What Determines the Transition Temperature of a 3mm Nitinol Rod?

2025-11-21 16:24:22

When engineers specify a 3mm nitinol rod for medical devices or industrial actuators, they often encounter unexpected performance failures traced back to one critical specification: transition temperature mismatch. The transition temperature of a 3mm nitinol rod is primarily determined by its nickel-to-titanium composition ratio, heat treatment parameters, and the presence of precipitate phases within the alloy microstructure. Understanding these factors is essential for selecting the right nitinol material that will reliably perform shape memory or superelastic functions in your specific application temperature range, whether it's body temperature for medical stents or sub-zero conditions for aerospace components.

Understanding Nitinol Composition and Its Impact on 3mm Nitinol Rod Performance

Nitinol is a nickel-titanium (Ni-Ti) shape memory alloy (SMA), and the performance of its 3mm nitinol rod is mainly determined by its composition. The core is the Ni-Ti ratio close to the equiatomic proportion (50:50 to 51:49 atomic%), and this alloy exhibits characteristic shape memory effect, superelasticity, and ductility, ensuring that the 3mm rod can meet the requirements of medical, aerospace, and precision engineering applications.

Heat Treatment Parameters That Control 3mm Nitinol Rod Transition Temperature

Heat treatment represents the most powerful tool for tailoring the transition temperature of a 3mm nitinol rod after the base composition has been established. The formation and distribution of nickel-titanium precipitates during heat treatment fundamentally alters the transformation temperatures and mechanical properties of the finished rod. When a nickel-rich 3mm nitinol rod is heat treated at temperatures between 400 and 500 degrees Celsius, coherent Ni4Ti3 precipitates form within the austenitic matrix, depleting the surrounding matrix of nickel and thereby increasing the transformation temperature relative to untreated material.

Research on nitinol wire heat treatment has demonstrated that processing at 400 degrees Celsius produces fine, densely distributed precipitates that significantly enhance the shape memory effect by restricting dislocation movement and increasing the critical stress required for slip. As heat treatment temperature increases toward 500 degrees Celsius, the precipitates grow larger and less dense, and at temperatures above this range, they begin to re-dissolve into the matrix, reducing the shape memory effect. For a 3mm nitinol rod, the heat treatment time must also be carefully controlled, with typical treatments ranging from 10 minutes for very thin wire to 30-120 minutes for larger diameter rods, as the thicker cross-section requires more time to achieve uniform precipitate distribution throughout the material.

The specific heat treatment parameters selected for your 3mm nitinol rod will depend on the target transformation temperature and the required mechanical properties for your application. Heat treatments that produce optimal shape memory performance often result in austenite finish temperatures shifting from approximately 43 degrees Celsius in as-received material down to 24 degrees Celsius after treatment at 500 degrees Celsius. This temperature shift occurs because the Ni4Ti3 precipitate formation removes nickel from solid solution, effectively raising the nickel-to-titanium ratio in the remaining matrix and lowering the transformation temperature. Surface oxidation during heat treatment can also affect the nickel-titanium ratio near the surface of a 3mm nitinol rod, potentially creating transformation temperature gradients from the surface to the core, which manufacturers mitigate through controlled atmosphere processing or rapid quenching after heat treatment.

Annealing and Shape Setting Processes

The annealing process used to set the memorized shape in a 3mm nitinol rod simultaneously determines the final transformation temperatures of the material. When you anneal a 3mm nitinol rod at approximately 500 degrees Celsius while constraining it in the desired final shape, you are both setting the austenitic crystal structure memory and modifying the precipitate microstructure that controls transformation behavior. The duration of this shape-setting anneal must be sufficient to allow complete recrystallization and precipitate formation throughout the 3mm cross-section, typically requiring 15-30 minutes depending on the specific alloy composition and the complexity of the desired shape.

After shape setting, the cooling rate from the annealing temperature influences the final precipitate distribution and transformation temperature of your 3mm nitinol rod. Rapid quenching in water helps minimize excessive surface oxidation that can alter the surface composition and transformation characteristics. The trade-off between annealing time, temperature, and cooling rate provides manufacturers with considerable flexibility in tailoring the properties of a 3mm nitinol rod to meet specific application requirements, whether that means a rod with a narrow transformation temperature range and sharp transition for precise thermal actuation, or a broader transformation range for gradual actuation behavior.

Thermal Cycling Effects on Stability

Repeated thermal cycling through the transformation temperatures can alter the transition temperature stability of a 3mm nitinol rod over its service life. During the first several dozen thermal cycles, a 3mm nitinol rod may exhibit gradual changes in its transformation temperatures as the microstructure stabilizes and the R-phase begins to develop. This training effect is particularly important for applications where the rod will undergo thousands or millions of actuation cycles, such as in automotive valve actuators or reciprocating mechanical systems. The appearance and growth of the R-phase during thermal cycling typically shifts the transformation temperatures to lower values and can increase the overall hysteresis of the transformation.

For critical applications of 3mm nitinol rod in medical devices or aerospace systems, manufacturers may perform stabilization cycling during production to pre-condition the material and ensure that transformation temperatures will remain stable throughout the product's intended service life. This stabilization process involves cycling the rod through its transformation temperature range multiple times under controlled conditions, allowing the microstructure to reach a more stable configuration before the rod is incorporated into the final device. Understanding how thermal cycling affects your specific 3mm nitinol rod formulation allows you to predict long-term performance and specify appropriate material treatments to minimize transformation temperature drift over the product lifetime.

Specification Standards and Quality Control for 3mm Nitinol Rod

3mm nitinol rod meet key specification standards (e.g., ASTM F2063 for medical applications, ASTM B348 for general engineering, ISO 5832-15 for implants), which stipulate composition limits, dimensional tolerances (diameter, straightness), mechanical properties (superelasticity, shape memory effect), corrosion resistance, and biocompatibility (for medical applications); tensile/fatigue testing is conducted to ensure mechanical performance; dimensional inspection and non-destructive testing are performed to detect defects (cracks, inclusions), further ensuring that the 3-millimeter rods meet the reliability and safety requirements of specific applications.

Application-Specific Transition Temperature Requirements for 3mm Nitinol Rod

Different applications of 3mm nitinol rod demand specifically tailored transformation temperatures to achieve optimal performance in their intended operating environments. Medical device applications including cardiovascular stents, orthopedic implants, and orthodontic appliances typically require 3mm nitinol rod with austenite finish temperatures between -10 and 10 degrees Celsius, ensuring the device operates in the superelastic regime at normal body temperature of 37 degrees Celsius. This superelastic behavior at body temperature provides the gentle, continuous forces needed for orthodontic tooth movement or the flexibility required for minimally invasive delivery of cardiovascular devices through tortuous anatomical pathways. The 3mm nitinol rod must exhibit stable transformation temperatures over the lifetime of the implanted device, maintaining its mechanical properties despite the constant temperature exposure and cyclic loading in the physiological environment.

Industrial and construction applications often utilize 3mm nitinol rod with different transformation temperature specifications optimized for their specific thermal environments and functional requirements. Fishing rod applications may specify transformation temperatures in the range of 14 to 20 degrees Celsius, providing superelastic behavior at typical outdoor temperatures while maintaining sufficient recovery forces if the rod is temporarily bent or deformed. Construction and architectural applications might employ 3mm nitinol rod as seismic dampers or adaptive structural elements, requiring transformation temperatures carefully matched to the anticipated temperature range at the installation site. Aerospace applications frequently demand 3mm nitinol rod materials capable of functioning across extreme temperature ranges, from sub-zero conditions at high altitude to elevated temperatures in engine compartments, necessitating either very low transformation temperatures for continuous superelastic operation or precisely controlled shape memory activation temperatures for actuation functions.

Manufacturing equipment and automation systems increasingly incorporate 3mm nitinol rod as thermal actuators or adaptive elements that respond to process temperature changes. These applications require precise specification of transformation temperatures matched to the process conditions, whether that means activation at a specific setpoint temperature for safety shutoff functions or continuous operation in the superelastic regime to provide vibration damping or compliant coupling functions. The reproducibility and stability of transformation temperatures across multiple production batches becomes critical in these applications, as replacement components must exhibit identical thermal response characteristics to ensure system performance remains consistent over time.

Conclusion

The transition temperature of a 3mm nitinol rod is a complex materials property controlled primarily by composition ratio, heat treatment parameters, and precipitate microstructure. Precise specification and control of transformation temperatures enables reliable performance across medical, industrial, construction, and aerospace applications where the unique shape memory and superelastic properties of nitinol provide solutions unavailable with conventional materials.

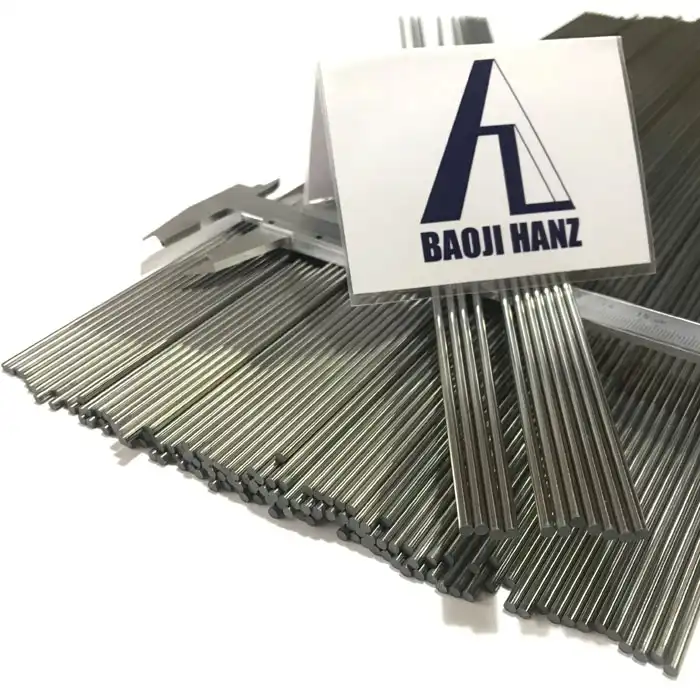

Cooperate with Baoji Hanz Metal Material Co., Ltd.

As a leading China 3mm nitinol rod manufacturer and China 3mm nitinol rod supplier with 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy production, Baoji Hanz Metal Material Co., Ltd. delivers High Quality 3mm nitinol rod with precisely controlled transformation temperatures for your specific application requirements. Our China 3mm nitinol rod factory offers competitive 3mm nitinol rod price through direct supply with China 3mm nitinol rod wholesale advantages, fast delivery from large stock of standard sizes including 3mm nitinol rod for sale with diameters from 0.1mm to 3mm, and OEM services for custom alloy compositions and specifications. With ISO9001, SGS, and TUV certifications ensuring quality excellence, comprehensive pre-sale technical consultation, order tracking with 5-year production monitoring documentation retention, and dedicated after-sales support, we provide complete industry solutions backed by advanced R&D and testing equipment. Contact our professional team at baojihanz-niti@hanztech.cn today to discuss your 3mm nitinol rod requirements and discover how our expertise in transition temperature control can optimize your application performance.

References

1. Otsuka, K. and Ren, X. "Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys" - Progress in Materials Science, examining the relationship between composition, microstructure, and transformation temperatures in nickel-titanium alloys.

2. ASTM International. "ASTM F2063 - Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants" - Establishing industry standards for transformation temperature specifications and mechanical properties.

3. Duerig, T., Melton, K., Stockel, D., and Wayman, C.M. "Engineering Aspects of Shape Memory Alloys" - Comprehensive reference on the engineering principles governing nitinol transformation behavior and application design.

4. Miyazaki, S. and Otsuka, K. "Development of Shape Memory Alloys" - ISIJ International, detailing the effects of alloy composition and thermomechanical processing on transformation temperatures and functional properties.

5. Pelton, A.R., Dicello, J., and Miyazaki, S. "Optimization of Processing and Properties of Medical Grade Nitinol Wire" - Minimally Invasive Therapy and Allied Technologies, examining heat treatment effects on transformation temperatures and mechanical performance in medical-grade nitinol.