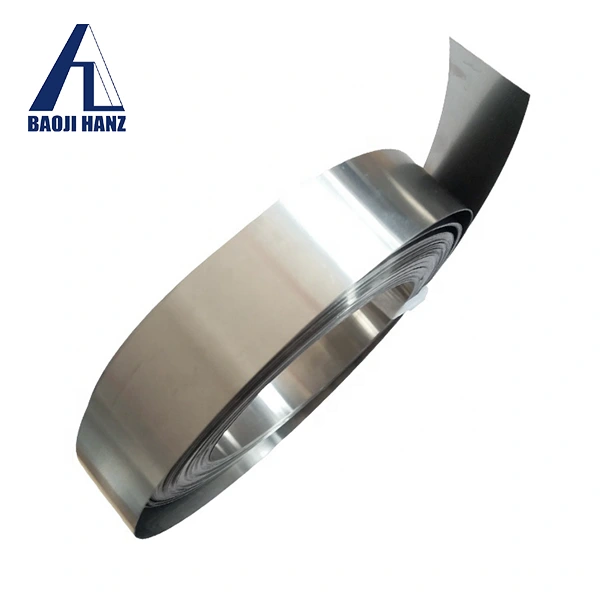

Baoji Hanz Metal Material Co., Ltd.: Your Trusted Corrosion-Resistant Nitinol Wire Manufacturer & Supplier

Baoji Hanz Metal Material Co., Ltd. mainly produces electrically shrinking nickel-titanium alloy memory wire, materials for brackets, materials for guide wires, and various Corrosion-Resistant Nitinol Wire materials, etc.

Baoji Hanz specializes in the production of nickel-titanium medical commercial and industrial materials. We welcome you to visit our company for sample testing, trial production, and providing users with comprehensive solutions. This is our mission at Baoji Hanz!

Corrosion-Resistant Nitinol Wire Basic knowledge

Corrosion-Resistant Nitinol Wire is a special material formed by nickel-titanium alloy, which can undergo plastic deformation at a certain specific temperature and automatically return to its original shape. And it has excellent features such as being super elastic and wear-resistant.

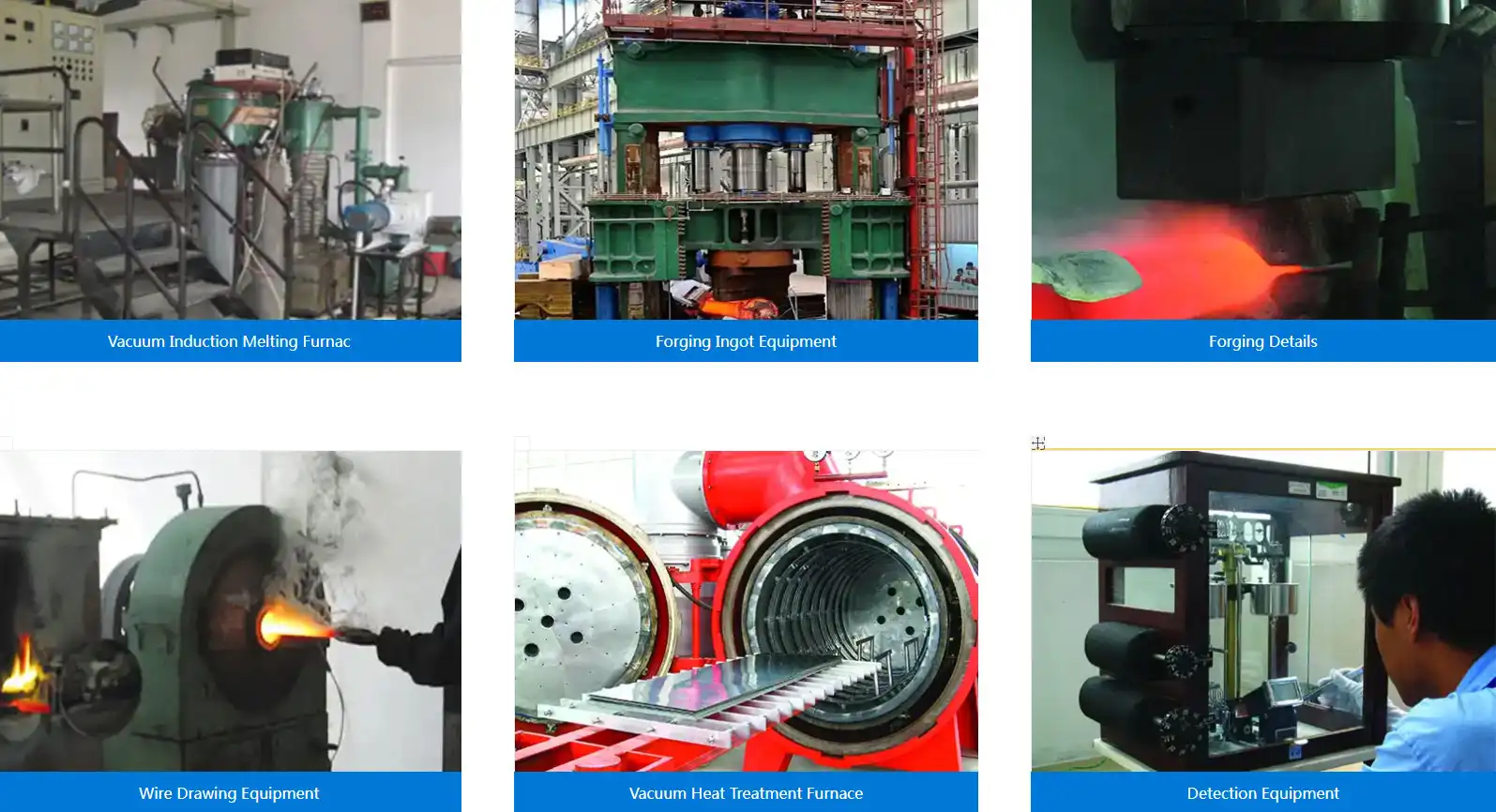

Production process

1. Ingredient smelting: Nickel and titanium are vacuum smelted in proportion to form ingots.

2. Hot working billet opening: After annealing the ingot, it is hot-rolled/forged into billet.

3. Cold drawing forming: Multi-pass drawing reduction, intermediate annealing for anti-hardening.

4. Heat treatment strengthening: Aging at 200-500℃ to optimize performance and form a corrosion-resistant oxide film.

5. Surface treatment: Polishing and cleaning to remove defects and impurities.

6. Performance testing: Sort after verifying the mechanical properties and corrosion resistance.

Specification

| Standard | ASTM F2063 |

| Production process | Bending, Welding, Decoiling, Cutting |

| Tensile strength | 800-1500MPa |

| Phase transition temperature (Afc) | -20℃~100℃ |

| Density | 6.45g/cm³ |

|

Surface |

mechanical polishing |

Chemical Composition

| Element | Mass percentage |

| Ni | 54.5-57.0 |

| C |

≤0.040 |

| Co |

≤0.050 |

| Cu |

≤0.010 |

| Cr |

≤0.010 |

| H |

≤0.005 |

| Fe |

≤0.050 |

| Nb |

≤0.025 |

| N |

≤0.005 |

| O |

≤0.040 |

| Ti | Margin |

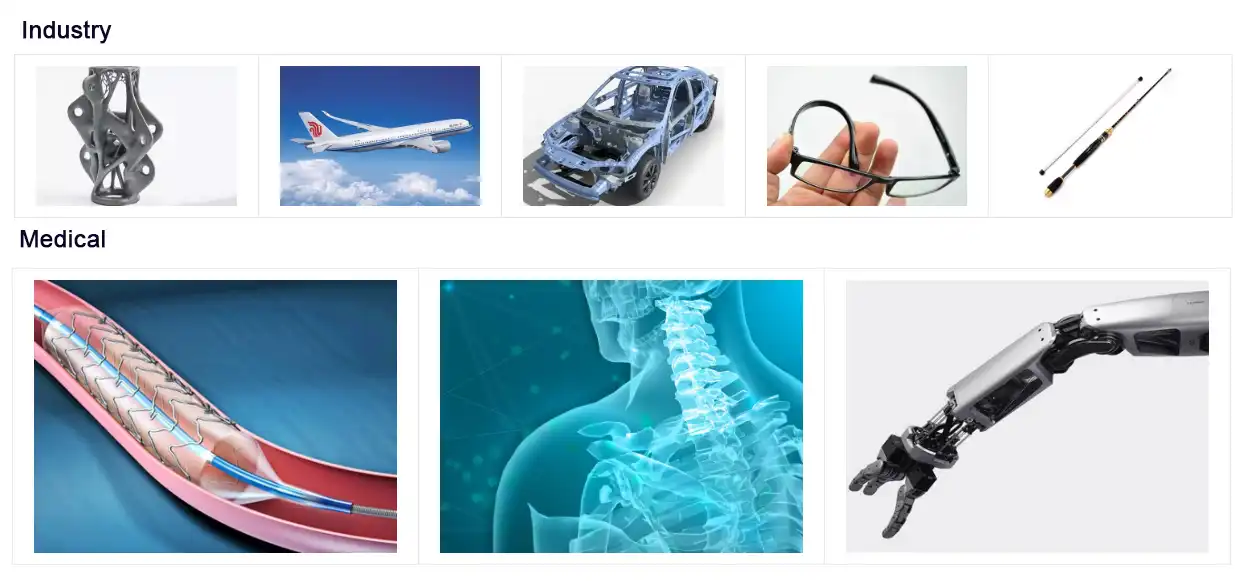

Application

Our Certificate

Our equipment

Packaging/Transportation/Payment method

OEM Services

In terms of nickel-titanium alloy materials, apart from providing 24-hour technical and after-sales service, we can customize products exclusively for you at any time based on the samples and pictures you provide. You are always welcome to call us.

FAQ

Q1: What is the material of the Corrosion-Resistant Nitinol Wire ?

A1: The Nitrex Guidewire is made from high-quality nitinol shape memory alloy, offering superior strength and flexibility.

Q2: Can the specifications and packaging be customized?

A2: Yes, both the specifications and packaging can be customized according to your samples or drawings as needed.

Q3: What is the minimum order quantity of the product?

A3: If in stock, the MOQ is 100 meters. If not, the minimum order quantity is 1kg or 1000 meters.

Contact Us

Corrosion-Resistant Nitinol Wire has broad application prospects in the medical and industrial fields. Studying its corrosion resistance and the changes in practical applications is of great significance for improving the service life and safety of materials. Use the latest technology in production. We are a direct manufacturer and have the greatest advantage in terms of price. Customization is available. We can provide you with a complete set of products and technical services. Please contact us at any time:

Email: baojihanz-niti@hanztech.cn

We are here to assist you and look forward to your inquiry!

_1740043052871.webp)