Product Description of Nitinol Memory Alloy Wire

The main material of nitinol memory alloy wire is nickel-titanium alloy. Nickel-titanium alloy is a shape memory alloy, a special type of alloy that can automatically recover its plastic deformation to the original shape at specific temperatures and has good plasticity. Its expansion rate exceeds 20%, its damping characteristics are 10 times that of ordinary springs, and its corrosion resistance is better than the best medical stainless steel currently available. Therefore, it can meet the application requirements of various engineering and medical fields and is an excellent spring functional material. In addition to the unique shape memory function, memory alloys also have excellent properties such as wear resistance, corrosion resistance, high damping, and superelasticity.

Specification

|

Material Grade |

Nickel titanium alloy |

|

Wire Shape |

Round Wire |

|

Diameter Range(mm) |

0.025min |

|

Standards |

ASTM F2063,GB 24627 |

|

Diameter Tolerance |

±0.001mm |

|

Surface Finish |

Black Oxidized, Lightly Oxidized, Bright, Ultra Bright, Polished, Clean |

|

Delivery Condition |

Straightened superelastic , Cold-worked |

|

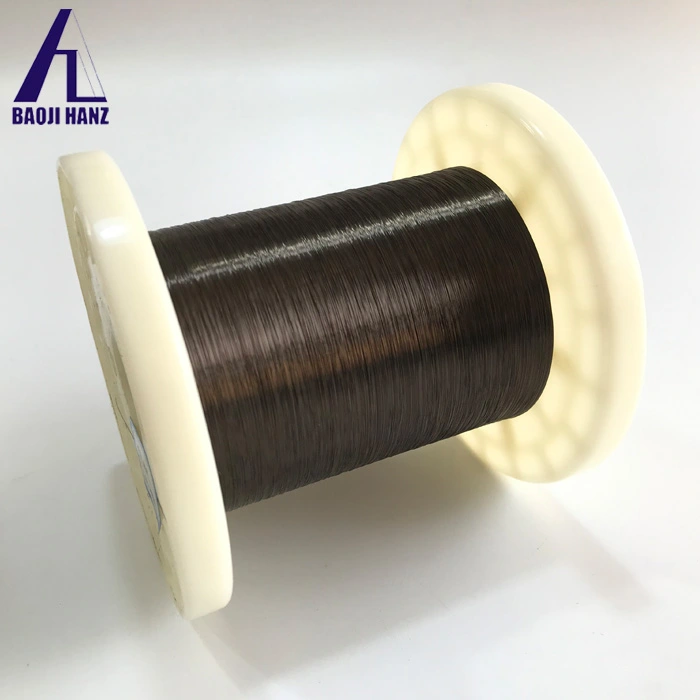

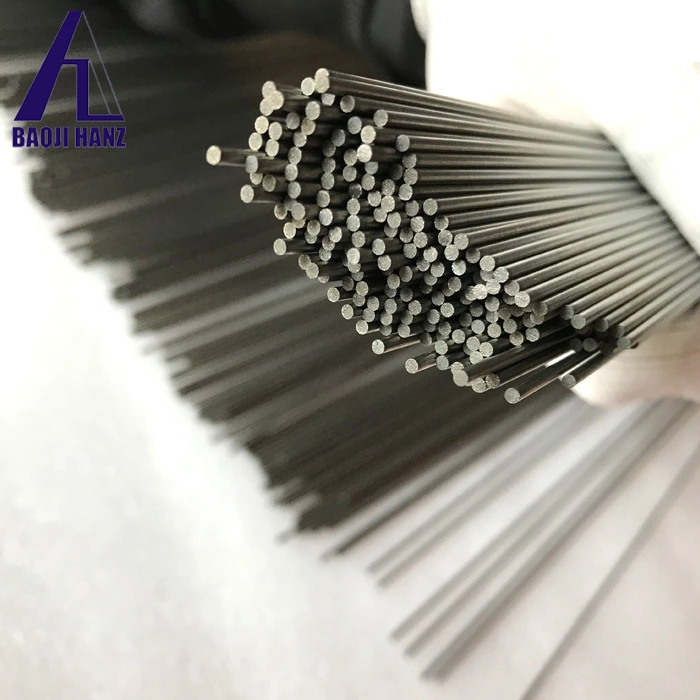

Supply Form |

Spool wound, Straight |

Properties of Nitinol Memory Alloy Wire

(1) Shape Memory

After certain heat treatment, Nitinol shape memory alloy can automatically recover its original shape. According to the recovery state, shape memory can be divided into one-way shape memory, two-way shape memory, and full-range shape memory.

(2) Superelasticity

When subjected to external force, Nitinol shape memory alloy will deform, and when the external force is removed, it will recover to its original shape. This is the superelastic property of Nitinol shape memory alloy.

(3) Damping Performance

Due to self-adjustment during the phase transition process and the interfaces and movements generated during phase transition, Nitinol shape memory alloy exhibits excellent damping performance.

(4) Resistivity

During the deformation process of martensitic Nitinol shape memory alloy, the relationship between resistivity and strain is linear. When phase transition occurs, the slope of the curve decreases, but the linear relationship can still be maintained before and after the martensitic phase transition.

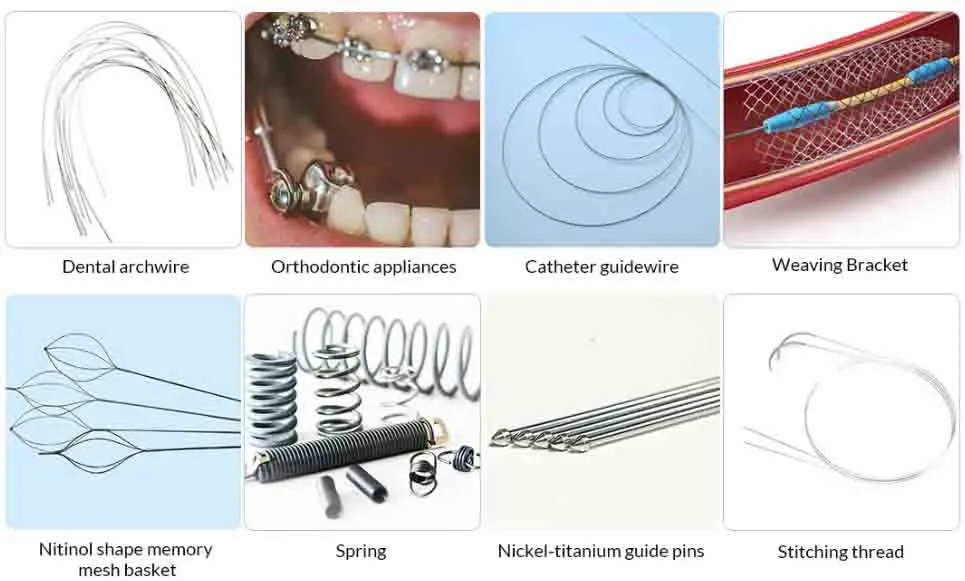

Applications of Nitinol Memory Alloy Wire

(1) Couplings

(2) Biomedical and Medical Fields

(3) Toys and Crafts

(4) Brake Systems

(5) Heat Engines

(6) Sensors

(7) Low-Temperature Activated Molds and Memory Slots

(8) Lifting Equipment.

|

Mechanical Properties: ASTM F2063 |

|||||

|

NiTi Alloy Code |

Straightened Superelastic Condition (SE) |

||||

|

Tensile Strengthσ,Mpa |

Elongationδ,% |

Upper Plateau Stress σ, MPa |

Residual Strain, % |

Active Af Temperature, ℃ |

|

|

D |

≥1300 |

≥10 |

≥480 |

<0.5 |

10±7 |

|

C |

≥1150 |

≥10 |

≥440 |

<0.5 |

17±7 |

|

S |

≥1000 |

≥10 |

≥400 |

<0.5 |

25±5 |

|

nitinol memory alloy wire Diameter Tolerance: |

|

|

Diameter(mm) |

Tolerance(mm) |

|

4.000-2.000mm |

±0.020mm |

|

2.000-1.000mm |

±0.010mm |

|

1.000-0.350mm |

±0.010mm |

|

0.350-0.260mm |

±0.007mm |

|

0.260-0.150mm |

±0.005mm |

|

0.150-0.080mm |

±0.004mm |

|

0.080-0.050mm |

±0.003mm |

|

0.050-0.013mm |

±0.002mm |

Contact us

Baoji Hanz Metal Material Co., Ltd.

Gaoxin Avenue, BaoJi city, ShaanXi province China

Tel: 86-917-3258889

Mobile, Whatsapp,Wechat: +8618091719909

Email:baojihanz-niti@hanztech.cn

.webp)

.webp)

.webp)