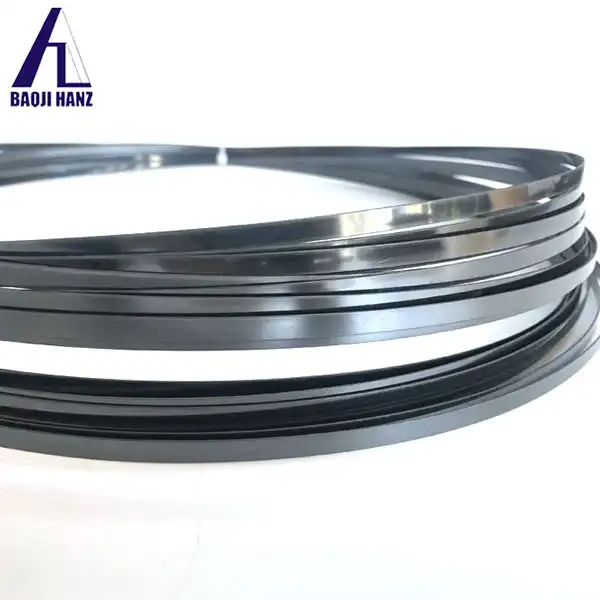

Products Description

Basic Information Of Nitinol Shape memory Pipe

Basic information

Nitinol shape memory pipe are mainly composed of nickel (Ni) and titanium (Ti) materials and are renowned for their unique shape memory effect, superelasticity and excellent biocompatibility. It complies with ISO 5832-11 and ASTM F2063 standards and is widely used in minimally invasive medical devices due to its ability to adapt to complex physiological environments.

Key Properties Of Nitinol Shape memory Pipe

| Property | Specification |

|---|---|

| Material Composition | Ni: 54.5-56.0%, Ti: Balance |

| Shape Memory Effect | Recovers to preset shape at 32-40°C (body temperature) |

| Tensile Strength | ≥ 1000 MPa |

| MOQ | 5pcs |

| Density | 6.45g/cm3 |

| Corrosion Resistance | Passive oxide film (TiO₂) for long-term implantation safety |

| Wall Thickness Range | 0.05-1.0 mm |

| Outer Diameter Range | 0.3-10.0 mm |

| Surface Finish | Polished or electropolished |

Core Advantages

The core advantages of nitinol shape memory pipe lie in their unique performance and scene adaptability. The following are the key highlights (balancing technical features and practical value) :

1. Shape memory effect: It can deform freely at low temperatures. When heated to a specific temperature, it can precisely restore the preset shape, making it suitable for scenarios such as minimally invasive implantation and precise component reset.

2. Super elasticity and fatigue resistance: The elastic deformation can reach 8-10% (while ordinary metals only have 0.1-0.2%), and there is no permanent damage after repeated deformation. The service life is far longer than that of traditional alloys.

3. Excellent biocompatibility: Non-toxic and non-allergenic. The naturally formed TiO₂ oxide film on the surface can resist the corrosion of body fluids and complies with ISO 10993 standards.

4. Precise controllability: By adjusting the ratio of nickel-titanium atoms and the heat treatment process, parameters such as shape memory temperature and elastic modulus can be precisely controlled to meet the requirements of different scenarios.

5. Lightweight and high strength: With a density of only 6.45g/cm³ (approximately 80% of that of stainless steel), its tensile strength is ≥1000MPa, balancing portability and structural stability.

Type Of Shipping

_1740043052871.webp)

_1729339138670.webp)