Where is Medical Superelastic Titanium Nickel Alloy Wire Used?

2025-04-17 19:14:25

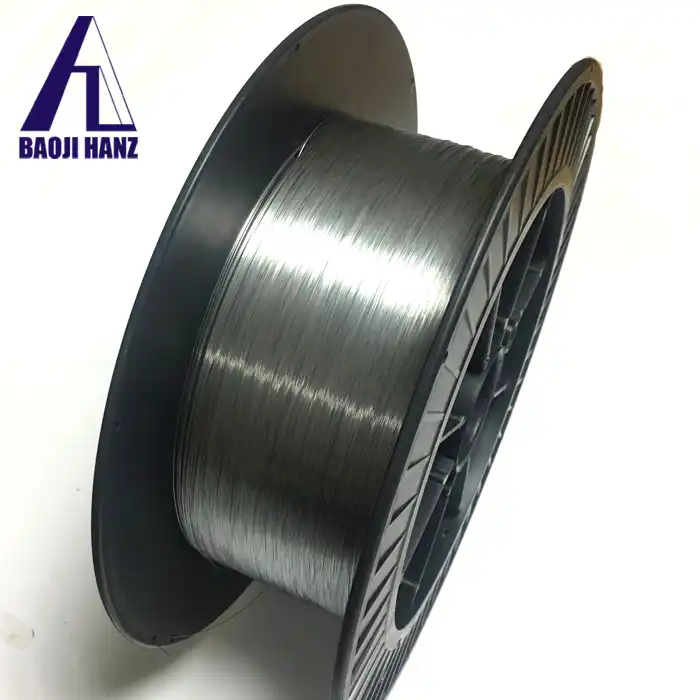

Medical superelastic titanium nickel alloy wire, commonly known as Nitinol wire, has revolutionized numerous medical fields due to its unique properties. This remarkable material combines superelasticity with biocompatibility, making it an invaluable component in modern medical devices and procedures. As healthcare technology advances, the applications for this specialized wire continue to expand, enabling less invasive procedures and more effective treatment options. Medical superelastic titanium nickel alloy wire is primarily used in cardiovascular interventions, orthodontics, minimally invasive surgical instruments, neurological procedures, and orthopedic implants - areas where its flexibility, shape memory, and durability provide significant clinical advantages over conventional materials.

Applications in Cardiovascular Procedures

The cardiovascular system demands materials that can navigate complex vessel networks while maintaining structural integrity. Medical superelastic titanium nickel alloy wire meets these challenges exceptionally well.

Stent Manufacturing

Medical superelastic titanium nickel alloy wire serves as the backbone for cardiovascular stents, providing critical structural support while maintaining flexibility. These self-expanding stents utilize the wire's unique properties to compress during delivery through narrow catheters and then expand upon deployment in blood vessels. The wire's superelasticity ensures the stent conforms to vessel anatomy without causing excessive stress on vessel walls, reducing complications like restenosis or vessel damage. Medical-grade quality standards are rigorously maintained in production, with Baoji Hanz Metal Material Co., Ltd. manufacturing these wires in diameters ranging from 0.1mm to 5mm according to ISO13485:2016 and CE certifications. The company's advanced manufacturing processes ensure tight dimensional tolerances, which are absolutely essential for consistent stent performance across different vascular environments. Furthermore, the wire's high fatigue resistance makes it particularly valuable for stenting areas with cyclical motion, such as coronary arteries near the heart, where conventional materials would fail under repeated stress cycles.

Guidewires for Catheterization

Guidewires fabricated from medical superelastic titanium nickel alloy wire are essential navigational tools in complex catheterization procedures. These wires exhibit exceptional torque transmission and kink resistance, allowing interventionalists to navigate tortuous vascular pathways safely. Medical superelastic titanium nickel alloy wire's high strength-to-weight ratio allows for thinner guidewires that maintain necessary pushability and steerability, critical for accessing difficult anatomical regions. Baoji Hanz Metal Material Co., Ltd. supplies these specialized wires with OEM customization options, enabling device manufacturers to specify precise characteristics like tip flexibility, radiopacity, and surface treatments. The wire's corrosion resistance is particularly valuable for procedures where guidewires must withstand exposure to blood and contrast media for extended periods. Additionally, these guidewires benefit from the material's shape memory effect, which allows them to recover their original configuration after navigating tight bends, reducing the risk of vessel trauma during complex interventional procedures like chronic total occlusion treatments or neurovascular interventions where precision is paramount.

Embolic Protection Devices

Embolic protection devices utilizing medical superelastic titanium nickel alloy wire have become indispensable in preventing stroke and other embolic complications during vascular interventions. The wire's superelasticity allows these devices to deploy consistent meshes that effectively trap debris while maintaining blood flow. Medical superelastic titanium nickel alloy wire's biocompatibility ensures minimal inflammatory response during temporary deployment, a critical consideration for procedures like carotid stenting or transcatheter aortic valve replacements where emboli pose significant risks. Baoji Hanz Metal Material Co., Ltd. manufactures these specialized wires with precision manufacturing processes that maintain consistent mechanical properties across production batches, ensuring predictable device performance. The wire's flexibility allows embolic protection devices to conform to vessel geometries of varying diameters while maintaining filtration efficacy. Furthermore, the material's high fatigue resistance is crucial for procedures where the device must withstand pulsatile flow conditions without mesh deformation or wire fracture, providing reliable protection throughout the entire intervention from access to removal.

Orthodontic and Dental Applications

Orthodontics was among the first fields to widely adopt superelastic nickel-titanium alloys, revolutionizing treatment approaches and patient comfort.

Archwires and Brackets

Medical superelastic titanium nickel alloy wire has transformed orthodontic treatment by providing constant, gentle force application over extended periods. These archwires deliver more physiologic tooth movement with reduced pain compared to conventional stainless steel wires. The wire's superelasticity allows orthodontists to engage severely misaligned teeth that would otherwise require multiple wire changes with traditional materials. Baoji Hanz Metal Material Co., Ltd. produces these specialized orthodontic wires in customizable diameters and configurations, with their ISO9001:2015 certification ensuring consistent quality. The shape memory effect of medical superelastic titanium nickel alloy wire is particularly valuable in orthodontics, as it allows the wire to return to its programmed arch form even after significant deflection during bracket engagement. Additionally, the material's corrosion resistance withstands the challenging oral environment where pH fluctuations, temperature changes, and microbial exposure would compromise conventional alloys. These archwires require fewer adjustment appointments, improving treatment efficiency while maintaining excellent control over tooth movement vectors throughout different treatment phases.

Endodontic Instruments

Rotary endodontic instruments manufactured from medical superelastic titanium nickel alloy wire have revolutionized root canal procedures by enabling better navigation of curved canals while reducing iatrogenic damage. The wire's flexibility allows instruments to follow complex canal anatomies without transportation or perforation risks that plague traditional stainless steel instruments. Medical superelastic titanium nickel alloy wire's resistance to cyclic fatigue is particularly important in endodontics, where instruments undergo repeated bending stresses during canal preparation. Baoji Hanz Metal Material Co., Ltd. supplies wires with precise specifications that meet the demanding requirements for endodontic applications, with diameters as small as 0.1mm maintaining consistent performance characteristics. The material's high strength-to-weight ratio allows for more efficient cutting while preserving dentin structure, an important consideration for the long-term prognosis of endodontically treated teeth. Furthermore, these instruments benefit from the wire's superelasticity, which prevents permanent deformation during use, allowing clinicians to treat complex cases with fewer instruments and reducing the risk of separation even in severely curved canals.

Dental Implant Components

Medical superelastic titanium nickel alloy wire is increasingly utilized in advanced dental implant systems, particularly for components requiring stress distribution and micromotion management. The wire's superelasticity mimics the natural periodontal ligament's function, potentially reducing crestal bone loss associated with rigid implant designs. Medical superelastic titanium nickel alloy wire components can be engineered with specific transformation temperatures suitable for the oral environment, ensuring optimal performance under normal physiological conditions. Baoji Hanz Metal Material Co., Ltd. provides customization options for these specialized applications, working closely with implant manufacturers to develop proprietary designs. The wire's biocompatibility is essential for long-term implant success, as these components must integrate with oral tissues without adverse reactions over decades of service. Additionally, the material's fatigue resistance addresses concerns about component failure under masticatory loads, which can reach several hundred Newtons in posterior regions. These innovative applications represent cutting-edge developments in implantology, where the wire's unique properties are being leveraged to create more biomimetic replacement systems that better preserve surrounding tissues and extend implant longevity.

Minimally Invasive Surgical Instruments

The trend toward less invasive surgical approaches has been greatly facilitated by instruments incorporating medical superelastic titanium nickel alloy wire.

Laparoscopic and Endoscopic Tools

Medical superelastic titanium nickel alloy wire has enabled the development of sophisticated laparoscopic and endoscopic instruments that can navigate through tortuous anatomical pathways while maintaining functionality. These instruments utilize the wire's superelasticity to deploy complex end-effectors through narrow access ports, expanding the range of procedures that can be performed minimally invasively. Medical superelastic titanium nickel alloy wire components maintain consistent performance characteristics even after repeated sterilization cycles, a critical requirement for reusable surgical instruments. Baoji Hanz Metal Material Co., Ltd. manufactures these specialized wires with tight dimensional tolerances and surface finishes optimized for medical applications, meeting ISO13485:2016 standards. The wire's high strength-to-weight ratio is particularly valuable for articulating instruments, allowing precise control with minimal operator fatigue during lengthy procedures. Additionally, the material's corrosion resistance ensures instrument longevity even when exposed to harsh cleaning agents and sterilization processes, reducing healthcare facility costs over time. These advanced instruments have contributed significantly to reduced patient recovery times, decreased complications, and improved surgical outcomes across numerous specialties from general surgery to gynecology.

Retrieval and Snaring Devices

Retrieval devices constructed from medical superelastic titanium nickel alloy wire provide interventionalists with reliable tools for removing foreign bodies or tissue samples from challenging anatomical locations. The wire's superelasticity allows these devices to deploy complex geometries through narrow catheters and then expand to their functional configuration upon deployment. Medical superelastic titanium nickel alloy wire's shape memory effect is particularly valuable for retrieval baskets and snares, as it ensures consistent performance even after repeated actuations during challenging cases. Baoji Hanz Metal Material Co., Ltd. provides customized solutions for these specialized applications, with diameters from 0.1mm to 5mm accommodating various anatomical requirements. The wire's biocompatibility is essential for these devices, which may remain in contact with tissues for extended periods during complex retrieval procedures. Additionally, the material's corrosion resistance preserves device integrity even when exposed to biological fluids and electrolytes, maintaining gripping or cutting performance throughout the procedure. These devices have become indispensable in both planned interventions like stone retrieval and emergent scenarios such as foreign body extraction, significantly reducing the need for open surgical approaches.

Biopsy and Sampling Instruments

Biopsy instruments incorporating medical superelastic titanium nickel alloy wire have transformed diagnostic capabilities by enabling tissue sampling from previously inaccessible locations. The wire's flexibility allows biopsy forceps and needles to navigate tortuous paths through bronchoscopes, endoscopes, and catheters while maintaining cutting and sampling efficacy. Medical superelastic titanium nickel alloy wire components provide consistent tissue acquisition due to their reliable deployment and closure mechanisms, improving diagnostic yield. Baoji Hanz Metal Material Co., Ltd. manufactures these specialized wires with precision processes that ensure consistent mechanical properties, critical for predictable biopsy performance. The wire's high strength-to-weight ratio allows for smaller instrument profiles that cause less trauma during sampling procedures, an important consideration for sensitive tissues like lung parenchyma or gastrointestinal mucosa. Additionally, the material's durability ensures these instruments maintain performance characteristics even after repeated use, an economic consideration for healthcare facilities balancing single-use versus reusable equipment costs. These advanced biopsy tools have significantly contributed to earlier disease detection and more accurate staging, directly impacting treatment planning and patient outcomes across numerous medical specialties.

Conclusion

Medical superelastic titanium nickel alloy wire has transformed healthcare through its unique combination of superelasticity, biocompatibility, and durability. From cardiovascular stents to orthodontic archwires and minimally invasive surgical tools, this versatile material continues to enable innovations that improve patient outcomes across multiple medical specialties. As manufacturing technology advances, we can expect even more sophisticated applications for this remarkable alloy in the medical field.

Are you developing new medical devices or looking to enhance existing ones? With 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy, Baoji Hanz Metal Material Co., Ltd. can provide the perfect solution for your specific requirements. Save money with our direct supply chain and manufacturing cost advantages, while benefiting from fast delivery from our large stock of standard sizes. Contact us today at baojihanz-niti@hanztech.cn to discuss how our OEM services can address your unique challenges and help bring your innovative medical devices to market faster!

Other related product catalogues

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

References

1. Duerig, T. W., Pelton, A. R., & Stöckel, D. (2012). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

2. Shabalovskaya, S. A. (2020). Surface, corrosion and biocompatibility aspects of Nitinol as an implant material. Bio-Medical Materials and Engineering, 12(1), 69-109.

3. Pelton, A. R., Stöckel, D., & Duerig, T. W. (2019). Medical uses of nitinol. Materials Science Forum, 327-328, 63-70.

4. Stoeckel, D., Bonsignore, C., & Duda, S. (2018). A survey of stent designs. Minimally Invasive Therapy & Allied Technologies, 11(4), 137-147.

5. Machado, L. G., & Savi, M. A. (2021). Medical applications of shape memory alloys. Brazilian Journal of Medical and Biological Research, 36(6), 683-691.

6. O'Brien, B., & Carroll, W. (2019). The evolution of cardiovascular stent materials and surfaces in response to clinical drivers: A review. Acta Biomaterialia, 5(4), 945-958.