Baoji Hanz Metal Material Co., Ltd.: Your Premier Nitinol Shape Memory Alloy Wire Supplier

Baoji Hanzhen Metal Materials Co., Ltd. has been deeply engaged in the field of Nitinol Shape Memory Alloy Wire for many years and is an industry-leading enterprise integrating production and sales. Relying on advanced production equipment and exquisite craftsmanship, we strictly control every process to ensure stable and reliable product quality, and all performances meet the high standards of the industry.

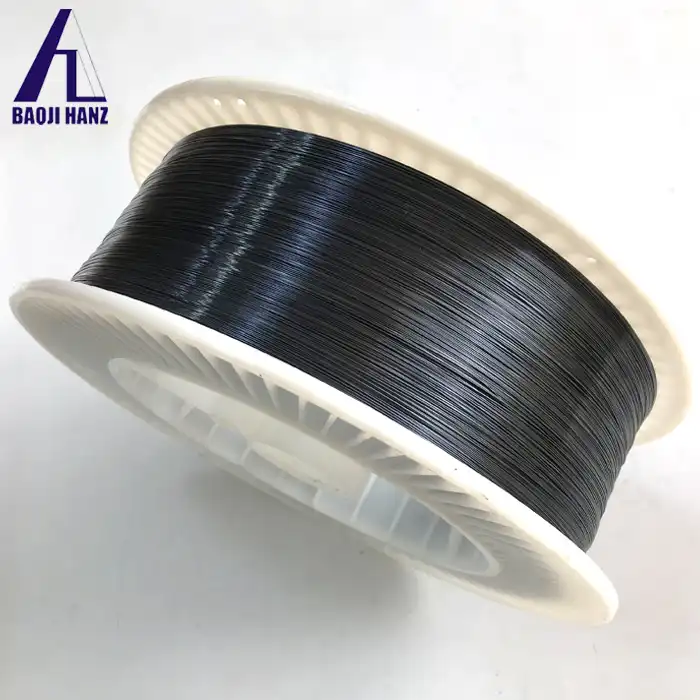

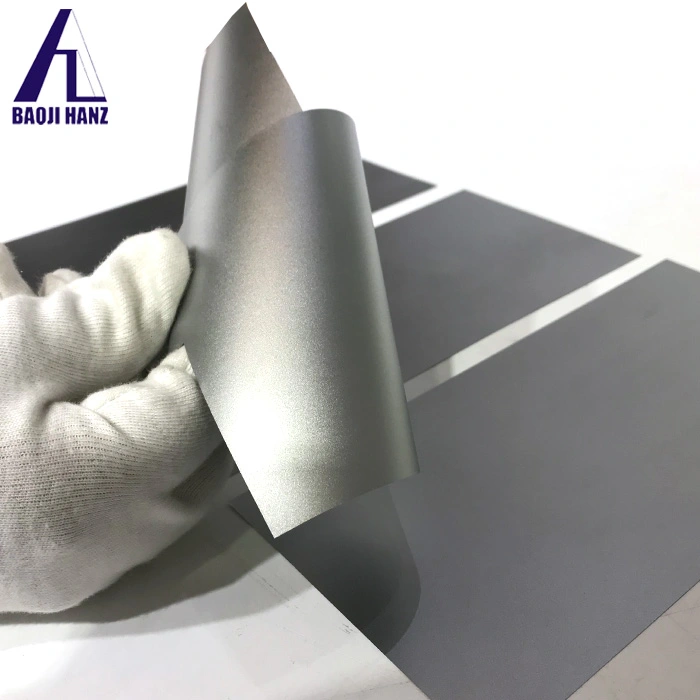

Nitinol Shape Memory Alloy Wire Product Introduction

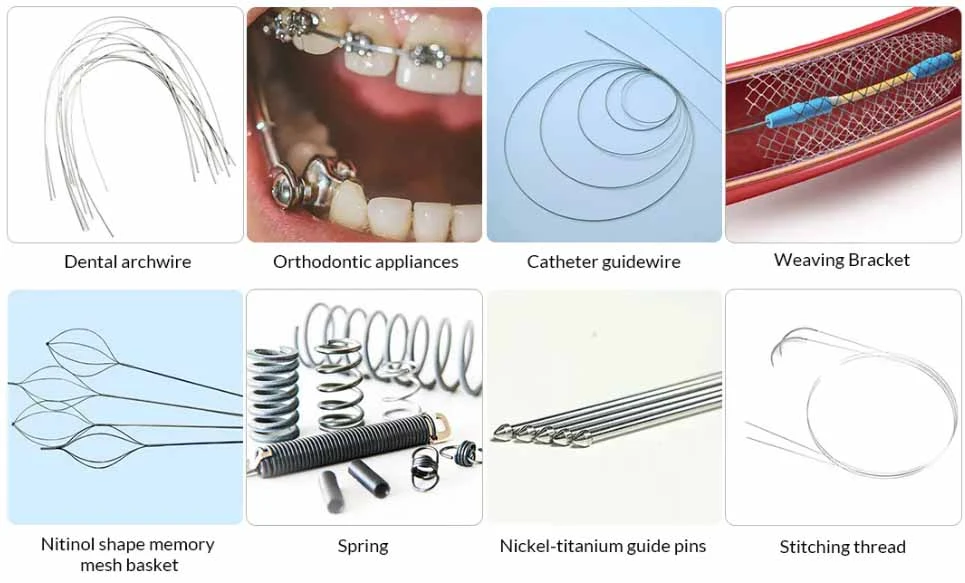

Nitinol Shape Memory Alloy Wire, also known as NiTi wire, is a type of Nickel-titanium alloy, featuring shape memory effect, superelasticity, excellent fatigue resistance and corrosion resistance. These unique properties enable Nitinol Alloy Wire to play a special role in the medical and industrial fields, including woven products, orthodontic wires, guide wires, etc.

Specifications

| Material Grade | niti alloy |

| Wire Shape | Wire Shape |

| Diameter Range(mm) | 0.01mm min |

| Diameter Tolerance | ±0.01mm |

| Standards | ASTM F2063 |

| Transformation Temperature | -50°C to 100°C |

| Surface Finish | Black surface |

| MOQ | 1kg or 500meters |

| Transport Package | Export safety packaging |

| Feture | Shape memory effect Super elasticity (pseudo-elasticity) Corrosion resistance Biocompatibility Temperature sensitivity The mechanical properties are stable |

Relevant parameters

|

NiTi Alloy Code |

A |

B |

S |

C |

D |

E |

J |

K |

L |

|

Austenite Finish Temperature (Af) After Heat Treatment, °C |

70+/-10 |

30+/-10 |

25+/-5 |

17+/-7 |

10+/-10 |

5+/-10 |

-30+/-10 |

30+/-10 |

-20+1-10 |

|

Mechanical Properties: ASTM F2063 |

|||||

|

NiTi Alloy Code |

Straightened Superelastic Condition (SE) |

||||

|

Tensile Strengthσ,Mpa |

Elongationδ,% |

Upper Plateau Stress σ, MPa |

Residual Strain, % |

Active Af Temperature, ℃ |

|

|

D |

≥1300 |

≥10 |

≥480 |

<0.5 |

10±7 |

|

C |

≥1150 |

≥10 |

≥440 |

<0.5 |

17±7 |

|

S |

≥1000 |

≥10 |

≥400 |

<0.5 |

25±5 |

Application Areas

In terms of medical care

Dental pulp file

Intrauterine device

Surgical sutures

Braided wire for vascular stents

Orthopedic implants

Non-medical

Thermosensitive actuator

Miniature components for robots and aerospace

Mirror frame

Springs and SIM card trays for mobile devices

Elastic elements in electronic devices

High-precision parts for industrial automation

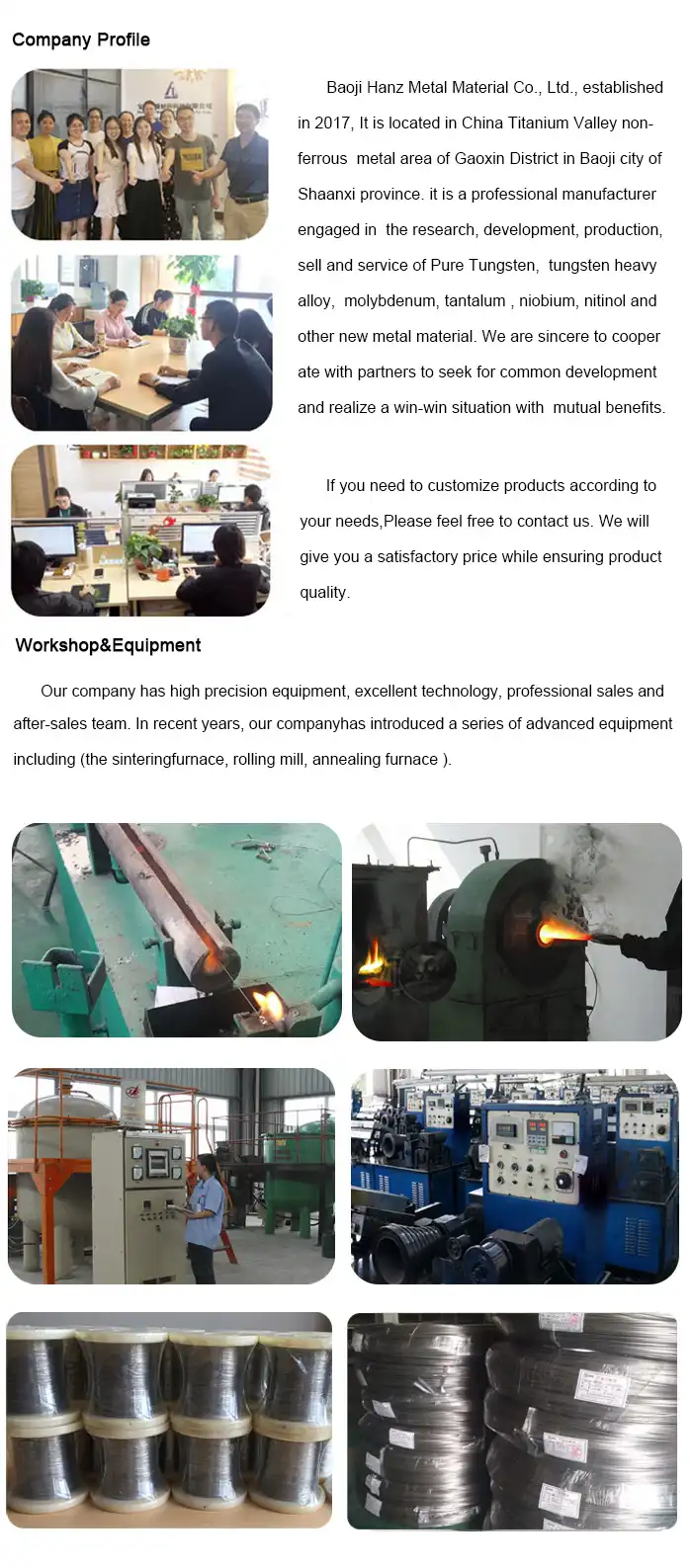

Our company

Our Certificate

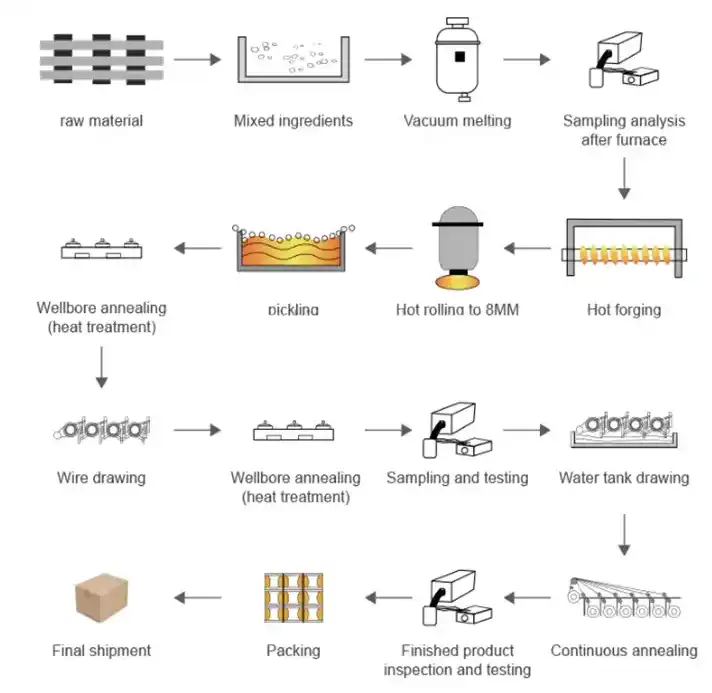

Nitinol Wire Production Process

Raw material → Mixed ingredients → Vacuum melting → Sampling analysis after furnace → Hot forging → Hot rolling to 8MM → Pickling → Wellbore annealing (heat treatment) → Wire drawing → Wellbore annealing (heat treatment) → Sampling and testing → Water tank drawing → Continuous annealing → Finished product inspection and testing → Packing → Final shipment

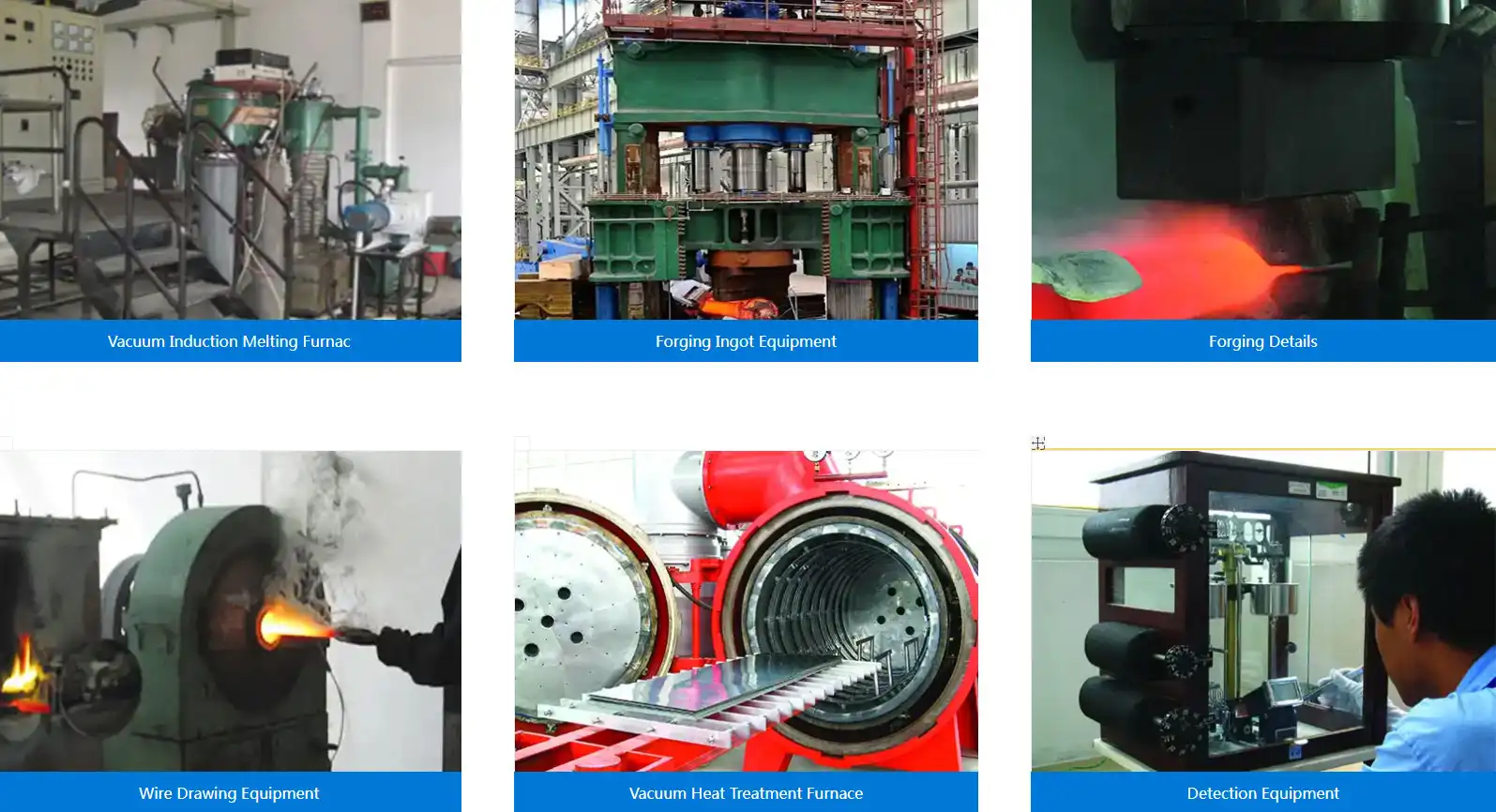

Our equipment

Quality control

1.Ensure that the product meets the established standards and user requirements, reduce defects, and enhance reliability and satisfaction.

2. Raw material control: Verify the qualifications of suppliers, conduct tests on incoming materials in terms of size, performance and other indicators, and avoid quality risks from the source.

3. Production process monitoring: Through inspection Tours, first-piece inspections and other methods, track the operation norms of each process, and promptly identify issues such as equipment malfunctions and process deviations.

4. Finished product inspection: Conduct a full inspection or sampling inspection of the finished products in accordance with the standards (such as appearance, function, and safety tests). Unqualified products need to be reworked or scrapped

Packaging/Transportation/Payment method

FAQ

Q1: Are you a manufacturer or a trading company?

A1: We are a direct manufacturer with over many years of experience in nickel and titanium production.

Q2: What nickel-titanium products do you offer?

A2: Our product range includes nickel-titanium wire, nickel-titanium flat wire, nickel-titanium wire rope, nickel-titanium plate, nickel-titanium tube, nickel-titanium bar, nickel-titanium spring, nickel-titanium paper clip, nickel-titanium processed parts, etc.

Q3: What are your payment terms?

A3: The payment method varies depending on the type of transaction (FOB, CIF, CNF, etc.).

Q4: How can I get the quotation?

A4: To provide an accurate quotation, please provide the following detailed information:

1. Product name

2. Standard

3. Material grade (Chemical Composition)

4. Specifications

5. Quantity

Q5: Do you offer custom manufacturing?

A5: Yes! We provide customized nickel-titanium products based on customers' drawings or samples.

Q6: How do you ensure product quality?

A6: We implement strict quality control at every stage of production and use advanced testing equipment to meet customer and international standards.

Q7: What transportation options do you have?

A7: We do it by sea or air, depending on the customer's requirements.

If you are interested in our Nitinol Shape Memory Alloy Wire after reading the above content, please contact us today for more details or a customized quotation!

Contact Us

Experience the superior quality and performance of Baoji Hanz Metal Material Co., Ltd.'s Nitinol Shape Memory Alloy Wire, please email us at baojihanz-niti@hanztech.cn. Partner with us for innovative, reliable, and customized solutions that drive your projects forward.

.webp)

.webp)