Baoji Hanz Metal Material Co., Ltd.: Your Trusted Niti Alloy Wire Manufacturer & Supplier

At Baoji Hanz Metal Material Co., Ltd., we take pride in manufacturing and supplying top-tier Niti Alloy Wire. Our expertise in nitinol alloys allows us to deliver exceptional quality and performance. With advanced production facilities and a commitment to innovation, we offer Nickel titanium straight wire that meets the highest industry standards. Our products are trusted by leading manufacturers worldwide for their reliability and versatility.

Niti Alloy Wire Basic knowledge

Nickel-titanium straight wire is a linear material made from nickel-titanium alloy as raw material, featuring unique shape memory effect and superelasticity, and is widely used in medical, industrial and other fields.

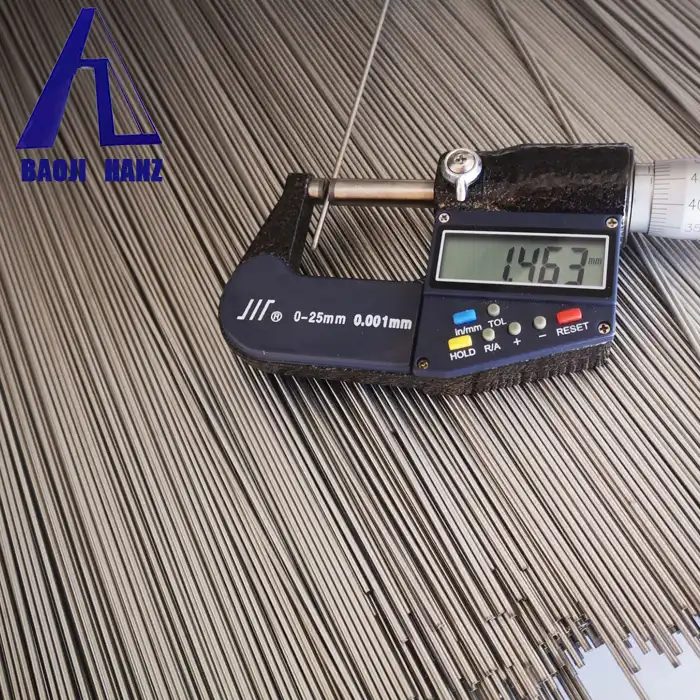

Specification

| Standard | ASTM F2063 |

| MOQ | 1kg |

| shape | Round straight wire |

| Phase transition temperature (Afc) | -20℃~100℃ |

| Density | 6.45g/cm³ |

| Packaging | Packed in wooden crates |

| Application | Industrial |

|

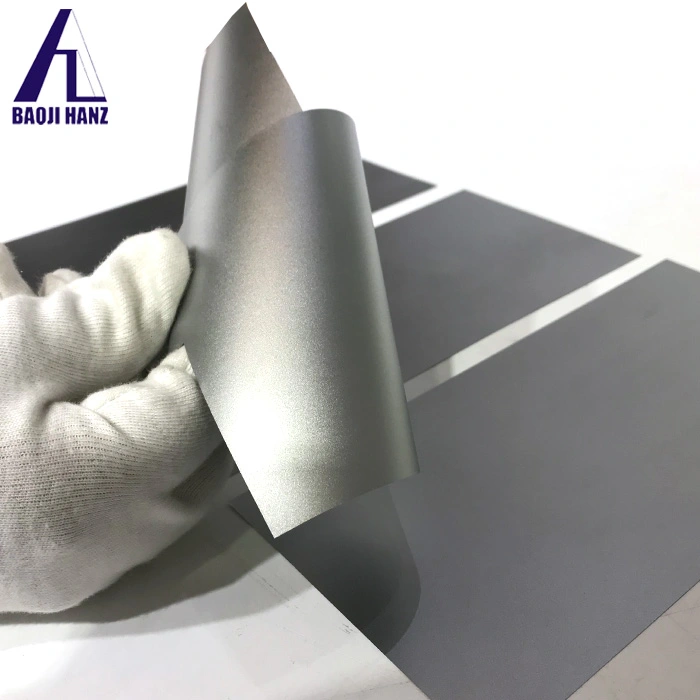

Surface |

Glossy finish, black finish |

Advantage

- Unique function: niti alloy wire has shape memory and superelastic properties that are difficult to be replaced by other metal materials.

- Strong applicability: Its excellent biocompatibility makes it safe and reliable in the medical field, and its corrosion resistance makes it suitable for various environments.

- Easy operation: In medical applications, it can automatically adjust according to human body temperature or external force, simplifying the treatment process.

Production process

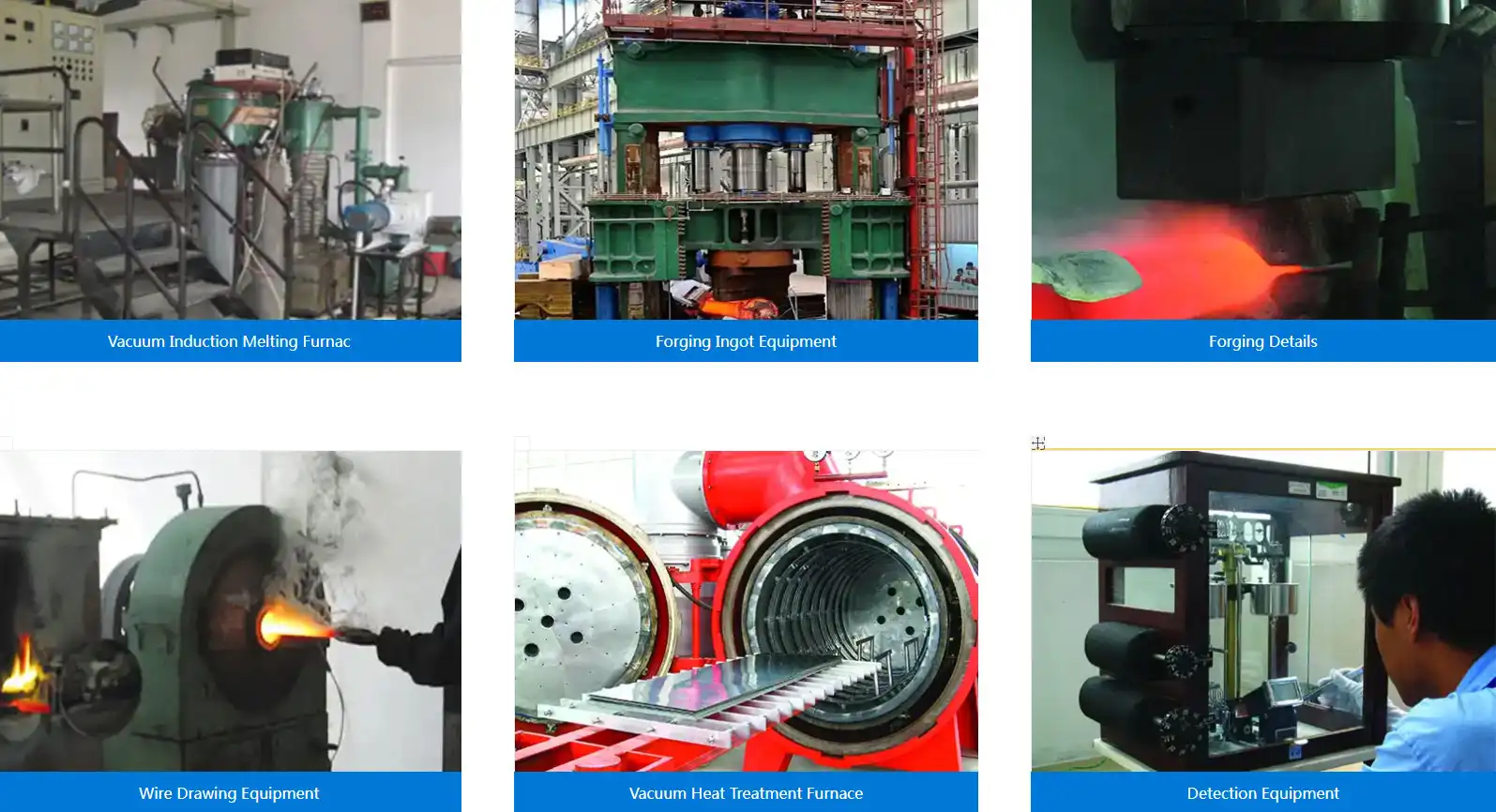

1. Raw material preparation: Nickel and titanium are melted in proportion to form nickel-titanium alloy ingots.

2. Plastic processing: Ingots are processed into wire rods through hot rolling, cold rolling and other processes.

3. Heat treatment: The wire is subjected to heat treatment at a specific temperature to endow it with shape memory effect and superelasticity.

4. Finishing: After acid washing, stretching and other finishing processes, straight wire products that meet the specifications are obtained.

Product features

Shape memory effect: After deformation at low temperatures, it can return to its

original shape when heated to a specific temperature.

- Superelasticity: It can undergo significant elastic deformation under external force and quickly return to its original state after the external force is removed.

- Biocompatibility: It has no obvious toxicity or rejection reaction to human tissues and is suitable for the medical field.

- Corrosion resistance: It is not easily corroded in environments such as body fluids and air, and has good stability.

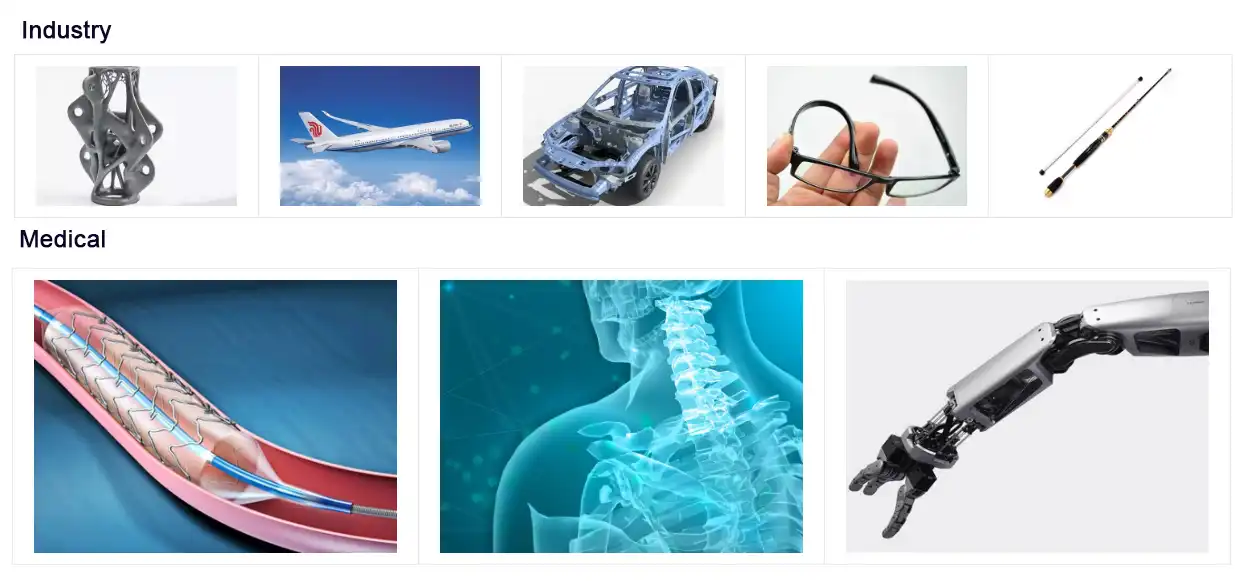

Application

Our equipment

Packaging/Transportation/Payment method

FAQ

Q1:What material is nickel-titanium straight wire made of?

A1: Made of nickel-titanium alloy, it is a linear material with special properties.

Q2:What are the core characteristics of nickel-titanium straight wire?

A2:The main features include shape memory effect, superelasticity, good biocompatibility and corrosion resistance.

Q3:Where are nickel titanium straight wires mainly used?

A3: Medical fields (such as orthodontics and orthopedics) and industrial fields (such as precision drive components).

Q4:Why is nickel-titanium straight wire suitable for the medical field?

A4:It has good biocompatibility, is non-toxic and has no side effects on the human body, and its performance is suitable for the human environment.

Q5: What are the advantages of nickel-titanium straight wire compared with ordinary metal wire?

A5: It features unique shape memory and super elasticity, making it suitable for more special scenarios, such as medical automatic adjustment.

Contact Us

For inquiries about our Niti Alloy Wire or to discuss your specific requirements, please contact us at:

Email: baojihanz-niti@hanztech.cn

Experience the superior quality and performance of our niti alloy wire. Trust Baoji Hanz Metal Material Co., Ltd. for all your nitinol wire needs. Let's collaborate to bring your innovative projects to life with our cutting-edge Nitinol straight wire solutions.

.webp)

.webp)

_1749798209934.webp)

.webp)