Why Is Nitinol SMA Wire a Game-Changer for Biocompatible Materials?

2025-06-18 17:18:52

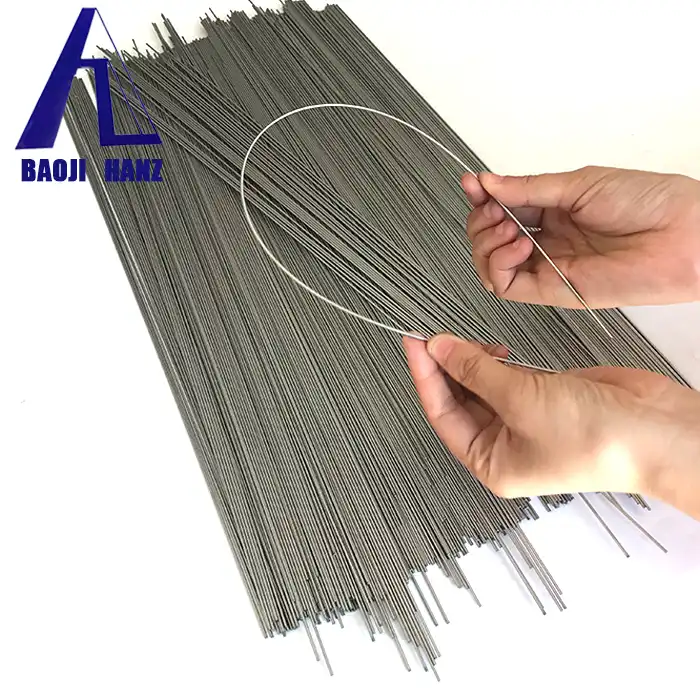

The revolution in biocompatible materials has found its champion in Nitinol SMA Wire, a remarkable shape memory alloy that is transforming medical device manufacturing and biomedical applications worldwide. This extraordinary material combines the unique properties of nickel and titanium in an atomic ratio of approximately 1:1, creating a wire that exhibits both superelasticity and shape memory effects. Nitinol SMA Wire represents a paradigm shift in how we approach biocompatible material design, offering unprecedented flexibility, durability, and biological compatibility that traditional materials simply cannot match. Its ability to return to predetermined shapes when heated, coupled with exceptional corrosion resistance and biocompatibility, makes it an invaluable asset in modern medical technology and industrial applications requiring superior material performance.

Revolutionary Properties That Define Nitinol SMA Wire Excellence

Superelasticity: The Foundation of Advanced Performance

Nitinol SMA Wire demonstrates exceptional superelastic properties that set it apart from conventional metallic materials used in biomedical applications. This superelasticity allows the wire to undergo substantial deformation—up to 8% strain—and still return to its original shape upon unloading, without permanent deformation. The material's unique crystal structure enables this remarkable behavior through a reversible phase transformation between austenite and martensite phases. Baoji Hanz Metal Material Co., Ltd. produces Nitinol SMA Wire with carefully controlled phase transition temperatures ranging from -50℃ to +120℃, ensuring optimal performance across diverse application environments. The superelastic nature of this material makes it particularly valuable in medical devices such as stents, guidewires, and orthodontic archwires, where constant stress and flexibility are required. The wire's ability to maintain consistent force delivery throughout large deflections ensures superior patient comfort and treatment efficacy compared to traditional stainless steel alternatives.

Shape Memory Effect: Programmable Material Intelligence

The shape memory effect of Nitinol SMA Wire represents one of the most fascinating aspects of this advanced material technology. This property allows the wire to be deformed at lower temperatures and then recover its pre-programmed shape when heated above its transformation temperature. The mechanism involves a temperature-induced phase transformation that enables the material to "remember" its original configuration. Baoji Hanz Metal Material Co., Ltd. leverages sophisticated annealing treatment processes to precisely control this shape memory behavior, allowing for customized transformation temperatures based on specific application requirements. The programmable nature of Nitinol SMA Wire makes it invaluable in applications such as self-expanding stents, temperature-activated actuators, and minimally invasive surgical instruments. The material's ability to generate substantial recovery forces during shape recovery—often exceeding 800 MPa tensile strength—enables the creation of devices that can perform complex mechanical functions with remarkable precision and reliability.

Biocompatibility: Safe Integration with Biological Systems

The exceptional biocompatibility of Nitinol SMA Wire stems from its unique surface characteristics and chemical stability in biological environments. The material forms a stable titanium oxide layer that provides excellent corrosion resistance and prevents the release of potentially harmful ions into surrounding tissues. Baoji Hanz Metal Material Co., Ltd. produces Nitinol SMA Wire with surface treatments that include brown state, black state, and bright state finishes, each optimized for specific biomedical applications. The wire's biocompatibility has been extensively validated through ISO9001, SGS, and TUV certifications, ensuring compliance with the most stringent medical device standards. The material's low elastic modulus, closely matching that of human bone tissue, reduces stress shielding effects commonly associated with stiffer metallic implants. This compatibility extends to cellular interactions, where Nitinol SMA Wire demonstrates excellent tissue integration properties, promoting natural healing processes while maintaining long-term mechanical stability in the challenging biological environment.

Manufacturing Excellence and Quality Assurance in Nitinol SMA Wire Production

Advanced Production Processes for Superior Material Properties

The manufacturing of high-quality Nitinol SMA Wire requires sophisticated production techniques that ensure consistent material properties and performance characteristics. Baoji Hanz Metal Material Co., Ltd. employs a comprehensive seven-step production process that begins with careful raw material preparation, where high-purity nickel and titanium are precisely measured to achieve the optimal atomic ratio. The smelting and casting phase utilizes advanced vacuum melting techniques to prevent contamination and ensure homogeneous alloy composition. Hot working processes shape the initial ingot into workable forms, followed by precise cold drawing operations that achieve the desired wire dimensions, including ultra-fine diameters as small as 0.04MM. The critical annealing treatment step programs the shape memory properties and optimizes the material's microstructure for specific applications. Surface treatment processes enhance corrosion resistance and biocompatibility, while final straightening and sizing operations ensure dimensional accuracy. This meticulous production approach enables Baoji Hanz Metal Material Co., Ltd. to consistently deliver Nitinol SMA Wire with tensile strengths ranging from 800-1500 MPa and elongation rates of 15-50%, meeting the demanding requirements of medical and industrial applications.

Quality Control Systems and Certification Standards

Quality assurance in Nitinol SMA Wire production extends far beyond basic material testing, encompassing comprehensive certification processes that validate every aspect of material performance and safety. Baoji Hanz Metal Material Co., Ltd. maintains rigorous quality control systems that comply with ASTM F2063 standards, specifically designed for nickel-titanium shape memory alloys used in medical applications. The company's quality management system incorporates ISO9001 principles, ensuring consistent product quality through systematic monitoring of production parameters and material properties. SGS and TUV certifications provide additional validation of the material's compliance with international standards for biomedical applications. The quality control process includes detailed testing of phase transition temperatures, mechanical properties, surface finish quality, and dimensional accuracy. Each production batch undergoes thorough documentation, with monitoring records retained for at least five years to ensure traceability and support continuous improvement initiatives. This comprehensive approach to quality assurance enables customers to confidently specify Nitinol SMA Wire for critical applications where material reliability and performance consistency are paramount.

Customization Capabilities and OEM Services

The versatility of Nitinol SMA Wire extends beyond standard product offerings through comprehensive customization capabilities that address specific application requirements. Baoji Hanz Metal Material Co., Ltd. provides extensive OEM services that include custom sizing, specific alloy compositions, and tailored surface treatments to meet unique customer specifications. The company's processing services encompass bending, welding, decoiling, cutting, and punching operations, enabling the delivery of ready-to-use components that integrate seamlessly into customer applications. Custom packaging solutions protect material integrity during transportation and storage while supporting efficient inventory management. The minimum order quantity of 1kg or 100 meters makes the technology accessible to both large-scale manufacturers and specialized research applications. Technical consultation services provide 24-hour support for product selection, application engineering, and troubleshooting, ensuring optimal material utilization. Multi-channel payment methods and customized logo options further enhance the customer experience, while the ability to work from customer-provided drawings enables the development of highly specialized solutions that leverage the unique properties of Nitinol SMA Wire for innovative applications.

Medical and Industrial Applications Driving Market Adoption

Medical Device Integration and Clinical Success

The integration of Nitinol SMA Wire in medical device manufacturing has revolutionized treatment approaches across multiple medical specialties, delivering improved patient outcomes and enhanced procedural efficiency. Cardiovascular applications represent the largest market segment, where Nitinol SMA Wire enables the production of self-expanding stents that conform perfectly to vessel geometry while maintaining optimal radial force throughout the healing process. The material's superelastic properties ensure that these devices can navigate tortuous anatomical pathways during minimally invasive procedures while recovering their predetermined shape at the target location. Orthodontic applications benefit from the wire's ability to deliver consistent, gentle forces that promote efficient tooth movement with reduced patient discomfort. The material's biocompatibility eliminates concerns about allergic reactions or tissue irritation commonly associated with traditional orthodontic wires. Surgical instrument applications leverage the shape memory effect to create tools that can be inserted in a compact configuration and then expand to their functional shape when activated by body temperature. Baoji Hanz Metal Material Co., Ltd.'s Nitinol SMA Wire, with its controlled phase transition temperature range and exceptional mechanical properties, enables medical device manufacturers to develop innovative solutions that were previously impossible with conventional materials.

Industrial Applications and Engineering Solutions

Beyond medical applications, Nitinol SMA Wire serves critical roles in industrial applications that demand superior material performance under challenging operating conditions. Aerospace applications utilize the material's lightweight properties and exceptional fatigue resistance in components that must withstand extreme temperature variations and cyclic loading. The wire's density of approximately 6.45g/cm³ provides an excellent strength-to-weight ratio that enhances overall system performance while reducing structural weight. Automotive applications increasingly incorporate Nitinol SMA Wire in actuator systems that require precise temperature-activated responses, such as thermal management systems and adaptive comfort features. The material's corrosion resistance makes it ideal for marine and chemical processing applications where traditional materials would degrade rapidly. Industrial automation systems benefit from the wire's programmable activation characteristics, enabling the development of smart actuators that respond to environmental changes without external control systems. The processing capabilities offered by Baoji Hanz Metal Material Co., Ltd., including precision cutting and forming operations, support the integration of Nitinol SMA Wire into complex industrial assemblies that leverage the material's unique properties for enhanced system performance and reliability.

Future Applications and Market Expansion

The expanding applications of Nitinol SMA Wire continue to drive market growth as engineers and designers discover new ways to leverage the material's unique properties for innovative solutions. Emerging applications in robotics utilize the material's ability to create artificial muscles that mimic biological movement patterns with remarkable efficiency and precision. The development of smart textiles incorporating Nitinol SMA Wire elements enables the creation of adaptive clothing that responds to temperature changes, providing enhanced comfort and functionality. Energy harvesting applications explore the material's ability to convert thermal energy into mechanical work, potentially revolutionizing small-scale power generation systems. Biomedical research continues to expand the frontiers of Nitinol SMA Wire applications, investigating its potential in drug delivery systems, tissue engineering scaffolds, and neural interface devices. The material's exceptional biocompatibility and mechanical properties make it an ideal candidate for next-generation implantable devices that integrate seamlessly with biological systems. Baoji Hanz Metal Material Co., Ltd.'s commitment to research and development, combined with their advanced manufacturing capabilities, positions them at the forefront of these emerging applications, ready to support customers in developing breakthrough technologies that leverage the revolutionary properties of Nitinol SMA Wire.

Conclusion

Nitinol SMA Wire has undeniably established itself as a transformative force in biocompatible materials, offering unprecedented combinations of superelasticity, shape memory effects, and biological compatibility. The material's revolutionary properties enable applications that were previously impossible, from life-saving medical devices to advanced industrial systems. Baoji Hanz Metal Material Co., Ltd.'s expertise in manufacturing high-quality Nitinol SMA Wire, combined with comprehensive quality assurance and customization capabilities, positions this technology at the forefront of material science innovation, driving continued advancement across multiple industries.

Ready to harness the game-changing potential of Nitinol SMA Wire for your next project? With 7 years of specialized expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy technologies, we deliver unmatched value through direct supply advantages and cost-effective solutions. Our extensive inventory ensures fast delivery of standard sizes, while our dedicated OEM services provide customized solutions tailored to your specific requirements. Whether you need custom dimensions, specialized alloy compositions, or unique packaging options, our experienced team collaborates closely with you to ensure seamless integration into your projects. Contact us today at baojihanz-niti@hanztech.cn to discover how our advanced Nitinol SMA Wire solutions can revolutionize your applications and drive your success in the competitive marketplace.

References

1. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

3. Lagoudas, D. C. (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

4. Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2012). Manufacturing and processing of NiTi implants: a review. Progress in Materials Science, 57(5), 911-946.

5. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge University Press.

6. Ryhänen, J., Niemi, E., Serlo, W., Niemelä, E., Sandvik, P., Pernu, H., & Salo, T. (1997). Biocompatibility of nickel-titanium shape memory metal and its corrosion behavior in human cell cultures. Journal of Biomedical Materials Research, 35(4), 451-457.