What are the challenges in working with super elastic nitinol?

2025-02-24 16:13:00

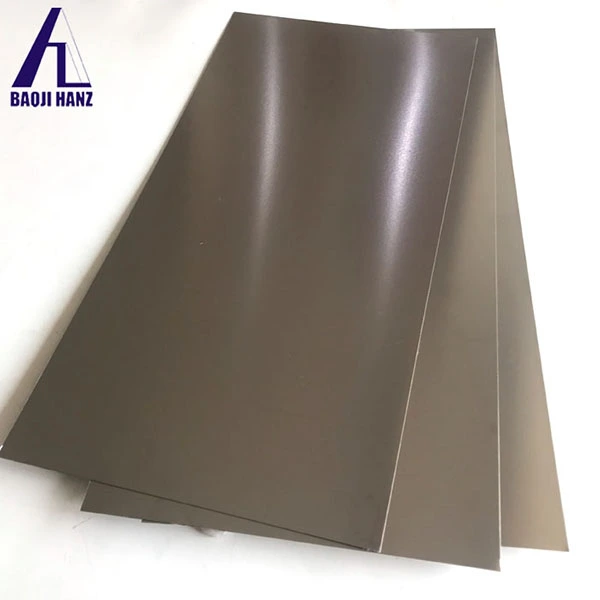

Super elastic nitinol foil,a remarkable shape memory alloy, has revolutionized various industries with its unique properties. However, working with this material presents several challenges that manufacturers and engineers must overcome. This blog explores the intricacies of super elastic nitinol, focusing on its foil form, and delves into the obstacles encountered during its production, processing, and application. From temperature sensitivity to precise composition control, we'll uncover the complexities that make working with super elastic nitinol both fascinating and demanding. Understanding these challenges is crucial for anyone involved in the development, manufacturing, or utilization of this extraordinary material.

Material Properties and Behavior

Temperature Sensitivity

One of the primary challenges in working with super elastic nitinol foil is its extreme sensitivity to temperature variations. The material's unique properties are highly dependent on its thermal history and the ambient temperature during processing and application. Even slight temperature fluctuations can significantly alter the alloy's behavior, making it difficult to maintain consistent performance across different batches or environmental conditions. Manufacturers must implement precise temperature control systems throughout the production process to ensure uniformity in the material's properties. This includes carefully monitored heat treatments, which are crucial for achieving the desired super elastic characteristics. The challenge lies in maintaining these tight temperature tolerances not only during production but also during storage and transportation, as exposure to extreme temperatures can permanently affect the material's performance.

Composition Control

The super elastic properties of nitinol foil are intricately linked to its composition, particularly the ratio of nickel to titanium. Achieving and maintaining the exact stoichiometric composition is a significant challenge. Even minute deviations in the alloy's composition can lead to drastic changes in its mechanical and thermal properties. The production of super elastic nitinol requires sophisticated metallurgical processes and advanced quality control measures. Manufacturers must employ high-precision techniques to ensure homogeneity throughout the material. This challenge is further compounded when producing large quantities of foil, as maintaining compositional consistency across entire production runs becomes increasingly difficult.

Phase Transformation Complexities

The super elastic behavior of nitinol foil is a result of its unique phase transformation properties. However, controlling and predicting these transformations presents significant challenges. The material's behavior can vary depending on factors such as stress state, temperature, and previous deformation history. Engineers and designers must account for these complexities when incorporating super elastic nitinol into their applications. The material's response to external stimuli can be non-linear and hysteretic, making it challenging to model and predict its behavior accurately. This unpredictability can lead to design complications and necessitates extensive testing and validation processes to ensure reliable performance in the final product.

Manufacturing and Processing Challenges

Forming and Shaping

The exceptional elasticity of super elastic nitinol foil, while beneficial in many applications, poses significant challenges during manufacturing and processing. Traditional forming techniques often prove inadequate when working with this material. The super elastic nature of nitinol means that it tends to spring back to its original shape after deformation, making it difficult to achieve precise and permanent shaping. Manufacturers must develop specialized techniques and tooling to overcome this challenge. These may include custom-designed dies, innovative heat treatment processes, and advanced forming equipment. The complexity of these processes often results in higher production costs and longer lead times compared to working with conventional materials.

Surface Finish and Cleanliness

Achieving a consistent and high-quality surface finish on super elastic nitinol is another significant challenge. The material is prone to oxidation, which can affect its surface properties and potentially impact its performance in certain applications. Maintaining cleanliness throughout the production process is crucial but can be difficult due to the material's reactivity. Specialized surface treatment techniques, such as electropolishing or passivation, are often required to enhance the foil's corrosion resistance and biocompatibility. These processes must be carefully controlled to avoid altering the material's super elastic properties while improving its surface characteristics. The need for such additional processing steps adds complexity and cost to the manufacturing process.

Thickness Control

Producing super elastic nitinolwith precise and uniform thickness is a formidable challenge. The material's unique properties make traditional rolling and drawing processes less effective. Achieving tight thickness tolerances, especially for ultra-thin foils, requires highly specialized equipment and expertise. Manufacturers must invest in advanced rolling mills and measurement systems to ensure consistent thickness across the entire length and width of the foil. Even slight variations in thickness can lead to significant differences in the material's mechanical properties, potentially affecting its performance in critical applications. This challenge is particularly acute when producing large quantities of foil, where maintaining consistency becomes increasingly difficult.

Application-Specific Challenges

Fatigue and Durability

While super elastic nitinol foil exhibits remarkable resilience, ensuring long-term durability in specific applications remains a significant challenge. The material's behavior under repeated cyclic loading can be complex and difficult to predict. Fatigue life can vary considerably depending on factors such as stress amplitude, mean stress, and environmental conditions. Engineers must conduct extensive fatigue testing to characterize the material's performance under various loading conditions. This is particularly crucial in applications where the nitinol foil is subjected to frequent deformation cycles, such as in medical devices or actuators. Developing reliable fatigue models for super elastic nitinol is an ongoing challenge in the field, requiring continuous research and development efforts.

Biocompatibility Concerns

In medical applications, ensuring the biocompatibility of super elastic nitinol presents unique challenges. While nitinol is generally considered biocompatible, concerns exist regarding the potential release of nickel ions in the body. This is particularly relevant for thin foils, where the surface area to volume ratio is high. Manufacturers must implement stringent quality control measures and surface treatment processes to minimize the risk of nickel leaching. Additionally, comprehensive biocompatibility testing is required to ensure the safety of nitinol foil in various medical applications. These requirements add complexity to the development and approval process for medical devices utilizing super elastic nitinol.

Integration with Other Materials

Incorporating super elastic nitinol into composite structures or bonding it with other materials presents significant engineering challenges. The material's unique properties, including its shape memory effect and superelasticity, can complicate traditional joining and integration techniques. Engineers must develop specialized bonding methods and interface designs to effectively integrate nitinol foil with other components. This may involve innovative adhesive formulations, novel mechanical fastening techniques, or advanced welding processes. The challenge lies in maintaining the integrity of the nitinol foil's properties while achieving strong and reliable bonds with other materials in the assembly.

Conclusion

Working with super elastic nitinol foil presents a myriad of challenges that span from material science to engineering applications. Overcoming these obstacles requires a deep understanding of the material's unique properties, advanced manufacturing techniques, and innovative design approaches. As research continues and technology advances, new solutions will emerge, expanding the potential applications of this remarkable material. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

Other related product catalogues

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1. Pelton, A. R., Stöckel, D., & Duerig, T. W. (2000). Medical uses of nitinol. Materials Science Forum, 327, 63-70.

2. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

3. Yoneyama, T., & Miyazaki, S. (Eds.). (2008). Shape memory alloys for biomedical applications. Elsevier.

4. Otsuka, K., & Ren, X. (2005). Physical metallurgy of Ti–Ni-based shape memory alloys. Progress in materials science, 50(5), 511-678.

5. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

6. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.