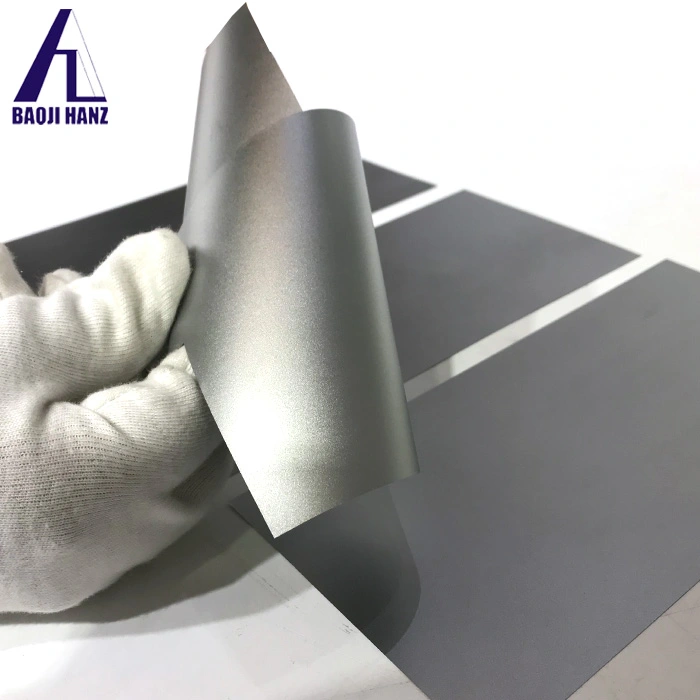

Titanium Nickel Alloy Wire: Superior Performance for Advanced Applications

Baoji Hanzi Metal Materials Co., Ltd. specializes in the production of high-quality titanium-nickel alloy wire rods. The company possesses advanced manufacturing techniques and strict quality control to ensure that our Titanium Nickel Alloy Wire meet industry standards. Titanium-nickel alloy wire combines unparalleled shape memory, super elasticity and corrosion resistance, making it suitable for mission-critical applications.

Product Introduction:

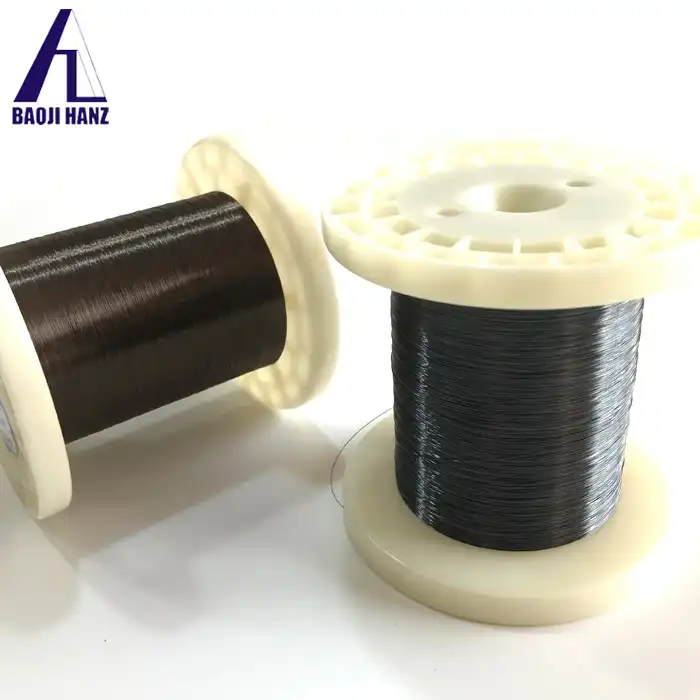

Titanium Nickel Alloy Wire is mainly composed of nickel and titanium. The nickel content is generally between 55.4% and 56.2%, the carbon content is ≤0.07, the hydrogen content is ≤0.005, the oxygen content is ≤0.050, the nitrogen content is ≤0.05, and the remainder is titanium. The common diameter specifications are above 0.1mm.

Specifications:

|

Material Grade |

NiTi |

|

Wire Shape |

Round Wire |

|

Diameter Range(mm) |

0.025mm min |

|

Standards |

ASTM F2063 |

|

Diameter Tolerance |

±0.001mm |

|

Surface Finish |

Black surface, brown surface |

| Transformation Temperature | -50°C to 100°C |

| Tensile Strength | 800-1500 MPa |

Chemical Composition:

|

Mechanical Properties: ASTM F2063 |

|||||

|

NiTi Alloy Code |

Straightened Superelastic Condition (SE) |

||||

|

Tensile Strengthσ,Mpa |

Elongationδ,% |

Upper Plateau Stress σ, MPa |

Residual Strain, % |

Active Af Temperature, ℃ |

|

|

D |

≥1300 |

≥10 |

≥480 |

<0.5 |

10±7 |

|

C |

≥1150 |

≥10 |

≥440 |

<0.5 |

17±7 |

|

S |

≥1000 |

≥10 |

≥400 |

<0.5 |

25±5 |

|

NiTi Round Wire Diameter Tolerance: |

|

|

Diameter(mm) |

Tolerance(mm) |

|

4.000-2.000mm |

±0.020mm |

|

2.000-1.000mm |

±0.010mm |

|

1.000-0.350mm |

±0.010mm |

|

0.350-0.260mm |

±0.007mm |

|

0.260-0.150mm |

±0.005mm |

|

0.150-0.080mm |

±0.004mm |

|

0.080-0.050mm |

±0.003mm |

|

0.050-0.013mm |

±0.002mm |

Why Choose Us?

1. ISO 9001 and ISO 13485 certified manufacturing process

2. Customizable wire diameters and properties

3. Extensive R&D capabilities for tailored solutions

4. Consistent quality and on-time delivery

5. Comprehensive technical support and after-sales service

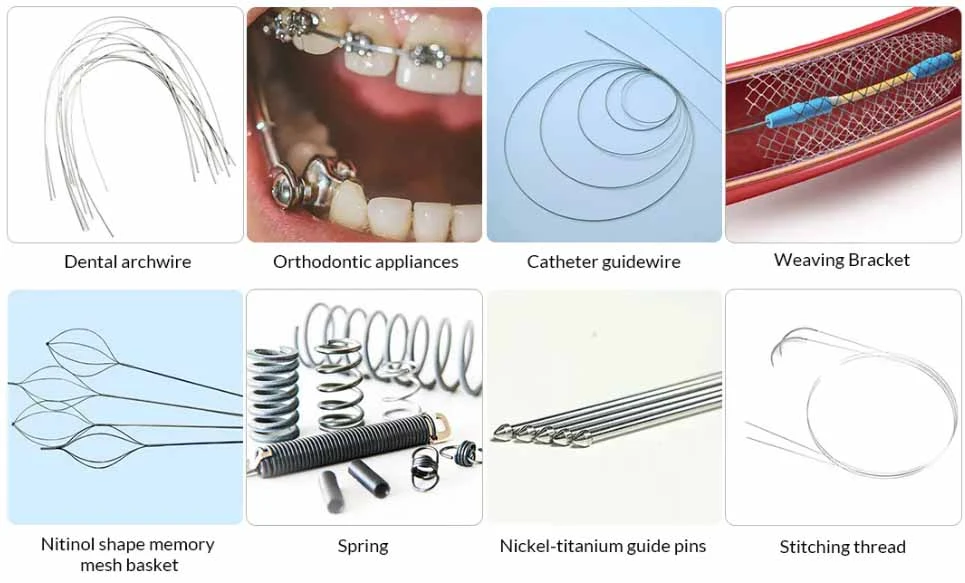

Application Areas

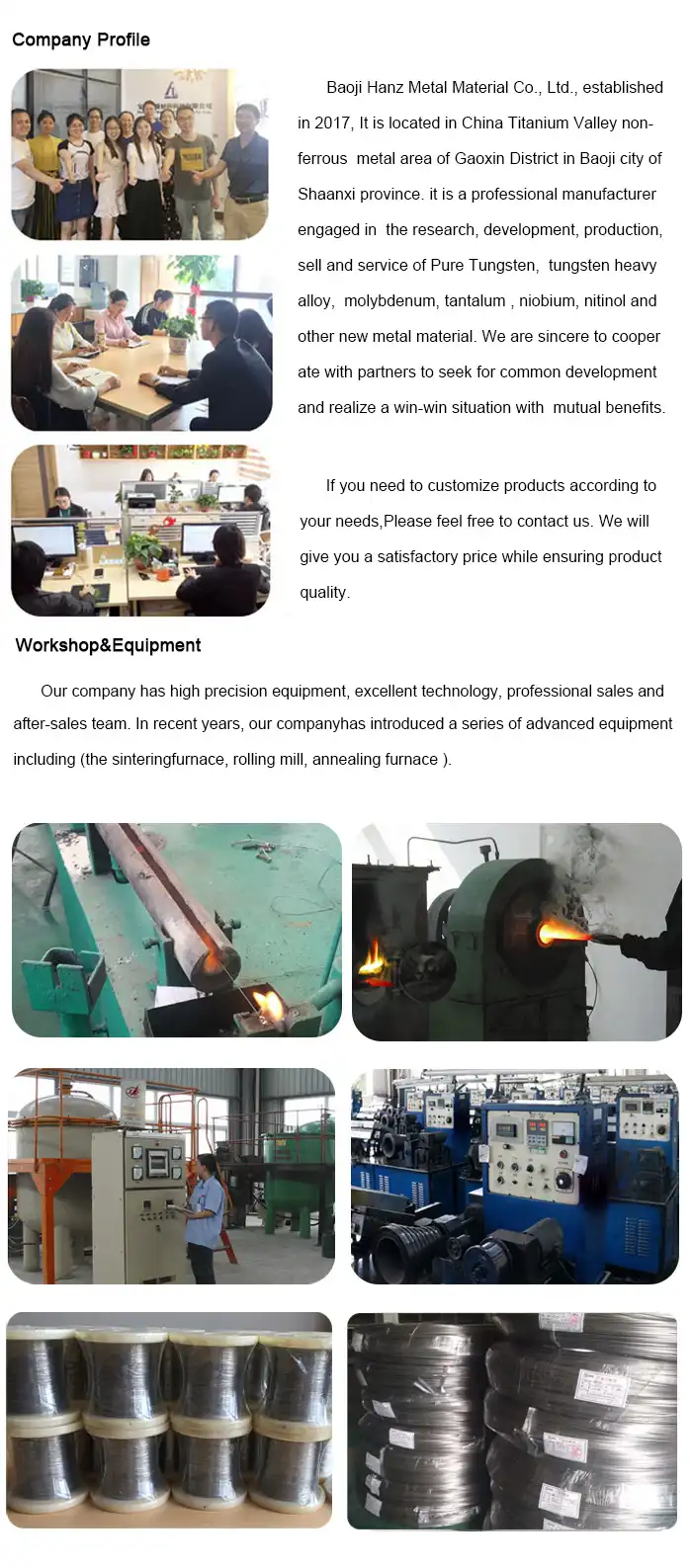

Our company

Our Certificate

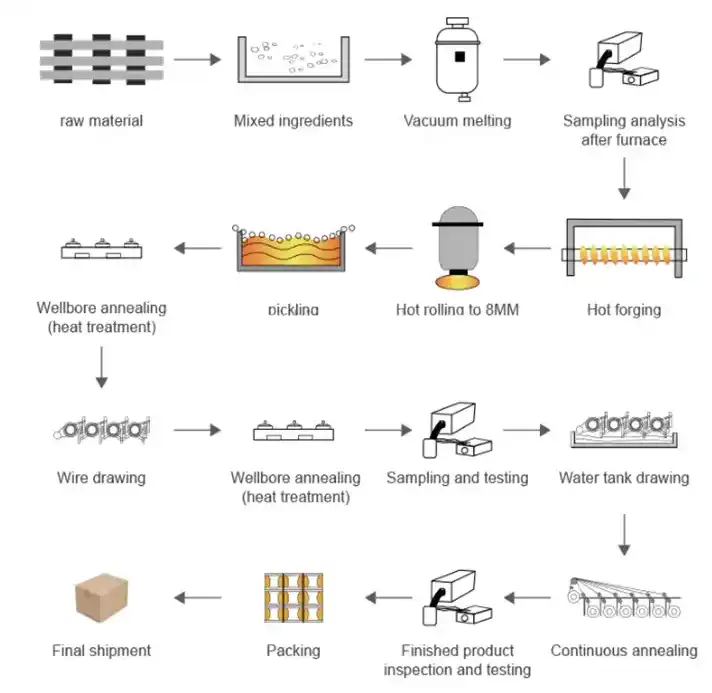

Nitinol Wire Production Process

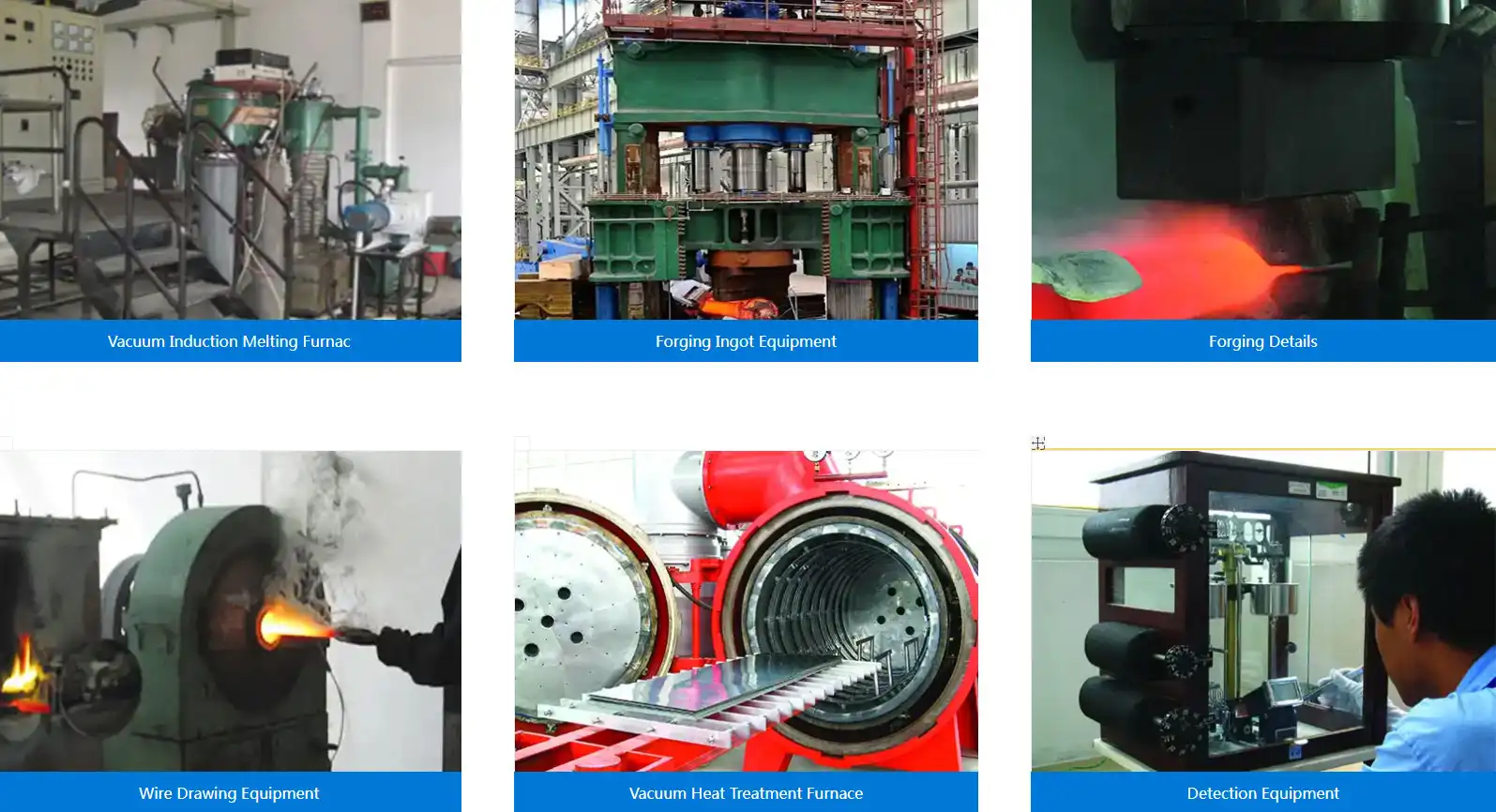

Our equipment

Quality control

1.Ensure that the produced products comply with the international implementation standard ASTM F2063.

2. Raw material control: Sampling inspection is carried out before the production of raw materials, and the quality of purchased materials is strictly controlled

3. Production process monitoring: Through methods such as first-piece inspection and process checks, inspect the operation norms of each process, and promptly identify issues such as processing deviations and equipment malfunctions.

4. Finished product inspection: Conduct a comprehensive inspection or sampling inspection of the finished products in accordance with the implemented standards. Unqualified products need to be reworked or scrapped.

Packaging

Transportation

Payment method

FAQ:

Q1: What is the minimum order quantity for Titanium Nickel Alloy Wire?

A1 is 1kg. The specific MOQ depends on the product and specifications.

Q2: Can you provide the material proof of the order?

A1: Yes, we can provide you with the material list along with the goods.

Q3: How does your titanium-nickel alloy wire compare with traditional materials?

Compared with traditional alloys, titanium-nickel alloys have outstanding superelasticity, shape memory and biocompatibility, and are the preferred materials in application fields.

Q4: How long is the delivery time for custom orders?

A4: Generally, custom orders take 2 to 4 weeks, depending on the specifications and quantity. We strive to meet the urgent deadlines where possible.

Q5: Can you provide technical support for the product?

A5: Sure. We are always ready to answer your questions.

Contact Us:

For inquiries or to discuss your Titanium Nickel Alloy Wire needs, please email us at baojihanz-niti@hanztech.cn. Our dedicated team is ready to assist you with any questions or custom requirements you may have.

.webp)

.webp)

.webp)