Baoji Hanz Metal Material Co., Ltd.: Your Trusted Braided Nitinol Stent Manufacturer & Supplier

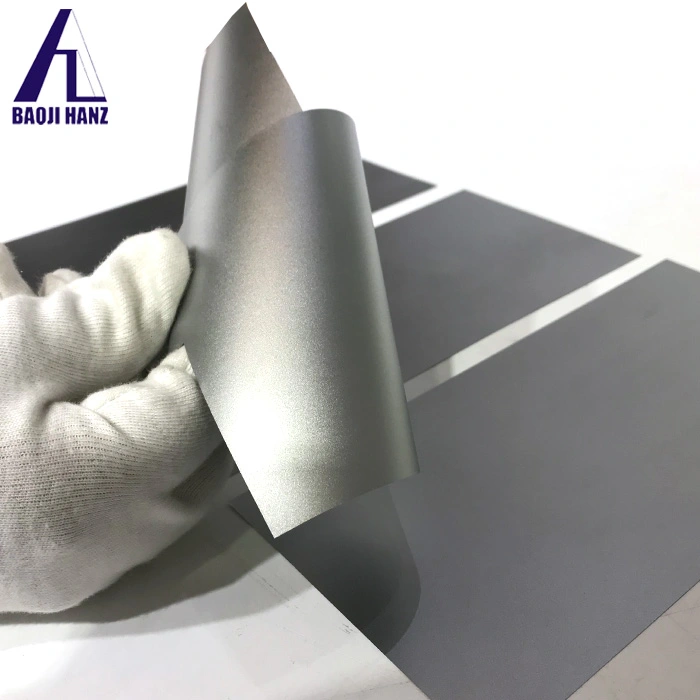

Braided nitinol stent is cutting-edge medical devices designed to provide structural support to blood vessels and other luminal structures. Made from a nickel-titanium alloy, these stents combine the unique properties of nitinol—such as superelasticity and memory effect—with the added strength and flexibility of a braided construction. The braiding pattern enhances the stent’s radial strength and flexibility, allowing it to conform to complex anatomical structures while maintaining excellent support. Our products are crafted with precision to ensure reliable performance in various medical applications, providing durability and safety for patients.

Braided Nitinol Stent Specification

| Parameter | Details |

|---|---|

| Material | Niti wire |

| MOQ: | 10pcs |

| Size | Customization based on provided pictures |

| Packaging | Disinfection compliant packaging |

| Payment methods: | Telegraphic transfer, Western Union, Paypal |

| Delivery date | It usually takes 25 to 30 days (the exact time depends on the chart). |

| Applicaiton | Medical |

Features

Enhanced Flexibility: The braided structure provides superior flexibility, allowing the stent to navigate through complex vessel pathways.

Increased Radial Strength: The braiding pattern increases the stent’s radial strength, providing reliable support and reducing the risk of collapse.

Biocompatibility: Made from biocompatible materials, ensuring minimal risk of adverse reactions within the body.

Conformability: Adapts well to the anatomical structure, ensuring a secure fit and effective support.

Ease of Deployment: Designed for smooth and efficient placement using catheter-based systems.

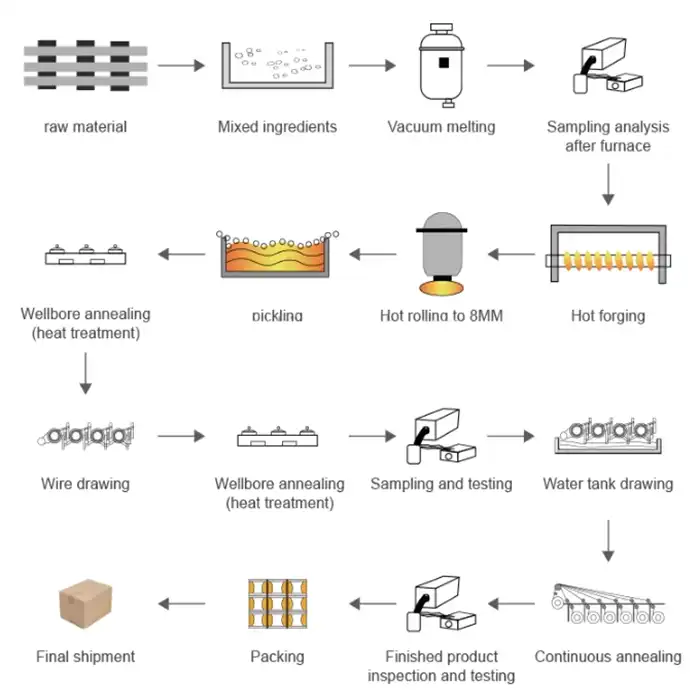

Production Technology

The manufacturing of our products involves several advanced processes to ensure high-quality and performance:

Material Preparation: Nitinol is processed to achieve the desired mechanical properties, including superelasticity and memory effect.

Braiding Process: The nitinol wires are braided using precision machinery to create the desired braiding pattern, enhancing the stent’s flexibility and strength.

Stent Fabrication: The braided stents are shaped and sized according to specifications through advanced cutting and forming techniques.

Heat Treatment: The stents undergo a controlled heat treatment process to optimize their superelastic properties and memory effect.

Sterilization: Each stent is sterilized using gamma radiation or ethylene oxide to ensure safety and prevent contamination.

Quality Control

Our quality control process ensures that each braided nitinol stent meets the highest standards:

Material Testing: Assessing the nitinol alloy’s chemical composition and mechanical properties.

Dimensional Inspection: Verifying the stent’s dimensions and tolerances to ensure consistency and accuracy.

Performance Testing: Evaluating the stent’s flexibility, strength, and deployment characteristics under simulated body conditions.

Sterility Testing: Ensuring that the stents are free from microbial contamination before they are shipped.

Production Process

Transportation

FAQ

Q: What makes it different from other stents?

A: Braided nitinol stents feature a braided structure that provides enhanced flexibility and radial strength, allowing for better adaptability and support in various anatomical locations.

Q: How are our products delivered and deployed?

A: Our products are delivered via catheter-based systems and are typically balloon-expandable, which helps in achieving accurate placement and expansion.

Q: Are our products suitable for long-term use?

A: Yes, Our products are designed for long-term use and are made from biocompatible materials that are well-tolerated by the body.

Q: Can our products be used in all types of medical conditions?

A: Our products are versatile and can be used in a variety of conditions, including cardiology, peripheral vascular disease, urology, gastroenterology, and pulmonology.

Q: How can I order custom braided nitinol stents?

A: For custom orders or specific requirements, please contact us at baojihanz-niti@hanztech.cn. We are ready to assist with your needs and provide tailored solutions.

Contact Us

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of braided nitinol stent. We offer a large inventory, comprehensive certifications, and prompt delivery. For custom solutions or further inquiries, please reach out to us at Email: hztech01@hanztech.cn

_1740043052871.webp)

.webp)

.webp)