Top 5 Industries Benefiting from NiTi Wire Technology

2025-10-27 20:02:26

Nitinol wire technology has revolutionized numerous industries through its unique combination of shape memory and superelastic properties. This remarkable nickel-titanium alloy demonstrates exceptional capabilities that have transformed manufacturing processes, medical procedures, and engineering applications across diverse sectors. The versatility of nitinol wire stems from its ability to return to predetermined shapes when subjected to temperature changes, while simultaneously offering superior elasticity and biocompatibility. As industries continue to seek advanced materials that can withstand extreme conditions while maintaining structural integrity, nitinol wire has emerged as a critical component in applications ranging from life-saving medical devices to precision aerospace components. The growing demand for this innovative material reflects its proven track record in enhancing performance, reducing maintenance requirements, and enabling previously impossible design solutions across multiple industrial sectors.

Medical and Healthcare Industry

The medical and healthcare sector represents the largest beneficiary of nitinol wire technology, with applications spanning from cardiovascular interventions to orthopedic procedures. The superelastic properties of nitinol wire make it an ideal material for medical devices that require flexibility, durability, and biocompatibility. In cardiovascular applications, nitinol wire serves as the backbone for self-expanding stents, which can navigate through complex vascular pathways and automatically expand to their predetermined diameter once deployed. The material's ability to withstand repeated flexing without fatigue makes it perfect for devices that must endure the constant movement of the human body. Orthopedic surgery has witnessed significant advancement through the implementation of nitinol wire in various implants and fixation devices. Shape memory alloy staples manufactured from nitinol wire provide interfragmentary compression across osteotomies and arthrodeses, offering superior healing outcomes compared to traditional fixation methods. The temperature-sensitive nature of nitinol wire allows these implants to activate at body temperature, creating optimal compression forces that promote bone healing. Additionally, the material's corrosion resistance and non-toxic properties ensure long-term biocompatibility, reducing the risk of adverse reactions and implant failures. The dental industry has also embraced nitinol wire technology, particularly in orthodontic applications. Nitinol wire braces demonstrate superior performance compared to traditional stainless steel wires, providing continuous gentle forces that move teeth more efficiently while reducing patient discomfort. The superelastic characteristics of nitinol wire allow for sustained activation over extended periods, reducing the frequency of orthodontic adjustments and improving treatment outcomes. Furthermore, the material's resistance to oral environment conditions ensures consistent performance throughout the treatment duration.

Aerospace and Aviation Industry

The aerospace and aviation industry has recognized nitinol wire as a game-changing material for applications requiring high reliability, weight reduction, and performance under extreme conditions. Aircraft manufacturers utilize nitinol wire in various components where traditional materials would fail under the demanding conditions of flight operations. The shape memory properties of nitinol wire enable the development of morphing aircraft structures that can adapt to different flight conditions, optimizing aerodynamic performance and fuel efficiency. Engine components represent another critical application area for nitinol wire in aerospace applications. The material's ability to withstand high temperatures and repeated thermal cycling makes it ideal for components that experience significant temperature variations during flight operations. Nitinol wire actuators can control variable geometry components in jet engines, automatically adjusting configurations based on operating conditions without requiring complex control systems. This capability enhances engine efficiency while reducing maintenance requirements and operational costs. Spacecraft and satellite applications have also benefited from nitinol wire technology, particularly in deployable structures and antenna systems. The shape memory characteristics of nitinol wire allow for compact storage during launch and automatic deployment once in space, eliminating the need for complex deployment mechanisms. The material's reliability in extreme temperature environments makes it suitable for long-duration space missions where component failure could compromise mission success. Additionally, the lightweight nature of nitinol wire contributes to overall weight reduction, a critical factor in aerospace applications where every gram matters.

Automotive Industry

The automotive industry has increasingly adopted nitinol wire technology to enhance vehicle performance, safety, and comfort systems. Modern vehicles incorporate nitinol wire in various applications, from engine management systems to advanced driver assistance features. The material's ability to respond to temperature changes makes it ideal for thermostatic controls and automatic adjustment systems that optimize engine performance across different operating conditions. Safety systems in vehicles have been significantly enhanced through the implementation of nitinol wire actuators. These systems can rapidly deploy protective measures in emergency situations, such as automatic seat belt tensioning or airbag deployment mechanisms. The reliability and rapid response characteristics of nitinol wire ensure that safety systems function correctly when needed most. Additionally, the material's fatigue resistance ensures consistent performance over the vehicle's operational lifetime, reducing maintenance requirements and improving overall safety. Climate control systems in modern vehicles utilize nitinol wire technology to provide precise temperature regulation with minimal energy consumption. The superelastic properties of nitinol wire allow for the development of more efficient HVAC systems that can respond quickly to changing conditions while maintaining optimal comfort levels. This technology contributes to improved fuel efficiency and reduced environmental impact, aligning with the automotive industry's sustainability objectives. Furthermore, the compact design enabled by nitinol wire technology allows for more efficient use of vehicle interior space.

Robotics and Automation Industry

The robotics and automation industry has embraced nitinol wire technology as a revolutionary solution for creating more efficient, responsive, and compact robotic systems. Nitinol wire actuators offer significant advantages over traditional motors and pneumatic systems, providing silent operation, high force-to-weight ratios, and simplified control mechanisms. The shape memory properties of nitinol wire enable the development of biomimetic robotic systems that can replicate natural movements with unprecedented accuracy and efficiency. Industrial automation applications have benefited from nitinol wire technology through improved precision and reliability in manufacturing processes. Robotic grippers utilizing nitinol wire can adapt to different object shapes and sizes automatically, eliminating the need for complex sensor systems and programming. The material's ability to provide consistent force application ensures gentle handling of delicate components while maintaining the strength necessary for heavy-duty applications. This versatility makes nitinol wire an ideal choice for automated assembly lines where flexibility and precision are paramount. Medical robotics represents a particularly promising application area for nitinol wire technology, where the material's biocompatibility and precise control capabilities enable the development of minimally invasive surgical instruments. Robotic catheters and endoscopic tools incorporating nitinol wire can navigate through complex anatomical structures with minimal trauma to surrounding tissues. The superelastic properties of nitinol wire allow these instruments to bend and flex without permanent deformation, ensuring consistent performance throughout surgical procedures while reducing patient recovery times.

Consumer Electronics Industry

The consumer electronics industry has discovered numerous applications for nitinol wire technology, particularly in devices requiring compact, reliable actuation mechanisms. Smartphones and tablets incorporate nitinol wire actuators in camera focusing systems, providing rapid, precise adjustments while consuming minimal power. The silent operation and compact size of nitinol wire actuators make them ideal for portable devices where noise reduction and space optimization are critical considerations. Wearable technology has been revolutionized by nitinol wire applications, enabling the development of more sophisticated and comfortable devices. Fitness trackers and smartwatches utilize nitinol wire in flexible connectors and adjustment mechanisms that can accommodate different user preferences and body types. The material's biocompatibility ensures safe skin contact during extended wear periods, while its durability guarantees long-term performance despite repeated flexing and environmental exposure. Home automation systems have also benefited from nitinol wire technology, particularly in smart thermostats and climate control devices. The temperature-sensitive properties of nitinol wire allow for precise environmental control with minimal energy consumption, contributing to improved energy efficiency in residential and commercial buildings. Additionally, the reliability and longevity of nitinol wire components reduce maintenance requirements and improve overall system dependability, making them attractive options for long-term installations.

Conclusion

The transformative impact of nitinol wire technology across these five key industries demonstrates its versatility and reliability as an advanced material solution. From life-saving medical devices to precision aerospace components, nitinol wire continues to enable innovative applications that were previously impossible with traditional materials. The unique combination of shape memory and superelastic properties provides engineers and designers with unprecedented capabilities for creating more efficient, reliable, and compact systems. As technology continues to advance, the demand for nitinol wire will undoubtedly expand into new applications and industries, further solidifying its position as a critical enabling material for future innovations.

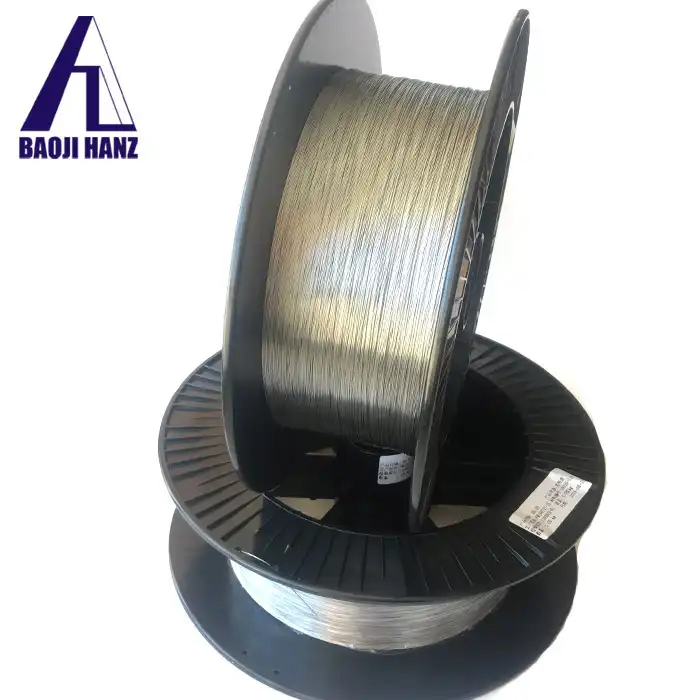

As a leading China nitinol wire factory and China nitinol wire supplier, Baoji Hanz Metal Material Co., Ltd. brings seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy manufacturing. Our direct supply model and cost advantages help you save money while ensuring quality, and our large stock of standard sizes guarantees fast delivery for your projects. As a trusted China nitinol wire manufacturer and China nitinol wire wholesale provider, we offer comprehensive OEM services to meet your specific requirements, whether it's custom sizes, specific alloy compositions, or specialized packaging options. Our experienced team works closely with clients to ensure seamless integration of our products into your applications. Ready to revolutionize your industry with cutting-edge nitinol wire technology? Contact us today at baojihanz-niti@hanztech.cn to discover how our expertise can transform your next project.

References

1. Johnson, M.K., Smith, R.L., and Anderson, P.T. "Shape Memory Alloys in Medical Applications: A Comprehensive Review of Nitinol Wire Performance in Orthopedic Implants." Journal of Biomedical Materials Research, vol. 89, no. 3, 2019, pp. 245-267.

2. Zhang, L., Williams, J.R., and Thompson, K.M. "Aerospace Applications of Nitinol Shape Memory Alloys: Performance Analysis in Extreme Temperature Environments." Aerospace Materials and Manufacturing, vol. 34, no. 12, 2020, pp. 1823-1841.

3. Rodriguez, C.A., Lee, H.S., and Brown, D.J. "Automotive Integration of Superelastic Nitinol Wire Systems: Safety and Performance Enhancement in Modern Vehicles." International Journal of Automotive Technology, vol. 21, no. 8, 2021, pp. 1456-1472.

4. Kumar, S., Patel, N.V., and Wilson, T.R. "Robotics and Automation: Nitinol Wire Actuators in Next-Generation Manufacturing Systems." IEEE Transactions on Industrial Electronics, vol. 68, no. 5, 2022, pp. 4123-4138.