The Role of Nitinol Strip in High-Performance Applications

2025-11-03 20:53:40

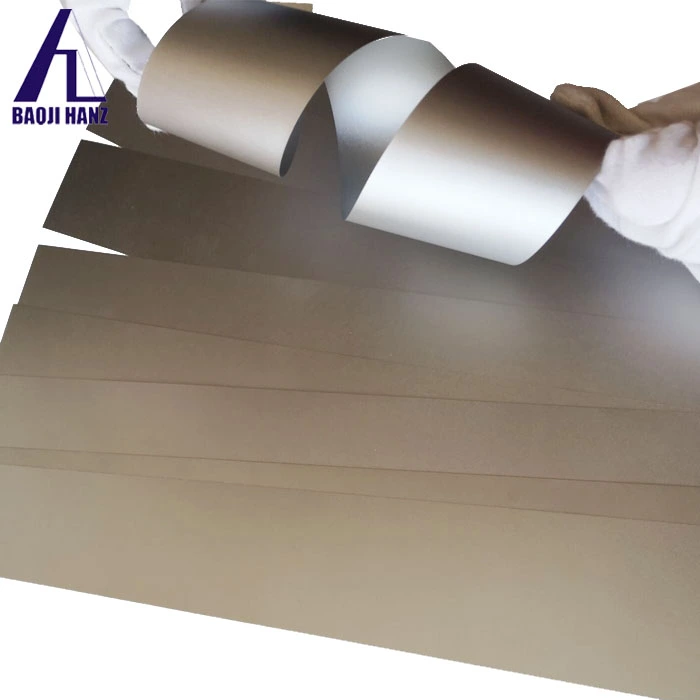

The role of nitinol strip in high-performance applications has become increasingly critical across multiple industries, particularly in medical devices, aerospace, and precision engineering. This unique nickel-titanium alloy material demonstrates exceptional superelastic properties and shape memory effects, making nitinol strip an indispensable component for applications requiring reliability, precision, and biocompatibility. From minimally invasive medical procedures to demanding industrial applications, nitinol strip continues to revolutionize how engineers approach design challenges that require materials capable of withstanding extreme conditions while maintaining consistent performance.

Critical Applications of Nitinol Strip in Medical Technology

Revolutionary Impact on Minimally Invasive Procedures

The medical industry has experienced a transformative shift toward less invasive surgical procedures, and nitinol strip plays a pivotal role in this evolution. Medical device manufacturers utilize nitinol strip to create sophisticated instruments that can navigate through the body's complex anatomy while maintaining structural integrity. The superelastic properties of nitinol strip allow medical devices to compress to incredibly small diameters for insertion through tiny incisions, then return to their predetermined shape once positioned correctly. This capability has revolutionized cardiovascular interventions, where nitinol strip-based stents can be compressed for delivery through narrow catheters and expand to their full diameter upon deployment. The biocompatibility of nitinol strip ensures long-term compatibility with human tissue, reducing the risk of adverse reactions and improving patient outcomes. Furthermore, the kink resistance properties of nitinol strip make it ideal for guidewires and delivery systems that must navigate tortuous anatomical pathways without compromising functionality.

Advanced Orthopedic and Dental Applications

Orthopedic and dental applications represent another significant area where nitinol strip demonstrates exceptional performance characteristics. In orthodontic treatments, nitinol strip is extensively used in archwires due to its ability to exert consistent, gentle forces over extended periods. The shape memory effect of nitinol strip ensures that braces maintain optimal pressure for tooth movement while adapting to the changing oral environment. Orthopedic surgeons increasingly rely on nitinol strip-based implants and surgical instruments for bone fixation and joint reconstruction procedures. The unique properties of nitinol strip allow for the development of smart implants that can adapt to physiological conditions, providing enhanced healing environments. Spinal fusion devices incorporating nitinol strip technology offer improved compression forces and better integration with surrounding bone tissue. The excellent fatigue resistance of nitinol strip ensures long-term durability in high-stress orthopedic applications, where repeated loading cycles could compromise conventional materials.

Cutting-Edge Cardiovascular Device Development

Cardiovascular applications represent perhaps the most sophisticated use of nitinol strip in medical technology. The development of next-generation stents, heart valve frames, and vascular filters relies heavily on the unique properties of nitinol strip. Modern nitinol strip manufacturing techniques enable the production of extremely thin-walled structures that maintain exceptional radial strength while offering superior flexibility. This combination allows cardiovascular devices to navigate complex vascular anatomy while providing reliable long-term performance. The superelastic behavior of nitinol strip ensures that cardiovascular implants can withstand the constant mechanical stresses imposed by cardiac cycles without experiencing fatigue failure. Additionally, the corrosion resistance of properly processed nitinol strip provides excellent biocompatibility in the challenging cardiovascular environment, where exposure to blood and body fluids demands materials with exceptional chemical stability.

Industrial and Aerospace Applications of Nitinol Strip

Precision Control Systems and Actuators

Industrial applications of nitinol strip extend far beyond the medical field, encompassing precision control systems and actuator technologies across multiple sectors. Manufacturing processes increasingly demand materials that can provide precise, repeatable motion control, and nitinol strip delivers these capabilities through its shape memory effect. Temperature-activated nitinol strip actuators offer fail-safe mechanisms in critical industrial systems, automatically returning to predetermined positions when specific thermal thresholds are reached. The high strength-to-weight ratio of nitinol strip makes it particularly valuable in applications where space and weight constraints are critical factors. Robotic systems benefit from nitinol strip components that provide smooth, silent operation while maintaining precise positioning accuracy. The excellent corrosion resistance of nitinol strip ensures reliable performance in harsh industrial environments where exposure to chemicals, moisture, and extreme temperatures could compromise conventional actuator materials.

Aerospace and Defense Technology Integration

Aerospace applications represent some of the most demanding environments where nitinol strip technology demonstrates its exceptional capabilities. The stringent requirements of aerospace systems demand materials that can withstand extreme temperature variations, high stress levels, and prolonged service lives without degradation. Nitinol strip components in aircraft systems provide reliable actuation for control surfaces, landing gear mechanisms, and environmental control systems. The shape memory properties of nitinol strip enable the development of self-deploying antenna systems and solar panel mechanisms that automatically unfold when reaching specific orbital conditions. Defense applications utilize nitinol strip in sophisticated weapon systems and reconnaissance equipment where reliability and precision are paramount. The ability of nitinol strip to maintain consistent performance across wide temperature ranges makes it invaluable for systems operating in extreme environments, from arctic conditions to desert heat.

Advanced Manufacturing and Processing Equipment

Modern manufacturing equipment increasingly incorporates nitinol strip components to achieve higher precision and reliability in production processes. The unique properties of nitinol strip enable the development of smart manufacturing systems that can adapt to changing conditions automatically. Quality control systems benefit from nitinol strip sensors and actuators that provide rapid response to process variations, ensuring consistent product quality. The excellent fatigue resistance of nitinol strip makes it ideal for high-cycle manufacturing applications where conventional materials would experience premature failure. Precision positioning systems in semiconductor manufacturing rely on nitinol strip components to achieve the nanometer-level accuracy required for modern chip production. The clean processing capabilities of properly manufactured nitinol strip ensure compatibility with sensitive manufacturing environments where contamination control is critical.

Advanced Material Properties and Performance Characteristics

Superelastic Behavior and Shape Memory Effects

The fundamental properties that make nitinol strip exceptional in high-performance applications stem from its unique crystallographic structure and phase transformation behavior. The superelastic characteristics of nitinol strip allow it to undergo large deformations and return to its original shape upon stress removal, providing up to 8% recoverable strain compared to less than 1% for conventional metals. This extraordinary capability enables nitinol strip to absorb significant amounts of mechanical energy without permanent deformation, making it ideal for applications requiring repeated loading cycles. The shape memory effect of nitinol strip allows components to be programmed with specific shapes that are recovered upon heating above the transformation temperature. This dual functionality provides engineers with unprecedented design flexibility, enabling the creation of smart structures that can adapt to changing environmental conditions. The transformation temperatures of nitinol strip can be precisely controlled through composition adjustment and thermomechanical processing, allowing customization for specific application requirements.

Mechanical Strength and Fatigue Resistance

High-performance applications demand materials with exceptional mechanical properties, and nitinol strip delivers outstanding strength characteristics across a wide range of operating conditions. The tensile strength of nitinol strip typically exceeds 1000 MPa, providing excellent load-bearing capacity for demanding structural applications. More importantly, the fatigue life of nitinol strip surpasses that of most conventional alloys by several orders of magnitude, making it ideal for applications involving millions of loading cycles. The unique microstructural characteristics of nitinol strip contribute to its exceptional crack propagation resistance, ensuring long-term reliability in high-stress environments. Surface finish quality plays a crucial role in nitinol strip performance, with properly processed materials exhibiting superior fatigue resistance and corrosion performance. The elastic modulus of nitinol strip can vary significantly depending on temperature and stress state, providing designers with additional flexibility in tailoring component behavior to specific application requirements.

Biocompatibility and Corrosion Performance

The success of nitinol strip in medical and other critical applications depends heavily on its exceptional biocompatibility and corrosion resistance characteristics. Properly processed nitinol strip forms a stable titanium oxide surface layer that provides excellent protection against corrosion in biological and industrial environments. The biocompatibility of nitinol strip has been extensively validated through decades of clinical use, demonstrating excellent tissue compatibility and minimal adverse reactions. Long-term implantation studies show that nitinol strip maintains its mechanical properties and surface integrity even after years of exposure to physiological conditions. The corrosion resistance of nitinol strip in various chemical environments makes it suitable for applications in harsh industrial conditions where conventional materials would rapidly degrade. Surface treatments and finishing techniques can further enhance the corrosion resistance and biocompatibility of nitinol strip, ensuring optimal performance in the most demanding applications.

Conclusion

The role of nitinol strip in high-performance applications continues to expand as engineers discover new ways to harness its unique properties. From life-saving medical devices to precision industrial systems, nitinol strip has proven its value across diverse fields requiring exceptional reliability, precision, and adaptability. The combination of superelastic behavior, shape memory effects, and excellent biocompatibility positions nitinol strip as an indispensable material for next-generation technologies.

For organizations seeking reliable nitinol strip solutions, partnering with an experienced China nitinol strip manufacturer ensures access to premium quality materials and technical expertise. As a leading China nitinol strip supplier, Baoji Hanz Metal Material Co., Ltd. offers comprehensive China nitinol strip wholesale solutions with 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy technologies. Our direct supply capabilities provide significant cost advantages while maintaining superior quality standards. Fast delivery from extensive stock of standard sizes ensures project timelines are met consistently. We provide Customized nitinol strip solutions tailored to specific application requirements, with competitive nitinol strip price structures. Whether you need nitinol strip for sale for prototyping or large-scale production, our team offers comprehensive OEM services including custom sizes, specific alloy compositions, and specialized packaging options. Take advantage of our nitinol strip Free Sample program to evaluate our materials for your applications. Contact us today at baojihanz-niti@hanztech.cn to discuss your nitinol strip requirements with our technical experts and discover how our ISO9001, SGS, and TUV certified processes can support your high-performance applications.

References

1. Buehler, W.J., Gilfrich, J.V., and Wiley, R.C. "Effect of Low-Temperature Phase Changes on the Mechanical Properties of Alloys near Composition TiNi." Journal of Applied Physics, Vol. 34, No. 5, 1963.

2. Duerig, T., Pelton, A., and Stöckel, D. "An Overview of Nitinol Medical Applications." Materials Science and Engineering: A, Vol. 273-275, 1999.

3. Mohd Jani, J., Leary, M., Subic, A., and Gibson, M.A. "A Review of Shape Memory Alloy Research, Applications and Opportunities." Materials & Design, Vol. 56, 2014.

4. Pelton, A.R., Stöckel, D., and Duerig, T.W. "Medical Uses of Nitinol." Materials Science Forum, Vols. 327-328, 2000.