasticity represents one of the most valuable characteristics of nitinol alloys, particularly in superelastic nitinol wire applications. This effect is caused by the stress-induced formation of some martensite above its normal temperature. Unlike conventional materials that undergo plastic deformation when stressed beyond their elastic limit, superelastic nitinol wire can sustain strains up to 8-10% while returning completely to its original shape upon stress removal. This extraordinary property enables the creation of medical devices that can withstand significant deformation during insertion, navigation through tortuous anatomical pathways, and deployment without permanent damage. The stress-strain curve of superelastic nitinol wire exhibits a characteristic flat plateau region where large strains occur at nearly constant stress levels. This unique mechanical response provides several advantages in medical applications: the material can absorb substantial mechanical energy without failure, it maintains consistent force levels during large deformations, and it provides gentle, continuous pressure when used in implants or surgical tools. These properties make superelastic nitinol wire ideal for applications requiring both flexibility and strength, such as cardiovascular stents, orthodontic archwires, and minimally invasive surgical instruments.

-

Clinical Advantages of Superelastic Properties

Superelasticity lets stents adjust to blood vessel movements, providing crucial flexibility in dynamic biological environments. Superelastic nitinol wire components can accommodate the natural motion of organs and tissues without losing their structural integrity or therapeutic function. This adaptability reduces mechanical stress on surrounding tissues, minimizes inflammatory responses, and improves long-term biocompatibility. In cardiovascular applications, superelastic nitinol wire stents can expand and contract with each heartbeat while maintaining their structural support, reducing the risk of fatigue failure and extending device lifespan. Similarly, in orthopedic applications, superelastic nitinol wire implants can flex with bone movement, promoting natural healing while providing necessary mechanical support.

Manufacturing Excellence and Quality Standards

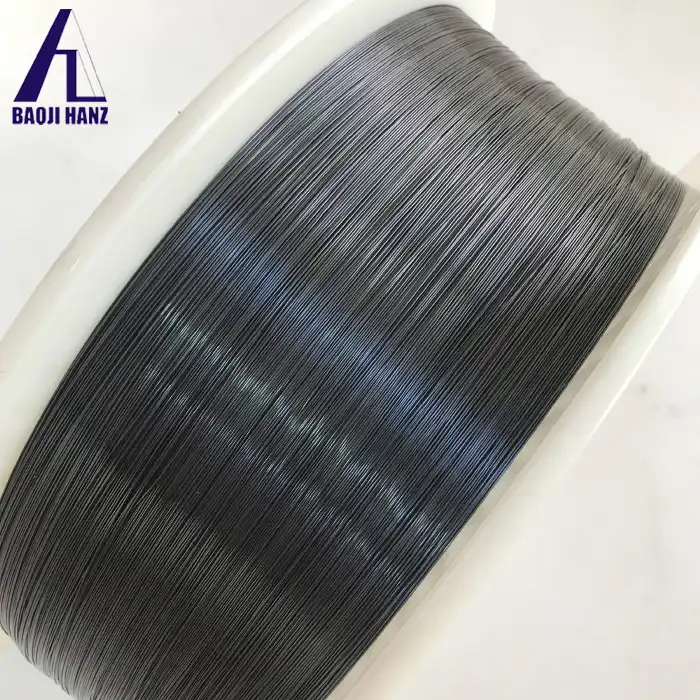

Baoji Hanz Metal Material Co., Ltd. represents the pinnacle of superelastic nitinol wire manufacturing, combining advanced production techniques with rigorous quality control systems. Our superelastic nitinol wire products adhere to strict international standards including ISO9001:2015 and ASTM F2063, ensuring consistent quality and performance across all applications. The manufacturing process involves precise control of alloy composition, typically containing approximately 50-51% nickel and 49-50% titanium by atomic percent, with trace elements carefully managed to achieve desired transformation temperatures and mechanical properties. The production of high-quality superelastic nitinol wire requires sophisticated melting techniques, often utilizing vacuum induction melting followed by vacuum arc remelting to achieve exceptional purity and homogeneity. Hot working processes, including forging and rolling, are performed within specific temperature ranges to optimize microstructure and minimize internal stresses. Cold working operations, particularly wire drawing, are conducted through multiple stages with intermediate annealing treatments to achieve the desired final diameter while maintaining superelastic properties. Surface finishing processes ensure smooth, defect-free surfaces that meet medical device requirements for biocompatibility and corrosion resistance.

-

Advanced Processing Techniques

Our superelastic nitinol wire undergoes specialized heat treatment processes that precisely control transformation temperatures and optimize superelastic behavior. Shape setting procedures allow complex geometries to be programmed into the material, enabling the creation of self-expanding medical devices and intricate surgical instruments. The careful control of aging treatments fine-tunes the material's properties, balancing superelasticity with mechanical strength to meet specific application requirements. Quality assurance protocols include differential scanning calorimetry to verify transformation temperatures, tensile testing to confirm mechanical properties, and fatigue testing to ensure long-term reliability under cyclic loading conditions.

Comprehensive Applications in Modern Medicine

Shape memory and superelasticity properties of Nitinol have allowed the development of many novel medical devices. Superelastic nitinol wire finds extensive applications across diverse medical specialties, revolutionizing treatment approaches and improving patient outcomes. In interventional cardiology, superelastic nitinol wire stents provide life-saving treatments for coronary artery disease, offering superior flexibility during delivery and excellent radial strength after deployment. These devices can navigate complex vascular anatomy while maintaining their structural integrity, reducing procedural complications and improving long-term patency rates. The shape memory effect helps stents open inside blood vessels, restoring blood flow and reducing repeat surgeries. Beyond cardiovascular applications, superelastic nitinol wire serves crucial roles in neurovascular interventions, where its unique properties enable the treatment of cerebral aneurysms and stroke through minimally invasive procedures. The material's ability to conform to vessel geometry while providing consistent radial force makes it ideal for flow diverters and embolic protection devices that must function reliably in the delicate cerebral vasculature.

-

Specialized Medical Device Integration

In orthopedic surgery, superelastic nitinol wire components enhance bone repair and reconstruction procedures through improved biomechanical compatibility. Spinal fusion devices incorporating superelastic nitinol wire elements provide dynamic stabilization that allows natural spinal motion while promoting bone healing. Hip and knee replacement components benefit from nitinol's fatigue resistance and biocompatibility, extending implant lifespan and reducing revision surgery rates. Trauma fixation systems utilizing superelastic nitinol wire offer superior adaptation to bone healing processes, providing stable fixation during initial healing phases while allowing gradual load transfer as bone strength returns.

-

Innovative Surgical Instrumentation

Miniature actuators made from nitinol tubing offer precise control and durability, making them ideal for advanced systems. Superelastic nitinol wire enables the development of sophisticated surgical instruments that combine flexibility with precise control. Laparoscopic tools incorporating nitinol elements can bend and flex through small incisions while maintaining their ability to grasp, cut, and manipulate tissues effectively. Robotic surgical systems benefit from nitinol's unique properties, allowing the creation of flexible end-effectors that can navigate confined spaces while providing haptic feedback to surgeons. These advanced instruments reduce surgical trauma, minimize recovery times, and improve surgical precision in complex procedures.

Technical Specifications and Performance Characteristics

Our superelastic nitinol wire products are available in diameters ranging from 0.025mm to 2mm, accommodating diverse application requirements from micro-surgical instruments to larger medical devices. The material exhibits exceptional mechanical properties, including tensile strengths exceeding 1000 MPa and elastic recovery strains up to 8%. Biocompatibility testing confirms excellent tissue compatibility, with low nickel ion release rates that meet stringent medical device safety standards. The corrosion resistance of superelastic nitinol wire ensures long-term stability in physiological environments, with demonstrated performance in accelerated aging studies simulating decades of in-vivo service. Fatigue resistance represents a critical performance parameter for superelastic nitinol wire applications, particularly in dynamic loading environments such as cardiovascular devices. Our materials demonstrate exceptional fatigue life, withstanding millions of loading cycles at clinically relevant stress levels without failure. This superior durability translates directly into improved medical device reliability and reduced risk of device-related complications. Temperature stability ensures consistent performance across the range of physiological temperatures, with transformation temperatures precisely controlled to optimize superelastic behavior under normal body conditions.

-

Customization and Engineering Support

Baoji Hanz Metal Material Co., Ltd. offers comprehensive customization services to meet specific application requirements. Our engineering team works closely with medical device manufacturers to optimize alloy compositions, processing parameters, and final geometries for particular applications. Custom transformation temperatures can be achieved through precise alloy modifications, enabling superelastic nitinol wire performance optimization for specific operating conditions. Surface treatments and coatings can be applied to enhance biocompatibility, radiopacity, or other functional requirements. Our advanced R&D facilities support prototype development and testing, accelerating the transition from concept to clinical application.

Quality Assurance and Regulatory Compliance

Our commitment to quality excellence encompasses every aspect of superelastic nitinol wire production, from raw material selection through final inspection and packaging. ISO9001:2015 certification demonstrates our adherence to internationally recognized quality management standards, ensuring consistent product quality and continuous improvement processes. SGS and TUV certifications provide additional validation of our quality systems and product performance. Comprehensive traceability systems maintain detailed records of material genealogy, processing parameters, and test results for every batch of superelastic nitinol wire produced. Statistical process control methods monitor critical process parameters in real-time, enabling immediate corrective actions when deviations occur. Incoming material inspection verifies the purity and composition of raw materials, while in-process testing confirms transformation temperatures, mechanical properties, and dimensional accuracy throughout production. Final inspection protocols include comprehensive testing of superelastic properties, surface quality, and dimensional conformance to customer specifications. Certificate of compliance documentation accompanies each shipment, providing detailed test results and confirmation of regulatory compliance.

-

Regulatory Excellence and Documentation Support

Our regulatory compliance program addresses the complex requirements of medical device markets worldwide. FDA guidance documents, ISO 5832 biocompatibility standards, and pharmacopeia requirements are integrated into our quality systems to ensure superelastic nitinol wire products meet global regulatory expectations. Master files and technical documentation support customer regulatory submissions, providing the detailed material characterization required for medical device approvals. Our technical support team assists customers with material selection, application engineering, and regulatory strategy development, leveraging years of experience in nitinol applications across diverse medical specialties.

Research and Development Innovation

Continuous innovation drives our superelastic nitinol wire development programs, focusing on enhanced properties, new applications, and improved manufacturing efficiency. Advanced metallurgical research explores novel alloy compositions and processing techniques to extend the performance envelope of nitinol materials. Additive manufacturing technologies are being investigated to enable complex geometries and customized properties not achievable through conventional processing methods. PBF-EB, particularly with ELO, is highlighted for its advantages in producing crack-free NiTi with tailored microstructures. Biocompatibility research continues to advance our understanding of tissue-material interactions, leading to surface modifications and coatings that further enhance clinical performance. Fatigue life extension studies explore processing modifications and design optimizations that extend device durability. Computational modeling capabilities enable prediction of material behavior under complex loading conditions, supporting device design optimization and clinical performance validation. Collaborative research programs with leading medical institutions and device manufacturers accelerate the translation of laboratory innovations into clinical applications.

-

Future Technology Development

Our research roadmap includes investigation of smart alloy systems that combine shape memory and superelastic properties with other functional capabilities. Sensor integration technologies enable the development of superelastic nitinol wire devices that can monitor their own performance and provide feedback to clinicians. Biodegradable coating systems are being developed to enable temporary implant applications where device removal is desired after healing. Multi-functional material systems combine structural support with drug delivery capabilities, opening new therapeutic possibilities for superelastic nitinol wire applications.

Conclusion

Nitinol's unique combination of shape memory effect and superelasticity has revolutionized medical device design and surgical procedures. The remarkable properties of superelastic nitinol wire enable innovative solutions to complex medical challenges, improving patient outcomes through enhanced device performance and reduced procedural risks.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

As a leading China superelastic nitinol wire manufacturer with seven years of expertise in nitinol shape memory alloy development, Baoji Hanz Metal Material Co., Ltd. offers unmatched technical capabilities and comprehensive customer support. Our China superelastic nitinol wire factory provides direct supply advantages with cost-effective pricing and fast delivery from extensive inventory. We serve as your trusted China superelastic nitinol wire supplier, offering high quality superelastic nitinol wire for sale at competitive superelastic nitinol wire prices. Our China superelastic nitinol wire wholesale services include complete OEM customization to meet your specific requirements. Contact us at baojihanz-niti@hanztech.cn for inquiries.

FAQ

Q: What is the difference between shape memory effect and superelasticity in nitinol?

A: Shape memory effect requires temperature change to recover original shape, while superelasticity recovers immediately upon stress removal at body temperature.

Q: What temperature range does superelastic nitinol wire operate effectively?

A: Superelastic nitinol wire functions optimally at temperatures above its austenite finish temperature, typically 20-40°C depending on alloy composition.

Q: How long can superelastic nitinol wire devices last in the human body?

A: With proper design and processing, superelastic nitinol wire devices can function reliably for 10-20 years or more in physiological environments.

Q: What are the main advantages of superelastic nitinol wire over traditional materials?

A: Key advantages include exceptional flexibility, fatigue resistance, biocompatibility, and the ability to undergo large deformations without permanent damage.

References

1. Duerig, T., Pelton, A., & Stöckel, D. "An Overview of Nitinol Medical Applications." Materials Science and Engineering: A, 273, 149-160.

2. Morgan, N. B. "Medical Shape Memory Alloy Applications: The Market and Its Products." Materials Science and Engineering: A, 378, 16-23.

3. Machado, L. G., & Savi, M. A. "Medical Applications of Shape Memory Alloys." Brazilian Journal of Medical and Biological Research, 36, 683-691.

4. Stoeckel, D., Pelton, A., & Duerig, T. "Self-Expanding Nitinol Stents: Material and Design Considerations." European Radiology, 14, 292-301.