The Truth About Nitinol Sheets

2025-09-25 20:26:19

When engineers and researchers face the challenge of finding materials that can withstand extreme deformation while returning to their original shape, traditional metals fall short. The frustration of dealing with permanent deformation, material fatigue, and limited flexibility has driven countless professionals to seek alternatives. The truth about nitinol sheet technology reveals a revolutionary solution that combines shape memory properties with superelastic behavior, offering unprecedented design possibilities for medical devices, aerospace applications, and advanced manufacturing processes. This comprehensive guide unveils the real capabilities, applications, and considerations surrounding nitinol sheet materials, providing the essential knowledge needed to harness their unique properties effectively.

What Makes Nitinol Sheet Different from Conventional Materials?

The fundamental truth about nitinol sheet lies in its extraordinary dual-phase crystal structure that enables both shape memory and superelastic properties. Unlike conventional materials that undergo permanent deformation when stressed beyond their elastic limit, nitinol sheet can recover its original configuration through two distinct mechanisms. The shape memory effect allows the material to return to a predetermined shape when heated above its austenite finish temperature, while superelasticity enables recovery at constant temperatures through stress-induced phase transformations. Manufacturing nitinol sheet requires precise control of composition, typically maintaining nickel content between 54.7% and 57% with the balance being titanium, following ASTM F2063 standards. This careful balance determines the transformation temperatures and mechanical properties that make each nitinol sheet unique. The manufacturing process involves sophisticated melting, hot rolling, and annealing procedures that align the crystal structure to achieve the desired properties. Quality control throughout production ensures consistent performance characteristics that meet the demanding requirements of critical applications. The material properties of nitinol sheet demonstrate remarkable capabilities, with ultimate tensile strength exceeding 500 MPa and elongation reaching 10% or more. These characteristics surpass many conventional materials while offering the added benefit of complete recovery from deformation. Temperature-dependent behavior allows engineers to tailor the material response by selecting appropriate transformation temperatures, with Af ranges spanning from -10°C to 100°C depending on the specific application requirements.

-

Understanding Shape Memory vs Superelastic Behavior

The distinction between shape memory and superelastic nitinol sheet behavior depends primarily on the relationship between operating temperature and transformation temperatures. When the Af temperature ranges between -10°C and 20°C, nitinol sheet exhibits superelastic properties at room temperature, allowing easy deformation with small applied forces and immediate recovery upon stress removal. This behavior makes superelastic nitinol sheet ideal for applications requiring constant flexibility and resilience. Conversely, when Af temperatures exceed 45°C, nitinol sheet demonstrates shape memory characteristics, remaining soft and easily deformable at room temperature until heated above the transformation temperature. This feature enables the creation of actuators, sensors, and deployable structures that activate in response to temperature changes. The programmable nature of shape memory nitinol sheet allows engineers to design complex deployment sequences and multi-stage activation systems. Processing considerations for both types include careful attention to heat treatment protocols, surface finishing requirements, and stress relief procedures. The working characteristics of nitinol sheet can be modified through controlled thermomechanical processing, allowing customization of properties for specific applications. Understanding these fundamental behaviors enables optimal material selection and design implementation.

Applications and Industries Using Nitinol Sheet Technology

Medical device manufacturing represents the largest application sector for nitinol sheet technology, leveraging its biocompatibility and unique mechanical properties. Cardiovascular stents, orthodontic appliances, and surgical instruments benefit from the material's ability to maintain constant forces while accommodating patient movement and biological changes. The biocompatibility of nitinol sheet eliminates many concerns associated with implantable devices, while its fatigue resistance ensures long-term reliability in demanding medical applications. Aerospace applications utilize nitinol sheet for deployable structures, vibration damping systems, and shape-changing components that must function reliably in extreme environments. The material's ability to undergo large deformations without permanent damage makes it invaluable for space applications where repair is impossible. Deployable antennas, solar panel mechanisms, and adaptive wing structures incorporate nitinol sheet technology to achieve complex functionality with minimal moving parts. Industrial automation and robotics increasingly rely on nitinol sheet for actuators, grippers, and flexible joints that require precise control and repeatability. The material's unique properties enable the creation of soft robotics systems that can interact safely with humans while maintaining the strength needed for productive work. Temperature-activated systems use shape memory nitinol sheet to create self-regulating mechanisms that respond automatically to environmental changes.

-

Emerging Market Applications

Consumer electronics applications are expanding rapidly, incorporating nitinol sheet into flexible displays, haptic feedback systems, and adaptive interfaces. The material's ability to change shape in response to electrical heating opens new possibilities for user interaction and device functionality. Smart textiles and wearable technology benefit from the comfortable flexibility and responsive nature of nitinol sheet components. Automotive applications leverage nitinol sheet for active aerodynamics, comfort systems, and safety mechanisms that adapt to changing conditions. The material's reliability and temperature stability make it suitable for automotive environments while providing unique functionality not achievable with conventional materials. Engine management systems, climate control components, and safety devices increasingly incorporate nitinol sheet technology. Research and development applications continue to push the boundaries of nitinol sheet capabilities, exploring new processing techniques, surface treatments, and hybrid material systems. Academic institutions and industrial research facilities utilize nitinol sheet for fundamental studies of phase transformations, mechanical behavior, and novel applications. This ongoing research drives continuous improvement in material properties and processing techniques.

Technical Specifications and Manufacturing Standards

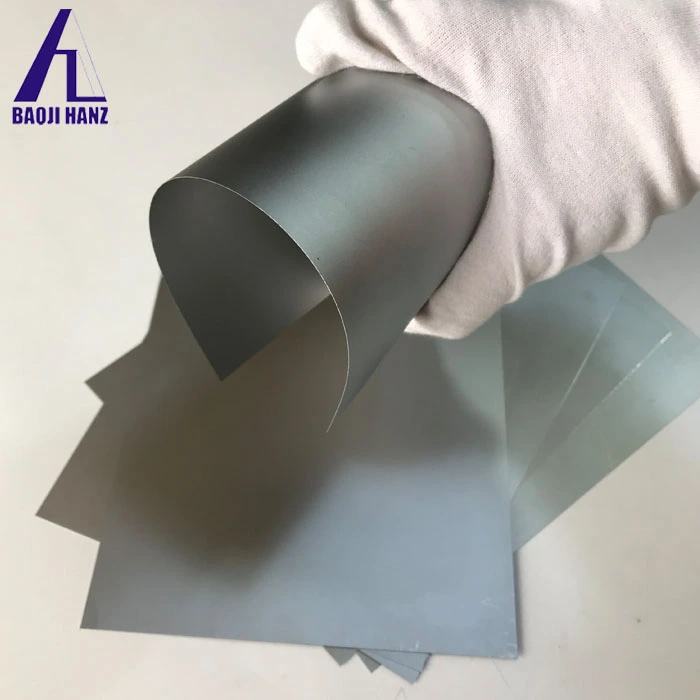

Professional-grade nitinol sheet must meet stringent specifications to ensure consistent performance across diverse applications. Standard dimensions range from minimum thickness of 0.1mm to maximum widths and lengths of 300mm × 800mm, though custom dimensions are readily available to meet specific project requirements. The precision manufacturing process maintains tight tolerances while preserving the critical microstructural features that enable shape memory and superelastic behavior. Certification standards including ISO 9001:2008, SGS, and TUV guidelines ensure that nitinol sheet products meet international quality requirements. These certifications provide confidence in material consistency, traceability, and performance reliability essential for critical applications. Manufacturing documentation includes material test certificates, transformation temperature verification, and mechanical property confirmation for each production batch. Surface finish options include mill finish, electropolished, and chemically etched surfaces depending on application requirements. Electropolishing removes surface impurities and work hardening while improving corrosion resistance and biocompatibility for medical applications. Chemical etching can create specific surface textures or patterns that enhance bonding with other materials or provide desired aesthetic characteristics.

-

Quality Control and Testing Procedures

Comprehensive testing protocols verify the mechanical properties, transformation temperatures, and fatigue resistance of each nitinol sheet batch. Differential scanning calorimetry (DSC) confirms transformation temperatures within specified ranges, while tensile testing validates strength and elongation characteristics. Fatigue testing ensures long-term reliability under cyclic loading conditions typical of real-world applications. Microstructural analysis using electron microscopy and X-ray diffraction confirms proper phase formation and grain structure development. These analytical techniques identify potential processing issues that could affect performance and ensure consistent material properties throughout each production run. Statistical process control methods track property variations and maintain production within acceptable limits. Traceability systems maintain complete records of raw materials, processing parameters, and test results for each nitinol sheet batch. This documentation enables rapid identification of any quality issues and supports continuous improvement efforts. Customer-specific testing and certification can be provided to meet unique application requirements or industry standards.

Cost Factors and Economic Considerations

The pricing structure for nitinol sheet reflects the sophisticated manufacturing processes and quality control measures required to produce consistent, high-performance material. Current market prices range from $150 to $300 per piece depending on dimensions, specifications, and order quantities. While initial costs may exceed conventional materials, the unique properties and performance benefits often justify the investment through improved functionality and reliability. Economic advantages become apparent when considering the total lifecycle costs of nitinol sheet applications. The material's fatigue resistance and corrosion immunity reduce maintenance requirements and extend service life compared to alternatives. Design simplification opportunities eliminate complex mechanisms and reduce assembly costs while improving overall system reliability. Volume pricing structures provide significant cost reductions for larger orders, making nitinol sheet more accessible for production applications. Minimum order quantities of single pieces for stocked items support prototype development and small-scale projects, while larger quantities benefit from economies of scale in manufacturing and processing.

-

Return on Investment Analysis

Medical device applications demonstrate clear economic benefits through improved patient outcomes, reduced complications, and enhanced device performance. The biocompatibility and unique mechanical properties of nitinol sheet enable new treatment options that were previously impossible with conventional materials. Reduced revision rates and improved long-term success justify the material costs through better clinical results. Industrial applications achieve cost savings through reduced maintenance, simplified designs, and improved performance characteristics. The self-actuating properties of shape memory nitinol sheet eliminate the need for external power sources in many applications, reducing operating costs and improving system reliability. Energy efficiency benefits result from the material's ability to perform work during phase transformations. Research and development investments in nitinol sheet technology continue to drive down costs while improving performance capabilities. Advances in manufacturing techniques, alloy development, and processing methods promise continued cost reductions and expanded application opportunities. Early adoption of nitinol sheet technology often provides competitive advantages that offset initial cost premiums.

Selection Criteria and Design Guidelines

Proper selection of nitinol sheet requires careful consideration of operating conditions, performance requirements, and design constraints. Temperature ranges, stress levels, and environmental exposure must be evaluated against material capabilities to ensure successful implementation. Transformation temperatures should be selected to match operating conditions while providing adequate margins for variability and aging effects. Design guidelines emphasize the importance of understanding material behavior throughout the intended operating range. Shape programming procedures must be carefully planned and executed to achieve desired performance characteristics. Heat treatment protocols, fixturing requirements, and quality verification procedures should be established early in the design process to ensure consistent results. Integration considerations include attachment methods, stress concentration factors, and thermal management requirements. Mechanical fastening, welding, and adhesive bonding techniques each have specific requirements and limitations when applied to nitinol sheet. Surface preparation, joint design, and assembly procedures must accommodate the unique properties of the material.

-

Performance Optimization Strategies

Thermal management plays a crucial role in optimizing nitinol sheet performance, particularly for shape memory applications requiring precise temperature control. Heating and cooling rates affect transformation kinetics and can influence the magnitude and speed of shape changes. Design of heating elements, thermal insulation, and heat dissipation systems requires careful analysis to achieve desired performance. Mechanical loading conditions must be considered throughout the design process to prevent overloading and ensure proper function. Stress concentrations at attachment points, bending radii limitations, and fatigue considerations influence design details and operating procedures. Proper understanding of these factors enables optimal performance while maintaining long-term reliability. Environmental factors including corrosion resistance, temperature stability, and biocompatibility requirements may necessitate specific surface treatments or protective coatings. Selection of appropriate surface finishes and environmental protection systems ensures reliable operation throughout the intended service life. Regular monitoring and maintenance procedures should account for any environmental degradation mechanisms.

Conclusion

The truth about nitinol sheet reveals a material technology that transcends conventional limitations through its unique combination of shape memory and superelastic properties, offering unprecedented design possibilities for advanced applications across medical, aerospace, and industrial sectors while providing reliable performance characteristics that justify investment considerations.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Partner with China's leading nitinol sheet manufacturer for superior quality products and comprehensive technical support. Baoji Hanz Metal Material Co., Ltd. brings 12 years of specialized expertise in nitinol shape memory alloy, superelastic nitinol alloy, and nickel titanium alloy development, backed by sophisticated production equipment and ISO 9001:2008 certification. As a trusted China nitinol sheet factory, we offer direct supply advantages with competitive pricing from $150-300 per piece, ensuring cost-effective solutions for your projects.

Our comprehensive service includes pre-sale technical consultation, real-time order tracking with 5-25 workday delivery, and extensive after-sales support with five-year documentation retention. Whether you need standard dimensions or customized specifications, our China nitinol sheet supplier capabilities include OEM services tailored to your exact requirements. From prototype development with single-piece minimum orders to large-scale production with 600kg monthly supply capacity, we provide high quality nitinol sheet solutions at competitive nitinol sheet prices.

Ready to explore premium nitinol sheet for sale from a reliable China nitinol sheet wholesale partner? Contact our technical team at baojihanz-niti@hanztech.cn for personalized consultation, detailed specifications, and competitive pricing. Save this resource for future reference and connect with China's premier nitinol sheet manufacturer today.

FAQ

Q: What is the main difference between shape memory and superelastic nitinol sheet?

A: Shape memory nitinol sheet returns to its original shape when heated above the Af temperature, while superelastic nitinol sheet recovers immediately upon stress removal at room temperature.

Q: What are the standard dimensions available for nitinol sheet?

A: Standard nitinol sheet ranges from 0.1mm minimum thickness to 300mm × 800mm maximum dimensions, with custom sizes available based on specific requirements.

Q: How long does nitinol sheet maintain its shape memory properties?

A: High-quality nitinol sheet maintains its properties for decades under normal operating conditions, with fatigue resistance exceeding millions of cycles in properly designed applications.

Q: What industries benefit most from nitinol sheet technology?

A: Medical devices, aerospace, automotive, robotics, and consumer electronics industries achieve significant benefits from nitinol sheet's unique properties and reliability.

References

1. "Shape Memory Alloys: Fundamentals and Applications" by K. Otsuka and C.M. Wayman, Cambridge University Press

2. "Nitinol Shape Memory Alloys: Properties, Processing and Applications" by D.C. Lagoudas, Materials Science and Engineering Research

3. "ASTM F2063 Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants" by ASTM International Committee

4. "Biomedical Applications of Shape Memory Alloys" by T. Duerig, A. Pelton, and D. Stöckel, Journal of Materials Engineering and Performance