Processing Techniques for Nitinol Tubes

2026-01-08 15:47:05

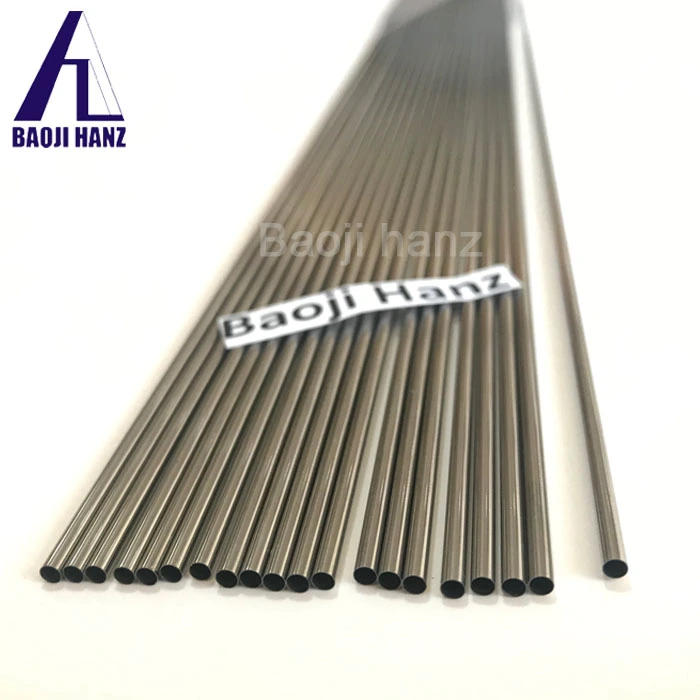

Processing Techniques for Nitinol Tubes

Nitinol, a nickel-titanium shape memory alloy (SMA), is renowned for its unique properties of superelasticity and shape memory effect. These characteristics make Nitinol tubes invaluable in demanding applications, particularly in the medical device industry (e.g., stents, guidewires, catheter components) and aerospace. However, its unique metallurgy also presents significant challenges in processing. Here is an overview of the key manufacturing and machining techniques for Nitinol tubes.

1. Primary Tube Manufacturing

The process begins with creating the raw tubular form.

-

Melting and Ingot Production: High-purity nickel and titanium are melted together using vacuum arc remelting (VAR) or induction skull melting. These methods prevent contamination from crucible materials, which is critical for maintaining Nitinol's transformation temperatures and mechanical properties.

-

Hot Working (Extrusion/Forging): The ingot is hot-extruded or forged at high temperatures (typically 700-900°C) to break down the coarse as-cast structure and form a seamless tube "hollow." This step requires precise control to avoid excessive oxidation and work hardening.

-

Cold Working and Intermediate Annealing: The tube is then drawn through a series of progressively smaller dies to achieve the final dimensions (often with OD as small as <1 mm and thin walls). This is a critical and challenging stage:

-

Cold Drawing: Due to Nitinol's high work hardening rate and springback, it is drawn with generous reductions per pass.

-

Mandrel Drawing: A mandrel inside the tube controls the inner diameter and wall thickness during drawing.

-

Annealing: Frequent intermediate anneals (at 600-800°C in a protective or vacuum atmosphere) are required to relieve stresses, restore ductility, and prevent cracking. The annealing parameters significantly influence the final microstructure and properties.

-

2. Secondary Machining and Fabrication

Once the basic tube is formed, further shaping is performed. These processes are difficult due to Nitinol's toughness, tendency to work-harden, and sensitivity to heat.

-

Cutting: Conventional sawing can cause deformation and heat-affected zones.

-

Prefered Methods: Abrasive Waterjet Cutting and Wire Electrical Discharge Machining (EDM) are highly favored. They provide clean, precise cuts with minimal thermal damage and mechanical stress, crucial for intricate components like stent patterns.

-

-

Drilling/Hole Making: Creating small or complex holes in tube walls is typically done via laser machining (e.g., for stent patterns) or micro-EDM for high precision and no tool wear issues associated with mechanical drilling.

-

Shape Setting (Heat Treatment): This is the defining step for activating Nitinol's functional properties. The tube is constrained on a mandrel or fixture in the desired final shape (e.g., a curved catheter tip) and heated in a furnace.

-

Process: Typically heated to 450-550°C for 5-30 minutes, followed by rapid quenching (e.g., water spray) or controlled cooling.

-

Purpose: This "trains" the material to remember its high-temperature austenitic shape, setting its transformation temperatures (AfAf) and superelastic plateau stresses.

-

3. Finishing and Surface Treatment

Final surface quality is paramount, especially for medical implants.

-

Pickling/Chemical Etching: Removes the thick, brittle oxide layer (scale) formed during high-temperature processing using acidic solutions (e.g., HF/HNO₃ mixtures). This reveals a clean surface for further steps.

-

Mechanical Polishing: Techniques like centerless grinding or abrasive flow machining can improve surface finish and dimensional accuracy.

-

Electropolishing: The most critical finishing step for medical devices. It electrochemically removes surface material, yielding a smooth, mirror-like finish. This process:

-

Elimates micro-cracks and inclusions that could be fatigue initiation sites.

-

Removes a layer potentially rich in nickel, improving biocompatibility.

-

Reduces surface friction for better device performance.

-

-

Passivation: After electropolishing, the tube is treated with nitric acid to promote a uniform, protective titanium oxide (TiO₂) layer on the surface, enhancing corrosion resistance and long-term stability.

4. Critical Considerations Throughout Processing

-

Temperature Control: Heat is both a tool and a risk. Every thermal operation (annealing, shape setting) must be tightly controlled to avoid altering the carefully engineered transformation temperatures.

-

Contamination Prevention: Oxygen, carbon, and other impurities must be minimized during melting and high-heat treatments to maintain material properties.

-

Tool Wear: Nitinol's toughness and work-hardening lead to rapid wear of conventional cutting tools, making non-contact machining methods (laser, EDM) often more economical for complex geometries.

In summary, the processing of Nitinol tubes is a sophisticated interplay of specialized thermo-mechanical working, precise heat treatments, and advanced machining/finishing techniques. The goal is to not only achieve complex miniature geometries but, more importantly, to meticulously engineer and preserve the unique functional properties that make Nitinol so valuable.