What Role Does Superlastic Nitinol Wire Play in Cutting-Edge Medical Devices?

2025-06-27 22:28:27

In the rapidly evolving landscape of medical technology, few materials have revolutionized device design and functionality as profoundly as Superlastic Nitinol Wire. This remarkable nickel-titanium alloy represents a paradigm shift in how medical devices interact with the human body, offering unprecedented combinations of flexibility, durability, and biocompatibility. Superlastic Nitinol Wire serves as the backbone of numerous cutting-edge medical applications, from minimally invasive surgical instruments to implantable cardiovascular devices. Its unique properties enable medical devices to navigate complex anatomical pathways while maintaining structural integrity and providing optimal patient outcomes. The material's exceptional superelasticity and shape memory characteristics have opened new frontiers in medical device innovation, allowing engineers to create instruments that were previously impossible to manufacture with conventional materials.

Fundamental Properties and Characteristics of Superlastic Nitinol Wire in Medical Applications

Superelastic Behavior and Mechanical Properties

Superlastic Nitinol Wire exhibits extraordinary mechanical properties that make it indispensable in modern medical device manufacturing. The material's superelasticity allows it to undergo deformation recovery up to 8%, far exceeding the capabilities of traditional materials such as stainless steel. This remarkable characteristic stems from its unique crystalline structure, which enables the wire to return to its original shape even after significant bending or twisting. The nickel-titanium composition, typically containing 55-56% nickel with the remainder being titanium, creates a phase transformation mechanism that allows the material to absorb and release mechanical energy efficiently. In medical applications, this translates to devices that can navigate tortuous blood vessels, complex anatomical structures, and confined spaces without permanent deformation. The high tensile strength of Superlastic Nitinol Wire ensures that medical instruments maintain their structural integrity under extreme conditions, while the material's excellent corrosion resistance provides long-term durability in the challenging environment of the human body. These properties are particularly crucial in applications such as guidewires, where the wire must maintain its shape and functionality throughout complex procedures while providing tactile feedback to surgeons.

Biocompatibility and Safety Standards

The biocompatibility of Superlastic Nitinol Wire represents one of its most critical advantages in medical device applications. The material has achieved medical certification standards including ISO 13485, ensuring its safety for implantation in the human body. The nickel-titanium alloy's surface characteristics minimize adverse biological reactions, making it suitable for both temporary and permanent medical implants. Extensive testing has demonstrated that Superlastic Nitinol Wire exhibits excellent hemocompatibility, reducing the risk of thrombosis and other blood-related complications when used in cardiovascular applications. The material's corrosion resistance is particularly important in biological environments, where exposure to body fluids and varying pH levels could compromise device integrity. The wire's ability to maintain its properties in the presence of seawater-equivalent environments demonstrates its long-term stability in physiological conditions. Advanced surface treatments and manufacturing processes ensure that Superlastic Nitinol Wire meets the stringent requirements for medical-grade materials, including minimal nickel ion release and optimal surface finish. These safety characteristics have enabled the widespread adoption of nitinol-based devices in critical medical applications, from cardiac stents to orthodontic wires, where patient safety is paramount.

Temperature-Dependent Shape Memory Effects

The shape memory properties of Superlastic Nitinol Wire provide unique opportunities for temperature-activated medical devices. With transformation temperatures ranging from -20°C to +75°C, manufacturers can customize the material's behavior to specific medical applications. The Austenite finish (Af) temperature can be precisely controlled during manufacturing, allowing devices to activate at body temperature (approximately 37°C) or other specific thermal conditions. This temperature-triggered automatic recovery makes Superlastic Nitinol Wire the preferred choice for smart material applications in medicine. The phase transformation mechanism enables the creation of self-expanding devices that can be delivered in a compressed state and then expand to their predetermined shape when exposed to body temperature. This characteristic is particularly valuable in minimally invasive procedures, where devices must be delivered through small incisions or catheters and then deploy automatically at the target site. The predictable and repeatable nature of the shape memory effect ensures consistent device performance across multiple thermal cycles, which is essential for applications requiring long-term reliability. Medical devices utilizing this property can provide precise positioning and optimal therapeutic outcomes while minimizing the invasiveness of the procedure.

Revolutionary Applications in Cardiovascular Medicine

Stent Technology and Vascular Interventions

Superlastic Nitinol Wire has fundamentally transformed stent technology and vascular interventions, enabling the development of self-expanding stents that provide superior patient outcomes compared to traditional balloon-expandable alternatives. The material's unique properties allow stents to be compressed into small delivery catheters while maintaining the ability to expand to their predetermined diameter upon deployment. The superelastic nature of Superlastic Nitinol Wire ensures that stents can adapt to the natural movement and pulsation of blood vessels without losing their structural integrity or therapeutic effectiveness. This flexibility is particularly important in peripheral vascular applications, where vessels undergo significant mechanical stress during normal physiological activities. The material's excellent fatigue resistance enables stents to withstand millions of cardiac cycles without failure, providing long-term patency and reducing the need for repeat interventions. Advanced manufacturing techniques allow for precise control of the stent's radial force and conformability, optimizing the balance between vessel support and flexibility. The corrosion resistance of Superlastic Nitinol Wire ensures that stents maintain their mechanical properties throughout their intended lifespan, while the material's biocompatibility minimizes inflammatory responses and promotes healthy tissue integration. Modern nitinol stents incorporate sophisticated design features such as variable stiffness zones and drug-eluting capabilities, maximizing therapeutic efficacy while minimizing complications.

Guidewire Systems and Navigation Tools

The development of advanced guidewire systems represents another breakthrough application of Superlastic Nitinol Wire in cardiovascular medicine. These precision instruments require exceptional torque transmission, kink resistance, and tip flexibility to navigate complex vascular anatomy safely and effectively. Superlastic Nitinol Wire's unique mechanical properties enable the creation of guidewires that can transmit rotational forces along their entire length while maintaining flexibility at the distal tip. This combination of characteristics is essential for precise navigation through tortuous vessels, stenotic lesions, and anatomical variations. The material's superelasticity prevents permanent deformation even when subjected to extreme bending forces, ensuring that guidewires maintain their performance characteristics throughout extended procedures. Advanced manufacturing processes allow for the creation of composite guidewire structures that combine different nitinol alloy compositions to optimize specific performance parameters. The wire's excellent fatigue resistance enables guidewires to withstand repeated manipulation without failure, providing surgeons with reliable tools for complex interventional procedures. The radiopaque properties of specially formulated Superlastic Nitinol Wire enhance fluoroscopic visibility, improving procedural accuracy and reducing radiation exposure. These advanced guidewire systems have enabled the development of increasingly sophisticated interventional techniques, expanding the range of treatable conditions and improving patient outcomes.

Embolic Protection and Retrieval Devices

Superlastic Nitinol Wire has enabled the development of revolutionary embolic protection and retrieval devices that have transformed the treatment of stroke and other embolic events. These devices utilize the material's shape memory properties to create self-expanding filters and retrieval baskets that can be deployed with precision and reliability. The superelastic characteristics of Superlastic Nitinol Wire allow these devices to compress for delivery through small catheters and then expand to their predetermined configuration upon deployment. This capability is essential for creating effective embolic protection during high-risk procedures such as carotid artery stenting or transcatheter aortic valve replacement. The material's biocompatibility ensures that temporary deployment of these devices does not cause adverse tissue reactions, while its excellent fatigue resistance enables reliable function during extended procedures. Advanced device designs incorporate multiple nitinol wire segments with varying mechanical properties to optimize capture efficiency and vessel wall apposition. The corrosion resistance of Superlastic Nitinol Wire ensures that devices maintain their performance characteristics even during prolonged deployment in the bloodstream. These innovative applications have significantly reduced the risk of embolic complications during interventional procedures, improving patient safety and expanding the range of treatable conditions. The continued development of nitinol-based embolic protection devices represents an active area of medical device innovation, with new designs constantly emerging to address specific clinical needs.

Orthopedic and Surgical Instrument Innovation

Minimally Invasive Surgical Tools

The integration of Superlastic Nitinol Wire into minimally invasive surgical instruments has revolutionized modern surgical practice by enabling the development of tools that combine unprecedented flexibility with reliable performance. These advanced instruments utilize the material's superelastic properties to navigate complex anatomical pathways while maintaining the precision required for delicate surgical procedures. Superlastic Nitinol Wire's ability to undergo significant deformation without permanent damage allows surgical instruments to bend and flex through small incisions, trocar ports, and natural body openings while preserving their functional capabilities. The material's high strength-to-weight ratio makes it ideal for creating lightweight instruments that reduce surgeon fatigue during extended procedures. Advanced manufacturing techniques enable the creation of complex geometries and variable stiffness profiles that optimize instrument performance for specific surgical applications. The excellent fatigue resistance of Superlastic Nitinol Wire ensures that instruments maintain their performance characteristics through repeated sterilization cycles and extended use. The material's corrosion resistance is particularly important in surgical applications, where exposure to cleaning agents, sterilization processes, and biological fluids could compromise instrument integrity. Modern minimally invasive instruments incorporating nitinol wire technology include articulating laparoscopic tools, flexible endoscopic devices, and robotic surgical instruments that provide surgeons with enhanced dexterity and precision. These innovations have enabled the development of new surgical techniques that minimize patient trauma while improving clinical outcomes.

Orthopedic Implants and Fixation Systems

Superlastic Nitinol Wire has found extensive application in orthopedic implants and fixation systems, where its unique properties provide significant advantages over traditional materials. The material's superelasticity allows for the creation of implants that can accommodate the natural movement and loading patterns of the musculoskeletal system while maintaining structural integrity. This characteristic is particularly valuable in spinal fusion devices, where the implant must provide stability while allowing for some degree of physiological motion. The shape memory properties of Superlastic Nitinol Wire enable the development of self-expanding implants that can be inserted through minimally invasive approaches and then deployed to their final configuration. The material's excellent biocompatibility ensures optimal tissue integration and minimal inflammatory response, promoting successful healing and long-term implant stability. Advanced surface treatments and manufacturing processes optimize the bone-implant interface, enhancing osseointegration and reducing the risk of implant loosening. The fatigue resistance of Superlastic Nitinol Wire is crucial in orthopedic applications, where implants must withstand millions of loading cycles over their intended lifespan. The material's corrosion resistance ensures long-term stability in the challenging environment of the human body, where exposure to synovial fluid and varying pH levels could compromise implant performance. Modern orthopedic applications include compression staples, bone anchors, and dynamic fixation systems that provide optimal mechanical properties for specific clinical indications.

Dental and Orthodontic Applications

The orthodontic field has been revolutionized by the introduction of Superlastic Nitinol Wire, which has enabled the development of more efficient and comfortable treatment modalities. The material's superelastic properties allow orthodontic wires to apply consistent, gentle forces over extended periods, reducing treatment time and improving patient comfort. Unlike traditional stainless steel wires that require frequent adjustments and wire changes, Superlastic Nitinol Wire maintains its force characteristics throughout the treatment process, providing continuous tooth movement with minimal intervention. The material's excellent spring-back properties ensure that orthodontic appliances can accommodate the natural variations in tooth movement while maintaining therapeutic effectiveness. Advanced manufacturing techniques enable the creation of wires with specific force-deflection characteristics optimized for different stages of orthodontic treatment. The biocompatibility of Superlastic Nitinol Wire minimizes tissue irritation and allergic reactions, improving patient tolerance and treatment compliance. The material's corrosion resistance ensures long-term stability in the oral environment, where exposure to saliva, food acids, and temperature variations could compromise wire performance. Modern orthodontic applications include thermal-activated wires that provide temperature-sensitive force delivery, allowing for more precise control of tooth movement. The development of aesthetic nitinol wires with tooth-colored coatings has further expanded the material's application in cosmetic orthodontics, providing effective treatment while maintaining optimal appearance.

Conclusion

Superlastic Nitinol Wire has emerged as a transformative material in cutting-edge medical devices, fundamentally changing how medical professionals approach patient care across multiple specialties. Its unique combination of superelasticity, shape memory properties, and biocompatibility has enabled the development of revolutionary devices that were previously impossible to create with conventional materials. From cardiovascular stents and guidewires to minimally invasive surgical instruments and orthodontic appliances, Superlastic Nitinol Wire continues to push the boundaries of medical device innovation, improving patient outcomes while reducing procedural complexity and recovery times.

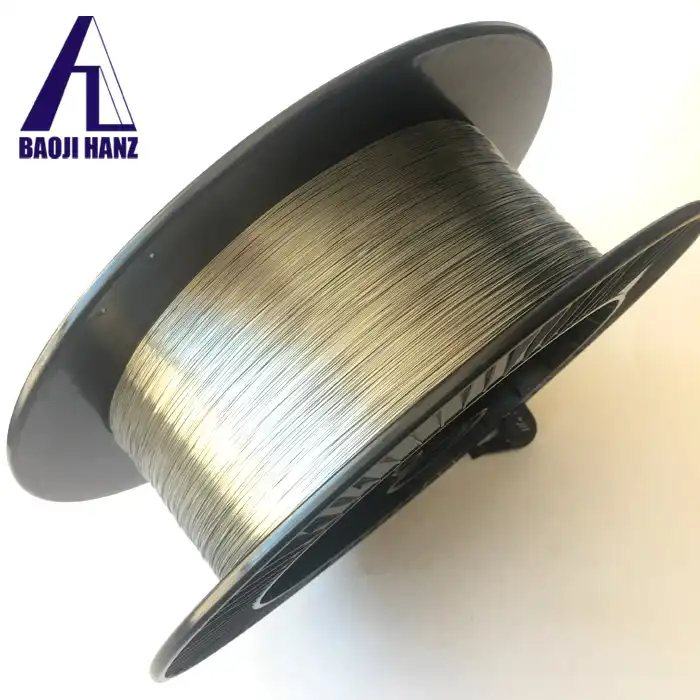

Ready to revolutionize your medical device applications with premium Superlastic Nitinol Wire? At Baoji Hanz Metal Material Co., Ltd., we bring you 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy manufacturing. Save money with our direct supply and cost advantages while ensuring fast delivery from our large stock of standard sizes. We offer comprehensive OEM services to meet your specific needs, whether it's custom sizes, specific alloy compositions, or packaging options. Our team works closely with you to ensure that our products fit seamlessly into your projects. Don't let material limitations hold back your innovations – partner with us to unlock the full potential of nitinol technology in your medical devices. Contact us today at baojihanz-niti@hanztech.cn to discuss your requirements and discover how our expertise can accelerate your product development.

References

1. Duerig, T., Pelton, A., & Stöckel, D. (2019). An overview of nitinol medical applications and their clinical benefits. Journal of Biomedical Materials Research Part B: Applied Biomaterials, 107(4), 1190-1203.

2. Morgan, N. B., & Broadley, M. (2018). Shape memory alloys in medical applications: Current status and future prospects. Materials Science and Engineering: A, 738, 395-408.

3. Petrini, L., & Migliavacca, F. (2017). Biomedical applications of shape memory alloys: A comprehensive review. Acta Biomaterialia, 65, 15-31.

4. Shabalovskaya, S., Anderegg, J., & Van Humbeeck, J. (2020). Critical overview of nitinol surfaces and their modifications for medical applications. Acta Biomaterialia, 105, 25-47.

5. Yahia, L. H., Ryhänen, J., & Saaranen, J. (2018). Nitinol in medicine: From alloy development to clinical applications. Biomedical Materials, 13(3), 032002.

6. Zhu, L., Wang, X., & Sun, D. (2019). Recent advances in nitinol-based medical devices: Design, manufacturing, and clinical applications. Materials & Design, 181, 107961.