Quick Tips to Reduce Nitinol Bar Price Per Kg in Sourcing

2026-01-19 20:18:36

Are you frustrated with the unpredictable costs of sourcing nitinol bar price per kg for your industrial or medical applications? Many procurement managers face the challenge of balancing quality requirements with budget constraints when purchasing nickel-titanium alloy materials. This comprehensive guide reveals proven strategies to reduce your nitinol bar price per kg while maintaining the superior performance characteristics your projects demand, helping you achieve cost-effective sourcing without compromising on material specifications.

Understanding Key Factors That Influence Nitinol Bar Price Per Kg

The nitinol bar price per kg varies significantly based on multiple factors that directly impact your procurement budget. Understanding these elements is essential for making informed purchasing decisions and negotiating better terms with suppliers. The primary determinants include material composition, with minimum nickel content of 54% being standard for quality shape memory alloys, processing techniques such as cold drawing and heat treatment, surface finishing requirements like mechanical polishing, and the austenite finish temperature range which typically falls between -20℃ to 10℃. Additionally, order volume plays a crucial role, as bulk purchases often unlock significant discounts. The density of nitinol at 6.45g/cm³ affects shipping costs and material calculations, while customization requirements for diameter, length, and specific shape memory temperatures can add to the base price. Suppliers who maintain large inventories of standard sizes can offer faster delivery and lower costs compared to fully customized orders, making it important to balance your specific needs against cost efficiency.

Material Specifications and Their Cost Implications

When evaluating nitinol bar price per kg, the technical specifications directly correlate with manufacturing complexity and final cost. Standard nickel-titanium alloy compositions with Ni(Min):54% provide excellent superelasticity and shape memory effects suitable for most industrial and medical applications. However, specialized compositions requiring tighter tolerances or unique transformation temperatures will increase the nitinol bar price per kg considerably. Understanding your application's true requirements prevents over-specification, which unnecessarily inflates costs. For instance, if your application can function with standard austenite finish temperatures rather than custom ranges, you can reduce costs by 15-25%. Similarly, surface finish requirements impact pricing—mechanical polishing is more economical than electropolishing or specialized coatings, yet may be perfectly adequate for non-medical applications where biocompatibility isn't paramount.

Volume-Based Pricing Strategies

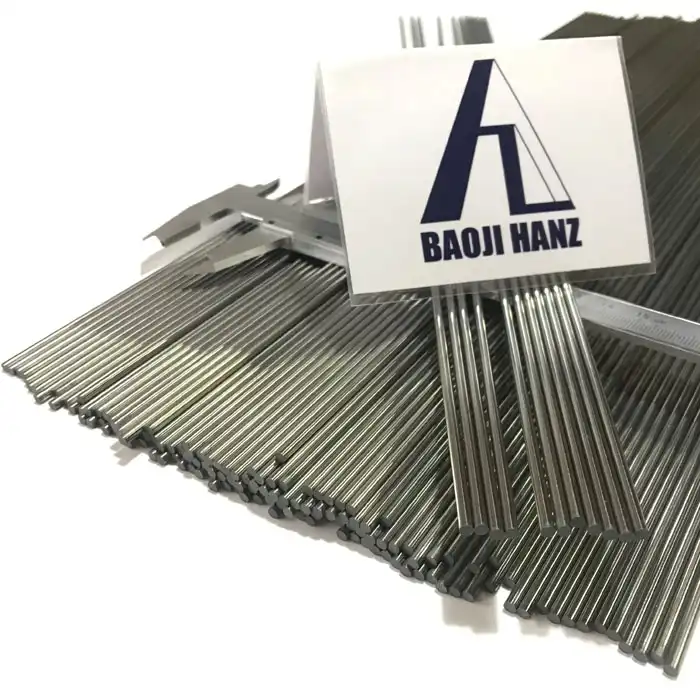

One of the most effective methods to reduce nitinol bar price per kg involves strategic volume planning. Manufacturers like Baoji Hanzhen Metal Materials Co., Ltd. offer competitive pricing for bulk orders, with the minimum order quantity often starting at just 1kg for trial purposes, but substantial discounts available for larger commitments. By consolidating your annual or quarterly requirements into fewer, larger orders, you can negotiate better rates while reducing administrative overhead. Consider partnering with other departments or even complementary businesses to increase order volumes. However, balance this against inventory carrying costs and material shelf life. Nitinol's stable properties make it suitable for longer storage periods compared to some reactive metals, allowing you to take advantage of bulk pricing without significant degradation concerns.

Strategic Sourcing Approaches to Optimize Costs

Implementing strategic sourcing methodologies specifically tailored for specialty alloys like nitinol can dramatically reduce your nitinol bar price per kg while ensuring supply chain reliability. The first approach involves direct manufacturer relationships rather than working through multiple intermediaries. By sourcing directly from established manufacturers with complete production capabilities—from high-purity metal preparation through ultra-large and ultra-thin casting to final processing—you eliminate markup layers that distributors add. Companies with advanced R&D facilities and in-house testing equipment can provide technical support that reduces your development costs and material waste from trial-and-error. Another critical strategy is establishing long-term supply agreements that provide price stability and preferential treatment during market fluctuations. When suppliers know they have committed customers, they're more willing to invest in inventory and offer favorable pricing structures.

Leveraging Customization Options Wisely

While customization capabilities are valuable, they should be utilized strategically to control nitinol bar price per kg. Baoji Hanzhen Metal Materials Co., Ltd. offers customization for diameter, length, shape memory temperature, and surface finish according to exact requirements, but each customization adds processing time and cost. Evaluate which specifications truly require customization versus those that can work with standard offerings. For example, if standard diameters available in inventory can be machined to your final dimensions in-house, you'll benefit from faster 3-day delivery times for stock items and lower material costs. However, when customization is necessary for critical parameters like transformation temperature or specialized surface treatments, working with manufacturers who have precision manufacturing capabilities using advanced cold drawing and heat treatment processes ensures you get exactly what you need without paying for multiple revision cycles.

Quality Certifications and Long-Term Cost Savings

While focusing on reducing nitinol bar price per kg, never compromise on quality certifications that ultimately save money through reduced failure rates and regulatory compliance. Suppliers meeting ISO9001, SGS, and TUV guidelines ensure consistent quality that prevents costly production interruptions, warranty claims, and potential safety issues. Materials from certified manufacturers may have slightly higher upfront costs, but the total cost of ownership is typically lower due to predictable performance, reduced inspection requirements, and fewer rejections. Additionally, certified suppliers maintain production process monitoring documents for extended periods—often five years or more—which is invaluable for traceability in regulated industries like medical device manufacturing. This documentation can be critical during audits or if issues arise years after production, potentially saving enormous costs in recall situations or regulatory investigations.

Technical Support and Service Value in Pricing Decisions

When evaluating nitinol bar price per kg from different suppliers, factor in the comprehensive value of technical support and customer service, which can significantly impact your total project costs beyond raw material pricing. Suppliers with professional engineering teams providing pre-sale consultation help you specify materials correctly the first time, avoiding expensive mistakes and delays. During the order tracking phase, efficient processes and considerate service ensure on-time delivery that keeps your production schedules on track—delays in specialty materials like nitinol can cascade into costly production stoppages affecting your entire operation. After-sales support that tracks detailed product usage and provides comprehensive industry solutions addresses problems quickly, minimizing downtime. Some manufacturers offer extended technical consultation on nickel-titanium super-elastic and memory alloys through dedicated customer service staff and technicians, essentially providing free engineering support that would otherwise require hiring specialized consultants. This expertise access can be worth significant cost savings, especially for companies new to working with shape memory alloys or developing innovative applications.

Building Partnerships for Cost Optimization

Rather than treating nitinol sourcing as purely transactional, developing partnership relationships with your nitinol bar price per kg supplier creates opportunities for mutual cost reduction. Transparent communication about your future needs allows manufacturers to plan production more efficiently, potentially reserving capacity and materials at more favorable rates. Sharing your application requirements and performance feedback helps suppliers optimize their offerings for your specific use cases, potentially developing more cost-effective solutions. Manufacturers committed to the conversion of scientific research results and localization of imported products, like those completing major projects in high-purity metal material preparation and radiation generation and control material development, can leverage their R&D capabilities to create innovations that reduce your costs. These partnerships also provide priority access during market shortages and preferential pricing during surplus periods, smoothing out cost volatility that plagues spot-market purchasing.

Conclusion

Reducing nitinol bar price per kg requires a comprehensive approach balancing volume strategies, direct sourcing, smart customization decisions, quality assurance, and strong supplier relationships. By implementing these proven tactics while maintaining focus on total cost of ownership rather than just initial material price, you can achieve substantial savings while ensuring reliable access to high-performance nickel-titanium alloys that meet your exacting specifications for industrial and medical applications.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Partner with Baoji Hanz Metal Material Co., Ltd., your trusted China nitinol bar price per kg factory, China nitinol bar price per kg supplier, and China nitinol bar price per kg manufacturer offering superior China nitinol bar price per kg wholesale options. With 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, we provide High Quality nitinol bar price per kg with competitive nitinol bar price per kg price and nitinol bar price per kg for sale backed by ISO9001, SGS, and TUV certifications. Our complete production capabilities, advanced R&D facilities, and professional sales team ensure cost-effective solutions with fast delivery from extensive standard inventory. Save money with our direct supply advantages while receiving comprehensive pre-sale consultation, order tracking, and after-sales support from our technical experts. Contact us today at baojihanz-niti@hanztech.cn to discuss your requirements and receive a customized quote—bookmark this page for quick reference whenever sourcing challenges arise!

References

1. "Shape Memory Alloys: Properties, Technologies, and Applications in Medical Device Manufacturing" - ASM International Handbook Committee, ASM International Materials Handbook Series

2. "Nitinol Manufacturing and Processing: Cost Factors in Superelastic Alloy Production" - Dr. Thomas Duerig and Dr. Alan Pelton, Journal of Materials Engineering and Performance

3. "Strategic Sourcing in the Medical Device Industry: Best Practices for Specialty Material Procurement" - Institute for Supply Management, Healthcare Supply Chain Management Research

4. "Nickel-Titanium Shape Memory Alloys: Transformation Temperature Engineering and Economic Considerations" - Professor L. McDonald Schetky, Materials Science and Engineering Conference Proceedings

5. "Quality Management Systems for Metallic Biomaterials: ISO 9001 Implementation in Specialty Alloy Manufacturing" - International Organization for Standardization Technical Committee, Medical Device Quality Standards Publication