Why Choose Nitinol Strip for High-Precision Applications?

2025-08-05 21:13:53

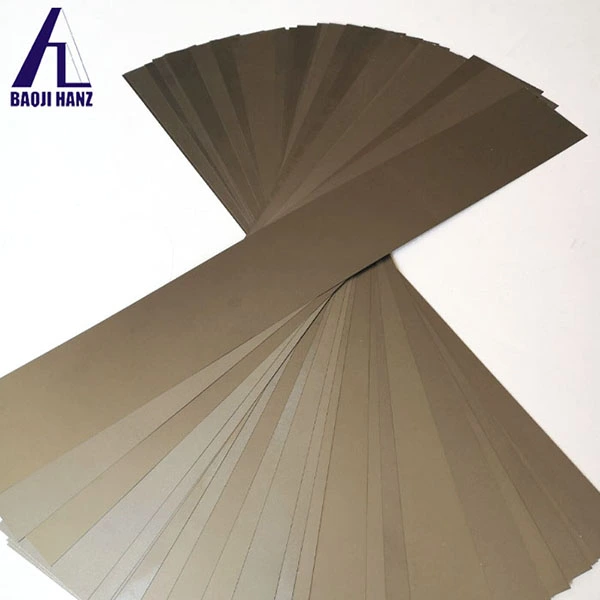

In the rapidly evolving world of advanced materials science, the demand for components that deliver exceptional performance under extreme conditions has never been higher. High-precision applications across aerospace, medical devices, robotics, and automotive industries require materials that can withstand demanding operational environments while maintaining their functional integrity. Among the most revolutionary materials meeting these stringent requirements is the nitinol strip, a nickel-titanium alloy that combines unique superelastic properties with shape memory capabilities. This extraordinary material offers engineers and designers unprecedented opportunities to create innovative solutions that were previously impossible with conventional materials. The nitinol strip's ability to return to its original shape after deformation, coupled with its biocompatibility and corrosion resistance, makes it an indispensable component in applications where precision, reliability, and performance are non-negotiable.

Superior Material Properties for Demanding Applications

Exceptional Superelastic Characteristics

The superelastic properties of nitinol strip represent one of its most compelling advantages for high-precision applications. Unlike conventional metals that undergo permanent deformation when stressed beyond their elastic limit, nitinol strip can undergo substantial mechanical deformation and return to its original shape upon unloading. This remarkable characteristic stems from the material's unique crystal structure transformation, which occurs at the atomic level during stress application. The nitinol strip manufactured by Baoji Hanz Metal Material Co., Ltd. demonstrates exceptional superelastic behavior with the ability to recover from strains up to 8-10%, significantly higher than traditional spring steels or stainless steel alloys. This property makes nitinol strip ideal for applications requiring repetitive flexing, bending, or compression cycles without material fatigue. In high-precision instruments, this translates to longer operational life, reduced maintenance requirements, and consistent performance over extended periods. The superelastic nature of nitinol strip also provides excellent damping characteristics, which is crucial in precision machinery where vibration control is essential for accurate operation.

Advanced Shape Memory Functionality

The shape memory effect of nitinol strip opens up revolutionary possibilities for high-precision applications that require active control and self-actuation capabilities. This unique property allows the nitinol strip to remember and return to a predetermined shape when heated above its transformation temperature. The material can be programmed to assume complex geometries, making it invaluable in applications where space constraints and precise positioning are critical. Baoji Hanz's nitinol strip offers customizable transformation temperatures ranging from -20°C to 100°C, allowing engineers to tailor the material's activation temperature to specific application requirements. This programmable nature of nitinol strip enables the creation of smart devices that can respond to environmental changes automatically, eliminating the need for external actuators or control systems. In precision applications, this self-actuating capability ensures consistent performance and eliminates potential points of failure associated with complex mechanical systems. The shape memory effect also provides excellent positioning accuracy, as the material returns to its programmed shape with remarkable precision, making it ideal for applications requiring micro-positioning and fine adjustments.

Optimal Chemical Composition and Structural Integrity

The chemical composition of nitinol strip plays a crucial role in determining its performance characteristics and suitability for high-precision applications. Baoji Hanz's nitinol strip contains 54.5-56.5% nickel with titanium balance, a composition that has been optimized through years of research and development to provide the ideal balance of superelastic properties, shape memory effects, and mechanical strength. This precise chemical composition ensures consistent transformation temperatures and reliable performance across various operating conditions. The atomic-level bonding between nickel and titanium atoms creates a crystal structure that can undergo reversible phase transformations without permanent damage to the material matrix. This structural integrity is particularly important in high-precision applications where material consistency and predictable behavior are essential. The nitinol strip's density of 6.5g/cc provides an excellent strength-to-weight ratio, making it suitable for applications where weight reduction is crucial without compromising performance. The material's inherent corrosion resistance, derived from its unique chemical composition, ensures long-term reliability in various environmental conditions, including exposure to moisture, chemicals, and temperature variations.

Manufacturing Excellence and Quality Assurance

Advanced Production Techniques and Equipment

The manufacturing process of nitinol strip requires sophisticated equipment and precise control over numerous variables to achieve the exceptional quality demanded by high-precision applications. Baoji Hanz Metal Material Co., Ltd. employs state-of-the-art production facilities equipped with advanced melting, rolling, and heat treatment systems specifically designed for nitinol alloy processing. The company's production line includes vacuum induction melting furnaces that ensure precise chemical composition control and minimize impurities that could affect the material's performance. The rolling process utilizes specially designed equipment capable of producing nitinol strip with thickness tolerances as tight as ±0.01mm and width tolerances of ±0.02mm, meeting the stringent dimensional requirements of high-precision applications. The heat treatment processes are carefully controlled using computer-automated systems that monitor temperature, atmosphere, and cooling rates to ensure consistent transformation temperatures and optimal mechanical properties. This manufacturing excellence ensures that every nitinol strip meets the demanding specifications required for precision applications, with minimal variation between batches and exceptional reproducibility of material properties.

Comprehensive Quality Control and Testing Protocols

Quality assurance in nitinol strip manufacturing involves extensive testing and validation procedures that go beyond standard material testing protocols. Baoji Hanz implements a comprehensive quality control system that includes chemical analysis, mechanical property testing, transformation temperature verification, and dimensional inspection for every batch of nitinol strip produced. The company's testing facilities are equipped with advanced analytical instruments including X-ray fluorescence spectrometers for chemical composition analysis, differential scanning calorimeters for transformation temperature measurement, and universal testing machines for mechanical property evaluation. Each nitinol strip undergoes rigorous inspection to verify its superelastic properties, shape memory characteristics, and dimensional accuracy. The company maintains detailed documentation of all production processes and testing results, providing full traceability for each batch of material. This comprehensive approach to quality control ensures that customers receive nitinol strip that meets or exceeds their specifications, with consistent performance characteristics that are essential for high-precision applications. The company's commitment to quality is further demonstrated by its compliance with international standards including ISO9001, SGS, and TUV guidelines.

Customization Capabilities and Technical Support

The ability to customize nitinol strip properties and dimensions is crucial for high-precision applications where standard specifications may not meet specific requirements. Baoji Hanz offers extensive customization capabilities, including the ability to adjust transformation temperatures, modify surface finishes, and produce strips with specific dimensional characteristics. The company's technical team works closely with customers to understand their application requirements and develop tailored solutions that optimize performance for specific use cases. This customization capability extends to the selection of appropriate surface treatments, with options for both bright and black finishes depending on the application requirements. The nitinol strip can be supplied in various forms including flat strips, coiled configurations, or spooled arrangements to facilitate different manufacturing processes and installation requirements. The company's technical support extends beyond material supply to include application guidance, processing recommendations, and troubleshooting assistance. This comprehensive support ensures that customers can successfully integrate nitinol strip into their high-precision applications with confidence in achieving optimal performance results.

Real-World Applications and Performance Benefits

Medical Device Integration and Biocompatibility

The medical device industry represents one of the most demanding applications for nitinol strip, where biocompatibility, precision, and reliability are paramount. Nitinol strip's exceptional biocompatibility makes it suitable for long-term implantation in the human body without adverse reactions or degradation of material properties. The material's superelastic properties closely match the elastic modulus of human bone, reducing stress shielding effects that can occur with stiffer materials. In cardiovascular applications, nitinol strip is used in the manufacture of stents, guidewires, and other interventional devices where precise deployment and consistent radial force are critical for successful outcomes. The material's shape memory properties enable the creation of self-expanding devices that can be compressed for delivery and automatically expand to their predetermined shape upon deployment. The nitinol strip's excellent fatigue resistance ensures long-term performance in applications involving repetitive loading, such as heart valve components and orthopedic implants. The material's corrosion resistance in bodily fluids provides long-term stability and biocompatibility, essential for permanent implants. Baoji Hanz's nitinol strip meets the stringent requirements for medical applications, with careful control over impurity levels and surface characteristics that could affect biocompatibility.

Aerospace and Automotive Engineering Solutions

The aerospace and automotive industries demand materials that can perform reliably under extreme conditions while contributing to weight reduction and improved efficiency. Nitinol strip's unique properties make it an ideal choice for applications ranging from actuators and sensors to structural components and control systems. In aerospace applications, the material's ability to function across a wide temperature range, from cryogenic conditions to high-temperature environments, makes it suitable for space applications where temperature variations are extreme. The nitinol strip's superelastic properties provide excellent vibration damping characteristics, crucial for precision instruments and navigation systems that must maintain accuracy despite the harsh operational environment. In automotive applications, nitinol strip is increasingly used in smart systems such as active aerodynamic components, temperature-controlled ventilation systems, and advanced safety mechanisms. The material's ability to provide consistent force output over its operational range makes it ideal for applications requiring precise control and positioning. The fatigue resistance of nitinol strip ensures long-term reliability in applications involving millions of cycles, such as engine components and suspension systems. Baoji Hanz's nitinol strip meets the demanding specifications required for these critical applications, with proven performance in extreme environmental conditions.

Industrial Automation and Robotics Applications

The growing field of industrial automation and robotics presents numerous opportunities for nitinol strip applications where precision, reliability, and compact design are essential. The material's ability to provide both sensing and actuation capabilities in a single component makes it particularly valuable for robotic systems where space and weight constraints are critical. Nitinol strip can be used to create flexible joints and actuators that provide smooth, precise motion control without the complexity of traditional mechanical systems. The material's superelastic properties enable the creation of gripper mechanisms that can adapt to various object shapes while maintaining consistent gripping force. In precision manufacturing equipment, nitinol strip components provide excellent repeatability and accuracy, essential for maintaining tight tolerances in automated production processes. The material's resistance to fatigue and environmental factors ensures long-term reliability in industrial environments where continuous operation is required. Smart manufacturing systems benefit from nitinol strip's ability to provide feedback on position, force, and temperature, enabling more sophisticated control algorithms and predictive maintenance capabilities. Baoji Hanz's nitinol strip is engineered to meet the demanding requirements of industrial automation, with consistent performance characteristics that ensure reliable operation in challenging manufacturing environments.

Conclusion

The unique combination of superelastic properties, shape memory effects, and exceptional reliability makes nitinol strip an indispensable material for high-precision applications across diverse industries. Its ability to deliver consistent performance under demanding conditions, coupled with excellent biocompatibility and corrosion resistance, positions it as the material of choice for next-generation precision devices. The advanced manufacturing capabilities and comprehensive quality assurance protocols ensure that every nitinol strip meets the stringent requirements of modern high-precision applications, providing engineers and designers with the confidence to push the boundaries of what's possible in their respective fields.

Ready to experience the superior performance of nitinol strip in your high-precision applications? As a leading China nitinol strip factory and China nitinol strip supplier, Baoji Hanz Metal Material Co., Ltd. combines seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy to deliver unmatched quality and value. Our direct supply model and cost advantages help you save money while ensuring fast delivery from our large stock of standard sizes. As your trusted China nitinol strip manufacturer and China nitinol strip wholesale partner, we provide OEM services tailored to your specific requirements, whether it's custom sizes, specific alloy compositions, or specialized packaging options. Our expert team works closely with you to ensure seamless integration of our products into your projects. Contact us today at baojihanz-niti@hanztech.cn to discuss how our premium nitinol strip solutions can enhance your high-precision applications and drive your innovation forward.

References

1. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

2. Duerig, T., Pelton, A., & Stöckel, D. (2013). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

3. Otsuka, K., & Wayman, C. M. (2011). Shape Memory Materials: Fundamentals of Nitinol Alloys and Their Engineering Applications. Cambridge University Press.

4. Lagoudas, D. C., & Vandygriff, E. L. (2015). Processing and characterization of NiTi porous SMA for biomedical applications. Smart Materials Research, 2015, 1-15.