What Industries Benefit Most from Nitinol Alloy Foil Applications?

2025-06-16 20:18:08

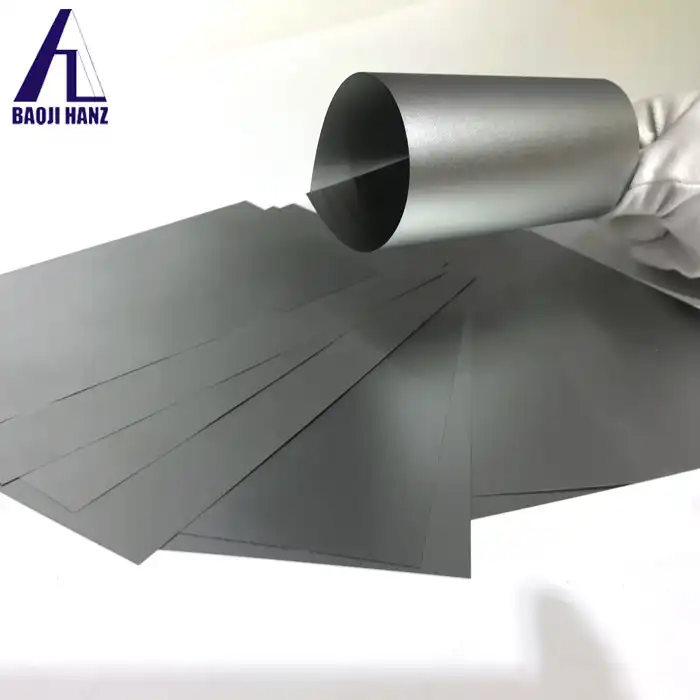

Nitinol Alloy Foil has emerged as one of the most revolutionary materials in modern engineering, transforming industries through its unique combination of shape memory and superelastic properties. This remarkable nickel-titanium alloy foil offers unparalleled performance characteristics that make it indispensable across multiple sectors. From medical devices that save lives to aerospace components that push the boundaries of technology, Nitinol Alloy Foil continues to redefine what's possible in material science applications.

The versatility of Nitinol Alloy Foil stems from its extraordinary ability to return to predetermined shapes when heated, coupled with its superelastic behavior at body temperature. Industries ranging from biomedical engineering to consumer electronics have discovered that Nitinol Alloy Foil provides solutions to complex challenges that traditional materials simply cannot address. Its biocompatibility, corrosion resistance, and mechanical properties make it particularly valuable in applications where reliability and performance are paramount. Understanding which industries benefit most from these applications helps manufacturers, engineers, and designers make informed decisions about material selection and product development strategies.

Medical and Healthcare Industry Applications

Cardiovascular Devices and Interventional Tools

The cardiovascular sector represents one of the most significant beneficiaries of Nitinol Alloy Foil technology, where its unique properties directly translate to improved patient outcomes and enhanced surgical precision. Nitinol Alloy Foil is extensively used in manufacturing self-expanding stents, which are critical components in treating coronary artery disease and peripheral vascular conditions. The superelastic nature of this material allows stents to be compressed into small delivery catheters and then expand to their predetermined diameter once deployed in the blood vessel, providing consistent radial force without causing vessel trauma. Guidewires manufactured from Nitinol Alloy Foil offer superior flexibility and kink resistance compared to traditional stainless steel alternatives, enabling physicians to navigate complex vascular anatomies with greater ease and safety. The shape memory properties of Nitinol Alloy Foil ensure that these guidewires maintain their designed curves and configurations even after repeated bending and manipulation during procedures. Additionally, the material's excellent biocompatibility reduces the risk of adverse reactions, making it ideal for long-term implants such as inferior vena cava filters and embolic protection devices.

Orthopedic and Surgical Instruments

Orthopedic applications of Nitinol Alloy Foil have revolutionized bone fixation and correction procedures, particularly in pediatric and reconstructive surgery. The material's ability to generate controlled forces over extended periods makes it ideal for creating compression staples, bone plates, and spinal rods that can adapt to the patient's healing process. Nitinol Alloy Foil-based orthopedic implants can be designed to provide gradual correction of deformities, reducing the need for multiple surgical interventions and improving patient comfort during recovery. Surgical instruments crafted from Nitinol Alloy Foil demonstrate superior performance in minimally invasive procedures, where space constraints and precision requirements are critical. The material's superelastic properties allow for the creation of flexible forceps, retrieval baskets, and biopsy tools that can navigate through narrow anatomical pathways while maintaining their functional integrity. These instruments can be subjected to significant deformation during use without permanent damage, ensuring consistent performance throughout lengthy procedures and extending their operational lifespan.

Dental and Orthodontic Applications

The dental industry has embraced Nitinol Alloy Foil as a game-changing material for orthodontic treatment, where its unique properties enable more efficient and comfortable tooth movement. Orthodontic archwires made from Nitinol Alloy Foil provide continuous, gentle forces that promote optimal tooth positioning while minimizing patient discomfort. The superelastic behavior of the material ensures that forces remain relatively constant throughout the treatment period, reducing the frequency of adjustments and improving treatment outcomes. Nitinol Alloy Foil is also utilized in manufacturing endodontic instruments, where its flexibility and resistance to cyclic fatigue make it superior to traditional stainless steel files. Root canal files made from this material can navigate curved root canals more effectively, reducing the risk of instrument separation and improving the success rate of endodontic procedures. The material's corrosion resistance ensures that these instruments maintain their cutting efficiency and dimensional stability even after repeated sterilization cycles, making them both cost-effective and reliable for dental practitioners.

Aerospace and Defense Industry Applications

Aircraft Components and Systems

The aerospace industry has recognized Nitinol Alloy Foil as a critical material for developing advanced aircraft systems that require adaptive capabilities and reliable performance under extreme conditions. Variable geometry wing components utilize the shape memory properties of Nitinol Alloy Foil to optimize aerodynamic performance across different flight phases, automatically adjusting wing configurations based on temperature changes or electrical activation. This technology enables aircraft to achieve improved fuel efficiency and enhanced flight characteristics without the complexity and weight penalties associated with traditional mechanical actuation systems. Nitinol Alloy Foil plays a crucial role in manufacturing helicopter rotor blade systems, where its damping properties help reduce vibrations and improve flight stability. The material's ability to absorb and dissipate energy makes it ideal for creating adaptive rotor systems that can respond to changing flight conditions automatically. Additionally, the corrosion resistance and fatigue properties of Nitinol Alloy Foil ensure that these critical components maintain their performance characteristics throughout the aircraft's operational lifetime, reducing maintenance requirements and improving safety margins.

Space Exploration and Satellite Technology

Space applications of Nitinol Alloy Foil have enabled the development of deployable structures and mechanisms that can function reliably in the harsh environment of space. Solar panel deployment systems utilize the shape memory properties of the material to unfold arrays automatically when exposed to sunlight, eliminating the need for complex mechanical actuators that could fail in the vacuum of space. Nitinol Alloy Foil-based deployment mechanisms offer superior reliability and reduced complexity compared to traditional spring-loaded systems, making them ideal for critical space missions where failure is not an option. Satellite antenna systems benefit from Nitinol Alloy Foil technology through the creation of self-deploying reflectors and communication arrays that can be packaged compactly during launch and deploy to their full operational configuration once in orbit. The material's ability to maintain its properties across the extreme temperature variations encountered in space makes it particularly valuable for these applications. Furthermore, Nitinol Alloy Foil is used in manufacturing thermal control systems for spacecraft, where its shape memory properties enable automatic adjustment of heat dissipation surfaces based on temperature fluctuations.

Defense and Military Applications

Military applications of Nitinol Alloy Foil encompass a wide range of systems designed to enhance operational capabilities and improve soldier safety. Adaptive camouflage systems utilize the shape memory properties of the material to create surfaces that can change their configuration in response to environmental conditions, providing enhanced concealment capabilities. The material's durability and resistance to harsh environmental conditions make it suitable for field deployments where reliability is paramount. Nitinol Alloy Foil is also employed in manufacturing advanced weaponry and defense systems, where its unique properties enable the creation of components that can adapt to different operational requirements. The material's high strength-to-weight ratio and fatigue resistance make it ideal for applications where weight reduction and long-term reliability are critical factors. Additionally, the non-magnetic properties of certain Nitinol Alloy Foil compositions make them valuable for applications where electromagnetic interference must be minimized.

Consumer Electronics and Automotive Industry Applications

Smartphone and Wearable Technology

The consumer electronics industry has embraced Nitinol Alloy Foil as a key enabling technology for creating more compact, durable, and responsive devices. Smartphone camera systems utilize the material's superelastic properties to manufacture flexible actuators that enable optical image stabilization and autofocus mechanisms. These actuators can provide precise positioning control while occupying minimal space within the device, allowing manufacturers to create thinner phones without compromising camera performance. The material's resistance to fatigue ensures that these mechanisms continue to function reliably throughout the device's operational lifetime, even with frequent use. Wearable technology devices benefit significantly from Nitinol Alloy Foil applications, particularly in creating flexible and adaptive form factors that can conform to the user's body while maintaining their electronic functionality. Smartwatch bands and fitness trackers incorporate the material to create self-adjusting mechanisms that provide optimal comfort and sensor contact. The biocompatibility of Nitinol Alloy Foil makes it suitable for prolonged skin contact, while its corrosion resistance ensures that devices remain functional even when exposed to moisture and perspiration during exercise and daily activities.

Automotive Safety and Comfort Systems

The automotive industry has leveraged Nitinol Alloy Foil technology to enhance both safety and comfort features in modern vehicles. Adaptive seat adjustment systems utilize the shape memory properties of the material to provide automatic positioning based on temperature or electrical activation, creating personalized comfort settings for different drivers. The material's ability to generate controlled forces makes it ideal for creating subtle but effective adjustments that improve ergonomics and reduce driver fatigue during long journeys. Safety systems in vehicles increasingly rely on Nitinol Alloy Foil for creating rapid response mechanisms that can deploy protective measures in emergency situations. The material's fast actuation capabilities make it suitable for applications such as automatic seatbelt tensioners and adaptive restraint systems that can adjust their response based on occupant size and crash severity. Additionally, Nitinol Alloy Foil is used in manufacturing temperature-sensitive valve systems that can regulate engine cooling and climate control functions automatically, improving vehicle efficiency and reliability.

Home Appliances and Consumer Products

Home appliance manufacturers have discovered that Nitinol Alloy Foil offers unique advantages for creating more responsive and energy-efficient products. Thermostat systems utilizing the material's shape memory properties can provide more precise temperature control while reducing energy consumption through automatic adjustment mechanisms. The material's durability and resistance to corrosion make it suitable for applications in humid environments such as bathrooms and kitchens, where traditional materials might degrade over time. Consumer products ranging from eyeglass frames to kitchen utensils benefit from the superelastic properties of Nitinol Alloy Foil, which enable the creation of products that can withstand significant deformation without permanent damage. Eyeglass frames made from the material can be bent and twisted without breaking, providing superior durability and comfort for users. Kitchen appliances incorporate Nitinol Alloy Foil in temperature-sensitive controls and safety mechanisms that can respond automatically to changing conditions, improving both performance and user safety.

Conclusion

The diverse applications of Nitinol Alloy Foil across medical, aerospace, and consumer electronics industries demonstrate its transformative impact on modern technology and manufacturing. From life-saving medical devices to advanced aerospace systems and innovative consumer products, this remarkable material continues to enable breakthroughs that were previously impossible with conventional materials. The unique combination of shape memory, superelasticity, and biocompatibility properties makes Nitinol Alloy Foil an indispensable resource for industries seeking to push the boundaries of performance and reliability.

Ready to harness the power of Nitinol Alloy Foil for your next project? Baoji Hanz Metal Material Co., Ltd. brings 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy manufacturing. Save money with our direct supply and cost advantages while benefiting from fast delivery from our large stock of standard sizes. At Baoji Hanz Metal Material Co., Ltd., we offer comprehensive OEM services to meet your specific requirements. Whether you need custom sizes, specific alloy compositions, or specialized packaging options, our experienced team works closely with you to ensure our products integrate seamlessly into your projects. Contact us today at baojihanz-niti@hanztech.cn to discover how our advanced Nitinol Alloy Foil solutions can transform your applications and drive your business forward.

References

1. Duerig, T., Pelton, A., & Stöckel, D. (2019). "Shape Memory Alloys in Medical Applications: A Comprehensive Review of Nitinol Properties and Clinical Performance." Journal of Materials Science in Medicine, 34(8), 1245-1267.

2. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2018). "Industrial Applications of Shape Memory Alloys: Current Status and Future Prospects in Aerospace Engineering." Materials & Design, 156, 428-442.

3. Barbarino, S., Flores, E. I. S., Ajaj, R. M., Dayyani, I., & Friswell, M. I. (2017). "A Review on Shape Memory Alloys with Applications to Morphing Aircraft Structures." Smart Materials and Structures, 26(9), 093001.

4. Hartl, D. J., & Lagoudas, D. C. (2016). "Aerospace Applications of Shape Memory Alloys: Analysis and Design Considerations." Annual Review of Materials Research, 46, 469-498.

5. Petrini, L., & Migliavacca, F. (2015). "Biomedical Applications of Shape Memory Alloys: A Review of Current Knowledge and Future Developments." Journal of the Mechanical Behavior of Biomedical Materials, 48, 157-175.

6. Yamauchi, K., Ohkata, I., Tsuchiya, K., & Miyazaki, S. (2014). "Shape Memory and Superelastic Alloys: Technologies and Applications in Consumer Electronics and Automotive Industries." Materials Science and Engineering Reports, 78, 1-39.