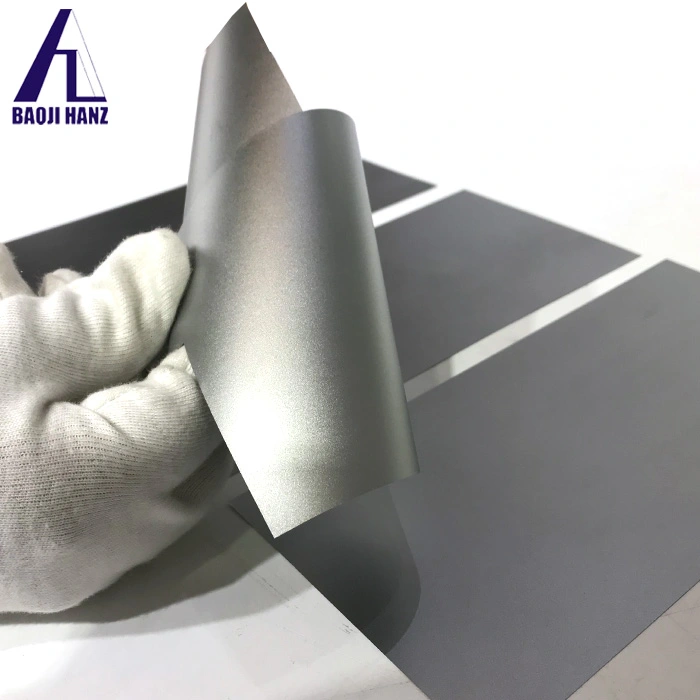

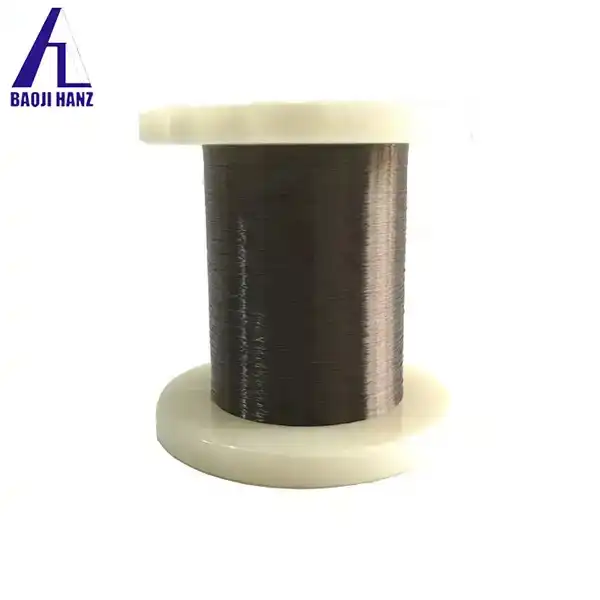

Baoji Hanz Metal Material Co., Ltd.: Your Trusted One way nickel titanium springSuperelastic Nickel Titanium Alloy Sheet Manufacturer & Supplier

As a leading manufacturer of high-quality super-elastic nickel-titanium plates, Baoji Hanz Metal Material Co., Ltd. can provide you with all-round one-stop services based on our long-term production and technical experience. We have advanced production equipment and a professional technical team, which can ensure the reliability of our product quality. Thanks to the corrosion resistance, super elasticity and memory performance of the material of this product, it is widely used in industries such as industry, electronics and medical care.

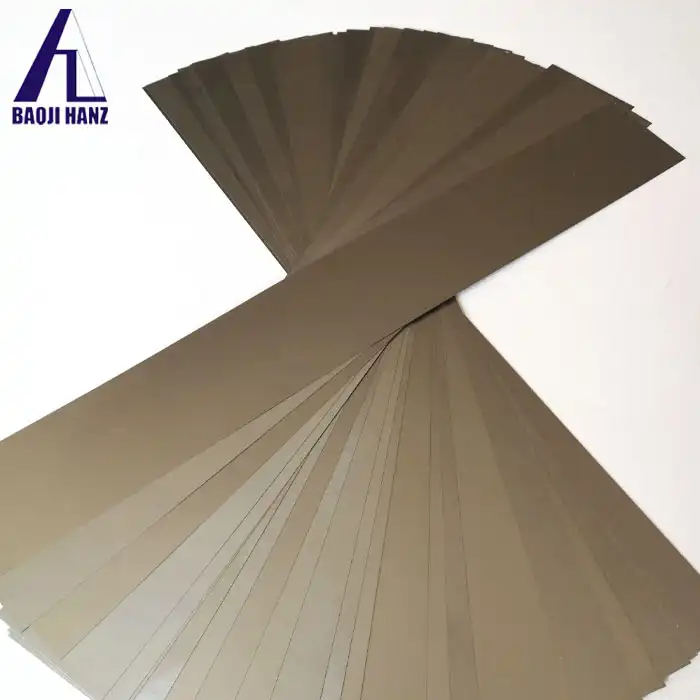

Superelastic Nickel Titanium Alloy Sheet Basic information

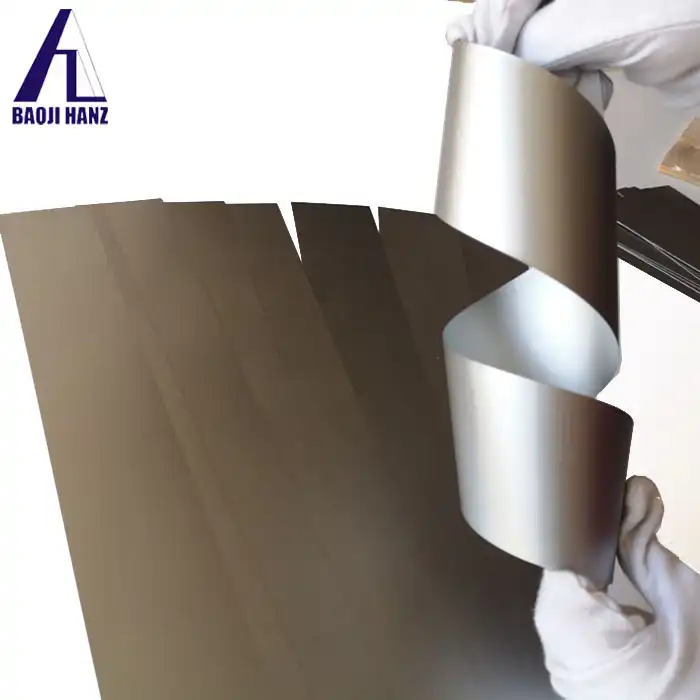

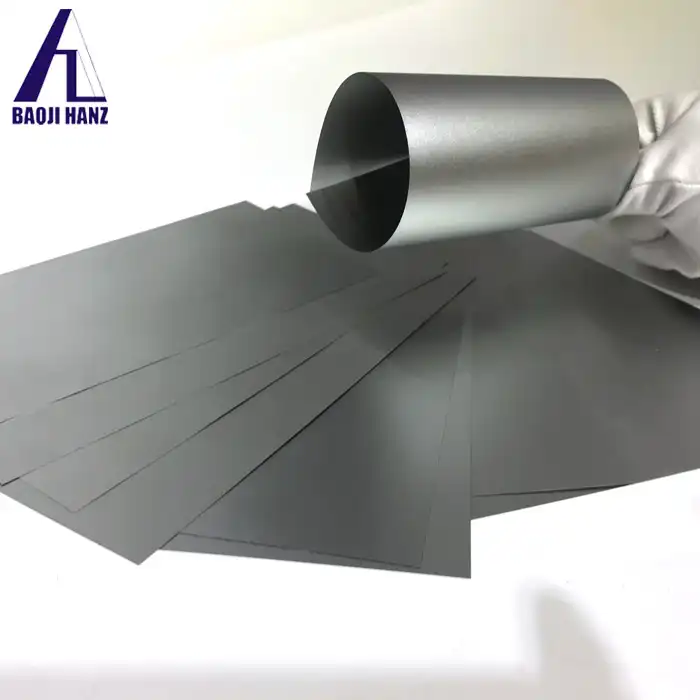

Our Superelastic Nickel Titanium Alloy Sheet is a state of the art material made with accuracy designing to give excellent execution in different applications. Made out of nickel and titanium, this amalgam offers momentous versatility and shape memory properties, making it ideal for requesting conditions where adaptability and strength are principal. With unrivaled versatility, our product guarantees life span and dependability in a large number of modern settings.

|

|

|

Superelastic Nickel Titanium Alloy Sheet Specifications

| Place of Origin | Shaanxi, China |

| Name | nitinol plates |

| Color | Bright surface |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Width | ≤200mm |

| Tensile strength | 920Mpa |

| Feature | Superelastic |

| Supply Status | Full annealed |

| The Max recovery stress | 600 MPa |

| Standard | ASTM F2063-18 |

| Certificate | ISO9001:2015 |

| Application | Medical device |

| Chemical element | Af range | Available production Line | Usage | Sample |

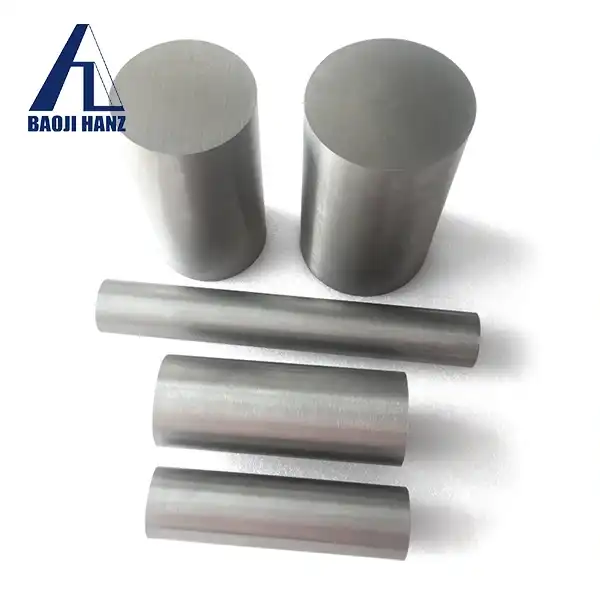

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| Mechanical Properties | ||||

| Thickness | UTS | Elongation | Upper Plateau Stress | Active Af |

| mm | σb MPa (min.) | δ % (min) | σload MPa (min.) | ℃ |

| 0.1 ~ 0.3 | 1100 | 15 | 480 | |

| 0.3 ~ 0.6 | 920 | 15 | 440 | - 20 ~ 100 ℃ |

| 0.6 ~ 6.0 | 850 | 15 | 440 | |

| Tolerance | |

| Nominal Thickness in mm | Permissible Variation from Nominal in mm |

| 6.00 ~ 1.00 | ± 0.05 |

| 1.00 ~ 0.26 | ± 0.03 |

| 0.26 ~ 0.15 | ± 0.02 |

| 0.15 ~ 0.10 | ± 0.01 |

Application Areas

Features

Here are a portion of its most significant qualities:

-

Extraordinary versatility: It can distort altogether under pressure and afterward return to its unique shape once the pressure is eliminated. This property empowers it to endure a lot of strain without extremely durable distortion, making it ideal for adaptable applications.

-

Shape memory impact: When exposed to explicit temperature changes, it can return to its pre-disfigured shape. This property permits it to adjust and recuperate its unique structure, making it helpful in applications like biomedical gadgets, actuators, and sensors.

-

High erosion obstruction: The product displays magnificent protection from different destructive conditions, including acidic and soluble circumstances. This component guarantees its life span and toughness, especially in brutal conditions or synthetic openness.

-

Weakness opposition: It can endure rehashed patterns of disfigurement without encountering debasement in its mechanical properties. This makes it appropriate for long haul dependability and perseverance applications, like aviation parts and muscular inserts.

-

Flexibility in creation: The material can be effectively created into various shapes and sizes, considering customization as indicated by unambiguous application necessities. It can likewise be gotten together with different materials utilizing different procedures, like welding or brazing.

-

Great biocompatibility: It displays great similarity with living tissues, lessening the gamble of unfriendly responses. This property pursues it an optimal decision for clinical and dental applications, like inserts and careful instruments.

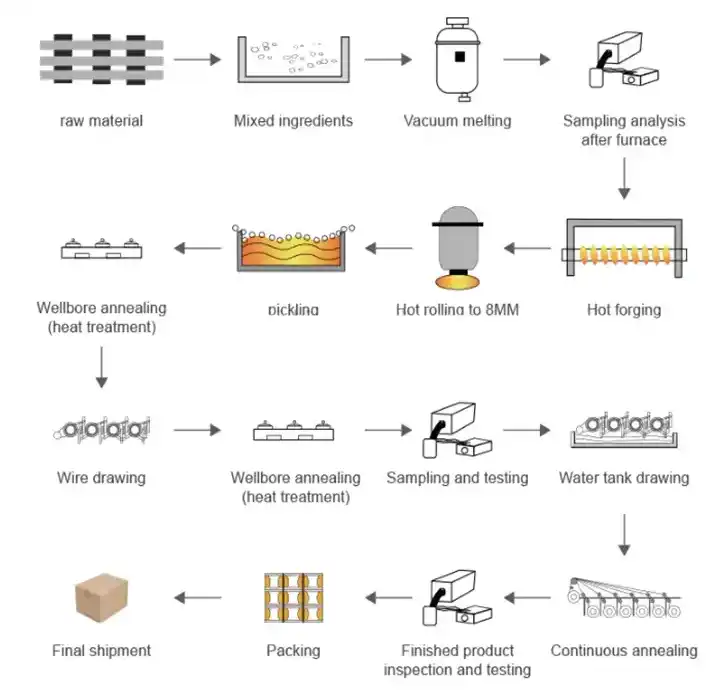

Production Technology

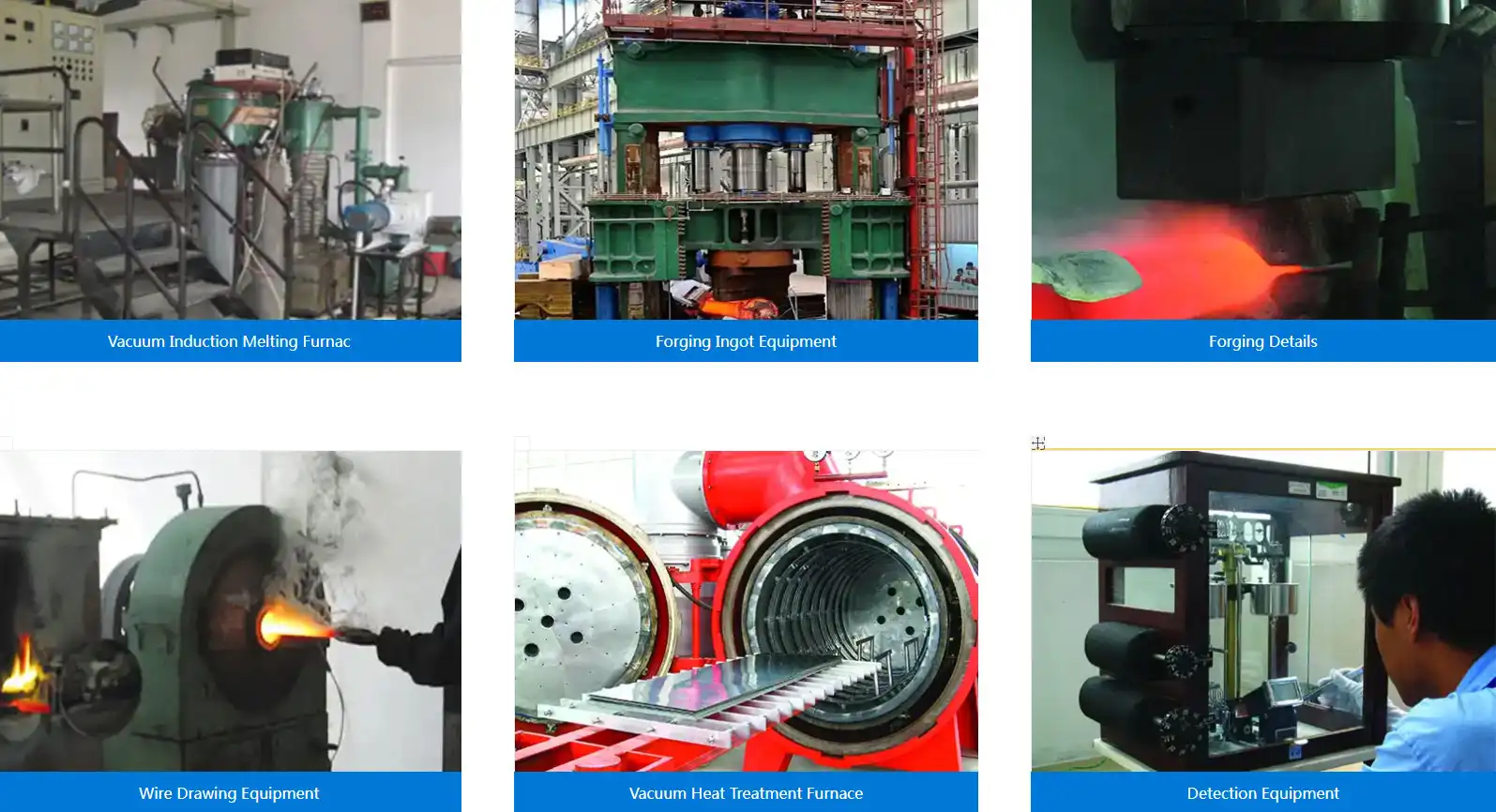

Quality Control

We stick to severe quality control measures to guarantee that our product fulfills the most noteworthy industry guidelines. Our quality affirmation group conducts thorough testing, including layered investigation, mechanical testing, and spectroscopic assessment, to ensure the dependability and execution of each sheet.

Production process

Our Certificate

Our equipment

Packaging/Transportation/Payment method

FAQ

Q1:What are the main benefits of nitinol plates products?

A1:Its main advantages include superelasticity, biocompatibility, high corrosion resistance, fatigue resistance and customizability.

Q2: Will the components of this piece of paper be changed at any point by explicit requirements?

A2:Yes, components can be customized to meet specific requirements.

Q3: Are mercuric alloys suitable for biomedical implants?

A1:Yes, due to its biocompatibility, it is suitable for biomedical implants.

Q4:How flexible is amalgam compared with traditional materials?

A4:Superelasticity offers greater flexibility than traditional materials.

Q5:What are your affirmations about your amalgam sheet products?

A5:We have ISO 13485 certification, comply with ASTM F2063, RoHS directives, and have undergone strict biocompatibility tests.

Contact Us