Basic Knowledge of Nitinol memory sheet

Nitinol memory sheet are functional alloy components based on shape memory effect (SME) and superelasticity. When heated above the phase transition temperature, they can retain a preset shape and recover that shape, with stable chemical properties and biocompatibility.

|

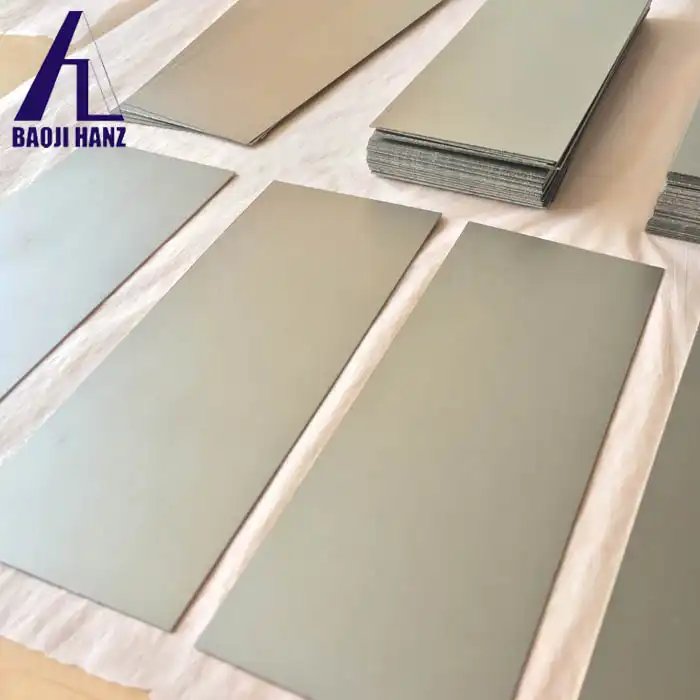

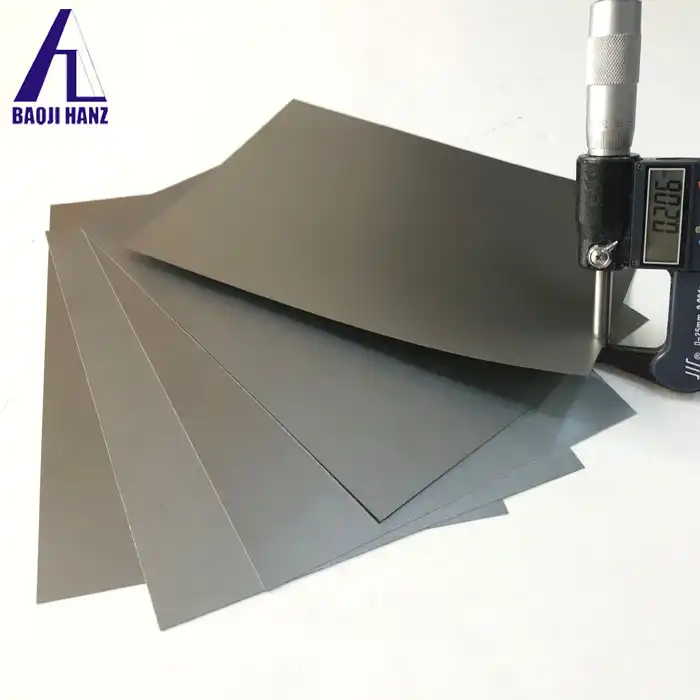

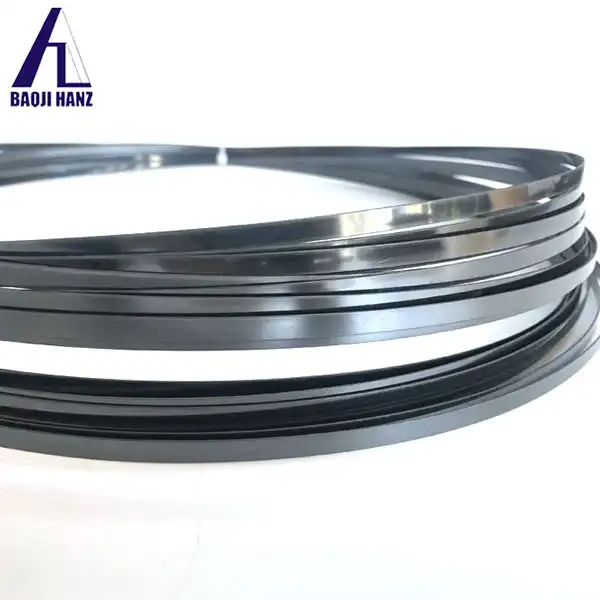

Dimension |

Thickness ≥ 0.1 mm, Width ≤ 300 mm |

| Material Composition | Nickel-Titanium alloy (NiTi, typically 50-55% Ni) |

| Density | 6.45g\ cm3 |

|

Features |

Shape Memory |

|

Temperature Range ( Af ) |

-20~100℃ |

|

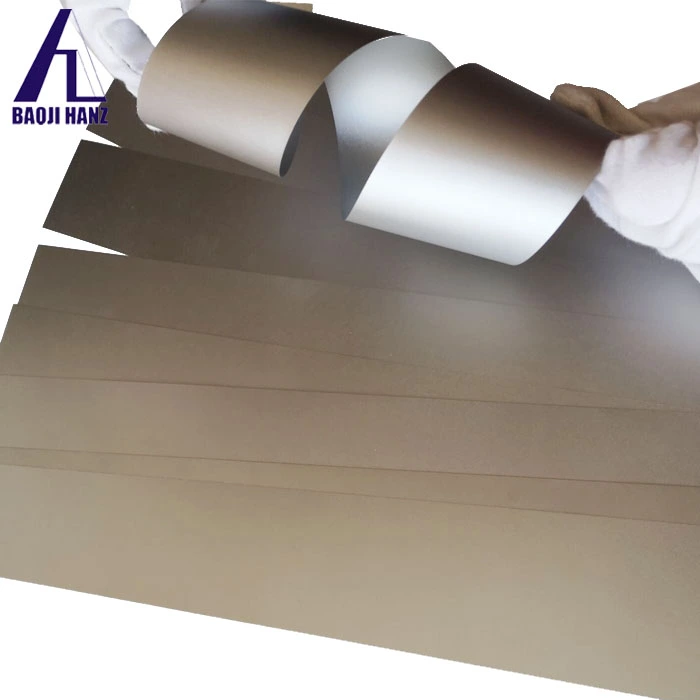

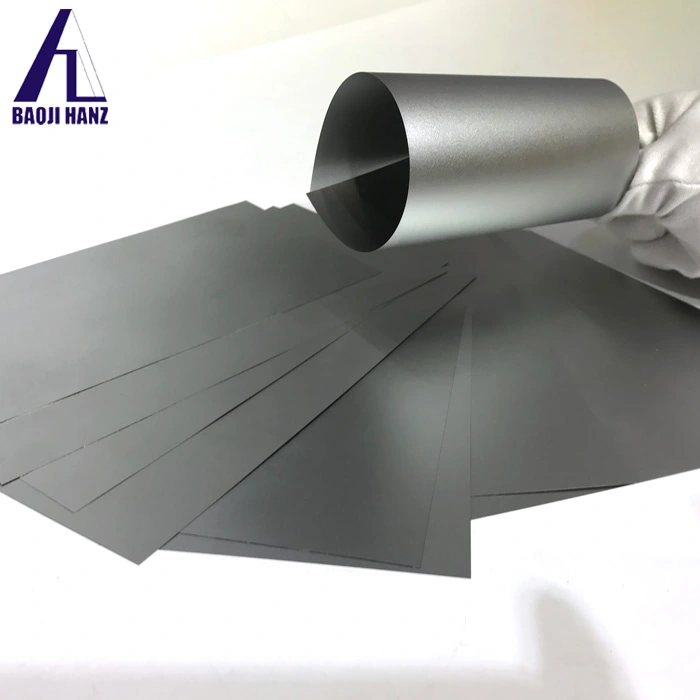

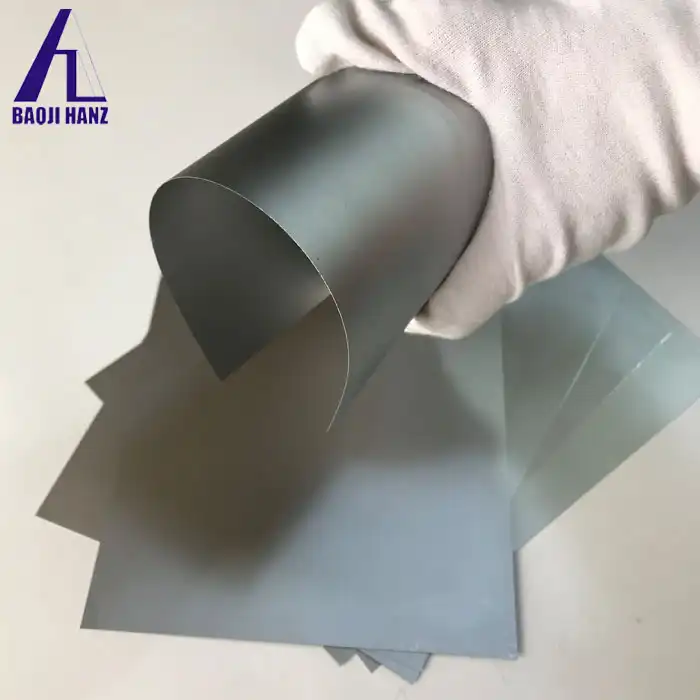

Surface |

Acid-washed surface, Bright surface |

| Transport Package | Seaworthy Packing/Wooden Box or at Client's Requir |

| Tensile Strength | 860-1100 MPa |

Parameter of nitinol memory sheet

| Products | Grade |

Transformation Temperature AF |

Form |

|

|

Shape Memory Nitinol Alloy |

Ti-Ni-01 |

20 °C~ 40 °C |

Wire,bar,plate |

Customer Specified or Industry standard |

|

Ti-Ni-02 |

45 °C~ 90 °C |

Wire,bar,plate |

||

|

Superelastic Nitinol Alloy |

TiNi-SS |

-5 °C~ 5 °C |

Wire,bar,plate |

|

|

Low Temperature Superelastic Nitinol Alloy |

TN3 |

-20°C~-30°C |

Wire,bar,plate |

|

|

TNC |

||||

|

Medical Nitinol Alloy |

TiNi-SS |

33 ± 3 °C |

Wire,bar,plate |

ASTM F2063 |

|

Narrow Hysteresis Nitinol Alloy |

Ti-Ni-Cu |

As-Ms ≤ 5 °C |

Wire,bar |

|

|

Wide Hysteresis Nitinol Alloy |

Ti-Ni-Fe |

As-Ms ≤ 150 °C |

Wire, bar |

|

| Alloy | Chemical composition | AF point | Min elongation (%) | Max Residual elongation after 6% strain | Application | Standard |

|

NiTi |

55.6-55.8wt%Ni |

Body Temperature 20ºC-40ºC |

15 | 0.1 | Orthotic Arches | ASTM F2063 |

Superelastic Nickel Titanium Alloys

When the active A(f) temperature is lower than the usage temperature, nickel titanium alloys exhibit superelasticity. Typically, applications designed to have superelasticity at room temperature generally use materials with an active A(f) temperature below room temperature, ranging from 0°C to 20°C. Superelastic materials maintain superelasticity within a range from the active A(f) temperature to approximately 50°C above the active A(f) temperature. Therefore, materials with an active A(f) of about 15°C can still exhibit good superelasticity at temperatures around 65°C.

Shape Memory Nickel Titanium Alloys

This product form has the ability to recover its shape when heated to a temperature above the active A(f) temperature. Therefore, the most critical property to clearly define is the active A(f). The transformation start temperature during heating is the austenite start temperature A(s), which is approximately 15°C to 20°C lower than the active A(f).

Key Features

- Shape Memory Effect: Can recover its original shape before deformation when heated.

- Superelasticity: Exhibits a wide range of reversible deformation (up to 8%) under external force at room temperature.

- Corrosion Resistance: Resists erosion from bodily fluids and harsh environments through an oxide film.

- Biocompatibility: Non-toxic, non-irritating, and compatible with human tissue.

Processing Technology

1. Vacuum Melting (Ensuring Alloy Uniformity).

2. Hot Rolling and Forging (Forming Billet Plates).

3. Solution Treatment (Optimizing Phase Structure).

4. Cold Rolling (Adjusting Thickness and Precision).

5. Shape Setting (Presetting Target Shape via Heat Treatment).

6. Surface Polishing (Improving Biocompatibility and Smoothness).

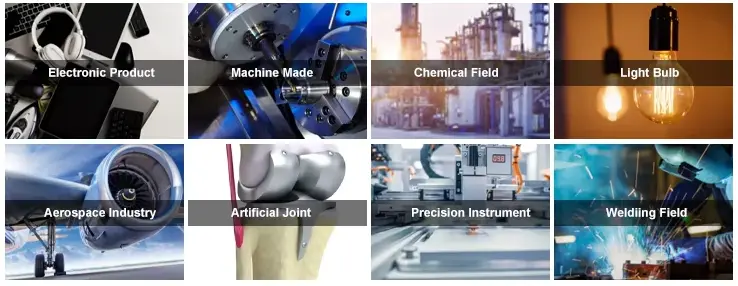

Applications

Medical field: Orthopedic fixation plates, dental orthodontic appliances, minimally invasive surgical instruments.

Automotive industry: Smart actuators, shock absorber components.

Electronic field: Temperature-sensitive switches.

FAQ

Q1: What product information must be provided before purchase?

A1:Please provide the grade, width, thickness, and surface treatment requirements, as well as the quantity you need.

Q2: How can I get product price information?

A2:Due to regular fluctuations in raw material prices, prices may vary.

Q3: Is custom product service available?

A3:Yes, we can produce according to your specifications and drawings.

Q4: What is your delivery time?

A4:For in-stock items, delivery takes 3-7 days after full payment. For custom products, it depends on the specific situation.

Contact us

Baoji Hanz Metal Material Co., Ltd.

Gaoxin Avenue, BaoJi city, ShaanXi province China

Tel: 86-917-3258889

Mobile, Whatsapp,Wechat: +8618091719909

Email:baojihanz-niti@hanztech.cn

_1729338131804.webp)