Thin-Wall Nitinol Tube: Maximizing Flexibility Without Sacrificing Strength

2025-09-19 20:32:07

The evolution of modern engineering has brought forth remarkable materials that challenge traditional limitations, and among these innovations, thin-wall nitinol tubes stand as a testament to advanced materials science. These extraordinary components represent a perfect balance between mechanical flexibility and structural integrity, making them indispensable in applications ranging from medical devices to aerospace systems. The unique properties of nitinol tube technology enable engineers to design solutions that were previously impossible with conventional materials. This nickel-titanium alloy exhibits superelasticity and shape memory characteristics that allow thin-wall configurations to maintain exceptional performance while offering unprecedented design flexibility. Understanding the intricate balance between wall thickness, flexibility, and strength is crucial for optimizing applications across diverse industries.

Engineering Principles Behind Thin-Wall Nitinol Tube Design

Superelastic Properties and Wall Thickness Optimization

The fundamental principle governing thin-wall nitinol tube performance lies in the material's superelastic behavior, which allows the tube to undergo substantial deformation while maintaining its original shape upon stress removal. This unique characteristic enables manufacturers to produce nitinol tubes with wall thicknesses as minimal as 0.05mm without compromising structural integrity. The superelastic plateau in nitinol occurs due to the stress-induced martensitic transformation, where the austenite phase transforms to martensite under applied stress and reverts upon stress removal. This transformation mechanism provides the material with its exceptional flexibility, allowing thin-wall designs to bend, compress, and stretch far beyond the capabilities of traditional materials. The relationship between wall thickness and superelastic response is carefully calibrated during manufacturing to ensure optimal performance characteristics. Engineers must consider the austenite finish temperature range of -20 to 80 degrees Celsius when designing thin-wall nitinol tube applications, as this temperature range directly influences the material's superelastic behavior and overall performance in various operating conditions.

Mechanical Stress Distribution in Thin-Wall Configurations

The mechanical stress distribution in thin-wall nitinol tube designs presents unique challenges that require sophisticated engineering analysis to overcome. When a nitinol tube experiences external forces, the stress distribution across the thin wall must be carefully managed to prevent localized failure while maintaining overall structural performance. The thin-wall design creates a more uniform stress distribution compared to thick-wall alternatives, reducing stress concentrations that could lead to premature failure. This uniform distribution is particularly beneficial in applications requiring repeated flexing or cyclic loading, where the superelastic properties of the nitinol tube provide exceptional fatigue resistance. The stress-strain relationship in thin-wall nitinol tubes exhibits the characteristic superelastic plateau, where large strains can be accommodated at relatively constant stress levels. This behavior is crucial for applications requiring controlled force delivery, such as medical stents or actuators. Advanced finite element analysis techniques are employed to optimize the wall thickness distribution, ensuring that the nitinol tube maintains its superelastic properties throughout its operational range while minimizing material usage and maximizing flexibility.

Shape Memory Effect Integration in Thin-Wall Applications

The integration of shape memory effects in thin-wall nitinol tube applications opens new possibilities for smart material systems that respond to environmental changes. The shape memory effect allows the nitinol tube to return to a predetermined shape when heated above its transformation temperature, providing active control capabilities in thin-wall configurations. This property is particularly valuable in applications where space constraints require compact designs that can expand or contract based on temperature changes. The thin-wall configuration enhances the responsiveness of the shape memory effect by reducing the thermal mass, allowing for faster temperature equilibration and more rapid shape changes. Manufacturers must carefully control the thermomechanical processing parameters to ensure that the shape memory properties are preserved in thin-wall nitinol tube designs. The austenite finish temperature is precisely controlled during manufacturing to match the intended application requirements, whether for body-temperature activation in medical devices or higher-temperature activation in industrial applications. The combination of shape memory effects with thin-wall design creates opportunities for self-deploying structures, temperature-responsive actuators, and adaptive systems that can change their configuration in response to environmental conditions.

Manufacturing Excellence and Quality Control Standards

Advanced Manufacturing Techniques for Thin-Wall Production

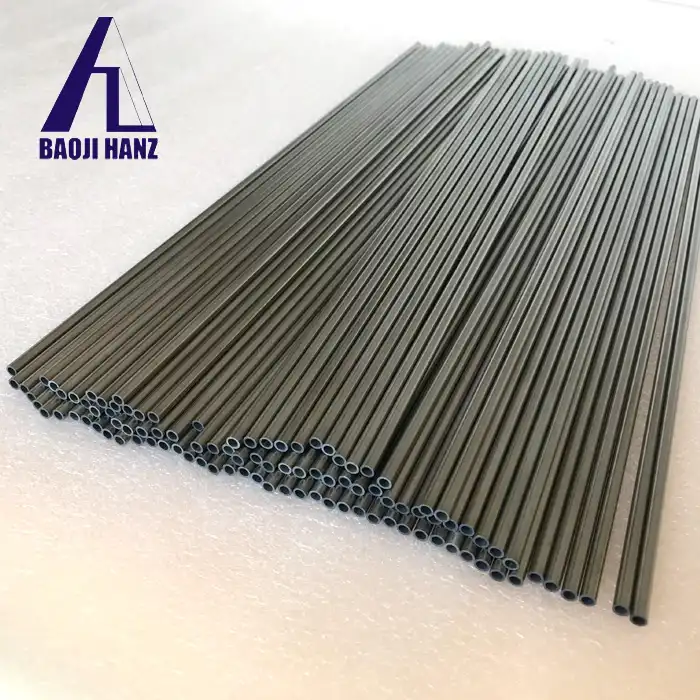

The production of thin-wall nitinol tubes requires sophisticated manufacturing techniques that push the boundaries of conventional tube fabrication methods. Advanced drawing processes are employed to achieve the precise dimensional control necessary for thin-wall applications, with outer diameters ranging from a minimum of 0.2mm to maximum of 30mm and wall thicknesses as thin as 0.05mm. The manufacturing process begins with high-purity nickel-titanium alloy preparation, where the atomic composition is carefully controlled to achieve the desired transformation temperatures and mechanical properties. Seamless tube production techniques are preferred for thin-wall nitinol tube manufacturing, as they eliminate potential weak points that could compromise the structural integrity of the thin walls. The cold drawing process used to achieve thin-wall dimensions requires specialized tooling and precise control of drawing parameters to prevent work hardening that could adversely affect the superelastic properties. Heat treatment processes are critical in thin-wall nitinol tube manufacturing, as they determine the final microstructure and transformation characteristics. The annealing temperatures and cooling rates must be carefully controlled to achieve the desired austenite finish temperature while maintaining the thin-wall geometry. Quality control during manufacturing involves continuous monitoring of dimensional tolerances, surface finish quality, and mechanical properties to ensure that each nitinol tube meets the stringent requirements for thin-wall applications.

Surface Treatment and Finishing Processes

Surface treatment and finishing processes play a crucial role in optimizing the performance of thin-wall nitinol tubes, particularly in applications where biocompatibility and corrosion resistance are paramount. The surface finish requirements for thin-wall nitinol tube applications are exceptionally demanding, with inside surface roughness specifications of Ra ≤ 1.2μm and outside surface roughness of Ra ≤ 0.6μm. These stringent surface finish requirements are achieved through advanced polishing techniques that remove surface defects without compromising the thin-wall integrity. Electropolishing is commonly employed for thin-wall nitinol tubes destined for medical applications, as it provides superior surface finish while enhancing biocompatibility and corrosion resistance. The polishing process must be carefully controlled to avoid excessive material removal that could compromise the thin-wall dimensions. Alternative surface treatments include burned blue finishes, which provide enhanced corrosion resistance and improved aesthetic appearance for industrial applications. The surface treatment selection depends on the specific application requirements, with medical-grade nitinol tubes typically requiring the highest level of surface finish quality. Chemical passivation treatments are often applied to thin-wall nitinol tubes to enhance their corrosion resistance and remove any surface contaminants that could affect biocompatibility. The surface treatment process must be validated through comprehensive testing to ensure that the thin-wall nitinol tube maintains its mechanical properties and transformation characteristics after surface modification.

Quality Assurance and Testing Protocols

Comprehensive quality assurance and testing protocols are essential for ensuring the reliability and performance of thin-wall nitinol tubes in critical applications. The testing regimen for thin-wall nitinol tubes includes dimensional verification, mechanical property testing, and transformation temperature characterization. Dimensional measurements are performed using advanced metrology equipment capable of measuring the small dimensions typical of thin-wall designs with high precision. The mechanical testing protocols for thin-wall nitinol tubes must account for the unique superelastic behavior of the material, requiring specialized testing equipment and procedures. Tensile testing is performed to verify the superelastic plateau stress and strain recovery characteristics, while fatigue testing evaluates the long-term durability under cyclic loading conditions. Transformation temperature testing using differential scanning calorimetry ensures that the austenite finish temperature meets the specified range for the intended application. Non-destructive testing methods, including ultrasonic inspection and eddy current testing, are employed to detect any internal defects or inconsistencies that could compromise the performance of thin-wall nitinol tubes. The quality assurance process also includes biocompatibility testing for medical applications, ensuring that the nitinol tube materials meet the requirements of relevant medical device standards. Statistical process control methods are implemented throughout the manufacturing process to maintain consistent quality and identify any trends that could affect product performance. Each batch of thin-wall nitinol tubes undergoes comprehensive testing and documentation to ensure traceability and compliance with customer specifications and industry standards.

Applications and Performance Optimization Strategies

Medical Device Applications and Biocompatibility

The medical device industry represents one of the most demanding applications for thin-wall nitinol tubes, where the combination of biocompatibility, flexibility, and strength creates unique opportunities for minimally invasive procedures. Thin-wall nitinol tubes are extensively used in catheter systems, where their superelastic properties enable navigation through tortuous anatomical pathways while maintaining structural integrity. The biocompatibility of nitinol tubes is well-established, with the material demonstrating excellent tissue compatibility and resistance to corrosion in biological environments. Cardiovascular stents represent another critical application where thin-wall nitinol tubes provide the optimal balance of radial strength and flexibility required for vessel support. The superelastic properties of thin-wall nitinol tubes enable stents to expand to their predetermined diameter while accommodating the natural movement of blood vessels. In colorectal surgery applications, nitinol tubes are used in anastomotic devices that reconnect intestinal segments after pathogen removal, where the thin-wall design provides the necessary flexibility for tissue accommodation. The shape memory properties of nitinol tubes enable the development of self-expanding medical devices that deploy automatically when exposed to body temperature. Orthopedic applications utilize thin-wall nitinol tubes in bone fixation devices and spinal implants, where the material's biocompatibility and mechanical properties provide long-term stability and patient comfort. The manufacturing of medical-grade thin-wall nitinol tubes requires adherence to strict quality standards and regulatory requirements, ensuring patient safety and device efficacy.

Industrial and Aerospace Applications

Industrial and aerospace applications of thin-wall nitinol tubes leverage the material's unique combination of properties to solve complex engineering challenges in demanding environments. In aerospace applications, thin-wall nitinol tubes are used in actuator systems where weight reduction is critical, and the superelastic properties provide reliable performance under extreme temperature variations. The automotive industry utilizes thin-wall nitinol tubes in various components, including sensor systems and actuators, where the material's durability and temperature stability provide long-term reliability. Oil well logging applications represent a challenging environment where thin-wall nitinol tubes must withstand high pressures and corrosive conditions while maintaining their functional properties. The marine industry benefits from the exceptional corrosion resistance of nitinol tubes in saltwater environments, where traditional materials would quickly degrade. Chemical processing plants utilize thin-wall nitinol tubes in specialized applications where chemical compatibility and temperature resistance are required. The sports equipment industry has adopted thin-wall nitinol tubes for applications requiring high flexibility and fatigue resistance, such as golf club shafts and tennis racquet frames. Power generation applications employ nitinol tubes in control systems and safety devices, where the shape memory properties provide fail-safe operation under extreme conditions. The versatility of thin-wall nitinol tubes in industrial applications continues to expand as engineers discover new ways to exploit the material's unique properties for innovative solutions.

Performance Optimization and Custom Solutions

Performance optimization of thin-wall nitinol tubes requires a comprehensive understanding of the relationship between material properties, geometric design, and application requirements. Custom solutions are often necessary to achieve optimal performance in specific applications, requiring close collaboration between manufacturers and end-users. The optimization process begins with a detailed analysis of the application requirements, including operating temperature range, mechanical loading conditions, and environmental factors. Advanced modeling techniques, including finite element analysis and computational fluid dynamics, are employed to optimize the thin-wall design for specific performance criteria. The selection of appropriate austenite finish temperature is crucial for applications requiring specific activation temperatures, whether for medical devices activated by body temperature or industrial applications requiring higher activation temperatures. Wall thickness optimization involves balancing flexibility requirements with structural strength needs, often requiring iterative design and testing cycles to achieve the optimal configuration. Surface treatment selection plays a critical role in performance optimization, with different treatments providing specific benefits for various applications. Custom alloy compositions may be developed for specialized applications requiring unique transformation temperatures or mechanical properties. The manufacturing process parameters, including heat treatment schedules and forming techniques, are optimized to achieve the desired microstructure and properties. Testing and validation protocols are customized for each application to ensure that the thin-wall nitinol tubes meet the specific performance requirements. Long-term performance monitoring and feedback from field applications provide valuable data for continuous improvement of thin-wall nitinol tube designs and manufacturing processes.

Conclusion

Thin-wall nitinol tubes represent a remarkable achievement in materials engineering, successfully maximizing flexibility while maintaining exceptional strength through the unique properties of nickel-titanium alloy. The combination of superelastic behavior, shape memory effects, and biocompatibility creates unprecedented opportunities for innovative applications across medical, industrial, and aerospace sectors. Advanced manufacturing techniques and stringent quality control standards ensure that these remarkable materials meet the demanding requirements of modern engineering applications. The continued development of thin-wall nitinol tube technology promises to unlock new possibilities for smart materials and adaptive systems.

As a leading China nitinol tube factory and China nitinol tube supplier, Baoji Hanz Metal Material Co., Ltd. brings seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy manufacturing. Our position as a premier China nitinol tube manufacturer allows us to offer direct supply advantages and cost savings to our clients worldwide. With fast delivery from extensive stock of standard sizes and comprehensive OEM services, we serve as your trusted China nitinol tube wholesale partner. Our experienced team works closely with clients to provide custom solutions tailored to specific requirements, whether for medical devices, industrial applications, or aerospace systems. Contact us today at baojihanz-niti@hanztech.cn to discover how our advanced thin-wall nitinol tube solutions can enhance your next project.

References

1. Pelton, A.R., Stöckel, D., and Duerig, T.W. "Medical Uses of Nitinol." Materials Science Forum, Vol. 327-328, pp. 63-70, 2000.

2. Mohd Jani, J., Leary, M., Subic, A., and Gibson, M.A. "A Review of Shape Memory Alloy Research, Applications and Opportunities." Materials & Design, Vol. 56, pp. 1078-1113, 2014.

3. Lagoudas, D.C., and Entchev, P.B. "Modeling of Transformation-Induced Plasticity and its Effect on the Behavior of Porous Shape Memory Alloys." International Journal of Plasticity, Vol. 20, pp. 877-909, 2004.

4. Ryhänen, J., Niemi, E., Serlo, W., Niemelä, E., Sandvik, P., Pernu, H., and Salo, T. "Biocompatibility of Nickel-Titanium Shape Memory Metal and its Corrosion Behavior in Human Cell Cultures." Journal of Biomedical Materials Research, Vol. 35, pp. 451-457, 1997.