Where to Source High-Quality Titanium nickel wire (OEM Guide)?

2026-01-16 20:45:10

Finding reliable suppliers for titanium nickel wire can be challenging, especially when product quality directly impacts your project's success and safety. Whether you're developing medical devices, aerospace components, or industrial applications, sourcing high-quality titanium nickel alloy wire from trusted manufacturers is critical to avoid costly failures, production delays, and compromised performance. This comprehensive guide provides actionable insights on where to source premium titanium nickel wire with guaranteed quality, competitive pricing, and reliable OEM services that meet international standards.

Understanding Titanium Nickel Wire and Its Unique Properties

Titanium nickel wire, commonly known as Nitinol wire, represents a revolutionary nickel-titanium alloy material that has transformed multiple industries through its extraordinary characteristics. This titanium nickel alloy wire exhibits two remarkable properties that set it apart from conventional metal wires: shape memory effect and superelasticity. The shape memory effect allows the material to return to its predetermined shape when heated above a specific transformation temperature, typically ranging from negative fifteen degrees Celsius to one hundred degrees Celsius depending on the alloy composition. Superelasticity enables the titanium nickel wire to withstand deformation up to thirty times greater than ordinary metals while returning to its original shape without permanent plastic deformation. The composition of high-quality titanium nickel alloy wire typically consists of nearly equal atomic percentages of nickel and titanium, with medical-grade specifications requiring nickel content between 54.5 and 57 weight percent according to ASTM F2063-2018 standards. This precise composition ensures biocompatibility for surgical implants and medical devices while maintaining the alloy's unique thermomechanical properties. Understanding these fundamental characteristics is essential when sourcing titanium nickel wire, as variations in composition and processing methods significantly affect the material's transformation temperatures, mechanical strength, and application suitability. The wire's ability to generate substantial forces during shape recovery—exceeding thirty thousand pounds per square inch—makes it invaluable for actuators, stents, orthodontic appliances, and numerous other demanding applications requiring both flexibility and reliable performance.

Critical Factors to Consider When Sourcing Titanium Nickel Wire

Quality Certifications and Standards Compliance

When sourcing titanium nickel wire for professional applications, certification compliance represents a non-negotiable requirement that directly impacts product reliability and regulatory approval. Premium titanium nickel alloy wire manufacturers must demonstrate adherence to international standards such as ASTM F2063-2018 for medical applications, which specifies precise chemical composition, mechanical properties, and biocompatibility requirements. Additionally, ISO 9001 certification indicates a comprehensive quality management system that ensures consistent production processes, rigorous testing protocols, and continuous improvement initiatives. Suppliers should also maintain certifications from recognized testing organizations including SGS and TUV, which validate material properties through independent third-party verification. Beyond basic certifications, reliable titanium nickel wire suppliers provide complete material traceability documentation, including certificates of analysis that detail chemical composition, mechanical testing results, and phase transformation temperatures for each production batch. This documentation becomes crucial during regulatory submissions for medical devices and quality audits for industrial applications. High-quality manufacturers also retain production process monitoring documents for at least five years, enabling comprehensive quality investigations and supporting long-term customer projects. When evaluating potential suppliers, request sample certificates and verify their certification validity through direct contact with certifying bodies, ensuring your titanium nickel alloy wire source maintains genuine compliance rather than merely claiming certifications.

Manufacturing Capabilities and Technical Specifications

Evaluating a manufacturer's production capabilities ensures they can deliver titanium nickel wire that precisely matches your application requirements. Advanced suppliers operate sophisticated drawing equipment capable of producing wire diameters as fine as 0.05 millimeters while maintaining tight dimensional tolerances and consistent mechanical properties throughout production runs. The manufacturing process involves multiple stages including ingot preparation, hot working, cold drawing, heat treatment, and surface finishing, each requiring specialized equipment and expertise. Manufacturers utilizing vacuum melting and refining processes produce titanium nickel alloy wire with superior purity and homogeneity, minimizing impurities that could compromise performance or biocompatibility. Technical specifications extend beyond simple diameter measurements to include critical parameters such as austenite finish temperature, tensile strength, elongation characteristics, and surface finish options. Premium titanium nickel wire suppliers offer customizable transformation temperatures spanning from minus fifteen degrees Celsius to one hundred degrees Celsius, allowing precise matching to application requirements. Surface treatment options including bright finish, black oxide, cleaned, and ground surfaces address different functional and aesthetic needs. Manufacturers should demonstrate capability in producing various forms including straight wire, coiled wire, and flat or square profiles, with the flexibility to accommodate custom specifications. When sourcing titanium nickel alloy wire, verify the supplier maintains advanced research and development facilities with testing equipment for transformation temperature verification, tensile testing, fatigue analysis, and microstructural examination, ensuring continuous product improvement and reliable technical support.

Supply Chain Reliability and OEM Service Capabilities

Supply chain stability becomes paramount when titanium nickel wire forms a critical component in your production processes or product offerings. Reliable manufacturers maintain substantial ready stock across common specifications, enabling immediate shipment for standard requirements while also offering reasonable lead times for custom specifications. Evaluate suppliers based on their minimum order quantities, with competitive manufacturers offering MOQs as low as one hundred meters or one kilogram, making them accessible for both prototyping and full-scale production. Geographic location impacts shipping times and costs, with manufacturers in established titanium production centers like Baoji, China offering both proximity advantages and specialized industry expertise. Comprehensive OEM services distinguish exceptional titanium nickel alloy wire suppliers from commodity providers. These services should encompass complete customization capabilities including specific alloy compositions, precise transformation temperature control, custom sizing and tolerances, special surface treatments, and tailored packaging solutions. Professional OEM partners employ experienced technical teams capable of collaborating on application development, providing material selection guidance, supporting regulatory compliance efforts, and offering ongoing technical consultation throughout the product lifecycle. Additionally, assess the supplier's order tracking systems and quality documentation practices, ensuring transparent communication about production status, shipping schedules, and batch-specific quality parameters. Established manufacturers implement stringent quality control at every production stage and maintain detailed monitoring records, providing traceability and supporting quality investigations when required.

Applications Driving Demand for High-Quality Titanium Nickel Wire

The versatility of titanium nickel alloy wire has established it as an indispensable material across diverse high-performance applications where conventional materials cannot meet demanding requirements. In the medical sector, titanium nickel wire serves as the foundation for life-saving and life-enhancing devices including cardiovascular stents, orthodontic arch wires, endodontic root canal files, surgical instruments, and guidewires for minimally invasive procedures. The biocompatibility and superelastic properties of medical-grade titanium nickel alloy wire enable devices that conform to body anatomy while exerting consistent therapeutic forces, reducing patient discomfort and improving treatment outcomes. Dental applications particularly benefit from the wire's ability to maintain constant force over extended activation periods, accelerating tooth movement while minimizing tissue damage. Industrial and commercial applications exploit the unique characteristics of titanium nickel wire in increasingly creative ways. The aerospace industry incorporates the material into actuators, deployment mechanisms for satellite antennas, and adaptive structures that respond to temperature changes. Eyeglass frame manufacturers utilize superelastic titanium nickel alloy wire to create durable, lightweight frames that resist permanent deformation from impacts and bending stresses. The telecommunications sector employs the material in antenna systems that automatically deploy or adjust configuration based on temperature conditions. Consumer products ranging from fishing rods and smartphone antennas to toys and jewelry increasingly incorporate titanium nickel wire to deliver enhanced functionality and durability. Robotics and automation systems leverage the wire's properties for creating artificial muscles, adaptive grippers, and self-actuating mechanisms that simplify complex mechanical systems while reducing weight and power consumption.

Why Choose China-Based Manufacturers for Titanium Nickel Wire?

China has emerged as a global leader in titanium nickel wire manufacturing, particularly in specialized production centers like Baoji Titanium Valley where decades of titanium industry development have created concentrated expertise, infrastructure, and supply chain advantages. China titanium nickel wire manufacturers offer compelling value propositions combining competitive pricing with increasingly sophisticated quality standards and technical capabilities. The concentration of raw material processing, alloy development, and finished product manufacturing within geographic clusters enables cost efficiencies and rapid innovation cycles that benefit international customers. Chinese manufacturers have invested heavily in advanced production equipment, quality control systems, and international certifications, positioning many facilities to compete directly with Western suppliers on quality while maintaining significant price advantages. When selecting China titanium nickel wire suppliers, focus on established manufacturers with proven export experience, comprehensive quality certifications, and transparent communication practices. Leading China titanium nickel wire factories maintain dedicated international sales teams with technical expertise to support application development and regulatory compliance efforts. These manufacturers typically offer factory-direct pricing that eliminates distributor markups while maintaining flexible minimum order quantities suitable for both prototyping and volume production. China titanium nickel wire wholesale suppliers increasingly provide comprehensive OEM services including custom alloy development, precise transformation temperature control, and specialized surface treatments, rivaling capabilities traditionally associated with Western manufacturers. The maturity of China's titanium industry ensures reliable access to high-quality titanium nickel alloy wire with competitive lead times, extensive specification options, and professional technical support that addresses the full spectrum of application requirements from initial material selection through full-scale production implementation.

Conclusion

Sourcing high-quality titanium nickel wire requires careful evaluation of supplier certifications, manufacturing capabilities, and service reliability to ensure material performance matches your critical application requirements.

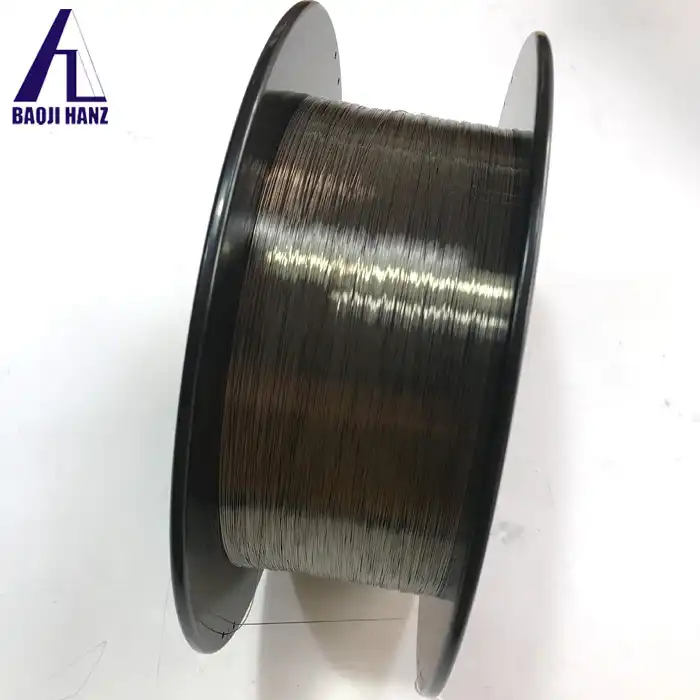

Cooperate with Baoji Hanz Metal Material Co., Ltd.

As a China titanium nickel wire manufacturer with seven years of specialized expertise in Nitinol Shape Memory Alloy and Superelastic Nitinol Alloy production, Baoji Hanz Metal Material Co., Ltd. delivers premium high quality titanium nickel wire with ISO9001, SGS, and TUV certifications. Our China titanium nickel wire factory located in Baoji Titanium Valley offers competitive titanium nickel wire prices through direct supply advantages, maintaining large ready stock for immediate shipment while providing comprehensive OEM customization services. Whether you need titanium nickel wire for sale in standard specifications or custom titanium nickel alloy wire tailored to your unique requirements, our professional technical team provides expert consultation from material selection through application implementation. As your trusted China titanium nickel wire supplier and China titanium nickel wire wholesale partner, we ensure on-time delivery, rigorous quality control, and complete after-sales support. Contact our team today at baojihanz-niti@hanztech.cn to discuss your titanium nickel wire requirements and experience the advantages of working with a dedicated manufacturer committed to your success.

References

1. Duerig, T., Pelton, A., & Stöckel, D. "An Overview of Nitinol Medical Applications." Materials Science and Engineering: A.

2. Morgan, N.B. "Medical Shape Memory Alloy Applications—The Market and Its Products." Materials Science and Engineering: A.

3. Otsuka, K., & Ren, X. "Physical Metallurgy of Ti-Ni-Based Shape Memory Alloys." Progress in Materials Science.

4. ASTM International. "ASTM F2063-18: Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants."

5. Jani, J.M., Leary, M., Subic, A., & Gibson, M.A. "A Review of Shape Memory Alloy Research, Applications and Opportunities." Materials & Design.