Superelastic NiTi01 Memory Tube vs. Shape‑Memory Alloys: Pros & Trade‑offs

2026-01-19 20:18:38

Every engineer faces the challenge of selecting materials that won't fail under extreme stress. When conventional metals crack, bend permanently, or fatigue after repeated cycles, your project timeline and budget suffer. The Superelastic NiTi01 memory tube offers a solution by combining extraordinary flexibility with the ability to return to its original shape, making it the ideal choice for applications where durability and performance cannot be compromised. This article explores how superelastic nitinol technology compares to traditional shape-memory alloys, helping you understand which material best serves your specific engineering needs.

Understanding Superelastic NiTi01 Memory Tube Technology

The Superelastic NiTi01 memory tube represents a specialized form of nickel-titanium alloy engineered specifically for applications requiring exceptional elastic recovery and mechanical reliability. Unlike conventional metal tubes that permanently deform under stress, the Superelastic NiTi01 memory tube utilizes a unique phase transformation mechanism at the atomic level. When subjected to mechanical loading above its transformation temperature, the material undergoes a stress-induced martensitic transformation from the austenitic phase to the martensitic phase. This transformation allows the tube to accommodate strains up to eight percent while maintaining complete shape recovery upon unloading. The austenitic finish temperature of the Superelastic NiTi01 memory tube is carefully controlled during manufacturing to remain below room temperature, typically between zero and twenty degrees Celsius, ensuring that the material exhibits superelastic behavior at both ambient and body temperatures. This precise temperature control distinguishes superelastic alloys from their shape-memory counterparts and enables consistent performance across a wide range of operating conditions without requiring external heating for shape recovery.

Phase Transformation Mechanisms in Superelastic Materials

The remarkable properties of the Superelastic NiTi01 memory tube stem from reversible solid-state phase transformations between crystallographically distinct structures. In the stress-free state above the austenitic finish temperature, the material exists in a highly ordered cubic crystal structure known as the B2 austenitic phase. When mechanical stress is applied, the material transforms into a monoclinic martensitic phase that can accommodate the imposed deformation through lattice distortion rather than through dislocation slip, which causes permanent deformation in conventional metals. This transformation occurs at a nearly constant stress level, creating the characteristic plateau region observed in stress-strain curves of superelastic materials. The Superelastic NiTi01 memory tube exhibits minimal hysteresis during loading and unloading cycles, typically ranging from ten to fifty degrees Celsius in temperature equivalent, which translates to efficient energy recovery and minimal heat generation during operation. The transformation stress increases with temperature at a rate of approximately five to ten megapascals per degree Celsius, allowing engineers to tune the mechanical response by controlling the operating temperature. This phase transformation mechanism provides the Superelastic NiTi01 memory tube with recoverable strains ten to thirty times greater than conventional elastic materials, enabling applications that would be impossible with traditional spring steels or elastic polymers.

Material Composition and Processing Requirements

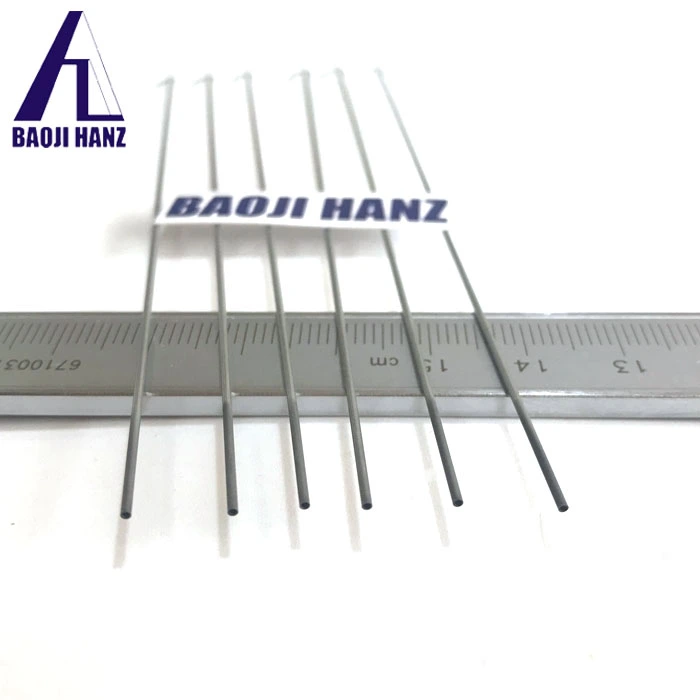

The Superelastic NiTi01 memory tube achieves its unique properties through precise control of chemical composition and thermomechanical processing. The alloy consists of approximately fifty to fifty-one atomic percent nickel, with the balance being titanium, though even minor compositional variations of zero point one percent can shift the transformation temperature by ten degrees Celsius. Manufacturing processes for the Superelastic NiTi01 memory tube begin with vacuum melting to minimize oxygen and carbon contamination, which can degrade superelastic properties and create inclusions that serve as crack initiation sites. Following ingot production, the material undergoes hot working and cold working with intermediate annealing steps to achieve the desired tube geometry with outer diameters ranging from three to one hundred fourteen millimeters and wall thicknesses from zero point one to fifteen millimeters. The final shape-setting heat treatment, typically performed at temperatures between four hundred fifty and five hundred fifty degrees Celsius, establishes the austenitic structure and determines the transformation temperatures that govern superelastic behavior. Surface finishing processes such as electropolishing remove the work-hardened surface layer and titanium oxide scale, resulting in a smooth, corrosion-resistant surface with roughness values below zero point one micrometers. Quality control testing of each Superelastic NiTi01 memory tube batch includes differential scanning calorimetry to verify transformation temperatures, tensile testing to confirm mechanical properties, and bend-free recovery testing to validate functional performance according to ASTM F2633-07 standards.

Shape-Memory Alloys: Operating Principles and Characteristics

Shape-memory alloys operate on fundamentally different principles than superelastic materials, despite sharing the same base nickel-titanium composition. In shape-memory mode, the material exists in the martensitic phase at room temperature, below the martensitic finish temperature. When deformed in this low-temperature state, the material undergoes martensitic twinning and detwinning rather than stress-induced phase transformation. The deformed shape is retained after load removal because the detwinned martensite structure is stable at room temperature. Shape recovery occurs only upon heating above the austenitic finish temperature, at which point the material transforms back to the parent austenitic phase and recovers its pre-programmed shape. This thermally activated recovery process can generate substantial recovery forces, typically ranging from one hundred to eight hundred megapascals, making shape-memory alloys ideal for actuator applications. The transformation temperatures of shape-memory alloys are intentionally set higher than the operating environment, with austenitic finish temperatures typically ranging from forty to one hundred ten degrees Celsius depending on the application requirements. Shape-memory materials can be trained to exhibit two-way memory, remembering different shapes at high and low temperatures, though the recoverable strain in two-way mode is limited to approximately three percent compared to the eight percent possible in one-way shape-memory effect.

Thermal Activation Requirements and Energy Consumption

The shape-memory effect requires external energy input for shape recovery, distinguishing it from the spontaneous recovery exhibited by the Superelastic NiTi01 memory tube. Thermal activation methods include resistive heating through applied electrical current, convective heating from surrounding fluid media, or radiative heating from external sources. The energy required for thermal activation depends on the mass of the shape-memory component, the specific heat capacity of nickel-titanium alloy at approximately four hundred fifty joules per kilogram per degree Celsius, and the temperature differential between the starting temperature and the austenitic finish temperature. For practical applications, shape-memory actuators typically require heating rates of ten to one hundred degrees Celsius per second to achieve acceptable response times, necessitating power inputs of one to ten watts per gram of active material. Cooling represents another critical consideration, as the material must return below the martensitic finish temperature before the next actuation cycle. Passive cooling through natural convection often proves too slow for high-frequency applications, requiring forced convection or conductive cooling pathways. The Superelastic NiTi01 memory tube eliminates these thermal management complexities by operating isothermally at ambient or body temperature, requiring no external heating or cooling systems and consuming zero energy for shape recovery, which dramatically simplifies system design and improves reliability in applications where electrical power availability or thermal management capabilities are limited.

Hysteresis and Transformation Temperature Considerations

Shape-memory alloys exhibit substantial thermal hysteresis between heating and cooling transformation sequences, typically spanning thirty to fifty degrees Celsius between the austenitic finish temperature during heating and the martensitic start temperature during cooling. This hysteresis arises from the energy required to nucleate and propagate transformation interfaces during forward and reverse transformations, combined with frictional dissipation at phase boundaries. While this hysteresis provides beneficial damping characteristics for vibration control applications, it also imposes constraints on actuation precision and cycling frequency. The transformation temperatures themselves shift with repeated thermal cycling, particularly during the initial training period, requiring designers to incorporate adequate temperature margins into their specifications. The Superelastic NiTi01 memory tube demonstrates significantly smaller mechanical hysteresis, typically equivalent to fifteen to thirty degrees Celsius in temperature, and exhibits stable transformation behavior after minimal mechanical training cycles. The narrow mechanical hysteresis of the Superelastic NiTi01 memory tube enables efficient energy storage and release during loading and unloading, with energy dissipation typically representing less than twenty percent of the total mechanical work, compared to thirty to fifty percent for thermally activated shape-memory cycles. Transformation temperature stability of the Superelastic NiTi01 memory tube remains excellent over millions of mechanical cycles when operated within design strain limits, whereas shape-memory materials may experience transformation temperature shifts of five to fifteen degrees Celsius over the device lifetime due to accumulated crystallographic defects from repeated thermal transformations.

Comparative Performance Analysis: Superelastic vs. Shape-Memory Mode

Direct performance comparison between the Superelastic NiTi01 memory tube and shape-memory alloys reveals distinct advantages and limitations for each material variant. The Superelastic NiTi01 memory tube excels in applications requiring instantaneous shape recovery, passive operation without external power, and high-frequency loading cycles at constant temperature. Mechanical cycling capability of superelastic nitinol reaches ten million cycles or more when operated at strain amplitudes below six percent, compared to typical fatigue limits of one hundred thousand to one million thermal cycles for shape-memory actuators due to accumulated damage from repeated phase transformations. Load-bearing capacity differs markedly between the two variants, with the Superelastic NiTi01 memory tube providing consistent stress levels during the transformation plateau, typically between three hundred and six hundred megapascals depending on temperature and processing, while shape-memory materials generate recovery stresses that can exceed eight hundred megapascals but decrease as the recovery stroke progresses. Response time represents another critical distinction, as the Superelastic NiTi01 memory tube responds instantaneously to applied loads at mechanical wave propagation velocities, whereas shape-memory actuators require hundreds of milliseconds to seconds for thermal activation depending on size and heating method. Environmental sensitivity also varies significantly, with the Superelastic NiTi01 memory tube maintaining stable performance across temperature ranges from minus fifty to plus one hundred degrees Celsius as long as the operating temperature remains above the austenitic finish temperature and below the martensite deformation temperature, while shape-memory devices require precise temperature control within the transformation range for optimal performance.

Mechanical Property Comparison and Design Implications

The mechanical properties of the Superelastic NiTi01 memory tube differ substantially from both shape-memory nitinol and conventional structural materials, creating unique opportunities and constraints for engineering design. Elastic modulus of the Superelastic NiTi01 memory tube in the austenitic phase measures approximately seventy to eighty gigapascals, increasing to approximately thirty to forty gigapascals during the stress-induced martensitic transformation due to the lower stiffness of the martensitic phase, then returning to the higher austenitic modulus after transformation completion. This variable modulus behavior contrasts with constant-modulus behavior of conventional metals and provides beneficial compliance matching for medical implants interfacing with biological tissues. Ultimate tensile strength of the Superelastic NiTi01 memory tube typically ranges from nine hundred to fourteen hundred megapascals depending on heat treatment conditions, comparable to high-strength stainless steels but achieved at significantly lower density of approximately six point five grams per cubic centimeter. The combination of high strength and low density gives the Superelastic NiTi01 memory tube an exceptional strength-to-weight ratio, particularly advantageous for aerospace applications and portable medical devices. Corrosion resistance of the Superelastic NiTi01 memory tube equals or exceeds that of titanium alloys and stainless steels due to the formation of a stable titanium oxide passive film, with pitting potentials above one volt versus saturated calomel electrode in physiological saline solution. Biocompatibility testing demonstrates excellent tissue compatibility with no cytotoxic effects, supporting widespread use in cardiovascular stents, orthodontic archwires, and orthopedic implants where the Superelastic NiTi01 memory tube contacts living tissue for extended periods.

Application-Specific Selection Criteria

Selecting between the Superelastic NiTi01 memory tube and shape-memory alloy variants requires careful analysis of application-specific requirements and operating conditions. Medical device applications typically favor superelastic materials when the device must function passively within the body, such as self-expanding stents that deploy upon release from a delivery catheter and then maintain radial force against vessel walls, or guidewires that navigate tortuous vascular anatomy without permanent deformation. The Superelastic NiTi01 memory tube proves ideal for these applications because it requires no external power, responds instantly to physiological forces, and demonstrates excellent fatigue resistance under the cyclic loading conditions imposed by cardiac pulsation or respiratory motion. Conversely, shape-memory alloys excel in active deployment applications such as embolic protection filters that remain compact during insertion and then expand to their functional configuration upon heating above body temperature, or orthodontic appliances that apply controlled corrective forces as they warm from refrigerated storage to oral temperature. Industrial applications divide similarly along passive versus active functionality lines, with the Superelastic NiTi01 memory tube serving in vibration damping, flexible couplings, and impact energy absorption where instantaneous mechanical response without power input provides system advantages, while shape-memory actuators enable compact high-force mechanisms for valve control, thermal switches, and assembly fixtures where thermal activation capability and high work output justify the added complexity. Aerospace applications increasingly employ the Superelastic NiTi01 memory tube for landing gear components, helicopter rotor flexures, and satellite deployment mechanisms where reliability, weight reduction, and maintenance-free operation over millions of cycles outweigh the higher material costs compared to conventional titanium or steel components.

Processing Capabilities and Customization Options for Superelastic NiTi01 Memory Tube

The Superelastic NiTi01 memory tube from Baoji Hanz Metal Material Co., Ltd. offers extensive processing and customization capabilities to meet diverse application requirements. Standard processing services include bending to create complex three-dimensional geometries for medical instruments and aerospace components, with minimum bend radii typically three to five times the tube outer diameter to avoid excessive strain that could compromise superelastic properties. Welding of the Superelastic NiTi01 memory tube requires specialized techniques including laser welding or resistance welding in controlled atmosphere environments to prevent oxidation and maintain transformation temperature uniformity across the weld zone. Decoiling services convert master coil stock into straight lengths up to six thousand millimeters, with straightness tolerances below one millimeter per meter achieved through precision straightening fixtures and stress-relief heat treatments. Cutting operations employ wire electrical discharge machining, laser cutting, or precision sawing to produce tube sections with length tolerances of plus or minus zero point five millimeters and burr-free edges suitable for immediate assembly without secondary finishing. Punching operations create holes, slots, and complex aperture patterns in tube walls for fluid flow control, electrical interconnection, or mechanical interlocking, with feature sizes down to one hundred micrometers achievable using photochemical etching processes. Custom outer diameters from three to one hundred fourteen millimeters accommodate applications ranging from minimally invasive medical devices to industrial actuators and structural components, while wall thickness options from zero point one to fifteen millimeters enable optimization of bending stiffness, radial strength, and fluid flow characteristics. The material supplied by Baoji Hanz Metal Material Co., Ltd. complies with ASTM F2633-07 specifications for wrought nickel-titanium shape memory alloys, ensuring consistent quality and traceability for regulatory compliance in medical device manufacturing.

Quality Control and Certification Standards

Baoji Hanz Metal Material Co., Ltd. implements comprehensive quality control protocols throughout the manufacturing process for the Superelastic NiTi01 memory tube to ensure material properties meet stringent application requirements. Raw material verification begins with chemical analysis using inductively coupled plasma optical emission spectroscopy to confirm nickel and titanium content within specification limits of plus or minus zero point zero five atomic percent, along with impurity analysis to verify that carbon, oxygen, nitrogen, and hydrogen levels remain below limits that could degrade mechanical properties or biocompatibility. Transformation temperature characterization employs differential scanning calorimetry on samples from each production lot, measuring austenitic start and finish temperatures along with martensitic start and finish temperatures with accuracy of plus or minus one degree Celsius. Mechanical property testing includes tensile testing to verify ultimate tensile strength, plateau stress levels, and recoverable strain according to ASTM F2516 standard test methods, along with cyclic loading tests to confirm fatigue performance over ten thousand representative loading cycles. Dimensional inspection utilizes coordinate measuring machines and optical comparators to verify outer diameter, wall thickness, length, and straightness against drawing specifications, with statistical process control ensuring that all dimensions remain within specified tolerance bands. Surface quality assessment includes visual examination at ten times magnification to detect surface defects, along with roughness measurements using contact or optical profilometry to confirm average roughness values below specified limits. The manufacturing facility maintains ISO 9001 quality management system certification, ISO 13485 medical device quality system certification, and CE marking authorization for medical products, with complete documentation retained for minimum five years to support traceability requirements. Product testing reports accompany each shipment of Superelastic NiTi01 memory tube, providing certified material properties and dimensional measurements for customer verification and regulatory submissions.

Original Equipment Manufacturer Services and Technical Support

Baoji Hanz Metal Material Co., Ltd. provides comprehensive OEM services to support customer-specific requirements for the Superelastic NiTi01 memory tube in medical, aerospace, and industrial applications. Custom alloy compositions can be developed to achieve transformation temperatures optimized for specific operating environments, with austenitic finish temperatures adjustable from minus twenty to plus one hundred ten degrees Celsius through controlled nickel-to-titanium ratio modifications and ternary element additions. Specialized heat treatment protocols enable property tailoring for enhanced fatigue resistance, higher plateau stress levels, or reduced hysteresis depending on application priorities, with processing parameters determined through collaborative development programs utilizing customer samples and application testing. Surface modification options include electropolishing to achieve mirror finishes with roughness below fifty nanometers for reduced friction in medical applications, passivation treatments to enhance corrosion resistance, and biocompatible coatings such as titanium nitride or diamond-like carbon for specific tribological requirements. Packaging configurations accommodate customer preferences ranging from individual tubes in protective sleeves to bulk coil stock for high-volume manufacturing, with custom labeling and documentation formats supporting traceability and inventory management systems. Technical consultation services provide expert guidance on material selection, design optimization, processing method selection, and application troubleshooting, drawing on seven years of specialized experience in nitinol shape memory alloy development and production. The engineering team collaborates with customers from initial concept through production qualification, offering finite element analysis support to predict component behavior, prototype fabrication for design validation testing, and process development to ensure manufacturing repeatability. Minimum order quantities as low as five pieces enable economical prototype development and small-batch production, while production capacity scales to support high-volume requirements with consistent quality and on-time delivery performance. Pre-sale technical consultation helps customers understand the capabilities and limitations of the Superelastic NiTi01 memory tube relative to application requirements, while post-sale application support tracks product performance in service and provides comprehensive industry solutions addressing any issues that emerge during device development or clinical use.

Medical Device Applications and Performance Requirements

The Superelastic NiTi01 memory tube has revolutionized medical device design by enabling minimally invasive procedures and improving patient outcomes across cardiovascular, neurovascular, orthopedic, and surgical specialties. Cardiovascular stents manufactured from the Superelastic NiTi01 memory tube provide self-expanding radial force to maintain vessel patency after angioplasty procedures, with the superelastic properties allowing crimping to three millimeter delivery profiles and expansion to diameters of ten millimeters or larger without permanent deformation. The kink resistance of the Superelastic NiTi01 memory tube prevents vessel collapse during patient movement while the material flexibility accommodates arterial pulsation and body motion without inducing mechanical irritation or stress concentration at implant edges. Guidewires fabricated from small-diameter Superelastic NiTi01 memory tube with outer diameters from zero point three to one millimeter combine the pushability needed to advance through tortuous anatomy with the flexibility to navigate complex vascular pathways without perforating vessel walls, while the torque transmission enables precise catheter steering under fluoroscopic guidance. Orthodontic archwires made from the Superelastic NiTi01 memory tube deliver consistent forces throughout the treatment cycle as teeth move, eliminating the need for frequent activation adjustments required with stainless steel wires and reducing overall treatment time by providing optimal force levels continuously. Orthopedic implants including bone plates, intramedullary rods, and spinal fixation devices utilize the Superelastic NiTi01 memory tube to achieve compliance matching with natural bone, reducing stress shielding that can lead to bone resorption while providing sufficient strength to support physiological loads during healing. The biocompatibility of the Superelastic NiTi01 memory tube, certified through ISO 13485 and EU CE compliance, ensures compatibility with human tissue for both short-term surgical tools and permanent implants, with extensive clinical experience demonstrating safety and efficacy across millions of patient implant-years.

Aerospace and Industrial Engineering Applications

Aerospace applications leverage the unique properties of the Superelastic NiTi01 memory tube to achieve weight reduction, improve reliability, and enable novel design concepts impossible with conventional materials. Helicopter rotor flexures manufactured from the Superelastic NiTi01 memory tube eliminate mechanical bearings by providing the compliance needed for blade pitch changes while supporting centrifugal loads, reducing maintenance requirements and extending service life compared to elastomeric bearings that degrade over time. Aircraft wing morphing structures incorporate the Superelastic NiTi01 memory tube to create variable geometry surfaces that optimize aerodynamic efficiency across flight regimes, with the superelastic behavior allowing large shape changes without actuator power consumption or mechanical complexity of conventional multi-segment designs. Landing gear components benefit from the vibration damping characteristics of the Superelastic NiTi01 memory tube, which dissipates impact energy during touchdown through the hysteresis of the stress-induced martensitic transformation, reducing transmitted loads to airframe structure and improving passenger comfort. Satellite deployment mechanisms utilize the Superelastic NiTi01 memory tube for antenna booms, solar panel supports, and instrument positioning systems where reliability after years of space environmental exposure and the absence of maintenance opportunities demand materials with exceptional fatigue resistance and freedom from lubrication requirements. Industrial robotics increasingly employ the Superelastic NiTi01 memory tube for flexible joints and compliant grippers that safely interact with delicate objects or operate in unstructured environments, with the material providing both the compliance to conform to irregular surfaces and the structural strength to manipulate significant payloads. Chemical processing equipment uses the Superelastic NiTi01 memory tube for flexible connections that accommodate thermal expansion, vibration isolation, and misalignment while maintaining corrosion resistance in aggressive environments where stainless steel or polymer materials would degrade. Precision instrumentation applications capitalize on the low hysteresis and stable properties of the Superelastic NiTi01 memory tube for force sensors, displacement transducers, and calibration fixtures requiring repeatable mechanical response over millions of measurement cycles.

Conclusion

The Superelastic NiTi01 memory tube and traditional shape-memory alloys each offer distinct advantages for engineering applications, with superelastic variants excelling in passive, high-cycle applications requiring instantaneous response, while shape-memory materials enable compact high-force actuators where thermal activation capability provides unique functionality for medical devices, aerospace systems, and industrial equipment.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Partner with Baoji Hanz Metal Material Co., Ltd., a leading China Superelastic NiTi01 memory tube manufacturer with seven years of expertise as a trusted China Superelastic NiTi01 memory tube supplier and China Superelastic NiTi01 memory tube factory. We offer High Quality Superelastic NiTi01 memory tube for sale with competitive Superelastic NiTi01 memory tube price through direct China Superelastic NiTi01 memory tube wholesale, combining sophisticated production equipment, professional R&D capabilities, and rigorous quality control certified to ISO9001, SGS, and TUV standards. Our customer service excellence includes pre-sale technical consultation, order tracking with production documentation retained for five years, and comprehensive after-sales support tracking product performance and providing industry solutions. Save money through our direct supply and cost advantages while ensuring fast delivery from extensive inventory of standard sizes with OEM customization available for specialized requirements. Contact our team at baojihanz-niti@hanztech.cn to discuss your Superelastic NiTi01 memory tube requirements and discover how our expertise transforms your design challenges into practical solutions that deliver superior performance and reliability.

References

1. Otsuka K, Ren X. Physical metallurgy of Ti-Ni-based shape memory alloys. Progress in Materials Science. Authors: Kazuhiro Otsuka, Xiaobing Ren.

2. Duerig T, Pelton A, Stöckel D. An overview of nitinol medical applications. Materials Science and Engineering: A. Authors: Thomas Duerig, Alan Pelton, Dieter Stöckel.

3. Mohd Jani J, Leary M, Subic A, Gibson MA. A review of shape memory alloy research, applications and opportunities. Materials & Design. Authors: Jaronie Mohd Jani, Martin Leary, Aleksandar Subic, Mark A. Gibson.

4. Elahinia MH, Hashemi M, Tabesh M, Bhaduri SB. Manufacturing and processing of NiTi implants: a review. Progress in Materials Science. Authors: Mohammad H. Elahinia, Masoud Hashemi, Mojtaba Tabesh, Sarit B. Bhaduri.

5. Morgan NB. Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A. Author: Nick B. Morgan.