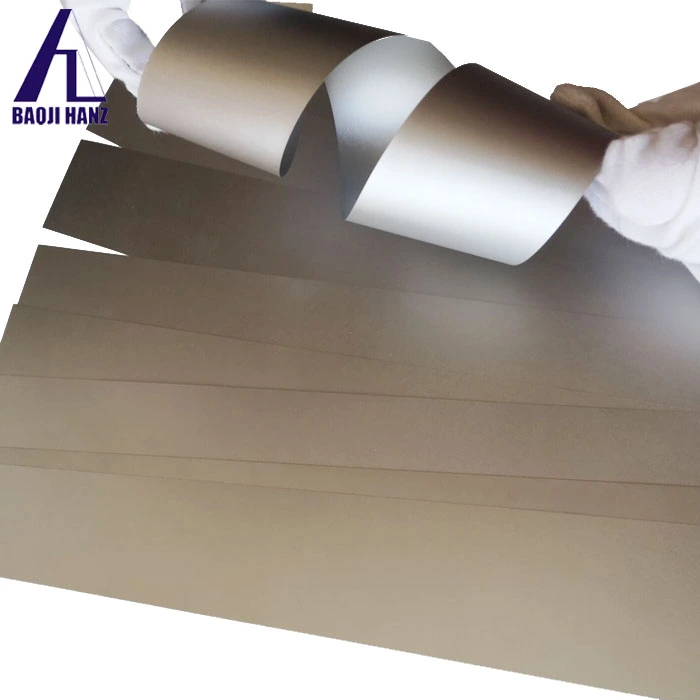

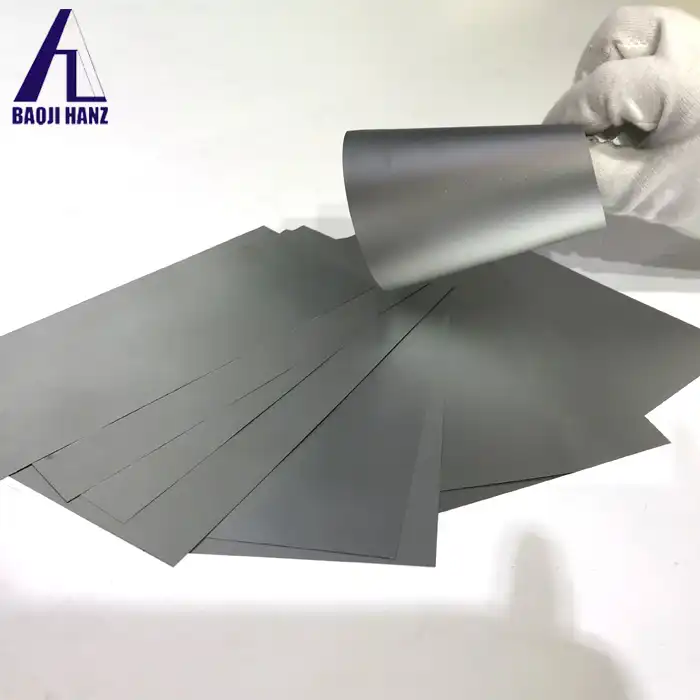

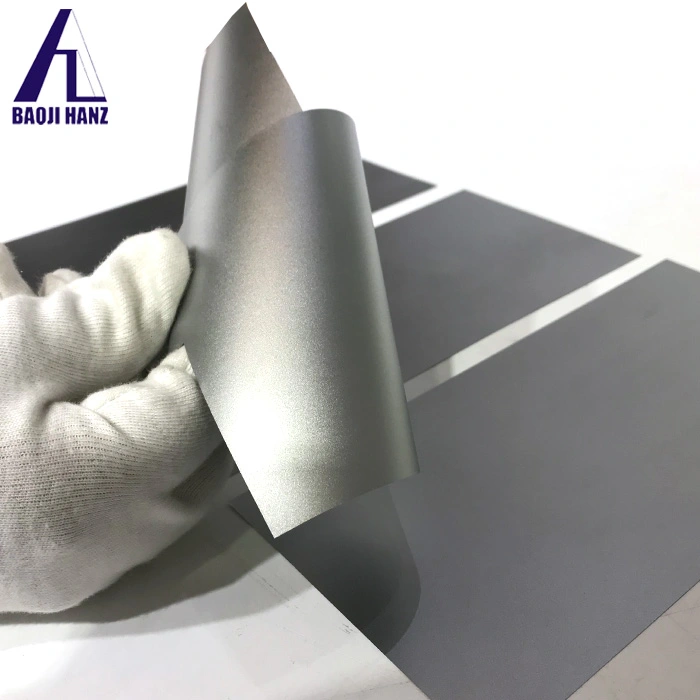

Baoji Hanz Metal Material Co., Ltd.: Your Trusted Nitinol Alloy Foil Manufacturer & Supplier

Baoji Hanz Metal Material Co., Ltd.as a leading producer of high-quality Nitinol Alloy Foil, is proud to be able to produce superior materials that meet international standards. With the most professional team and the most advanced production equipment of our company, we ensure that the products of our company are the best, the best-performing and the most reliable. Our nickel-titanium straight wire is specially designed for applications that require high corrosion resistance, sensitivity and the ability to withstand extreme conditions.

Nitinol Alloy Foil Basic Knowledge

Nickel-titanium (also known as Nitinol or NiTi) is a unique shape memory alloy. A thermoelastic martensitic phase.The transformation of the Nitinol Alloy Foil material is the reason for its extraordinary properties. Nickel-titano alloy is usually made of 55%-56% Nickel and 44%-45% titanium. Minor changes in composition can significantly affect the performance of the material.

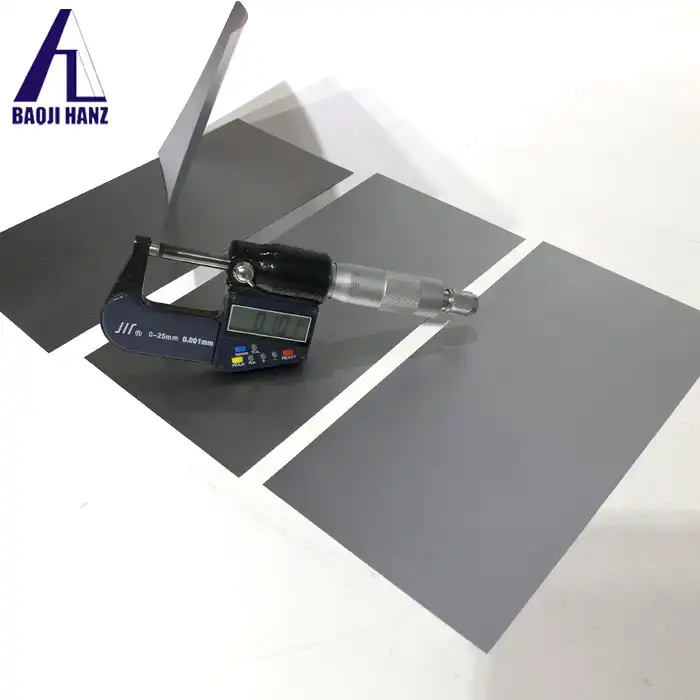

Specifications

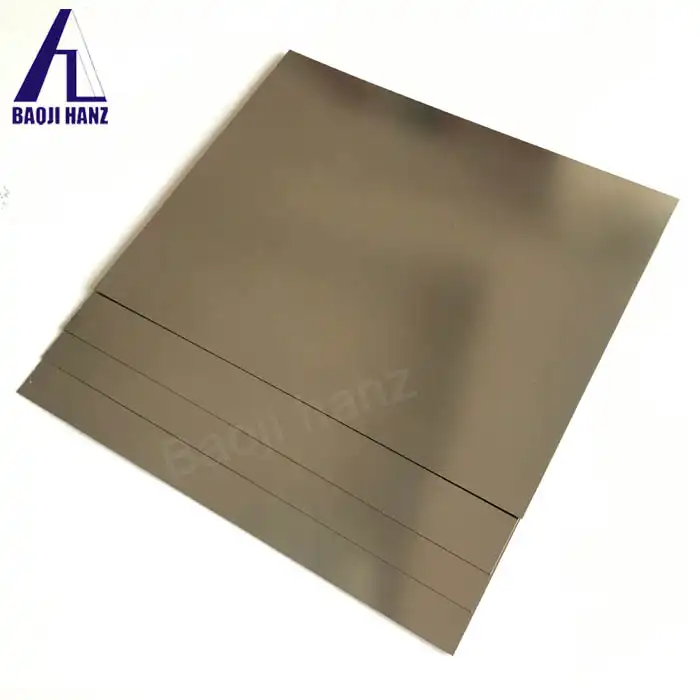

| Surface | Polished surface |

| Certificate | ISO9001,ROHS, TUV |

| Elongation | 25-50% |

| Melting point | 1310°C |

| Tensile strength | 800-1500MPa |

| Density | 6.45g/cm³ |

| MOQ | 1kg or 10pcs |

| standard | ASTM F2063 |

Chemical Composition

| Element | Mass percentage |

| Ni | 54.5-57.0 |

| C |

≤0.040 |

| Co |

≤0.050 |

| Cu |

≤0.010 |

| Cr |

≤0.010 |

| H |

≤0.005 |

| Fe |

≤0.050 |

| Nb |

≤0.025 |

| N |

≤0.005 |

| O |

≤0.040 |

| Ti | Margin |

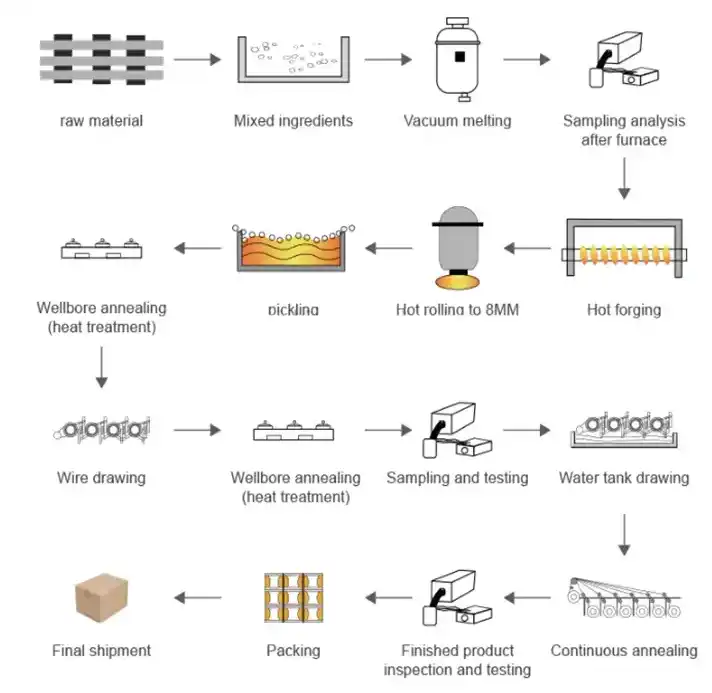

Production Process

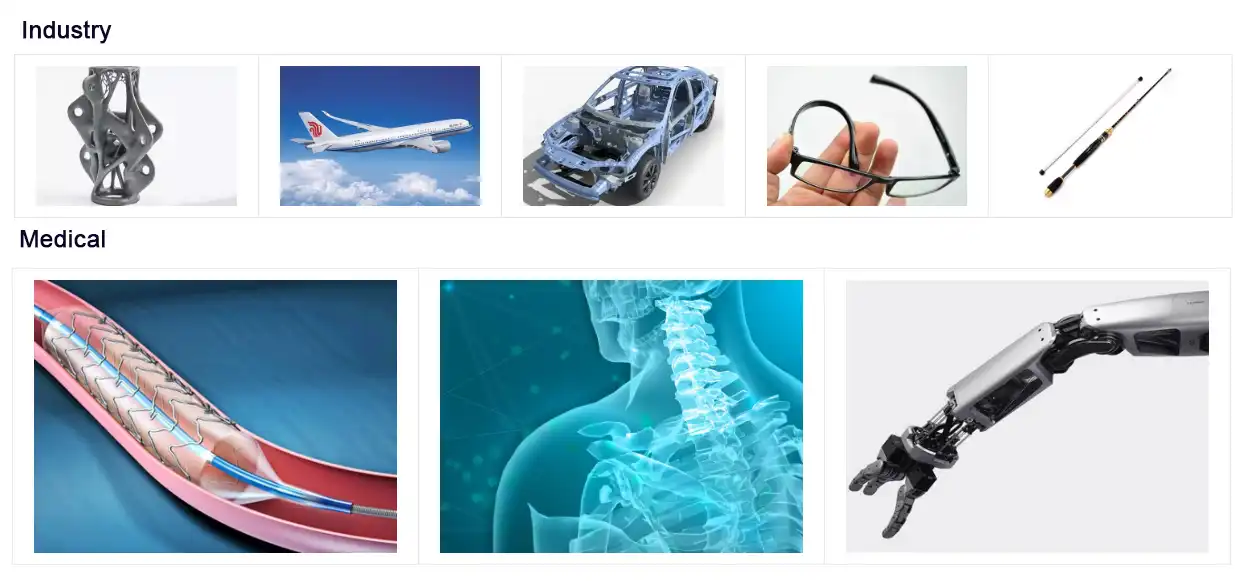

Application

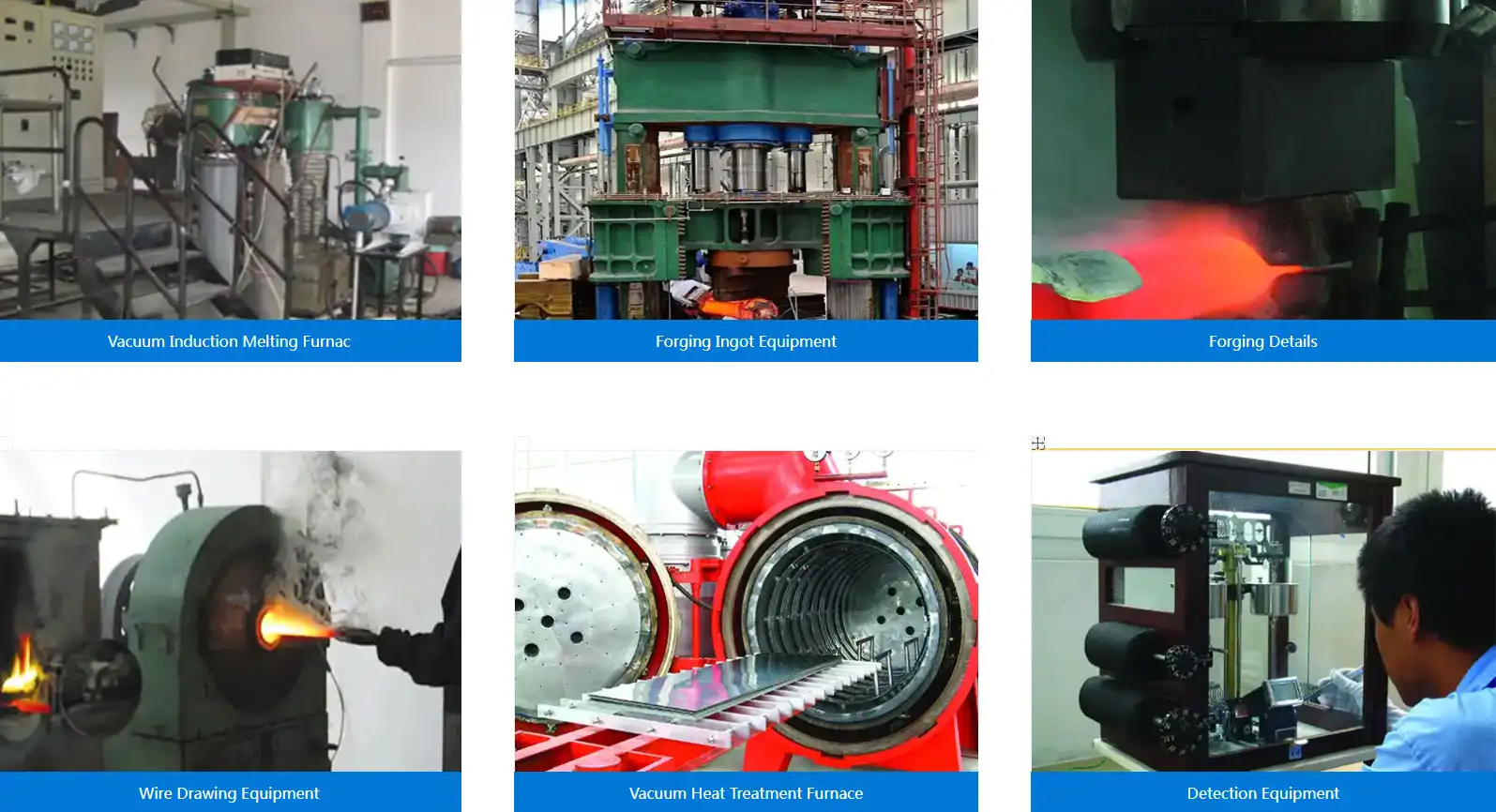

Our Equipment

Packaging/Transportation/Payment Method

OEM Services

1. Pre-sale consultation: Professional consultants respond promptly and precisely match demands.

2. Mid-sale guarantee: Full progress tracking and efficient order processing.

3. After-sales service: 7× 24-hour customer service support to quickly solve usage problems.

4. Value-added services: Free technical guidance and customized services.

FAQ

Q1: What are the core advantages of nickel-titanium foil?

A1:It has the function of shape memory and superelasticity, and can restore its original shape after deformation. Strong corrosion resistance and excellent biocompatibility.

Q2: In which fields is nickel-titanium foil mainly applied?

A2:It is widely used in medical equipment, aviation, etc.

Q3: What should be noted when using nickel-titanium foil?

A3: Avoid high temperatures. Special tools should be used during processing to prevent damage or deformation of the material surface.

Q4: Is nickel-titanium foil safe and non-toxic?

A4: It meets biosafety standards, is non-toxic, has low allergenicity, and can come into direct contact with human tissues.

Contact Us

Nitinol Alloy Foil, due to its unique memory and super elasticity, plays an unprecedentedly important role in the industrial, aviation and medical fields. We have been engaged in the research and production of nickel-titanium straight wire for a long time. No matter what your needs are for products and technologies, we will answer your questions as soon as possible. Please contact us at any time!

Email: baojihanz-niti@hanztech.cn

We are here to assist you and look forward to your inquiry!

_1740043052871.webp)

.webp)

.webp)

.webp)