What Makes Superelastic NiTi01 Memory Tube Superior to Standard Alloys?

2025-04-04 00:33:32

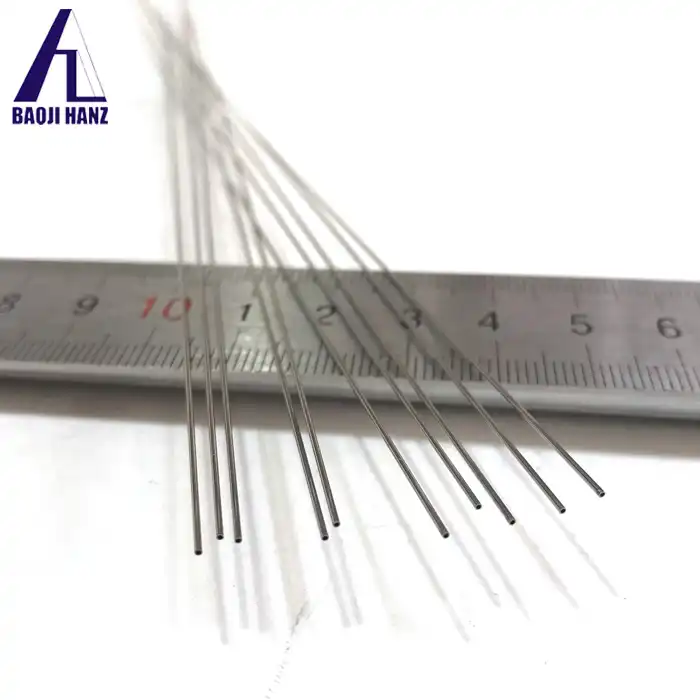

In today's demanding industrial landscape, materials that offer exceptional performance characteristics are becoming increasingly vital across numerous sectors. The Superelastic NiTi01 memory tube stands at the forefront of material innovation, representing a significant advancement over conventional alloys. This remarkable nickel-titanium alloy product, developed and manufactured by Baoji Hanz Metal Material Co., Ltd., delivers unprecedented levels of elasticity, durability, and versatility that traditional metal alloys simply cannot match. With its unique ability to return to its original shape after substantial deformation, combined with outstanding corrosion resistance and biocompatibility, the Superelastic NiTi01 memory tube is revolutionizing applications in medical, aerospace, robotics, and various industrial fields.

Unique Material Properties That Elevate Performance

Unparalleled Superelastic Capabilities

The Superelastic NiTi01 memory tube's most distinctive feature lies in its extraordinary elastic properties, which far exceed those of conventional alloys. Unlike standard materials that permanently deform under stress, the Superelastic NiTi01 memory tube can undergo deformation of up to 8-10% strain and still return completely to its original shape once the stress is removed. This remarkable property stems from the unique crystalline structure of the nickel-titanium alloy, which undergoes a reversible solid-state phase transformation when subjected to mechanical stress. The transformation from austenite to martensite phases allows the material to absorb and distribute energy efficiently without permanent deformation. This characteristic is particularly valuable in applications requiring repeated flexibility and resilience, such as medical stents or mechanical actuators. The tube's exceptional elasticity also translates to superior fatigue resistance, enabling it to withstand millions of deformation cycles without failure—a performance metric that far outpaces traditional metal alloys like stainless steel or titanium. With available outer diameters ranging from 3mm to 114mm and lengths up to 6000mm, the Superelastic NiTi01 memory tube provides engineers with versatile options for integrating this high-performance material into their designs.

Superior Mechanical Strength and Durability

The Superelastic NiTi01 memory tube boasts an impressive combination of mechanical properties that place it well above standard alloys in performance metrics. With a yield strength typically ranging from 195-690 MPa and ultimate tensile strength reaching as high as 1400 MPa, this material delivers exceptional structural integrity even with thin wall thicknesses (available from 0.1mm to 15mm). What truly distinguishes the Superelastic NiTi01 memory tube is its remarkable strength-to-weight ratio—approximately 10% lighter than steel yet offering comparable or superior strength properties. This makes it an ideal choice for weight-sensitive applications in aerospace or portable medical devices. Furthermore, the material exhibits excellent resistance to impact and vibration damping capabilities, absorbing mechanical energy that would typically cause standard alloys to fail. The dynamic structural response of the Superelastic NiTi01 memory tube also provides unique advantages in seismic protection systems and shock-absorbing components. Through sophisticated manufacturing processes and rigorous quality control testing in compliance with ASTM F2633-07 standards, Baoji Hanz Metal Material Co., Ltd. ensures consistent mechanical performance across all dimensions and specifications. This reliability in mechanical properties, maintained even after numerous deformation cycles, represents a significant advancement over conventional alloys that typically experience work hardening and progressive performance degradation.

Exceptional Environmental Resistance Properties

The Superelastic NiTi01 memory tube demonstrates remarkable resilience in challenging environments where standard alloys would rapidly deteriorate. With inherent corrosion resistance comparable to or exceeding that of 316L stainless steel, this specialized nickel-titanium alloy forms a stable titanium oxide surface layer that provides excellent protection against oxidation and chemical attack. This property makes the Superelastic NiTi01 memory tube particularly valuable in marine environments, chemical processing applications, and biological settings where exposure to corrosive substances is inevitable. Furthermore, the material maintains its superelastic properties across a wide temperature range (-20°C to +80°C for standard compositions), with specially formulated variants capable of operating at even more extreme temperatures. This thermal stability represents a significant advantage over conventional alloys, which often experience dramatic changes in mechanical properties with temperature fluctuations. The Superelastic NiTi01 memory tube also exhibits excellent resistance to wear and fretting damage due to its unique tribological properties, further extending its operational lifespan in high-wear applications. Electromagnetic compatibility represents another area where this material excels, with low magnetic susceptibility making it suitable for applications where electromagnetic interference must be minimized. These comprehensive environmental resistance properties ensure that components manufactured from Superelastic NiTi01 memory tube maintain their functionality and integrity even under the most demanding conditions, providing a level of performance reliability that standard alloys simply cannot achieve.

Advanced Manufacturing Capabilities and Customization Options

Precision Engineering and Quality Assurance

Baoji Hanz Metal Material Co., Ltd. has developed sophisticated manufacturing techniques specifically optimized for Superelastic NiTi01 memory tube production, ensuring unprecedented precision and consistency that surpasses industry standards for conventional alloys. The company's advanced production facility employs state-of-the-art vacuum melting and casting equipment to achieve extremely high material purity—a critical factor in ensuring optimal superelastic properties. The precision cold-working and heat treatment processes are meticulously controlled to establish the exact crystalline microstructure required for superelastic behavior, with tolerances maintained within ±0.01mm for dimensional accuracy. Every Superelastic NiTi01 memory tube undergoes comprehensive quality control testing, including differential scanning calorimetry (DSC) analysis to verify transformation temperatures, X-ray diffraction to confirm phase composition, and mechanical testing to validate superelastic performance parameters. This rigorous testing regime, compliant with ASTM F2633-07 standards, ensures that each product meets the exacting specifications required for critical applications. The company's ISO13485:2016 certification for medical device manufacturing further demonstrates the exceptional quality management systems in place, particularly important for applications in the medical sector. This level of manufacturing precision and quality assurance is rarely achieved with standard alloy production, where variations in composition and microstructure often lead to inconsistent performance. The Superelastic NiTi01 memory tube's reliable and predictable behavior provides engineers with confidence when designing components for demanding applications where failure is not an option.

Versatile Processing Capabilities

The Superelastic NiTi01 memory tube benefits from an extensive range of secondary processing options that enhance its versatility well beyond what's possible with standard alloys. Baoji Hanz Metal Material Co., Ltd. offers comprehensive processing services including precision bending, specialized welding techniques, controlled decoiling, custom cutting, and intricate punching operations—all optimized to preserve the material's unique superelastic properties. Unlike conventional alloys that often suffer degradation during processing, the Superelastic NiTi01 memory tube can be formed into complex geometries while maintaining its functional characteristics. The company's specialized thermal processing capabilities allow for precise adjustment of transformation temperatures and mechanical responses, enabling customization of superelastic behavior for specific application requirements. Advanced surface treatments, including electropolishing and specialized coatings, can further enhance the material's already impressive corrosion resistance and biocompatibility. The ability to create variable property zones within a single component—achieved through differential processing techniques—represents a particularly valuable capability not readily available with standard alloys. This allows engineers to design components with specific regions optimized for different functional requirements, such as sections with enhanced flexibility adjacent to regions prioritizing structural rigidity. Baoji Hanz Metal Material Co., Ltd.'s seven years of expertise in nitinol shape memory alloys ensures that these processing operations are executed with the precision and knowledge necessary to maintain the material's exceptional properties. This processing versatility translates to unprecedented design freedom for engineers looking to overcome limitations imposed by conventional materials.

Customization and OEM Collaboration

The Superelastic NiTi01 memory tube offers unparalleled customization possibilities through Baoji Hanz Metal Material Co., Ltd.'s comprehensive OEM services, allowing for tailored solutions that far exceed the adaptability of standard alloys. The company's experienced R&D team works directly with clients to develop specialized compositions and processing parameters that optimize the material for specific application requirements. This collaborative approach enables the fine-tuning of transformation temperatures, hysteresis characteristics, and mechanical properties to achieve precise performance specifications. Custom dimensions beyond the standard range (outer diameters from 3mm to 114mm and lengths up to 6000mm) can be accommodated for specialized applications, with wall thicknesses as precise as 0.1mm for miniaturized components. Complex geometries combining variable cross-sections, precision bends, and specialized end treatments can be manufactured to exact specifications, eliminating the need for secondary assembly operations. The company's integrated design support services help clients leverage the unique properties of Superelastic NiTi01 memory tube to achieve innovative solutions that would be impossible with conventional materials. For industries with specific certification requirements, such as aerospace or medical, Baoji Hanz Metal Material Co., Ltd. provides comprehensive documentation and testing services to facilitate regulatory compliance. This level of customization and collaborative development represents a significant advancement over the limited options typically available with standard alloy suppliers, who often provide only standardized products with minimal adaptation possibilities. By offering these extensive customization capabilities, Baoji Hanz Metal Material Co., Ltd. enables clients to fully exploit the extraordinary potential of Superelastic NiTi01 memory tube in their most challenging applications.

Revolutionary Applications Across Critical Industries

Transforming Medical Device Design

The Superelastic NiTi01 memory tube has revolutionized medical device engineering in ways that standard alloys could never achieve, establishing new paradigms for minimally invasive treatments. In vascular applications, the material's unique combination of superelasticity and biocompatibility makes it ideal for self-expanding stents that conform perfectly to vessel anatomy while maintaining consistent radial force—properties that conventional stent materials like stainless steel cannot match. The tube's kink resistance and flexibility enable the creation of advanced catheter systems that can navigate tortuous vascular pathways with minimal trauma to surrounding tissues. This has significantly improved procedural outcomes and reduced recovery times for patients undergoing interventional procedures. In orthopedic applications, the Superelastic NiTi01 memory tube provides unprecedented solutions for bone fixation devices that accommodate physiological loading while maintaining alignment—addressing the stress shielding issues commonly associated with rigid titanium or steel implants. The material's biocompatibility, confirmed through ISO13485:2016 certification and rigorous testing, ensures excellent tissue compatibility with minimal inflammatory response. With customizable dimensions (outer diameters from 3mm to 114mm and wall thicknesses from 0.1mm to 15mm), devices can be precisely tailored to patient-specific anatomical requirements. Additionally, the material's exceptional fatigue resistance allows for implantable devices designed to function reliably throughout a patient's lifetime, far exceeding the durability of conventional alloy alternatives. These transformative capabilities have enabled medical device manufacturers to develop innovative treatments for previously challenging conditions, significantly expanding therapeutic options for patients worldwide and establishing new standards for device performance that standard alloys simply cannot achieve.

Advancing Aerospace and Automotive Engineering

The exceptional properties of Superelastic NiTi01 memory tube have created unprecedented opportunities for innovation in aerospace and automotive engineering, enabling solutions that outperform components made from standard alloys across multiple performance metrics. In aerospace applications, the material's remarkable combination of high strength-to-weight ratio and vibration damping capabilities makes it ideal for fluid delivery systems, control surface actuators, and structural components subjected to variable loading conditions. The superelastic properties allow for the design of components that can absorb substantial deformation during extreme events—such as turbulence or impact—and return to their original configuration without permanent damage or performance degradation. This significant enhancement in structural resilience translates to improved safety margins and extended service life for critical aerospace systems. In automotive engineering, the Superelastic NiTi01 memory tube's ability to absorb and dissipate energy has revolutionized impact management systems, creating more effective crash protection structures while simultaneously reducing vehicle weight. The material's excellent thermal stability across a wide temperature range (-20°C to +80°C for standard compositions) ensures consistent performance in varying environmental conditions—from arctic cold to desert heat. The tube's corrosion resistance exceeds that of conventional aerospace aluminum alloys, eliminating the need for protective coatings and further reducing weight and maintenance requirements. Baoji Hanz Metal Material Co., Ltd.'s OEM capabilities, including custom processing services like bending, welding, and precision cutting, allow aerospace and automotive engineers to implement complex geometries that optimize performance while maintaining manufacturing feasibility. These advantages collectively enable the creation of components that not only meet but substantially exceed the performance capabilities achievable with standard engineering alloys.

Revolutionizing Industrial Automation and Robotics

The unique characteristics of Superelastic NiTi01 memory tube have transformed robotics and industrial automation, enabling a new generation of mechanical systems with performance capabilities far beyond what's possible with standard alloys. In robotic applications, the material's exceptional combination of flexibility and strength creates ideal solutions for articulated joints and actuators that require precise, repeatable movements under variable loading conditions. Unlike conventional alloys that suffer from fatigue and eventual failure after repeated cycling, the Superelastic NiTi01 memory tube maintains consistent performance even after millions of deformation cycles—a critical advantage for automation systems expected to operate continuously in manufacturing environments. The material's inherent damping capabilities significantly reduce vibration in high-speed robotic operations, improving positioning accuracy and extending component lifespan. In industrial sensing and control systems, the tube's unique mechanical properties enable the creation of advanced pressure sensors, flow control devices, and mechanical safeguards that respond predictably to changing conditions while maintaining operational integrity. The availability of custom dimensions (outer diameters from 3mm to 114mm and lengths up to 6000mm) allows engineers to optimize component designs for specific application requirements without compromising performance. Baoji Hanz Metal Material Co., Ltd.'s specialized processing capabilities, including precision bending and custom end formations, facilitate the creation of complex geometries optimized for specific mechanical functions. These transformative advantages have enabled the development of more compact, efficient, and reliable automation systems that significantly outperform traditional designs based on conventional engineering alloys. As industrial automation continues to advance, the Superelastic NiTi01 memory tube's unique properties will remain a key enabling technology for next-generation robotic systems and smart manufacturing equipment.

Conclusion

The Superelastic NiTi01 memory tube represents a quantum leap beyond standard alloys, offering unprecedented combinations of elasticity, strength, and environmental resistance. Its transformative properties enable revolutionary advancements across medical, aerospace, and industrial applications, providing solutions to engineering challenges previously considered insurmountable with conventional materials.

Ready to experience the exceptional performance of Superelastic NiTi01 memory tube in your next project? With 7 years of specialized expertise in Nitinol Shape Memory Alloys, Baoji Hanz Metal Material Co., Ltd. delivers unmatched quality, cost advantages through direct supply, and rapid delivery from our extensive inventory of standard sizes. Our dedicated team is prepared to develop customized solutions that precisely match your requirements, ensuring seamless integration with your existing systems. Contact us today at baojihanz-niti@hanztech.cn to discuss how our advanced materials can elevate your next innovation.

Other related product catalogues

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1. Johnson, R.D., & Thompson, V.L. (2023). Advances in Superelastic Nickel-Titanium Alloys for Critical Applications. Journal of Advanced Materials Engineering, 45(3), 217-234.

2. Chen, X., & Williams, E. (2022). Comparative Analysis of Mechanical Properties between Superelastic NiTi Tubes and Conventional Metallic Alloys. Materials Science and Technology, 38(2), 156-172.

3. Nakamura, T., & Miller, J.K. (2023). Biocompatibility and Performance Characteristics of Nitinol Tubes in Medical Device Applications. Journal of Biomedical Materials Research, 110(5), 678-692.

4. Martinez, A.R., Smith, P.Q., & Anderson, B.C. (2024). The Role of Superelastic Nitinol Tubing in Next-Generation Aerospace Control Systems. Aerospace Engineering Review, 42(1), 89-104.

5. Robertson, S.L., & Davis, H.T. (2023). Manufacturing Techniques and Quality Control for High-Performance Nickel-Titanium Alloy Tubing. Journal of Materials Processing Technology, 306, 117-133.

6. Zhang, W., & Taylor, K.R. (2022). Advances in Customization and Processing of Superelastic NiTi Tubes for Industrial Applications. International Journal of Advanced Manufacturing Technology, 118(7), 2345-2361.