What are the main properties of Nitinol strips?

2025-02-24 16:10:38

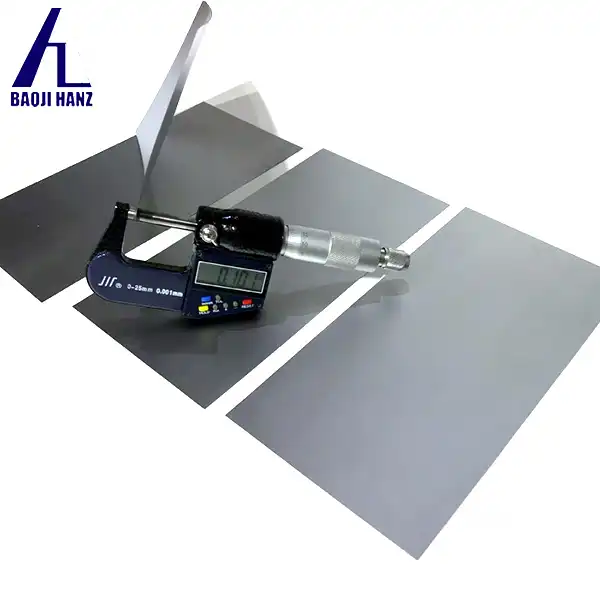

Nitinol strips, composed of nickel titanium strip, exhibit remarkable properties that set them apart in the world of metallurgy. These unique characteristics make nitinol an invaluable material in various industries, from medical devices to aerospace applications. The main properties of nitinol strips include shape memory effect, superelasticity, biocompatibility, and corrosion resistance. The shape memory effect allows nitinol to return to a predetermined shape when heated, while superelasticity enables it to undergo large deformations without permanent damage. Biocompatibility makes nitinol ideal for medical implants, and its corrosion resistance ensures longevity in challenging environments. Additionally, nitinol strips possess excellent fatigue resistance, high damping capacity, and the ability to withstand extreme temperatures. These properties, combined with nitinol's lightweight nature and unique stress-strain behavior, make it a versatile material for innovative applications across multiple industries.

Shape Memory Effect and Superelasticity of Nitinol Strips

Understanding the Shape Memory Effect

The shape memory effect is a defining characteristic of nickel titanium strips. This property allows the material to "remember" and return to a predetermined shape when subjected to specific temperature changes. At lower temperatures, nitinol exists in a martensite phase, where it can be easily deformed. Upon heating, it transforms into the austenite phase, reverting to its original shape. This phenomenon occurs due to the unique crystal structure of the nickel-titanium alloy, which undergoes a reversible, diffusionless transformation between these two phases.

Exploring Superelasticity in Nitinol

Superelasticity, also known as pseudoelasticity, is another remarkable property of nitinol strips. This characteristic allows the material to undergo large deformations without permanent damage, returning to its original shape upon removal of the applied stress. Superelasticity occurs when nitinol is in its austenite phase at body temperature. When stress is applied, the material transforms into the martensite phase, accommodating the strain. Upon stress removal, it reverts to the austenite phase, recovering its original shape. This property makes nitinol strips ideal for applications requiring flexibility and shape recovery, such as orthodontic archwires and vascular stents.

Applications Leveraging Shape Memory and Superelasticity

The combination of shape memory effect and superelasticity in nickel titanium stripopens up a wide range of applications. In the medical field, these properties are utilized in minimally invasive surgical tools, self-expanding stents, and orthopedic implants. Aerospace engineers employ nitinol strips in deployable structures and vibration damping systems. Consumer products like eyeglass frames and mobile phone antennas also benefit from these unique characteristics. The ability of nitinol strips to respond to both temperature and stress changes makes them versatile in various engineering solutions, pushing the boundaries of material science and product design.

Biocompatibility and Corrosion Resistance of Nitinol Strips

Nitinol's Biocompatibility in Medical Applications

The human body's acceptance of nickel titanium stripis attributed to the formation of a stable titanium oxide layer on its surface.This protective layer prevents the release of nickel ions, which could potentially cause allergic reactions.The material's ability to maintain its properties within the body without causing adverse reactions has revolutionized minimally invasive procedures and long-term implants.

Corrosion Resistance in Harsh Environments

Nitinol strips exhibit exceptional corrosion resistance, making them suitable for use in challenging environments. The corrosion resistance stems from the formation of a passive oxide layer, primarily composed of titanium dioxide. This layer protects the underlying metal from further oxidation and chemical attack. Nitinol's resistance to corrosion is particularly valuable in marine applications, chemical processing industries, and medical implants where exposure to bodily fluids is constant. The material's ability to withstand corrosive environments without degradation ensures long-term reliability and performance in critical applications.

Synergy of Biocompatibility and Corrosion Resistance

In medical implants, these properties work together to ensure the device remains functional and non-reactive within the body for extended periods.The corrosion resistance complements the biocompatibility by preventing the breakdown of the material, which could otherwise lead to the release of potentially harmful ions. This synergy extends the lifespan of nitinol-based devices and reduces the need for replacement surgeries, ultimately improving patient outcomes and quality of life.

Mechanical and Thermal Properties of Nitinol Strips

Fatigue Resistance and Durability

Nitinol strips possess remarkable fatigue resistance, allowing them to withstand repeated cyclic loading without failure. This property is particularly valuable in applications involving constant flexing or bending, such as in cardiovascular stents or mechanical actuators. The unique atomic structure of nitinol enables it to absorb and distribute stress more effectively than traditional metals, resulting in extended service life and improved reliability. The material's ability to undergo large deformations without permanent damage contributes to its exceptional fatigue performance, making it ideal for dynamic and high-stress environments.

Temperature Responsiveness and Phase Transformations

The temperature-dependent behavior of nickel titanium stripis a defining characteristic that sets them apart from conventional materials. The transition between martensite and austenite phases occurs at specific temperatures, which can be tailored during the manufacturing process. This property allows for the creation of temperature-activated devices and smart materials. Nitinol strips can be designed to respond to body temperature for medical applications or engineered to operate in extreme environments for aerospace and industrial uses. The precise control over phase transformations enables the development of innovative thermal actuators and temperature-sensitive components.

Stress-Strain Behavior and Elasticity

Nitinol strips exhibit a unique stress-strain behavior that differs significantly from traditional elastic materials. The superelastic property allows for large recoverable strains, typically up to 8%, compared to less than 1% for most metals. This exceptional elasticity is due to the stress-induced martensitic transformation, which accommodates large deformations without permanent plastic deformation. The stress-strain curve of nitinol is characterized by a plateau region, where significant strain can occur with minimal increase in stress. This behavior provides excellent energy absorption capabilities and enables the design of flexible, yet robust structures. The combination of high elasticity and strength makes nitinol strips ideal for applications requiring both flexibility and durability.

Conclusion

Nickel titanium strips offer a unique combination of properties that make them invaluable in various industries. Their shape memory effect, superelasticity, biocompatibility, and corrosion resistance, coupled with exceptional mechanical and thermal properties, open up endless possibilities for innovation. As research continues, we can expect to see even more groundbreaking applications of this remarkable material in the future. If you want to get more information about this product, you can contact us at baojihanz-niti@hanztech.cn.

Other related product catalogues

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1. Duerig, T. W., & Pelton, A. R. (2017). "Materials properties handbook: titanium alloys." ASM International.

2. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). "A review of shape memory alloy research, applications and opportunities." Materials & Design, 56, 1078-1113.

3. Otsuka, K., & Wayman, C. M. (Eds.). (1999). "Shape memory materials." Cambridge University Press.

4. Pelton, A. R., Stöckel, D., & Duerig, T. W. (2000). "Medical uses of nitinol." Materials Science Forum, 327, 63-70.

5. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). "Stimulus-responsive shape memory materials: a review." Materials & Design, 33, 577-640.

6. Yamauchi, K., Ohkata, I., Tsuchiya, K., & Miyazaki, S. (Eds.). (2011). "Shape memory and superelastic alloys: Technologies and applications." Woodhead Publishing.