What makes nitinol suitable for medical applications?

2025-02-26 15:08:21

Nitinol, a remarkable nickel-titanium alloy, has revolutionized the medical industry with its unique properties that make it exceptionally suitable for various medical applications. This innovative material combines biocompatibility, superelasticity, and shape memory characteristics, making it an ideal choice for medical devices and implants. Nitinol's ability to return to its predetermined shape when exposed to specific temperatures or stress conditions has opened up new possibilities in minimally invasive surgeries and long-term implantable devices. Its corrosion resistance and fatigue strength further enhance its suitability for use in the human body. From stents and guidewires to orthodontic archwires and surgical instruments, nitinol has found its way into numerous medical applications, improving patient outcomes and expanding treatment options. The versatility of nitinol, particularly in the form of medical nitinol pipes, has led to groundbreaking advancements in cardiovascular, orthopedic, and neurological interventions, among others. As we delve deeper into the properties and applications of nitinol in medicine, it becomes clear why this extraordinary alloy has become a game-changer in the healthcare industry.

Unique Properties of Nitinol for Medical Use

Shape Memory Effect

The shape memory effect is one of the most fascinating properties of nitinol that makes it highly valuable in medical applications. This characteristic allows nitinol to remember and return to a pre-programmed shape when heated above a specific transformation temperature. In medical devices, this property enables the creation of self-expanding stents, which can be compressed into a small diameter for insertion into blood vessels and then expand to their original shape once in place. This shape memory effect also finds applications in orthodontics, where nitinol archwires can apply constant, gentle forces to move teeth over time.

Superelasticity

Superelasticity is another crucial property that makes nitinol an excellent choice for medical applications. This characteristic allows nitinol to undergo large deformations without permanent damage, returning to its original shape when the stress is removed. In the context of medical nitinol pipes, this property is particularly beneficial for creating flexible and kink-resistant catheters and guidewires. These instruments can navigate through tortuous blood vessels without losing their shape or functionality, improving the success rates of minimally invasive procedures. The superelastic behavior of nitinol also contributes to the durability and longevity of medical implants, reducing the need for replacements and follow-up surgeries.

Biocompatibility

Biocompatibility is a critical factor in the selection of materials for medical applications, and nitinol excels in this aspect. The alloy's resistance to corrosion in bodily fluids and its ability to form a stable, protective oxide layer on its surface contribute to its excellent biocompatibility. This characteristic minimizes the risk of adverse reactions or rejection by the body, making nitinol suitable for long-term implantation. The biocompatibility of nitinol extends to its use in medical nitinol pipes, which can be safely used in various interventional procedures without causing significant tissue irritation or inflammation. Furthermore, the low nickel release from properly treated nitinol surfaces reduces the potential for allergic reactions, enhancing its safety profile for a wide range of patients.

Applications of Nitinol in Medical Devices

Cardiovascular Interventions

Nitinol has found extensive use in cardiovascular interventions, revolutionizing the treatment of heart and blood vessel disorders. Self-expanding nitinol stents are widely used to treat coronary artery disease, peripheral artery disease, and aortic aneurysms. These stents can be compressed into a small diameter for minimally invasive insertion and then expand to their pre-programmed shape once deployed in the blood vessel. The superelastic properties of nitinol allow these stents to adapt to the natural movement of blood vessels without fracturing or causing damage. Medical nitinol pipes are also used in the manufacturing of guidewires and catheters for angioplasty procedures, offering superior flexibility and kink resistance compared to traditional materials. Additionally, nitinol-based vena cava filters, used to prevent pulmonary embolism, can be easily inserted and retrieved due to their shape memory properties.

Orthopedic Implants

In the field of orthopedics, nitinol has enabled the development of innovative implants and surgical instruments. Nitinol bone staples, for instance, utilize the shape memory effect to provide controlled compression for fracture fixation. When cooled, these staples can be easily inserted into bone, and upon warming to body temperature, they exert a constant, gentle force that promotes proper bone healing. Nitinol has also been used in spinal implants, such as dynamic stabilization devices, which allow for controlled movement while providing support to the spine. The superelastic properties of nitinol make it an excellent material for intramedullary nails used in long bone fracture repair, as it can adapt to the natural curvature of bones. Furthermore, nitinol-based orthopedic instruments, such as flexible reamers and drills, allow for less invasive surgical procedures and improved access to challenging anatomical locations.

Dental and Orthodontic Applications

The unique properties of nitinol have made it a valuable material in dentistry and orthodontics. Nitinol archwires are widely used in orthodontic treatments due to their ability to apply constant, gentle forces over extended periods. These wires can be easily bent and inserted into brackets at room temperature and then gradually return to their original shape as they warm to body temperature, effectively moving teeth into the desired position. In endodontics, nitinol files are used for root canal treatments, offering increased flexibility and resistance to cyclic fatigue compared to traditional stainless steel instruments. This flexibility allows for better navigation of curved root canals, reducing the risk of instrument breakage and improving treatment outcomes. Nitinol has also been incorporated into dental implants and prostheses, where its biocompatibility and mechanical properties contribute to long-term stability and patient comfort.

Manufacturing and Processing of Medical Nitinol Devices

Precision Machining Techniques

The manufacturing of medical nitinol devices requires specialized precision machining techniques to ensure the highest quality and performance. Laser cutting is a commonly used method for creating intricate shapes and patterns in nitinol sheets or tubes, particularly for stents and other delicate components. This technique allows for precise control over the cut geometry and minimizes material waste. Electrical discharge machining (EDM) is another valuable method for shaping nitinol, especially for complex three-dimensional structures. EDM can produce smooth surfaces and tight tolerances without introducing significant thermal stress to the material. For medical nitinol pipes and other tubular components, centerless grinding is often employed to achieve precise dimensions and surface finishes. These advanced machining techniques, combined with rigorous quality control measures, ensure that medical nitinol devices meet the stringent requirements for safety and efficacy in clinical applications.

Heat Treatment and Shape Setting

Heat treatment and shape setting are crucial processes in the manufacturing of nitinol medical devices, as they determine the final shape memory and superelastic properties of the material. The shape setting process involves constraining the nitinol component in the desired final shape and then heating it to a specific temperature for a controlled duration. This process programs the shape memory effect into the material, allowing it to return to this predetermined shape when heated above its transformation temperature. For superelastic applications, such as guidewires or stents, the heat treatment is carefully controlled to achieve the desired balance between flexibility and strength. The heat treatment process also plays a vital role in optimizing the fatigue resistance and biocompatibility of nitinol devices. Precise control over temperature, time, and cooling rates during heat treatment is essential to achieve consistent and reliable performance in medical nitinol products.

Surface Treatments and Coatings

Surface treatments and coatings play a crucial role in enhancing the performance and biocompatibility of medical nitinol devices. Electropolishing is a common surface treatment used to improve the corrosion resistance and reduce the nickel release from nitinol surfaces. This process removes surface impurities and creates a smooth, uniform oxide layer that enhances the material's biocompatibility. For applications requiring improved visibility under X-ray imaging, such as guidewires and stents, nitinol components may be coated with radiopaque materials like gold or platinum. Bioactive coatings, such as hydroxyapatite, can be applied to nitinol orthopedic implants to promote bone integration and improve long-term stability. In cardiovascular applications, drug-eluting coatings on nitinol stents can help prevent restenosis and improve patient outcomes. These surface treatments and coatings, when applied to medical nitinol pipes and other devices, significantly enhance their functionality, safety, and clinical effectiveness.

Conclusion

Nitinol's unique combination of shape memory, superelasticity, and biocompatibility makes it an invaluable material in modern medicine. From cardiovascular stents to orthopedic implants and dental applications, nitinol continues to drive innovation in medical device design. As manufacturing techniques and surface treatments advance, we can expect even more groundbreaking applications of this remarkable alloy in the future of healthcare. If you want to get more information about this product, you can contact us at baojihanz-niti@hanztech.cn.

Other related product catalogues

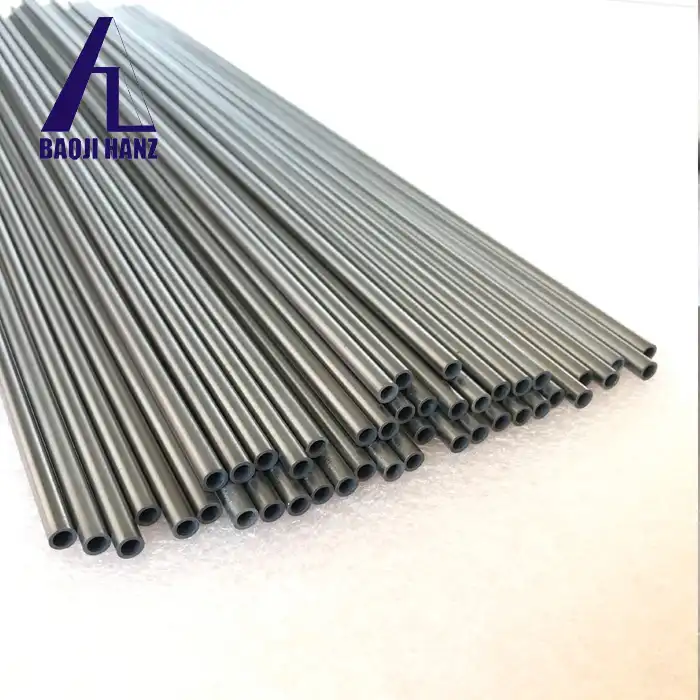

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1.Pelton, A. R., Stockel, D., & Duerig, T. W. (2000). Medical Uses of Nitinol. Materials Science Forum, 327-328, 63-70.

2.Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

3.Shabalovskaya, S. A. (2002). Surface, corrosion and biocompatibility aspects of Nitinol as an implant material. Bio-Medical Materials and Engineering, 12(1), 69-109.

4.Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

5.Petrini, L., & Migliavacca, F. (2011). Biomedical Applications of Shape Memory Alloys. Journal of Metallurgy, 2011, 1-15.

6.Es-Souni, M., Es-Souni, M., & Fischer-Brandies, H. (2005). Assessing the biocompatibility of NiTi shape memory alloys used for medical applications. Analytical and Bioanalytical Chemistry, 381(3), 557-567.