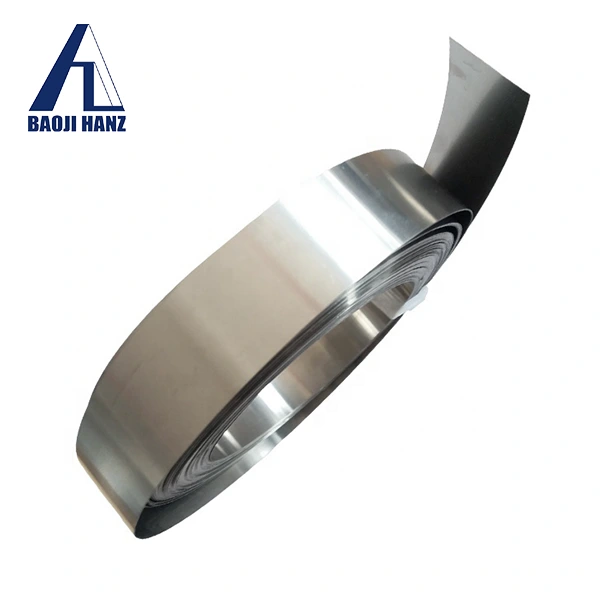

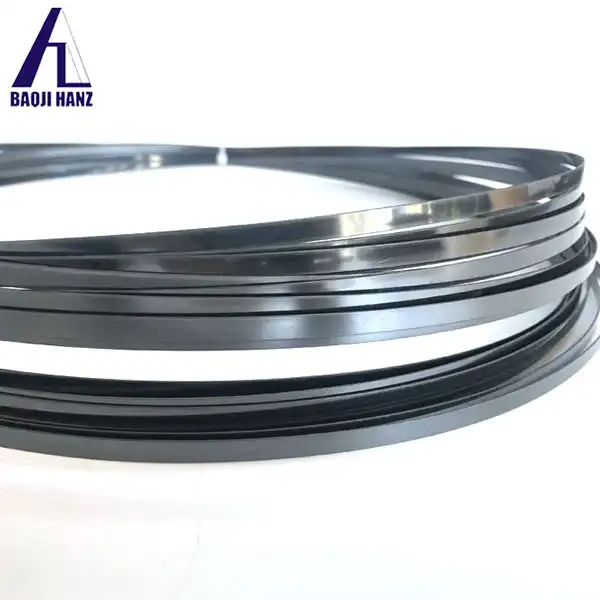

Products Description

Basic knowledge of sma nitinol spring

The main material component of sma nitinol spring is Ni-Ti shape memory alloy, which is a very interesting material because they have shape memory effect (SME) and possess high strength and ductility.

Parameter of sma nitinol spring

| Product name | sma nitinol spring |

| wire size | 0.5~3mm |

| Spring size | customized |

| Af temperature range | - 20℃~100℃ |

| Surface | pickling,polished |

| Standard | ASTM F 2603 |

|

Contract No. |

Name |

Brand |

LotNo. |

Condition |

Size (mm) |

Qty (M) |

NW (kg) |

Standard |

|

------ |

Ti-Ni memory alloy rod |

Seabird |

20160528 |

annealed |

Dia 0.1 mm |

1000 |

/ |

ASTMF2063 |

|

Tensile Test |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Elongation (%) |

reduction of aera |

grain size |

Bend Test a>130 |

ak(J/cm²) |

IE Impact strength (mm) |

|

950 |

180 |

17 |

/ |

6 |

Q |

/ |

/ |

|

|

Chemical Composition |

Ti (%) |

Fe (%) |

C (%) |

O (%) |

N (%) |

H (%) |

Co (%) |

Ni (%) |

|

Remainder |

0.008 |

0.044 |

0.026 |

0.00 2 |

0.001 |

/ |

55.76 |

Production process of sma nitinol spring

The production process of sma nitinol spring can be briefly described as raw material preparation → forming processing → heat treatment and shaping → surface treatment → finished product inspection

FAQ

Question: Are you a trading company or a manufacturer?

A: We are the manufacturer of sma nitinol spring

Question: Do you provide samples? Is it free or comes with an extra charge?

A: Yes, whether it's free or not depends on the type of product.

Question: How do you ensure product quality?

A: All our products are manufactured in accordance with ASTM standards and we conduct 100% inspection before shipment.

Q: Can you print our logo on the product?

A: Yes, we make it through laser printing and engraving.

Question:What is your payment method?

A: Wire transfer, Western Union, PayPal, etc.

Question: How long is your delivery time?

A:2 to 30 days.

About us

Baoji Hanz Metal Material Co., Ltd. is a manufacturer specializing in the research and development of Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, Nickel Titanium Alloy.

Support

Baoji Hanz offers expert assistance, advanced technology, and dedicated service for all your metal and alloy needs.

Mobile, Whatsapp,Wechat: +8618091719909

Email:baojihanz-niti@hanztech.cn