Why Buy OEM Titanium nickel wire? Advantages Explained

2026-01-07 14:30:42

When precision medical devices fail mid-procedure or industrial components break under stress, the consequences can be catastrophic. Traditional wire materials often fall short in demanding applications, leaving engineers and medical professionals searching for solutions that deliver both flexibility and strength without compromise. OEM titanium nickel wire solves these critical challenges with its unique shape memory and superelastic properties, making it the material of choice for applications where failure is not an option. Understanding why OEM titanium nickel wire offers superior advantages can transform your product performance and reliability.

Understanding the Unique Properties of Titanium Nickel Wire

Titanium nickel wire, commonly known as nitinol or nickel titanium alloy wire, represents a breakthrough in material science that combines approximately equal parts nickel and titanium to create an alloy with extraordinary capabilities. Unlike conventional metal wires, this titanium nickel alloy wire exhibits two remarkable and closely related properties that set it apart in critical applications across multiple industries. The shape memory effect allows the material to undergo significant deformation at one temperature, maintain its deformed configuration when external forces are removed, then recover its original shape upon heating above its transformation temperature. This thermomechanical behavior makes titanium nickel wire invaluable for applications requiring temperature-activated deployment, such as cardiovascular stents that navigate through narrow blood vessels in a compressed state before expanding to their functional shape at body temperature. The superelasticity characteristic of titanium nickel wire enables it to withstand elastic deformations ten to thirty times larger than alternative metals, immediately returning to its undeformed shape upon removal of external load without requiring any heating. This superelastic behavior occurs within a narrow temperature range just above the transformation temperature, making titanium nickel alloy wire perfect for applications demanding exceptional flexibility combined with reliable shape recovery. Medical guidewires manufactured from this material can navigate through tortuous anatomical pathways while maintaining their integrity, dental arch wires provide consistent orthodontic forces throughout treatment cycles, and industrial components endure repeated loading cycles without permanent deformation. The phase transition temperature of titanium nickel wire can be precisely controlled during manufacturing, ranging from negative fifteen degrees Celsius to one hundred degrees Celsius, allowing engineers to customize the material's behavior for specific application requirements and environmental conditions.

Mechanical Advantages Over Traditional Wire Materials

The mechanical performance of titanium nickel wire surpasses traditional materials in several critical aspects that directly impact product functionality and longevity. When compared to stainless steel wire, titanium nickel alloy wire demonstrates superior fatigue resistance, withstanding millions of loading cycles without failure in applications involving repeated flexing or stress. This exceptional fatigue life makes it ideal for dynamic medical devices such as retrieval baskets and surgical instruments that must perform reliably throughout numerous procedures without material degradation. The high tensile strength combined with remarkable flexibility allows titanium nickel wire to maintain structural integrity even when subjected to significant bending or torsional forces that would permanently deform or fracture conventional wire materials. The corrosion resistance of titanium nickel alloy wire exceeds both titanium and stainless steel alloys, enabling it to withstand exposure to harsh chemical environments, body fluids, and extreme temperatures without degradation. This durability proves essential for long-term medical implants that remain in the body for years, industrial furnace components operating at elevated temperatures, and marine applications exposed to saltwater corrosion. The biocompatibility of properly processed titanium nickel wire makes it safe for direct contact with human tissue, with the surface oxide layer providing protection against nickel ion release when correctly treated through electropolishing or other surface finishing techniques. Medical-grade titanium nickel alloy wire meeting ASTM F2063-2018 standards undergoes rigorous testing to ensure consistent transformation temperatures, material homogeneity, and microstructure quality, guaranteeing reliable performance in critical healthcare applications where patient safety depends on material reliability.

Why Choose OEM Titanium Nickel Wire Solutions?

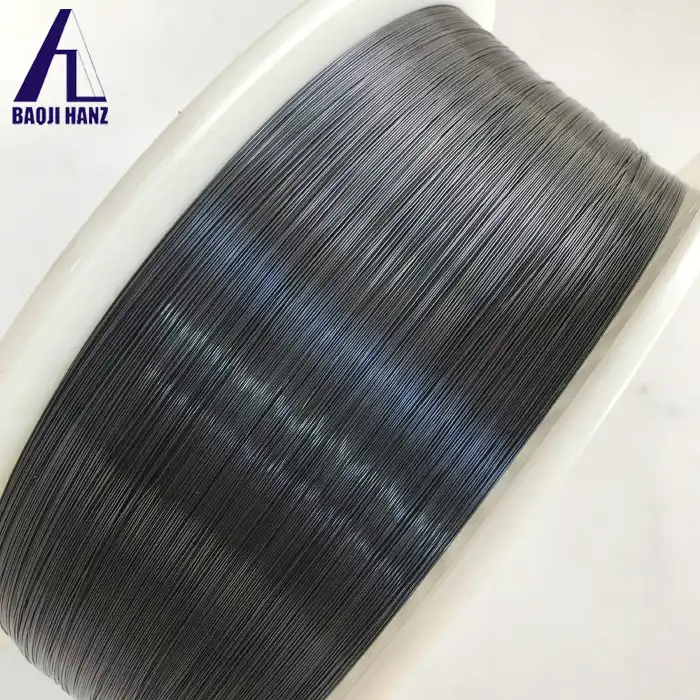

Selecting OEM titanium nickel wire from specialized manufacturers provides distinct advantages over generic wire products, particularly regarding customization capabilities and quality assurance. OEM manufacturers possess the advanced equipment and technical expertise required to precisely control the complex metallurgical processes that determine the final properties of titanium nickel alloy wire. The shape-setting heat treatment, which establishes the material's transformation temperatures and mechanical characteristics, requires specialized knowledge and controlled atmosphere furnaces to achieve consistent results. Manufacturers offering OEM services can customize wire specifications including diameter dimensions starting from as small as 0.05 millimeters, transformation temperature ranges tailored to specific applications, surface finishes from bright to black oxide or electropolished, and delivery formats whether as straight wire, coiled wire, or custom-formed components. The quality control systems implemented by reputable OEM titanium nickel wire manufacturers ensure every production lot meets stringent international standards including ISO9001, SGS, and TUV certifications. These certification requirements mandate comprehensive testing protocols that verify chemical composition accuracy, transformation temperature consistency, mechanical property uniformity, and surface quality standards. Manufacturers retain production process monitoring documents for a minimum of five years, providing complete traceability for medical device applications subject to regulatory scrutiny. This documentation capability proves invaluable when quality issues arise or when regulatory bodies require evidence of manufacturing compliance. Working directly with OEM suppliers eliminates intermediary markups, providing cost advantages while ensuring direct communication with technical experts who understand the material's nuances and can provide application-specific recommendations based on years of manufacturing experience.

Customization Capabilities for Specific Applications

The flexibility of OEM titanium nickel wire manufacturing allows for precise customization that standard off-the-shelf products cannot provide, enabling engineers to optimize material properties for their unique application requirements. Phase transition temperatures can be adjusted across a wide range from negative fifteen degrees Celsius to one hundred degrees Celsius by carefully controlling the nickel-to-titanium ratio and incorporating ternary alloying elements such as copper. This temperature customization capability allows medical device designers to create instruments that activate at body temperature, industrial engineers to develop temperature-sensitive actuators, and robotics specialists to build adaptive structures that respond to environmental thermal changes. The wire diameter can be manufactured to extraordinarily precise tolerances, with medical-grade production utilizing proprietary single and multi-crystalline diamond drawing die technology that promotes exceptionally smooth and uniform surface finish quality essential for minimizing tissue trauma in medical applications.

Surface treatment options for titanium nickel alloy wire significantly impact both functional performance and aesthetic appearance, with OEM manufacturers offering multiple finishing alternatives. Pickled surfaces involve chemical removal of the oxide layer along with slight base metal removal, creating a rough texture appropriate for enhanced adhesion in coated applications. Etched and mechanically polished surfaces combine chemical oxide removal with mechanical polishing to achieve a stainless steel-like appearance, though microscopic scratches remain visible under high magnification. Electropolishing produces the smoothest surface finish by selectively removing surface irregularities through electrochemical dissolution, resulting in a bright, uniform appearance with enhanced corrosion resistance and reduced risk of particulate generation. Black oxide heat treatment creates a thick protective layer that some applications prefer for visual identification or reduced reflectivity, though this finish requires careful handling to prevent flaking. OEM suppliers can also provide custom wire configurations including braided constructions for catheter reinforcement, coiled forms for stent applications, and precision-formed shapes for specialized medical or industrial components.

Cost-Effectiveness and Long-Term Value

Despite the higher initial material cost compared to conventional wire alloys, OEM titanium nickel wire delivers superior long-term value through extended service life, reduced maintenance requirements, and enhanced performance capabilities. The exceptional fatigue resistance of titanium nickel alloy wire dramatically reduces replacement frequency in dynamic applications, translating to lower lifecycle costs when total ownership expenses are calculated over the product's operational lifetime. Medical devices manufactured from this material require fewer adjustments during use, reducing procedure time and associated costs while improving patient comfort and treatment outcomes. Industrial components fabricated from titanium nickel wire demonstrate extended operational life in harsh environments where traditional materials would fail prematurely, avoiding costly downtime and replacement expenses. The enabling nature of titanium nickel alloy wire allows engineers to design products that simply cannot be created with conventional materials, opening new market opportunities and competitive advantages. Minimally invasive surgical devices leverage the material's ability to navigate through small access points before deploying into functional configurations, reducing patient trauma and recovery times compared to traditional open surgical approaches. Aerospace actuators utilize the shape memory effect to create lightweight, electrically-activated mechanisms that replace heavier hydraulic or pneumatic systems, improving fuel efficiency and reducing maintenance complexity. The superior strength-to-weight ratio of titanium nickel wire compared to stainless steel enables weight reduction in applications where mass minimization provides performance benefits, particularly in aerospace, automotive, and portable medical device applications where every gram matters. Working with experienced OEM suppliers ensures access to technical support throughout the product development cycle, from initial material selection and prototype development through volume production and ongoing quality improvement initiatives.

Applications Driving Demand for Titanium Nickel Wire

The medical device industry represents the largest and fastest-growing market for titanium nickel wire, driven by the material's unique combination of biocompatibility, flexibility, and shape memory properties. Cardiovascular stents manufactured from superelastic titanium nickel alloy wire provide life-saving treatment for blocked arteries, navigating through blood vessels in a compressed configuration before self-expanding to hold vessels open and restore blood flow. The superelasticity ensures these devices conform to vessel anatomy while maintaining radial force, and the corrosion resistance guarantees long-term performance within the challenging environment of the human circulatory system. Orthodontic arch wires fabricated from heat-activated titanium nickel wire deliver consistent corrective forces throughout treatment, reducing the number of adjustment appointments required and improving patient comfort compared to stainless steel alternatives that apply higher initial forces. Surgical instruments including root canal files, retrieval baskets, biopsy forceps, and minimally invasive surgical tools rely on the exceptional flexibility and kink resistance of titanium nickel alloy wire to perform delicate procedures through small incisions or natural body openings. The material's ability to flex repeatedly without permanent deformation allows these instruments to navigate anatomical curves while maintaining tip control and tactile feedback essential for surgical precision. Medical guidewires incorporating titanium nickel wire cores provide the pushability required to advance catheters through vascular systems while maintaining the flexibility necessary to follow vessel tortuosity without causing trauma or perforation. The biocompatibility and corrosion resistance ensure these devices can remain in contact with tissues and body fluids throughout lengthy procedures without adverse reactions or performance degradation.

Industrial and Aerospace Applications

Beyond healthcare, titanium nickel wire serves critical functions in aerospace, automotive, robotics, and industrial applications where its unique properties enable performance breakthroughs. Aerospace actuators and deployment mechanisms leverage the shape memory effect to create compact, lightweight systems that activate through electrical heating rather than requiring heavy hydraulic or pneumatic infrastructure. Satellite antennas and solar panel deployment systems utilize titanium nickel alloy wire components that fold into compact configurations for launch before deploying into operational positions through temperature activation once in orbit. The high strength-to-weight ratio and resistance to temperature extremes make titanium nickel wire ideal for aerospace environments where traditional materials would add unacceptable mass or fail under thermal cycling conditions. Automotive applications increasingly incorporate titanium nickel wire in advanced safety systems, engine components, and adaptive structures that respond to operating conditions. Shape memory alloy actuators provide precise control for applications including variable valve timing, active aerodynamic adjustments, and automated climate control systems. The material's vibration damping characteristics make it valuable for noise reduction applications, while its corrosion resistance extends component life in harsh under-hood environments exposed to heat, chemicals, and moisture. Industrial furnace applications utilize titanium nickel alloy wire for high-temperature resistant components, radiation shielding, and specialized heating elements where conventional materials would oxidize or lose mechanical properties. Robotics and automation systems employ titanium nickel wire for creating flexible joints, adaptive grippers, and soft actuators that mimic biological movement patterns, enabling robots to safely interact with humans and handle delicate objects without damage.

Quality Standards and Manufacturing Excellence

The production of high-quality titanium nickel wire requires sophisticated manufacturing capabilities, rigorous quality control systems, and deep metallurgical expertise. Raw material preparation begins with high-purity nickel and titanium sourcing, followed by vacuum induction melting to create homogeneous ingots with precisely controlled chemical compositions. The ingot transformation temperature, material homogeneity, and microstructure are verified before proceeding to hot drawing operations that reduce the ingot diameter while maintaining uniform properties throughout the material. Cold drawing processes using diamond dies progressively reduce wire diameter to final dimensions, with intermediate annealing cycles relieving work hardening and controlling grain structure. Each processing step influences the final wire properties, requiring careful parameter control and continuous monitoring to ensure consistency. The critical shape-setting heat treatment determines the wire's transformation temperatures, establishing whether it exhibits shape memory behavior, superelastic characteristics, or intermediate properties depending on the intended application requirements. This heat treatment must be performed in controlled atmosphere or vacuum furnaces to prevent surface oxidation and contamination that would compromise biocompatibility and corrosion resistance. Temperature accuracy, time at temperature, and cooling rate all impact final properties, requiring precise furnace control and validated thermal cycles. Surface finishing through mechanical polishing, chemical etching, or electropolishing removes the thick black oxide layer formed during heat treatment, creating smooth surfaces essential for medical applications while enhancing corrosion resistance and aesthetic appearance. Quality testing includes transformation temperature verification through differential scanning calorimetry, mechanical property evaluation through tensile testing, surface quality assessment through microscopy, and chemical composition confirmation through spectroscopic analysis.

Certifications and Compliance Requirements

Medical-grade titanium nickel wire must meet stringent international standards including ASTM F2063-2018 for wrought nickel-titanium shape memory alloys used in medical devices and implants. This specification defines chemical composition ranges, mechanical property requirements, transformation temperature testing methods, and quality assurance procedures that manufacturers must follow to ensure material consistency and reliability. ISO13485 certification demonstrates a manufacturer's commitment to quality management systems specifically designed for medical device production, encompassing design controls, risk management, process validation, and post-market surveillance. SGS and TUV certifications provide third-party verification that products meet international quality and safety standards, giving buyers confidence that materials will perform as specified in critical applications. Manufacturers serving the medical device industry must maintain comprehensive documentation systems that provide complete traceability from raw material sourcing through final product delivery. Batch certificates provide detailed information about chemical composition, mechanical properties, transformation temperatures, and surface quality for each production lot, enabling device manufacturers to verify that materials meet their specifications and regulatory requirements. Production process monitoring documents including furnace temperature charts, drawing die inspection records, and testing results must be retained for a minimum of five years to support regulatory submissions and respond to quality investigations. This documentation rigor ensures that any quality issues can be traced to root causes and corrective actions implemented to prevent recurrence, protecting both patient safety and manufacturer reputation in highly regulated markets.

Selecting the Right OEM Manufacturer Partner

Choosing the appropriate OEM titanium nickel wire supplier significantly impacts product development success, manufacturing efficiency, and long-term business relationships. Manufacturers located in established material production regions such as Baoji Titanium Valley in China benefit from concentrated expertise, specialized supply chains, and advanced infrastructure dedicated to titanium and nickel-titanium alloy production. These industrial clusters provide access to raw material suppliers, processing equipment manufacturers, testing laboratories, and skilled workforce, creating efficiencies that translate to competitive pricing and shorter lead times. Supplier experience measured in years of specialized production provides assurance that technical challenges can be anticipated and resolved, drawing upon accumulated knowledge from thousands of prior applications and problem-solving situations. Technical support capabilities distinguish exceptional OEM suppliers from commodity wire providers, offering value that extends far beyond the physical material. Pre-sale consultation services provide access to materials engineers and applications specialists who can recommend optimal alloy compositions, transformation temperatures, wire diameters, and surface finishes based on specific application requirements and operating conditions. This expertise proves invaluable during product development when design decisions impact manufacturability, performance, and cost. Prototyping and sample testing services allow designers to evaluate material performance in actual application conditions before committing to volume production, reducing risk and avoiding costly design iterations. Order tracking services provide visibility into production status, quality testing results, and shipping logistics, enabling buyers to plan inventory and coordinate with downstream manufacturing operations.

Building Long-Term Supplier Relationships

After-sales support distinguishes world-class OEM titanium nickel wire manufacturers from transactional vendors, creating partnerships that drive continuous improvement and mutual success. Usage tracking services monitor how products perform in actual applications, identifying opportunities for material optimization, processing refinement, or specification adjustments that enhance performance or reduce costs. Comprehensive industry solution development leverages supplier expertise to solve emerging challenges, adapt to new regulations, or capitalize on market opportunities requiring material innovation. Technical problem-solving support provides rapid response when quality issues arise, drawing upon metallurgical knowledge and manufacturing experience to diagnose root causes and implement corrective actions that restore performance and prevent recurrence. Flexibility in minimum order quantities accommodates both small development projects and large production runs, removing barriers for startups and researchers while scaling efficiently to support established manufacturers' volume requirements. Custom packaging options protect wire during shipping and storage while facilitating efficient handling in customer manufacturing operations, whether that means precision-wound spools, protective tubes for straight wire, or specialized configurations for automated processing equipment. Delivery reliability ensures materials arrive when needed, supporting just-in-time manufacturing strategies and avoiding costly production interruptions due to material shortages. Pricing transparency and long-term supply agreements provide cost predictability that enables accurate product costing and competitive market positioning, while protecting against market volatility and ensuring supply security for strategic products.

Conclusion

OEM titanium nickel wire delivers unmatched advantages through its unique shape memory and superelastic properties, making it essential for demanding medical, aerospace, and industrial applications where conventional materials fail. Selecting experienced manufacturers ensures quality, customization capabilities, and technical support that transform this remarkable material into successful products.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Partner with Baoji Hanz Metal Material Co., Ltd., your trusted China titanium nickel wire manufacturer and China titanium nickel wire supplier with seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy production. As a leading China titanium nickel wire factory offering China titanium nickel wire wholesale, we deliver high quality titanium nickel wire for sale at competitive titanium nickel wire prices through direct supply and cost advantages. Fast delivery from large stock ensures your projects stay on schedule. Our ISO9001, SGS, and TUV certifications guarantee the highest quality standards, while our professional customer service staff and technicians provide comprehensive pre-sale consultation, order tracking with five-year process documentation retention, and dedicated after-sales support. We offer complete OEM services to customize specifications meeting your exact requirements. Contact us at baojihanz-niti@hanztech.cn to discuss your titanium nickel wire needs. Save this page for easy reference when quality and reliability matter most.

References

1. Duerig, Thomas W., Alan R. Pelton, and Denis Stöckel. "An Overview of Nitinol Medical Applications." Materials Science and Engineering: A, Elsevier Science Publishers.

2. Morgan, Neil B. "Medical Shape Memory Alloy Applications—The Market and Its Products." Materials Science and Engineering: A, International Journal of Materials Science.

3. Otsuka, Kazuhiro, and Clarence M. Wayman. "Shape Memory Materials." Cambridge University Press, Cambridge Materials Science Series.

4. Pelton, Alan R., Scott M. Russell, and John DiCello. "The Physical Metallurgy of Nitinol for Medical Applications." Journal of Metals, The Minerals, Metals & Materials Society.

5. Shabalovskaya, Svetlana A. "Surface, Corrosion and Biocompatibility Aspects of Nitinol as an Implant Material." Bio-Medical Materials and Engineering, IOS Press.