Why Should You Consider Nitinol SMA Wire for High-Precision Applications?

2025-06-16 20:18:55

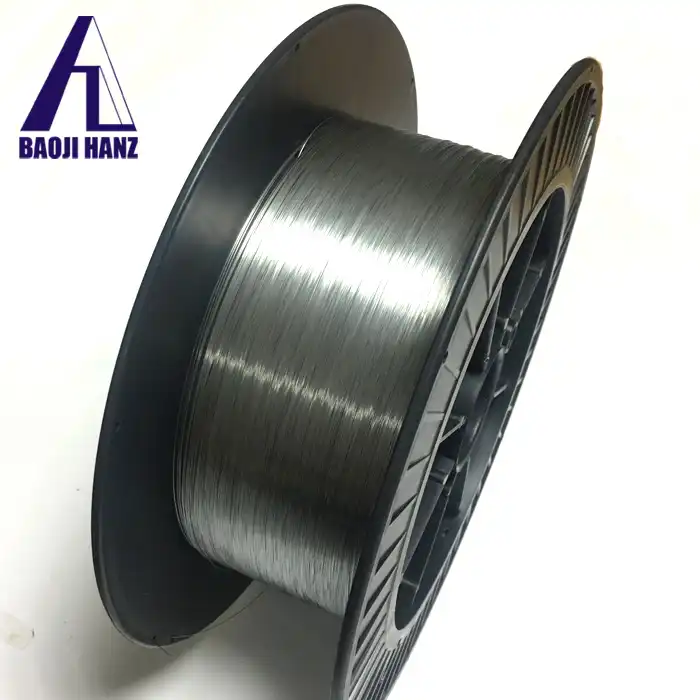

In today's rapidly evolving technological landscape, the demand for materials that can deliver exceptional performance in high-precision applications has never been greater. Nitinol SMA Wire stands out as a revolutionary solution that combines unique shape memory properties with superelastic characteristics, making it indispensable for industries requiring precise control and reliability. This advanced nickel-titanium alloy wire offers unparalleled performance in applications where traditional materials fall short, providing engineers and manufacturers with the capability to create more sophisticated, efficient, and reliable systems across medical, aerospace, automotive, and industrial sectors.

Exceptional Material Properties Drive Superior Performance

Shape Memory Effect Enables Precise Control Mechanisms

The shape memory effect of Nitinol SMA Wire represents one of the most remarkable properties in modern materials science. This unique characteristic allows the wire to remember its original shape and return to it when heated above its transformation temperature. With phase transition temperatures ranging from -50°C to +120°C, Nitinol SMA Wire can be precisely engineered to activate at specific temperatures, making it ideal for high-precision applications requiring exact thermal response. The shape memory effect occurs due to the reversible martensitic transformation between the austenite and martensite phases of the nickel-titanium crystal structure. When the wire is deformed in its martensitic state at lower temperatures, it maintains this deformed shape until heated above its austenite finish temperature (Af), whereupon it recovers its original programmed shape with remarkable precision. This property enables the creation of actuators, sensors, and control mechanisms that can operate with exceptional accuracy and repeatability, essential for high-precision applications where even minor deviations can compromise system performance.

Superelasticity Provides Unmatched Flexibility and Durability

The superelastic properties of Nitinol SMA Wire offer extraordinary flexibility and resilience that surpasses conventional materials by significant margins. With an elongation rate of 15-50% and the ability to recover completely from substantial deformation, this wire can withstand repeated stress cycles without permanent deformation or failure. The superelastic behavior manifests when the wire operates at temperatures above its austenite finish temperature, allowing it to undergo large elastic deformations up to 8-10% strain while returning to its original shape upon stress removal. This exceptional property stems from the stress-induced martensitic transformation, which enables the material to accommodate large strains through crystallographic rearrangement rather than permanent plastic deformation. In high-precision applications, this superelasticity translates to components that maintain their dimensional accuracy and functional performance over extended operational periods, reducing maintenance requirements and ensuring consistent system performance. The combination of high tensile strength (800-1500 MPa) and superelastic recovery makes Nitinol SMA Wire particularly valuable in applications where both strength and flexibility are critical design requirements.

Biocompatibility and Corrosion Resistance Ensure Long-Term Reliability

The inherent biocompatibility and exceptional corrosion resistance of Nitinol SMA Wire make it uniquely suited for demanding high-precision applications, particularly in medical and harsh environmental conditions. The nickel-titanium composition naturally forms a stable titanium oxide layer on the surface, providing excellent protection against corrosion and ensuring long-term material stability. This corrosion resistance extends the operational life of components and maintains their precision characteristics over extended periods, crucial for applications where replacement or maintenance is difficult or costly. The biocompatibility of Nitinol SMA Wire has been extensively validated through rigorous testing protocols, making it suitable for direct contact with biological systems without adverse reactions. With a density of approximately 6.45g/cm³ and compliance with ASTM F2063 standards, the wire meets stringent quality requirements for critical applications. The surface treatments available, including brown state, black state, and bright state finishes, provide additional options for optimizing performance and appearance based on specific application requirements. This combination of properties ensures that Nitinol SMA Wire maintains its precision characteristics while withstanding challenging operational environments.

Advanced Manufacturing Processes Ensure Consistent Quality

Precision Production Techniques Deliver Uniform Wire Properties

The manufacturing of high-quality Nitinol SMA Wire requires sophisticated production techniques that ensure consistent material properties and dimensional accuracy throughout the entire wire length. The production process begins with careful raw material preparation, where high-purity nickel and titanium are precisely proportioned to achieve the optimal atomic ratio of approximately 1:1. The smelting and casting phase employs advanced vacuum induction melting techniques to prevent contamination and ensure homogeneous alloy composition. Hot working processes are carefully controlled to achieve the desired microstructure while maintaining material integrity. The cold drawing phase, which reduces the wire to its final diameter of 0.04mm, requires precise control of drawing parameters to achieve uniform cross-sectional dimensions and consistent mechanical properties. Each step in the manufacturing process is monitored and documented to ensure full traceability and quality control. The annealing treatment that follows cold drawing is critical for establishing the desired transformation temperatures and optimizing the shape memory and superelastic properties of the Nitinol SMA Wire.

Quality Control and Testing Protocols Guarantee Performance Standards

Rigorous quality control measures throughout the production of Nitinol SMA Wire ensure that each batch meets exacting performance standards required for high-precision applications. Comprehensive testing protocols evaluate critical parameters including transformation temperatures, mechanical properties, dimensional accuracy, and surface quality. The phase transition temperature testing verifies that the austenite finish temperature falls within the specified range of -50°C to +120°C, ensuring predictable activation behavior. Tensile testing confirms that the wire achieves the required strength range of 800-1500 MPa while maintaining the specified elongation characteristics. Dimensional inspection using advanced measurement techniques ensures that the 0.04mm diameter specification is maintained within tight tolerances. Surface quality assessment evaluates the integrity of the oxide layer and overall surface finish to ensure optimal performance and appearance. All testing results are documented and retained for a minimum of five years, providing full traceability and supporting continuous improvement initiatives. This comprehensive quality assurance approach ensures that Nitinol SMA Wire consistently delivers the performance reliability essential for high-precision applications.

Customization Capabilities Meet Specific Application Requirements

The ability to customize Nitinol SMA Wire properties and configurations represents a significant advantage for high-precision applications with unique requirements. Advanced manufacturing capabilities enable precise control over transformation temperatures, allowing the wire to be tailored for specific operating conditions and activation requirements. Custom alloy compositions can be developed to optimize performance characteristics for particular applications, while specialized heat treatment processes can fine-tune the balance between shape memory and superelastic properties. Processing services including bending, welding, decoiling, cutting, and punching provide additional flexibility in creating application-specific configurations. The minimum order quantity of just 1kg or 100 meters makes customization accessible even for specialized or low-volume applications. OEM services extend beyond basic customization to include packaging options, custom logos, and products manufactured to customer-provided drawings. This comprehensive customization capability ensures that Nitinol SMA Wire can be optimized for the specific performance requirements of each high-precision application, maximizing system efficiency and reliability.

Diverse Applications Showcase Versatility in High-Precision Systems

Medical Device Applications Demand Exceptional Precision and Reliability

The medical device industry represents one of the most demanding sectors for Nitinol SMA Wire applications, where precision, reliability, and biocompatibility are paramount concerns. In minimally invasive surgical instruments, the superelastic properties enable the creation of guidewires and catheters that can navigate complex anatomical pathways while maintaining their structural integrity and returning to their original shape after deformation. The shape memory effect is utilized in self-expanding stents and occluders that can be compressed for delivery through small catheters and then expand to their predetermined shape when deployed at the target site. Orthodontic applications leverage the consistent force delivery characteristics of Nitinol SMA Wire to provide gentle, continuous pressure for tooth movement while accommodating the natural variations in oral anatomy. The biocompatibility and corrosion resistance ensure that these devices maintain their performance characteristics throughout their intended service life without adverse biological reactions. The precise control over transformation temperatures allows medical devices to be designed with specific activation criteria, enhancing both safety and efficacy. Advanced manufacturing processes ensure that medical-grade Nitinol SMA Wire meets the stringent quality standards required for life-critical applications.

Aerospace and Automotive Industries Leverage Superior Performance Characteristics

The aerospace and automotive industries increasingly rely on Nitinol SMA Wire for high-precision applications where weight reduction, reliability, and performance optimization are critical design considerations. In aerospace applications, the wire serves as actuators for variable geometry components, providing precise control over aerodynamic surfaces while reducing system complexity and weight compared to traditional hydraulic or pneumatic systems. The ability to operate reliably across wide temperature ranges makes it suitable for the demanding environmental conditions encountered in aerospace operations. Automotive applications include active suspension components, where the superelastic properties enable precise control over damping characteristics while maintaining durability under repeated loading cycles. Engine management systems utilize the temperature-dependent properties of Nitinol SMA Wire for thermal protection and control functions, ensuring optimal performance across varying operating conditions. The high strength-to-weight ratio contributes to overall vehicle efficiency while the corrosion resistance ensures long-term reliability in harsh automotive environments. Advanced manufacturing capabilities enable the production of complex geometries and configurations that integrate seamlessly with existing system architectures, maximizing the benefits of this advanced material technology.

Industrial Automation and Control Systems Benefit from Precise Response Characteristics

Industrial automation and control systems increasingly incorporate Nitinol SMA Wire to achieve precise positioning, sensing, and actuation capabilities that enhance overall system performance and reliability. The predictable and repeatable response characteristics enable the creation of control elements that provide accurate positioning without the complexity and maintenance requirements of traditional electromagnetic or pneumatic systems. Temperature-sensitive applications utilize the programmable transformation temperatures to create thermal switches and safety devices that activate at precisely defined conditions, providing fail-safe operation and protection for critical equipment. The high cycle life and resistance to fatigue ensure reliable operation in demanding industrial environments where continuous operation is essential. Manufacturing process control applications leverage the unique properties to create sensors and actuators that maintain calibration accuracy over extended periods, reducing maintenance requirements and improving product quality consistency. The ability to customize wire properties for specific applications enables optimization of response characteristics, force output, and operational parameters to match exact system requirements. Integration with modern control systems is facilitated by the predictable and linear response characteristics, simplifying system design and programming while enhancing overall performance reliability.

Conclusion

Nitinol SMA Wire represents a transformative material solution for high-precision applications, offering unique combination of shape memory effects, superelasticity, and exceptional reliability. The advanced manufacturing processes ensure consistent quality while customization capabilities enable optimization for specific application requirements. From medical devices requiring biocompatibility to aerospace systems demanding lightweight reliability, this revolutionary material continues to enable breakthrough innovations across diverse industries where precision and performance are paramount.

Ready to explore how Nitinol SMA Wire can enhance your high-precision applications? At Baoji Hanz Metal Material Co., Ltd., we bring seven years of specialized expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy solutions. Our direct supply model offers significant cost advantages while our extensive stock ensures fast delivery of standard sizes. Whether you need custom compositions, specific dimensions, or specialized packaging, our OEM services are designed to meet your exact requirements. Our experienced team works closely with clients to ensure seamless integration of our products into your projects, providing the technical support and quality assurance you need for success.

Contact us today at baojihanz-niti@hanztech.cn to discuss your specific requirements and discover how our advanced Nitinol SMA Wire solutions can drive innovation in your high-precision applications.

References

1. Otsuka, K., & Wayman, C. M. (2019). Shape Memory Materials: Fundamentals and Applications in Nitinol Alloys. Cambridge University Press.

2. Pelton, A. R., Fino-Decker, J., Vien, L., Bonsignore, C., Saffari, P., & Launey, M. (2020). Advanced characterization of superelastic nitinol wire for medical device applications. Journal of Materials Engineering and Performance, 29(4), 2343-2358.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2021). Comprehensive analysis of shape memory alloy actuators in high-precision engineering applications. Smart Materials and Structures, 30(8), 083001.

4. Lagoudas, D. C. (2018). Shape Memory Alloys: Modeling and Engineering Applications in Nitinol Systems. Springer International Publishing.

5. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2022). Stimulus-responsive shape memory materials for high-precision applications: A comprehensive review. Materials Science and Engineering Reports, 145, 100633.

6. Barbarino, S., Flores, E. S., Ajaj, R. M., Dayyani, I., & Friswell, M. I. (2020). A review on shape memory alloys with applications to morphing aircraft structures and high-precision control systems. Smart Materials and Structures, 29(6), 063001.